Connecting joint of prefabricated steel pipe restraining reinforced concrete pier and bearing platform

A technology of reinforced concrete and connecting nodes, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of insufficient bearing capacity and rigidity, unfavorable structural safety, damage and collapse of bridge piers, etc., to achieve high bearing capacity, simplify the formwork process, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

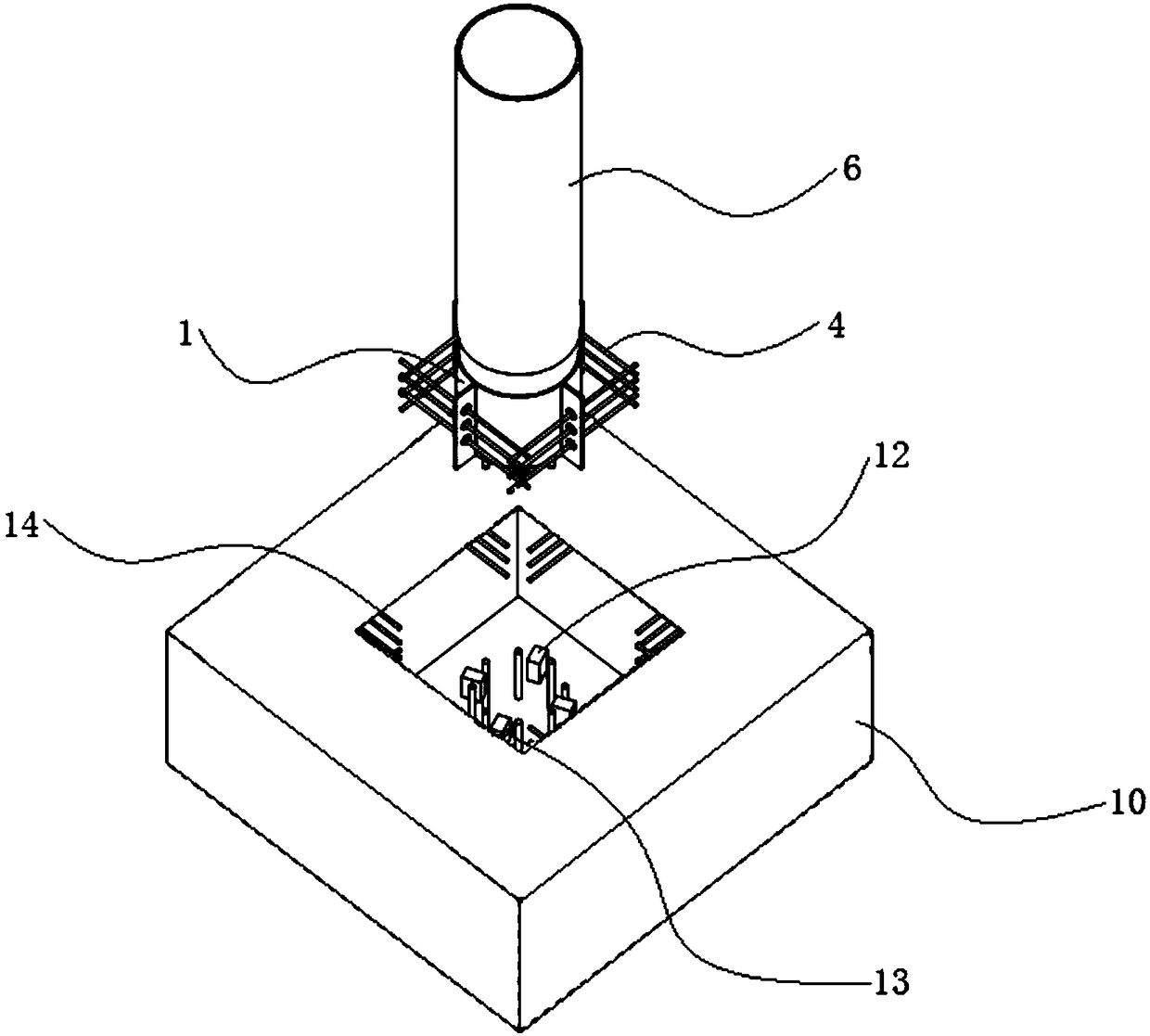

[0039] see figure 1 , this embodiment discloses a connection node between a prefabricated steel pipe-constrained reinforced concrete bridge pier and a cap, including a prefabricated bridge pier and a cap 10 .

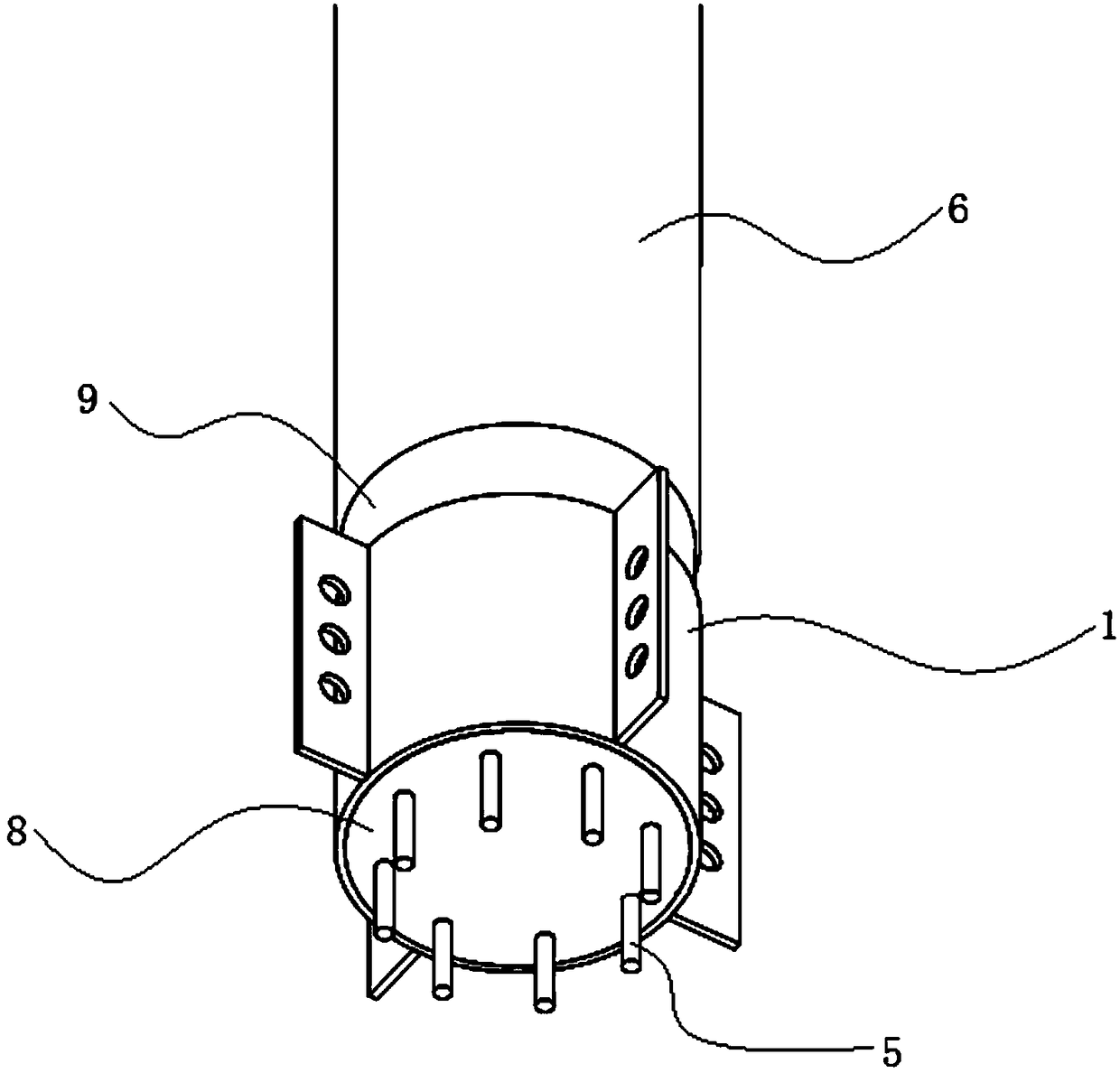

[0040] The prefabricated bridge pier includes steel pipe nodes, upper steel pipes 6 and concrete 8 .

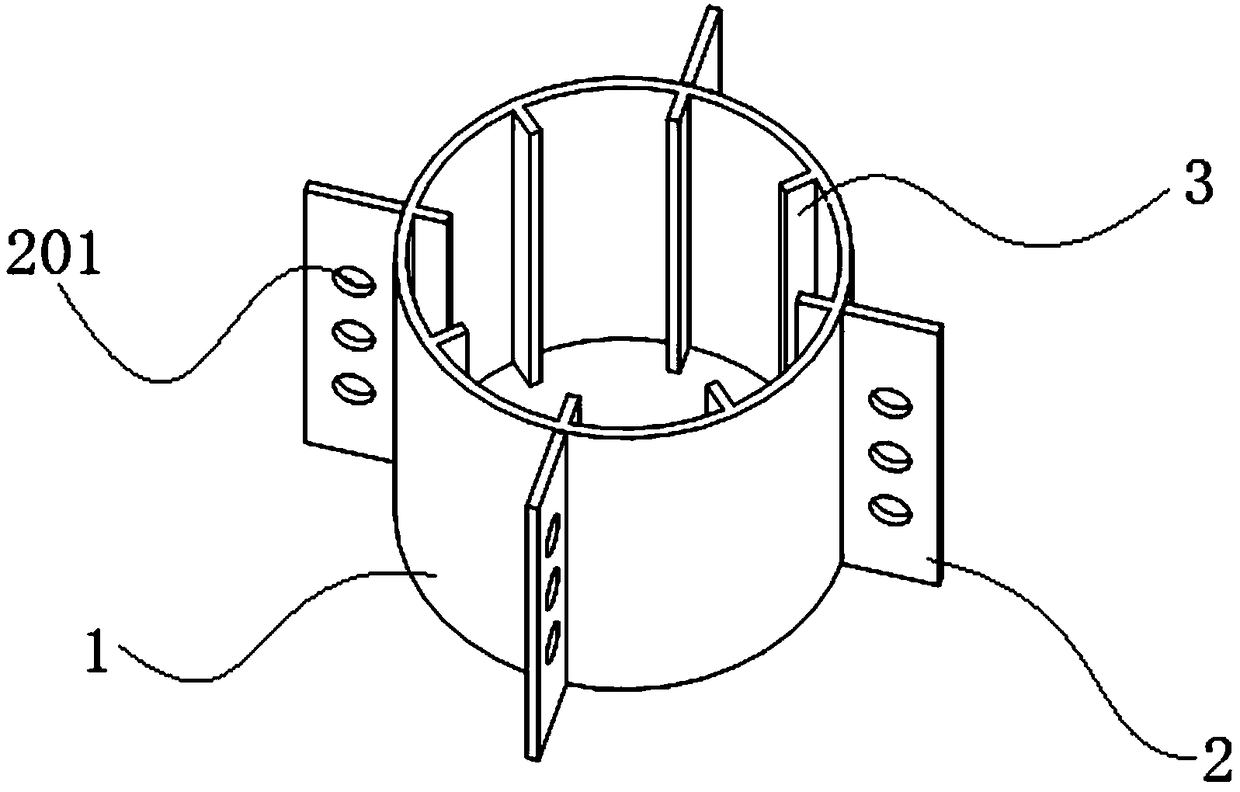

[0041] see figure 2 , the steel pipe node includes a lower steel pipe 1 , a perforated steel plate 2 and a connecting steel plate 3 .

[0042] The lower steel pipe 1 is a hollow cylinder with open upper and lower ends. On the peripheral outer wall of the lower steel pipe 1, four steel plates 2 with vertical holes are evenly arranged along the circumferential direction. Three holes 201 are arranged vertically on the surface of the perforated steel plate 2 . Corresponding holes 201 on two adjacent perforated steel plates 2 are arranged in dislocation. The perforated steel bars 4 are perforated in the holes 201 . The 12 perforated steel bars 4 form 4 rows, with 3 ba...

Embodiment 2

[0047] In order to improve the mechanical properties at the joint between the prefabricated bridge pier and the cap, this embodiment discloses a connection node between the prefabricated steel pipe-constrained reinforced concrete pier and the cap, including the prefabricated bridge pier and the cap 10 .

[0048] The prefabricated bridge pier includes steel pipe nodes, upper steel pipes 6 and concrete 8 .

[0049] The steel pipe node includes a lower steel pipe 1 , a perforated steel plate 2 and a connecting steel plate 3 .

[0050] The lower steel pipe 1 is a hollow cylinder with open upper and lower ends. On the peripheral outer wall of the lower steel pipe 1, four steel plates 2 with vertical holes are evenly arranged along the circumferential direction. Five holes 201 are arranged vertically on the surface of the perforated steel plate 2 . Corresponding holes 201 on two adjacent perforated steel plates 2 are arranged in dislocation. The perforated steel bars 4 are perfor...

Embodiment 3

[0056] This embodiment discloses a construction method for the connection node between the prefabricated steel pipe restrained reinforced concrete bridge pier and the bearing platform described in Embodiment 2, including the following steps:

[0057] 1) Make steel pipe nodes. The perforated steel plate 2 is welded on the outer wall of the lower steel pipe 1 . The steel plate 3 is welded and connected to the inner wall of the lower steel pipe 1 .

[0058] 2) Arranging the longitudinal reinforcement bars 5, and welding the longitudinal reinforcement bars 5 and the connecting steel plates 3 in one-to-one correspondence.

[0059] 3) Pouring pier concrete 8. Formwork is supported at the disconnected part in the middle of the lower steel pipe 1 and the upper steel pipe 6 and the top surface of the upper steel pipe 6 . After the template is fixed, concrete 8 is poured in the vertical cavity formed by the lower steel pipe 1, the upper steel pipe 6 and the template. Curing concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com