High-strength concrete prefabricated pile doped with fiber-reinforced plastic bar

A fiber-reinforced plastic and high-strength concrete technology, which is applied in sheet pile walls, buildings, infrastructure engineering, etc. General performance and other problems, to achieve the effect of low density, excellent fatigue resistance, strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

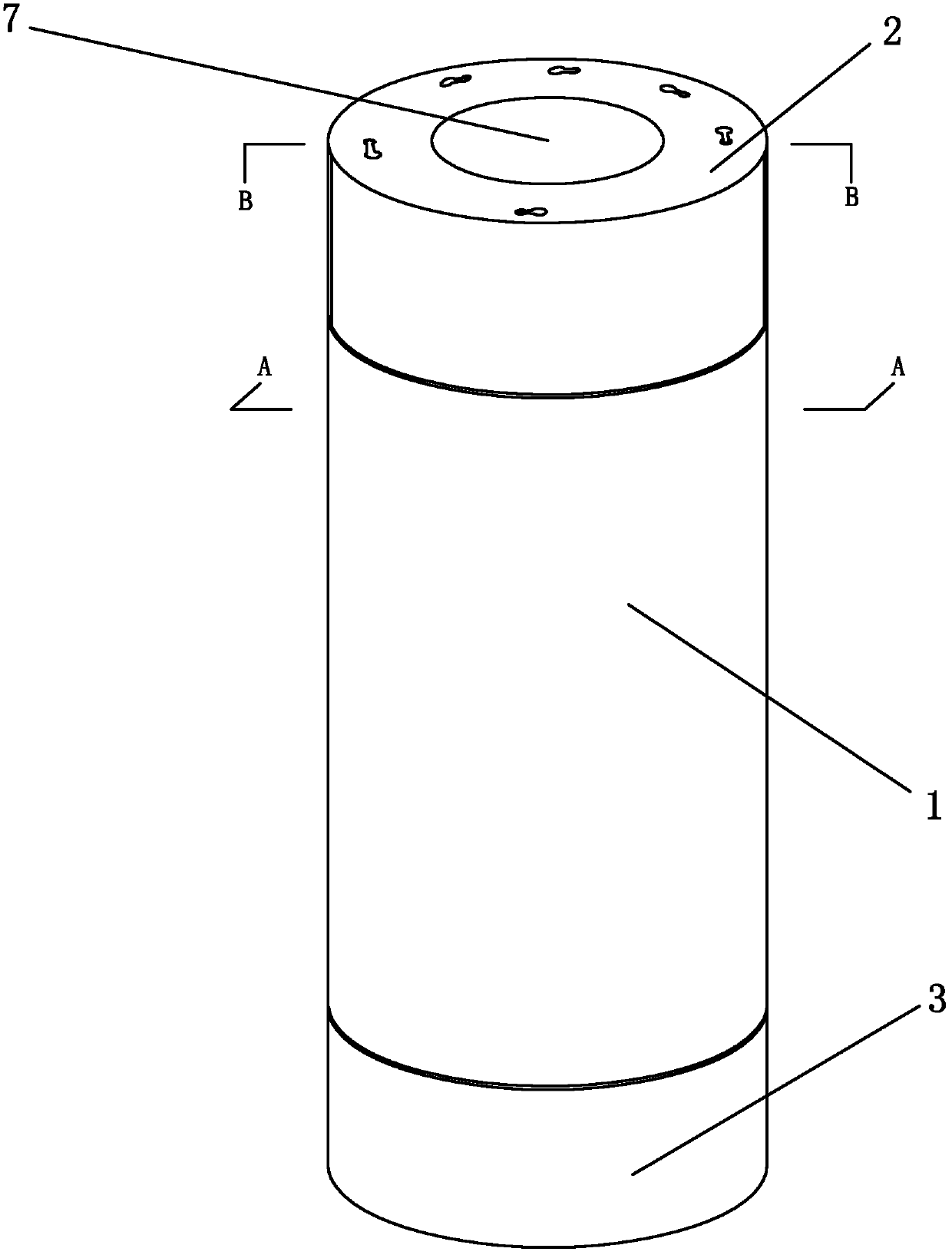

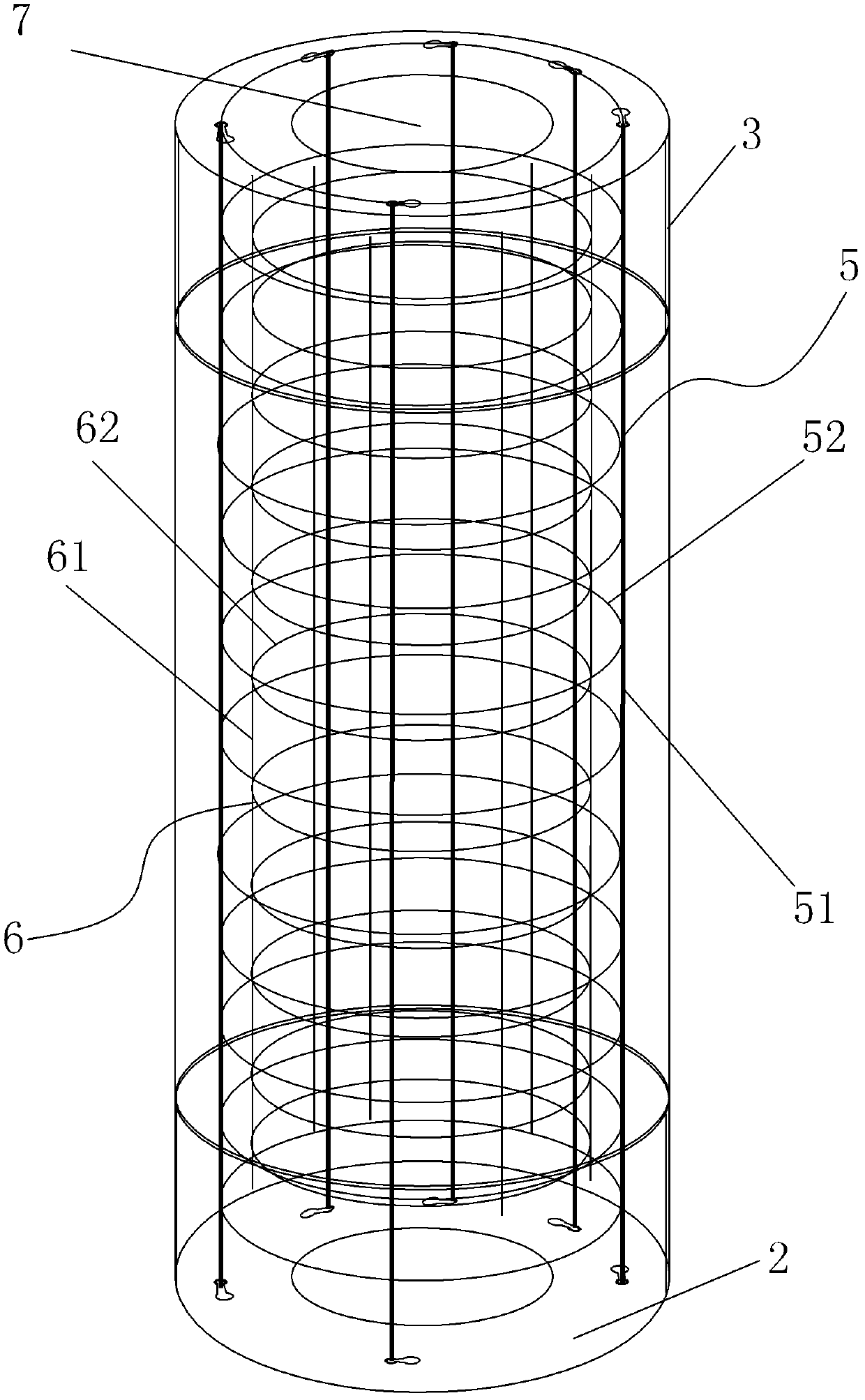

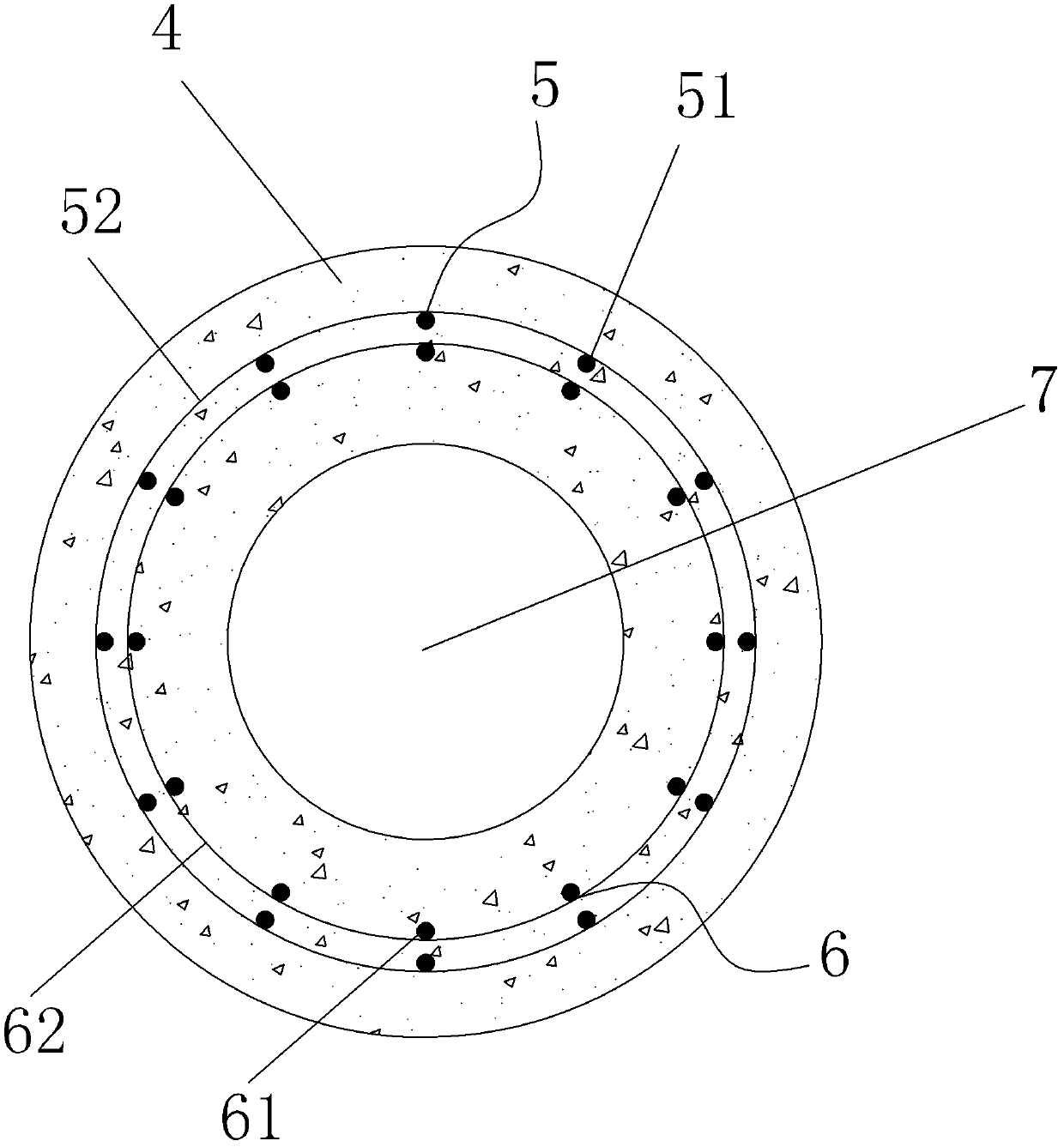

[0047] Such as Figures 1 to 4As shown, a high-strength concrete prefabricated pile mixed with fiber-reinforced plastic bars is specifically a hollow circular pile, including a pile body 1, an end plate 2, a pile hoop 3, a steel cage skeleton 5, and a fiber-reinforced plastic cage skeleton 6, Concrete 4; the cross-section of described reinforcement cage skeleton 5 is circular, and described reinforcement cage skeleton 5 is made up of prestressed steel bar 51 and stirrup 52, is provided with by concrete perfusion outside described reinforcement cage skeleton 5 A high-strength concrete pile body 1 that is formed and combined with a steel cage skeleton. The pile body 1 is circular, and the pile body 1 contains concrete 4, a steel cage skeleton 5 and a fiber-reinforced plastic reinforcement skeleton 6. The fiber The cross-section of the reinforced plastic cage frame 6 is circular, and the fiber reinforced plastic cage frame 6 is composed of fiber reinforced plastic ribs 61 and fib...

Embodiment 2

[0049] Such as Figures 5 to 8 As shown, a high-strength concrete prefabricated pile mixed with fiber-reinforced plastic bars is specifically a hollow circular pile, including a pile body 1, an end plate 2, a pile hoop 3, a steel cage skeleton 5, fiber-reinforced plastic bars 6, and concrete 4 The cross-section of the described reinforcement cage skeleton 5 is circular, and the described reinforcement cage skeleton 5 is made up of prestressed steel bars 51 and stirrup bars 52, and is provided with and formed by concrete perfusion outside the described reinforcement cage skeleton 5. A high-strength concrete pile body 1 integrated with a steel cage skeleton, the pile body 1 is circular, and the pile body 1 contains concrete 4, a steel cage skeleton 5 and a fiber-reinforced plastic bar 6, and the fiber-reinforced plastic bar 6 rings are arranged between adjacent prestressed steel bars 51; the diameter of the fiber reinforced plastic bars 6 is greater than the diameter of the pres...

Embodiment 3

[0051] Such as Figures 9 to 12 As shown, a high-strength concrete prefabricated pile mixed with fiber-reinforced plastic bars is specifically a hollow square pile, which is characterized in that it includes a pile body 1, an end plate 2, a pile hoop 3, a steel cage skeleton 5, and a fiber-reinforced plastic bar 6. Concrete 4; the cross section of the described reinforcement cage skeleton 5 is square, and the described reinforcement cage skeleton 5 is made up of prestressed steel bar 51 and stirrup 52, is provided with by concrete pouring outside described reinforcement cage skeleton 5 A high-strength concrete pile body 1 combined with a steel cage skeleton, the pile body 1 is square, and the pile body 1 contains concrete 4, steel cage skeleton 5 and fiber-reinforced plastic bars 6, and the fiber-reinforced plastic bars 6 squares are arranged between adjacent prestressed steel bars 51; the diameter of the fiber reinforced plastic bars 6 is greater than the diameter of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com