Production method of pretensioning prestressed concrete dynamic load piles

A production method and prestressing technology, applied in sheet pile wall, foundation structure engineering, ceramic molding machine, etc., can solve the problem of high brittleness, poor flexural bearing capacity of prestressed concrete pipe piles, and it is difficult to meet the requirements of design, dynamic load, etc. The requirements of actual use, etc., to achieve the effect of high cost performance, convenient design and use, and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

[0029] A kind of production method of pretensioned prestressed concrete dynamic load pile of the present invention comprises the following steps:

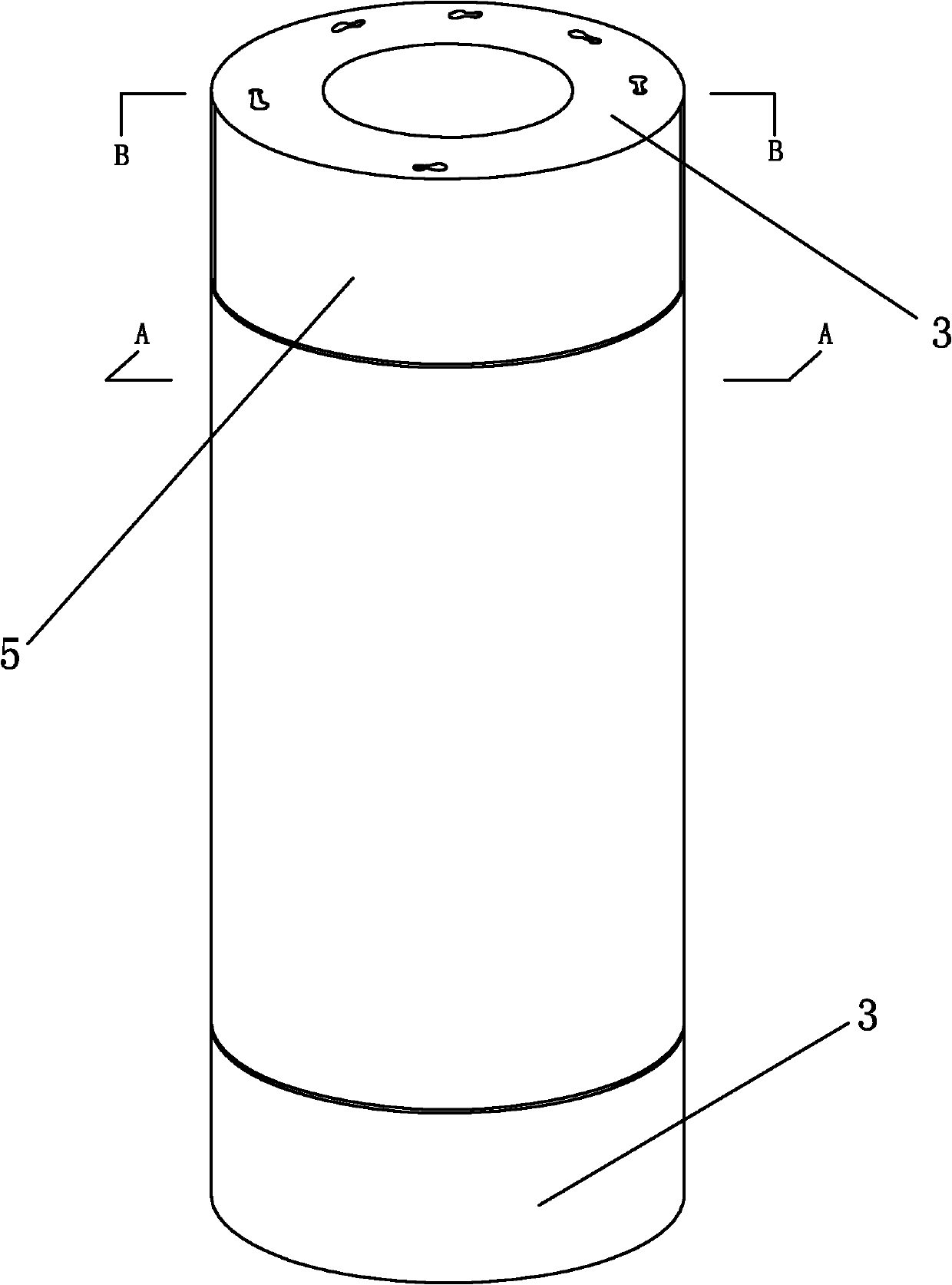

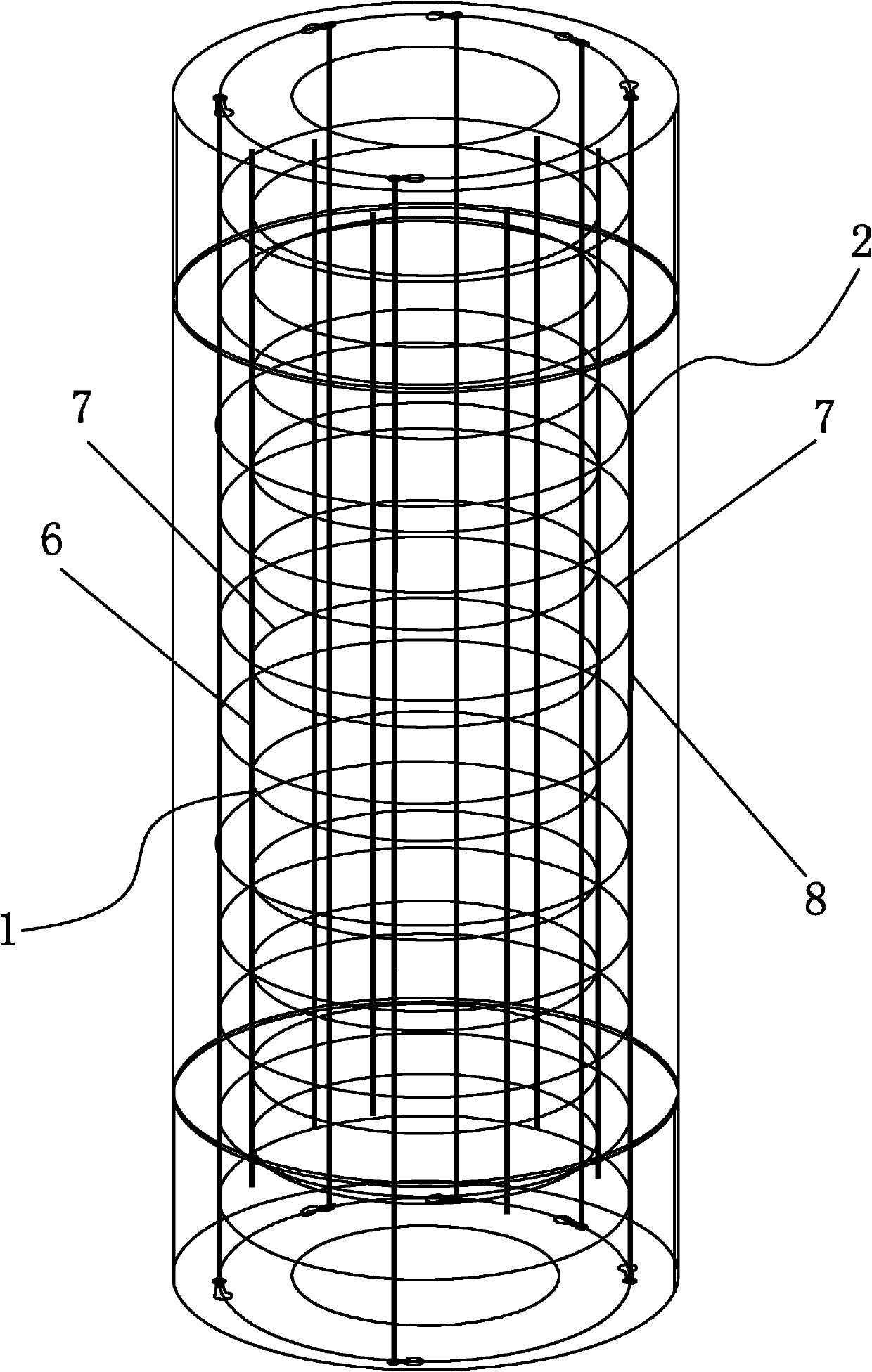

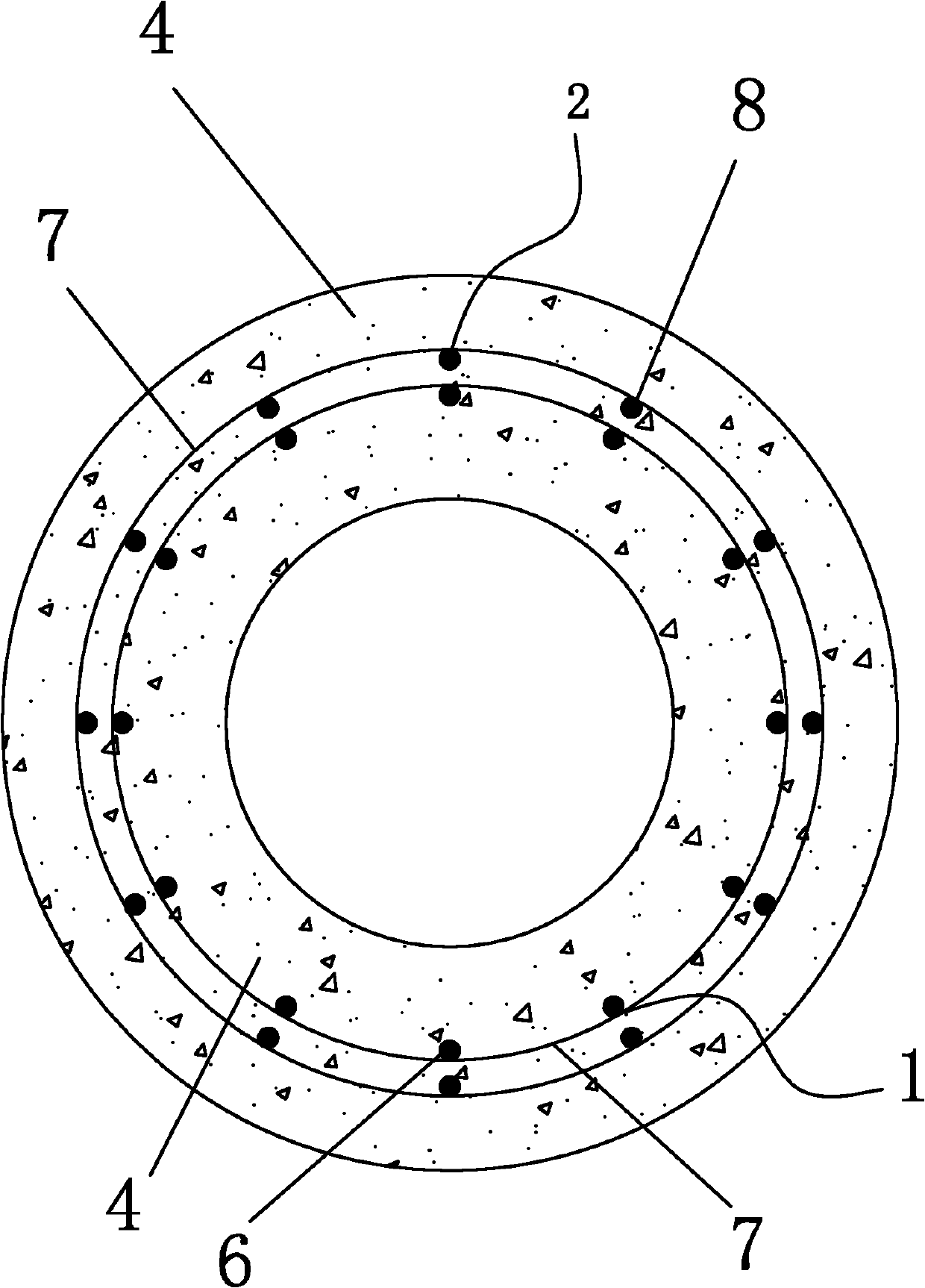

[0030] A, a plurality of prestressed reinforcing bars 8 are arranged circularly, and then a spiral rib 7 is welded outside the described plurality of prestressed reinforced bars 8 to form a prestressed reinforcing bar skeleton cage 2; a plurality of non-prestressed reinforcing bars 6 are arranged in a circular manner, Then a spiral rib 7 is welded on the outside of the plurality of non-prestressed steel bars 6 to form a non-prestressed steel bar skeleton cage 1, and the non-prestressed steel bar skeleton cage 1 is installed in the prestressed steel bar skeleton cage 2;

[0031] B. Clean up the corresponding steel mold and apply release agent;

[0032] C, hang the double-layer reinforcement sk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com