Fully-prefabricated cold-formed steel house modular unit and assembly connection method

A housing module and pre-cooling technology, which is applied in construction, building structure, and building material processing, can solve the problems of slowing down the construction progress of wall structures, cumbersome and complicated construction processes, and uneven load distribution, etc., and achieve good collaborative work Ability, simple construction process, and the effect of reducing construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

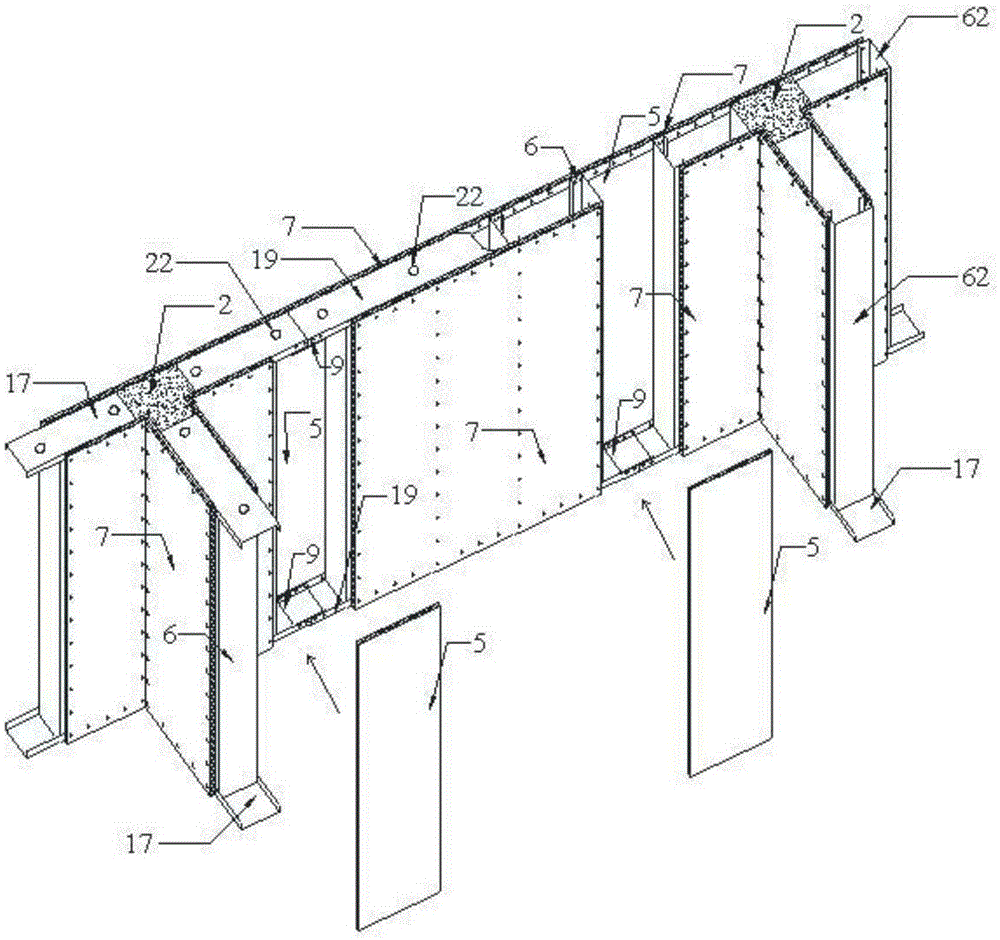

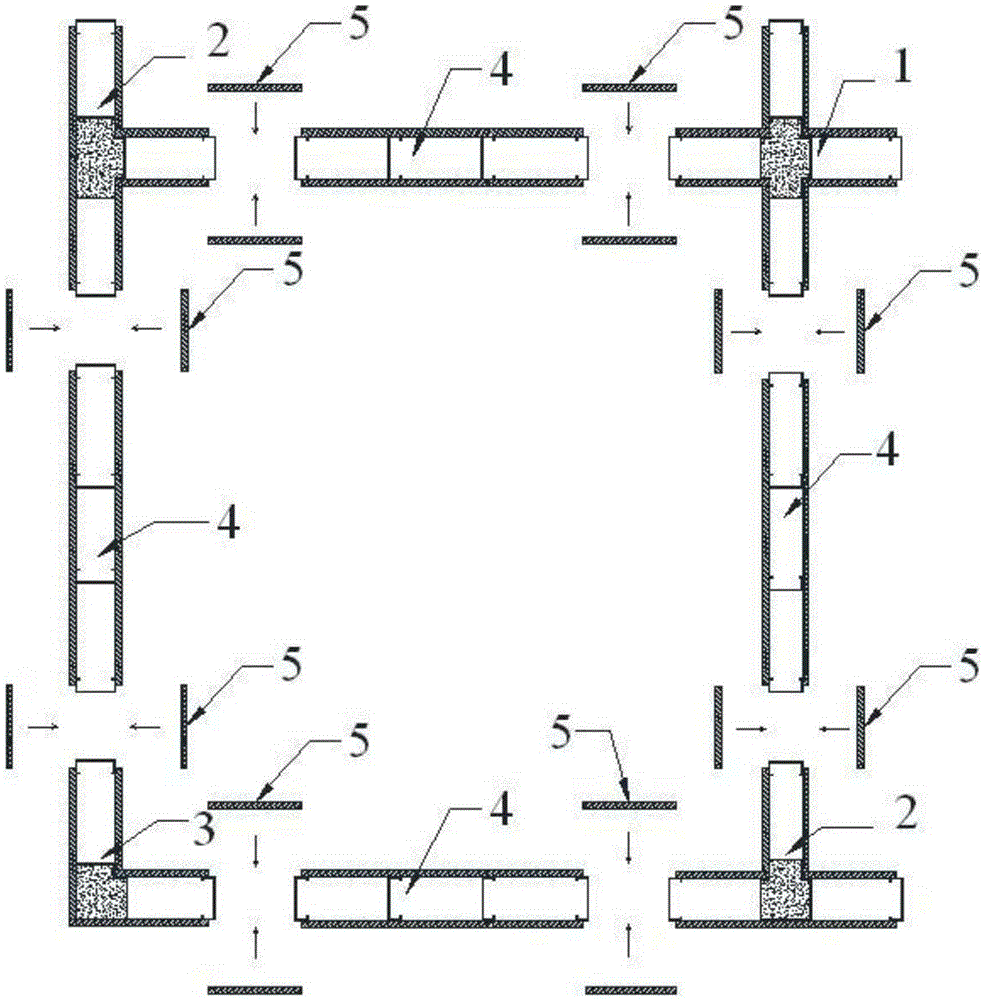

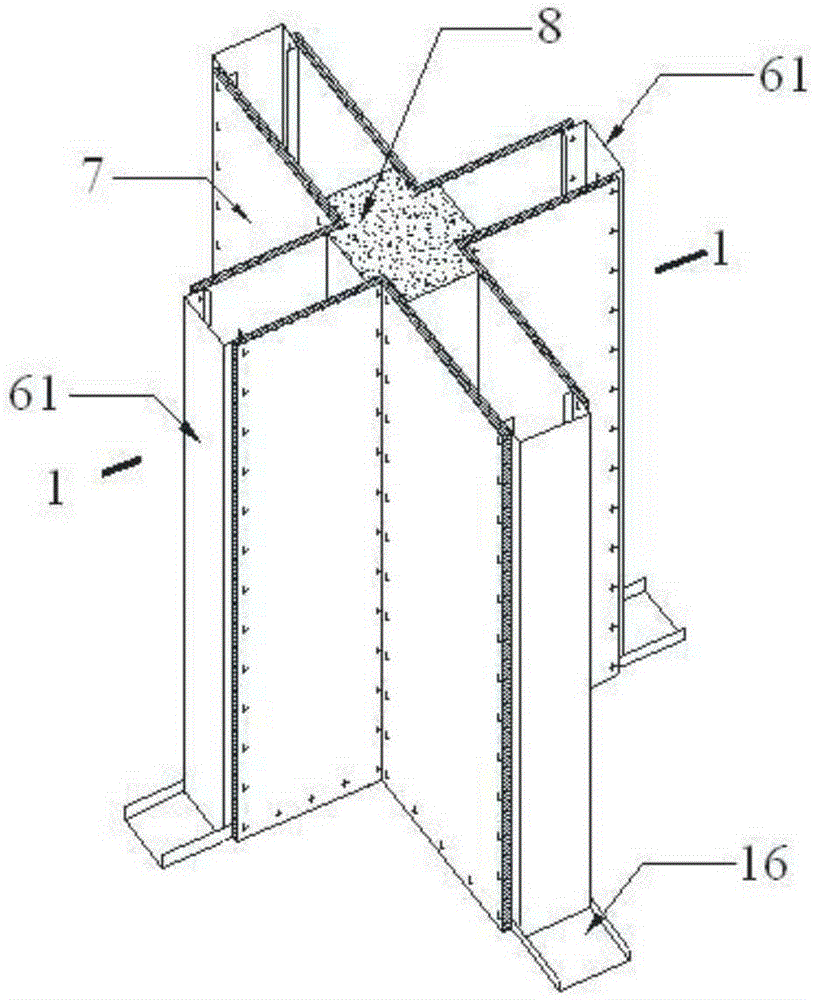

[0045] Such as Figure 1-17 Shown is a modular unit of a fully pre-cooled formed steel house, including a spliced special-shaped column unit, a wall unit 4 and a connecting wall panel unit 5. The connection between the column unit and the wall unit 4 is assembled through the connecting wall panel unit 5 .

[0046] Wherein, the combined special-shaped column unit includes a combined special-shaped central column unit 1, a combined special-shaped side column unit 2 and a combined special-shaped corner column unit 3, and the combined special-shaped central column unit 1, combined special-shaped side column unit 2 and combined special-shaped corner column unit 3 The wall units 4 are assembled between the two. In order to ensure the safety of each split special-shaped column unit during transportation and hoisting, the width of the overhanging wall in each direction sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com