Novel combined stone beam

A new type of technology for stone beams, applied in the direction of bridges, joists, girders, etc., can solve the problems of limiting the application range of granite stone, low flexural bearing capacity, and large brittle failure, so as to improve the shear performance and flexural bearing capacity force, improving the effect of brittle failure properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

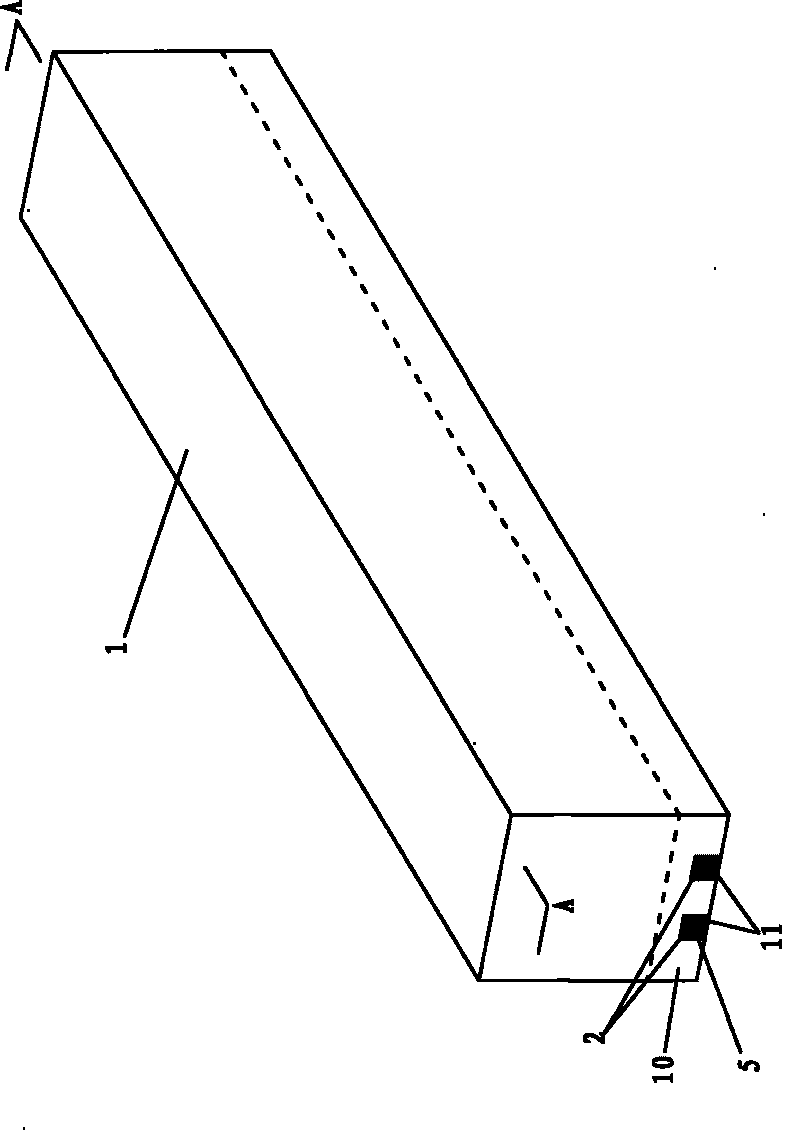

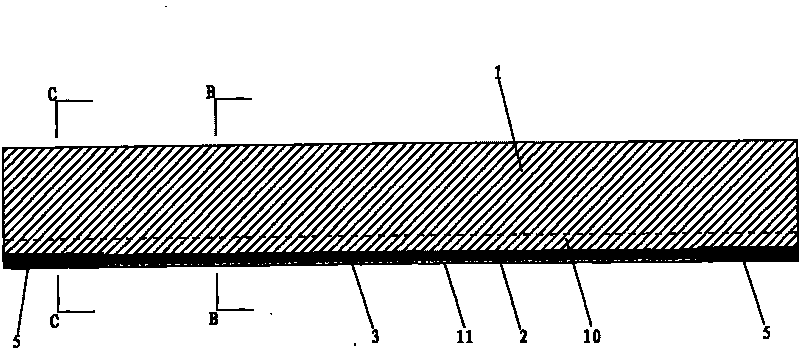

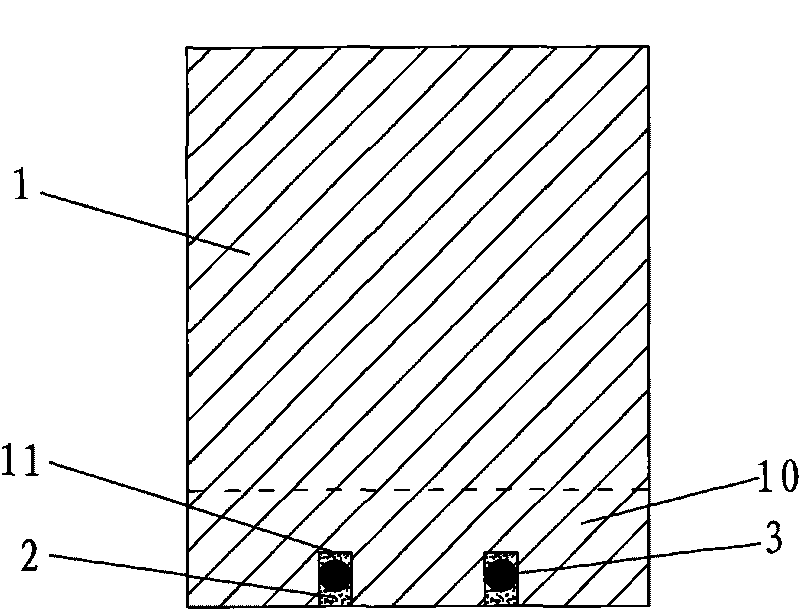

[0013] A kind of novel composite stone beam of the present invention, as figure 1 , figure 2 , image 3 , Figure 4 As shown, including the stone beam body, the stone beam body in the present embodiment is a complete granite stone beam 1 conforming to the engineering geometric size, and the side of the stone beam 1 located at its tension zone 10 is provided with a square groove 11 along the longitudinal direction of the stone beam 1, In the square groove 11, high-strength ribs 3 are longitudinally laid. The high-strength ribs 3 are prestressed by special tensioning equipment. 2 Bonding and fixing in the square groove 11, and the two ends of the high-strength reinforcement 3 are respectively anchored to the longitudinal ends of the stone beam 1 through anchors 5, and finally the stone beam 1, the bonding material 2 and the high-strength reinforcement 3 are combined into a Composite stone beams that can bear forces together.

[0014] Among them, the high-strength reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com