Novel steel pipe crossed core-inserting pile

A technology of steel pipes and crosses, applied in the field of offshore platform bottom support devices, can solve problems such as high cost, aging of component materials, threats to offshore platform safety, etc., and achieve the effects of simple and reliable overall structure, simple manufacturing and construction, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

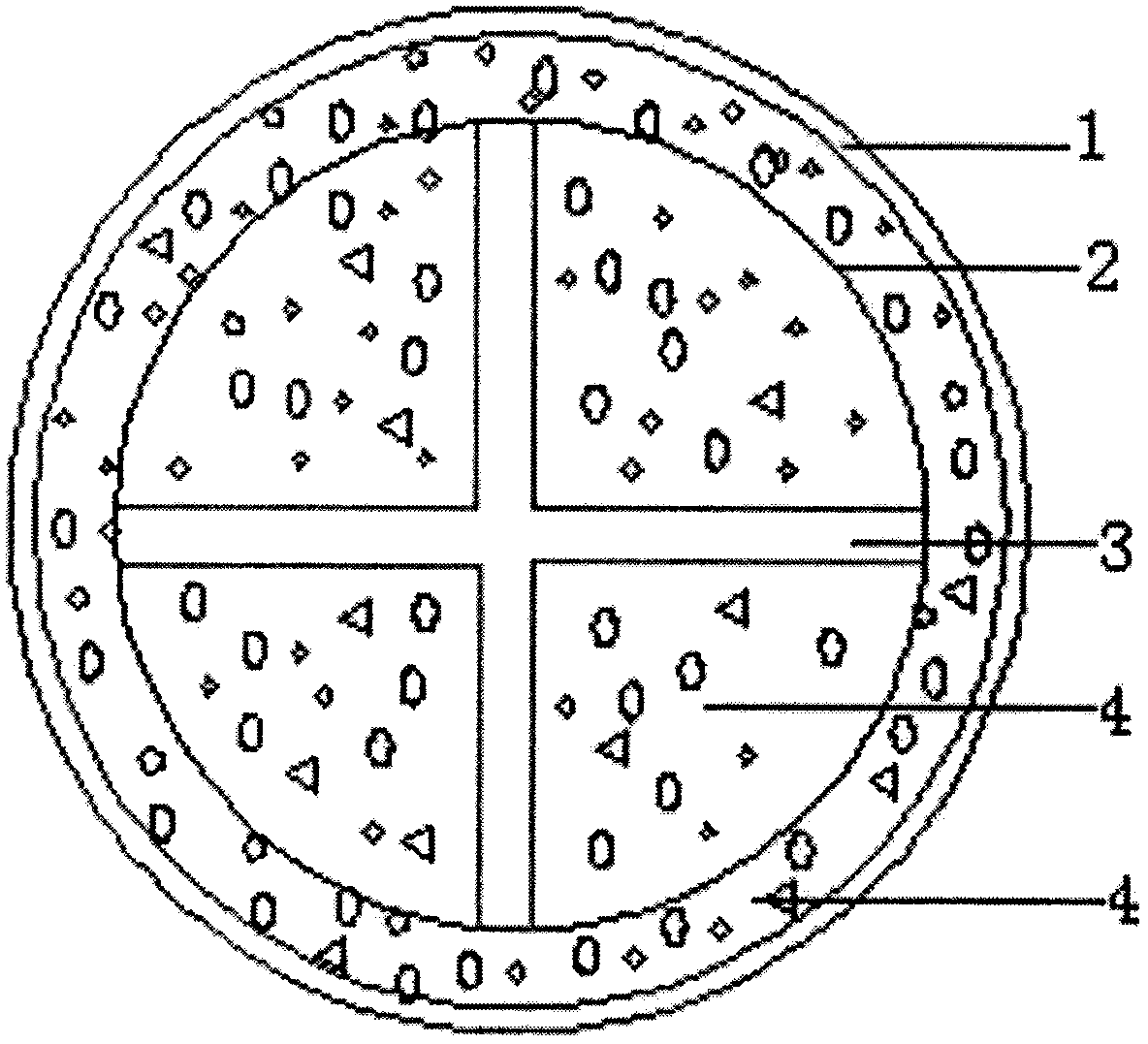

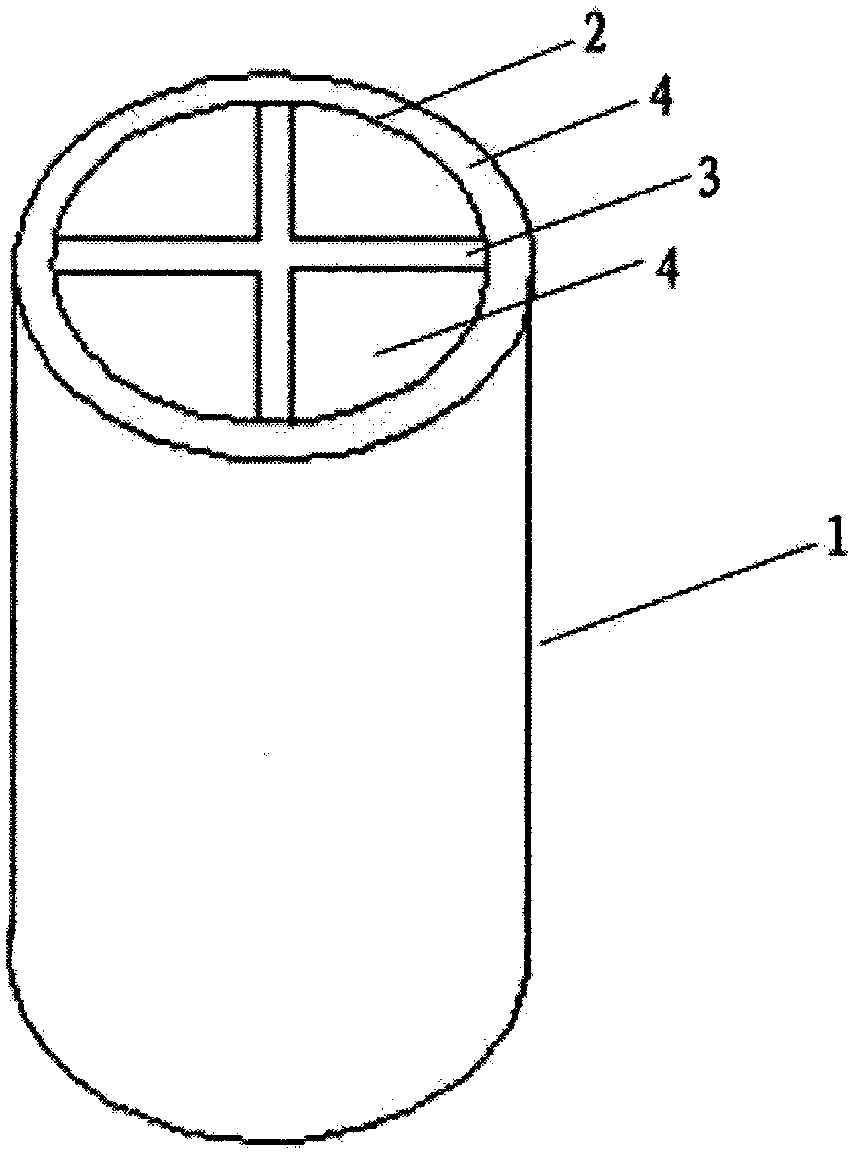

[0009] Such as figure 1 with figure 2 As shown, a new type of steel pipe cross core pile of the present invention includes a steel pipe body, a cross steel support is vertically inserted in the center of the steel pipe body, and a hollow steel bar is welded and fixed on the outside of the cross steel support Cage, the gap between the steel cage and the inner wall of the steel tube body is filled with concrete, and the gap between the steel cage and the cross steel support is also filled with concrete.

[0010] A new steel pipe cross core pile described in this patent is used in the field of bottom support of offshore platforms and marine structures. The installation process is as follows: insert the steel pipe cylinder body into the seabed bearing layer, insert the cross steel support into the center of the steel pipe pile And embedded in the bearing layer of the seabed, the steel cage is set on the outer circumference of the cross steel support and welded firmly, the gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com