Method for supporting and protecting building foundation pit by employing transverse-diaphragm prestressing concrete pipe pile

A concrete pipe pile and prestressing technology, applied in construction, excavation, sheet pile walls, etc., can solve the problems of poor foundation pit safety, increasing the number of prestressed pipe piles, and low flexural bearing capacity. Flexural bearing capacity and anti-side movement stiffness, the effect of improving anti-lateral movement stiffness and improving flexural bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

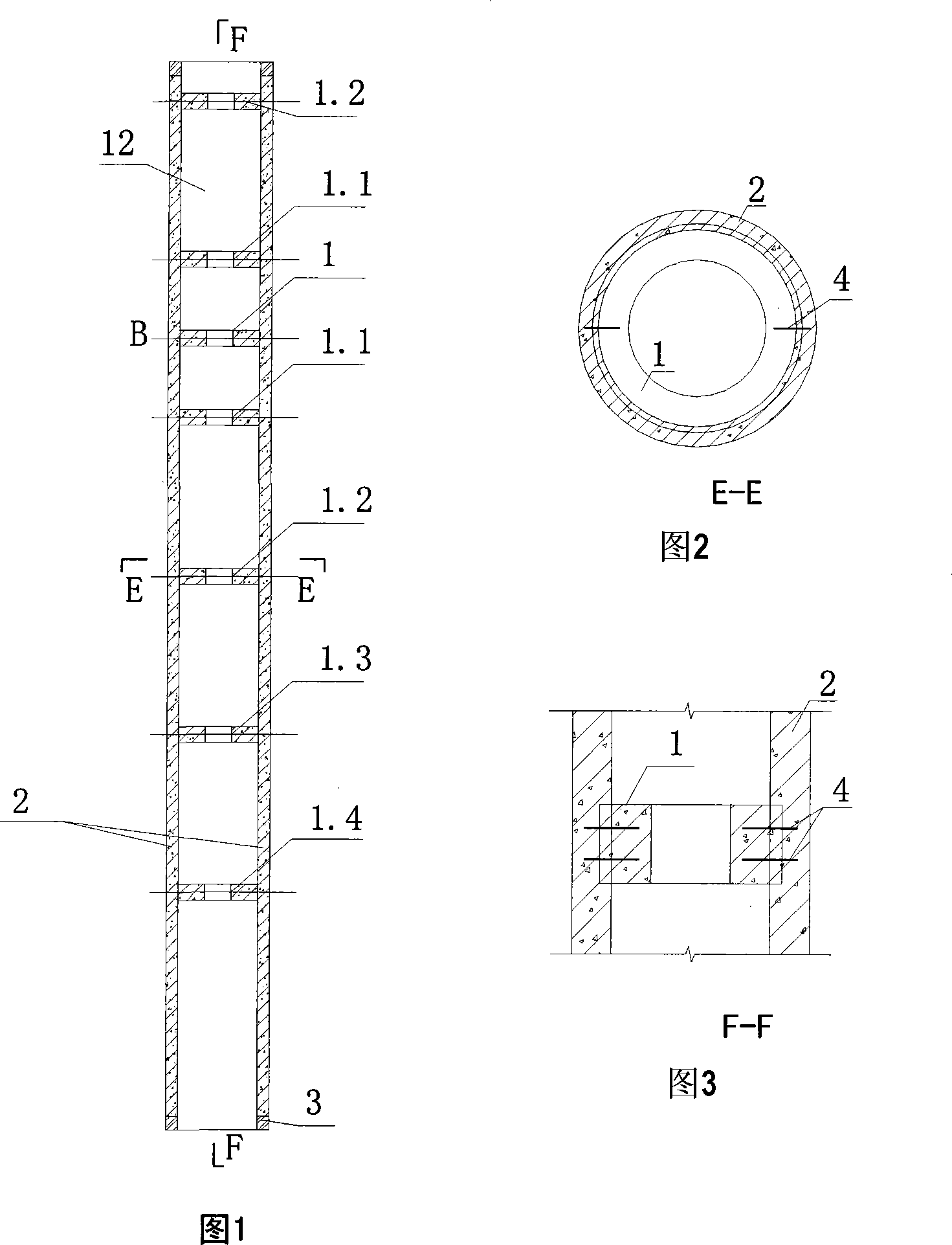

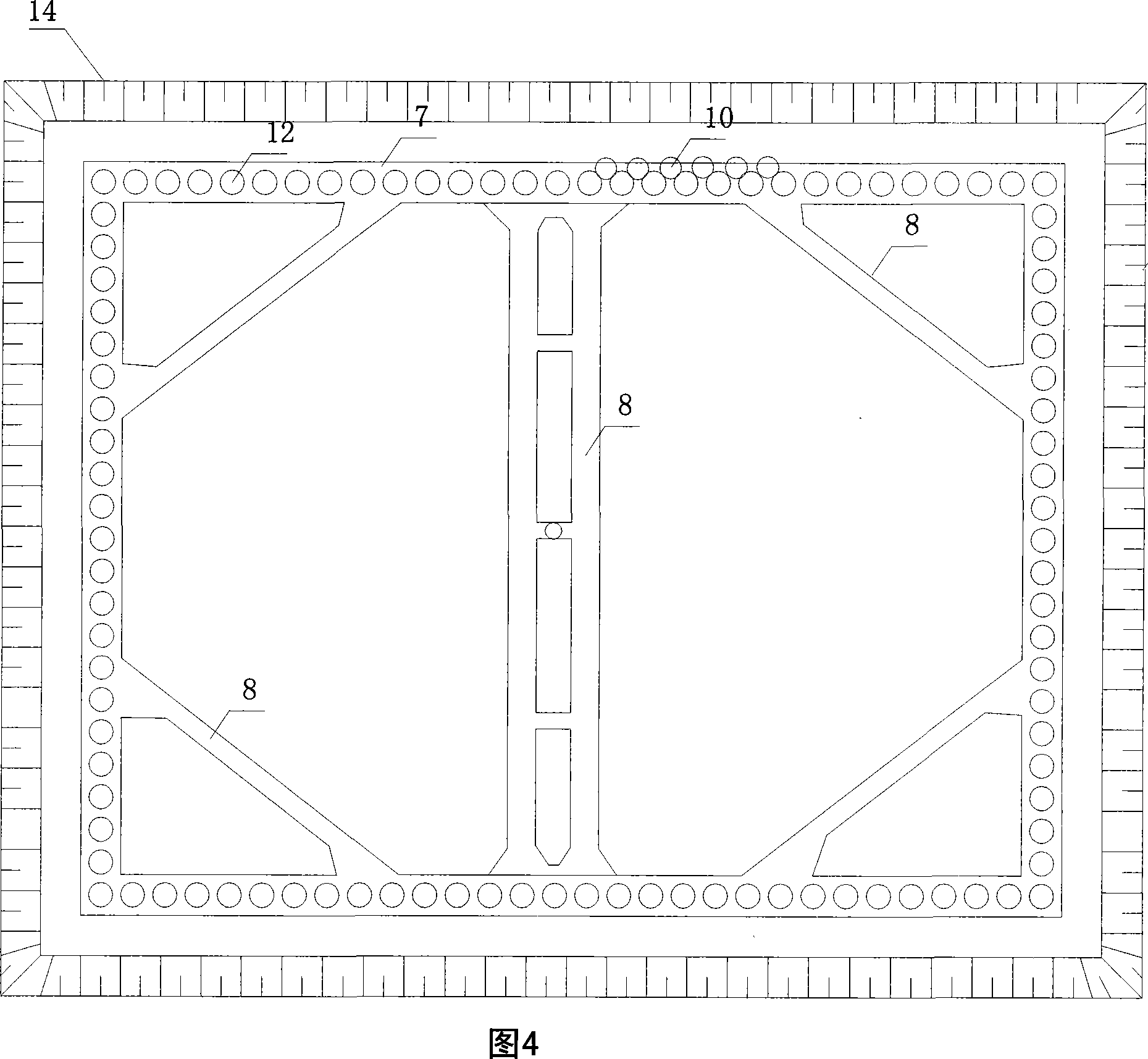

[0049] As shown in Figure 1 to Figure 5. This embodiment is based on the support construction steps when there is no open space around the foundation pit for grading or when no grading is required according to the actual situation.

[0050] Its construction steps are as follows:

[0051] A. Calculate and determine the diameter and length of the diaphragm prestressed concrete pipe pile 12 and the axial position of the diaphragm in the diaphragm prestressed concrete pipe pile 12: according to the geological report of the foundation pit, the foundation pit Calculate the bending distance (bending distance line) 6 of the transverse prestressed pipe pile 12 according to the actual excavation depth and construction load, and then follow the national standard "Pretensioned Prestressed Concrete Pipe Pile" 03SG409 or the provincial standard "Pretensioned Prestressed Concrete Pipe Pile". Pile" 2002 Zhejiang G22 selected section model is to determine the diameter of the diaphragm prestre...

Embodiment 2

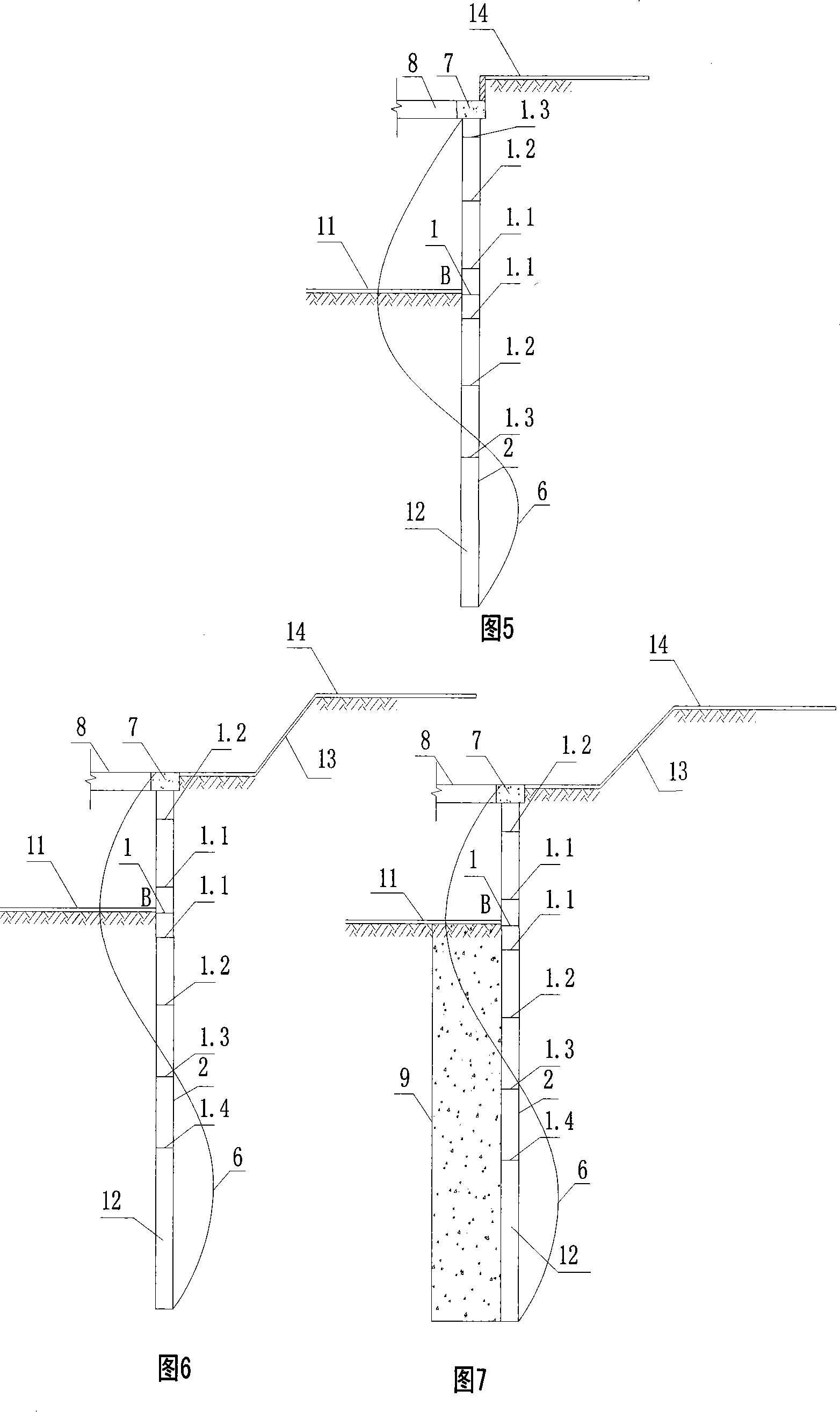

[0069] Referring to Figure 6, on the basis of the method of using transverse prestressed concrete pipe piles to support the foundation pit of the building in Example 1, if there is an open space for grading according to the surrounding environment, it is generally placed around the foundation pit. Slope, starting from the natural ground 14, grading with a slope of 1:1, marked 13 in the figure is the grading section. After grading, the design elevation of the pile top of the transverse prestressed concrete pipe pile 12 can be reduced, thereby reducing the bending moment borne by the transverse prestressed concrete pipe pile 12 . Under the same conditions, the safety of the foundation pit is improved. It is also possible to increase the spacing of the transverse prestressed concrete pipe piles 12 to reduce the number of transverse prestressed concrete pipe piles 12 to reduce the cost and save costs. Other construction methods are with embodiment 1.

Embodiment 3

[0071] Referring to Fig. 7, on the basis of the method of adopting the diaphragm prestressed concrete pipe pile to support the building foundation pit in embodiment 2, it also includes driving the cement mixing pile 9 on the inner side of the diaphragm prestressed concrete pipe pile 12 .

[0072] Compared with the soil in the foundation pit in Example 2, this embodiment is softer, that is to say, it is flow-plastic silt described in the geological report, so that when the active earth pressure on the outside of the foundation pit is large, it can On the left side) cement mixing pile 9 is driven to increase the passive earth pressure and prevent the inner side of the lower part of the retaining pile from moving to the inner side of the foundation pit, which is called "kicking phenomenon" in the industry. Other construction methods are with embodiment 2. When the active earth pressure is equal, there is no increase in cost compared with other forms of enclosure structure after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com