Composite non-off-bridge assembly tube structure

A tube structure, composite technology, applied in the direction of wing fan frame, sealing device, etc., can solve the problems of high installation difficulty, difficult realization, complicated process, etc., and achieve the effect of enhanced splicing strength and simple and convenient installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is a detailed description of a preferred embodiment of a composite non-broken bridge pipe structure of the present invention in conjunction with the accompanying drawings:

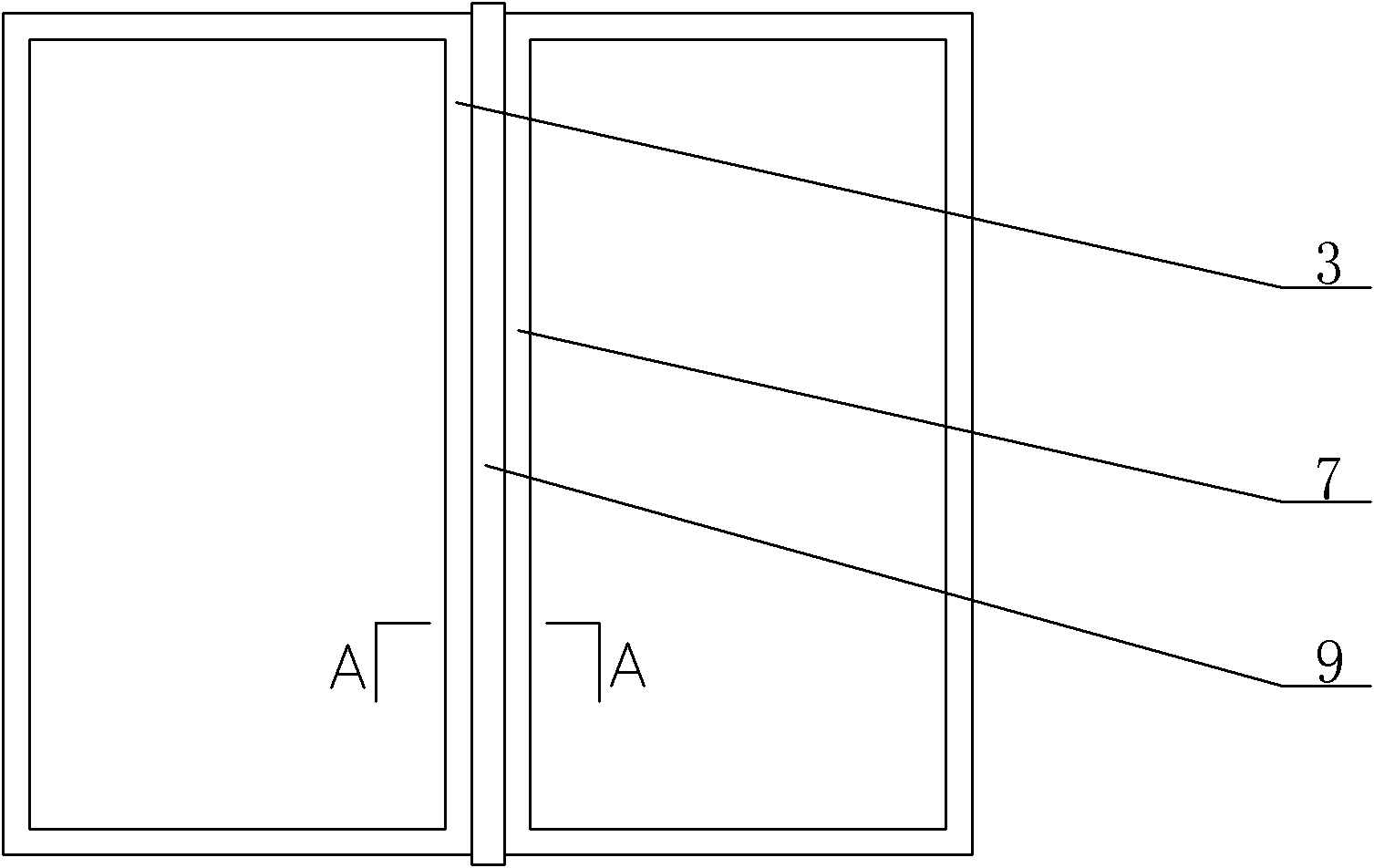

[0014] like figure 1 As shown, the left outer frame 3 and the right outer frame 7 are connected by splicing pipes 9 to form a spliced window. The splicing pipe 9 is in the shape of a bar, and its length is equivalent to the splicing side length of the left outer frame 3 and the right outer frame 7.

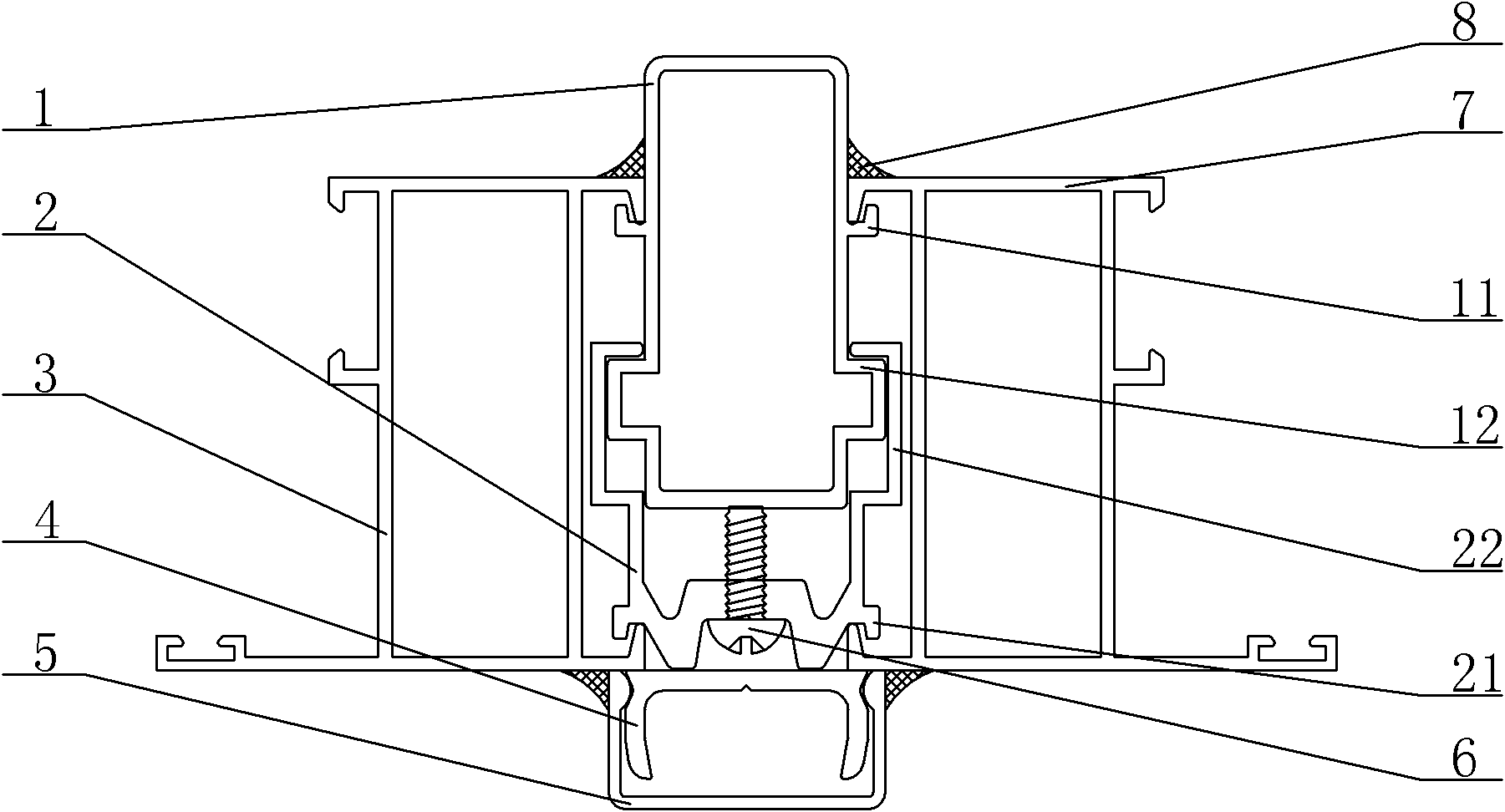

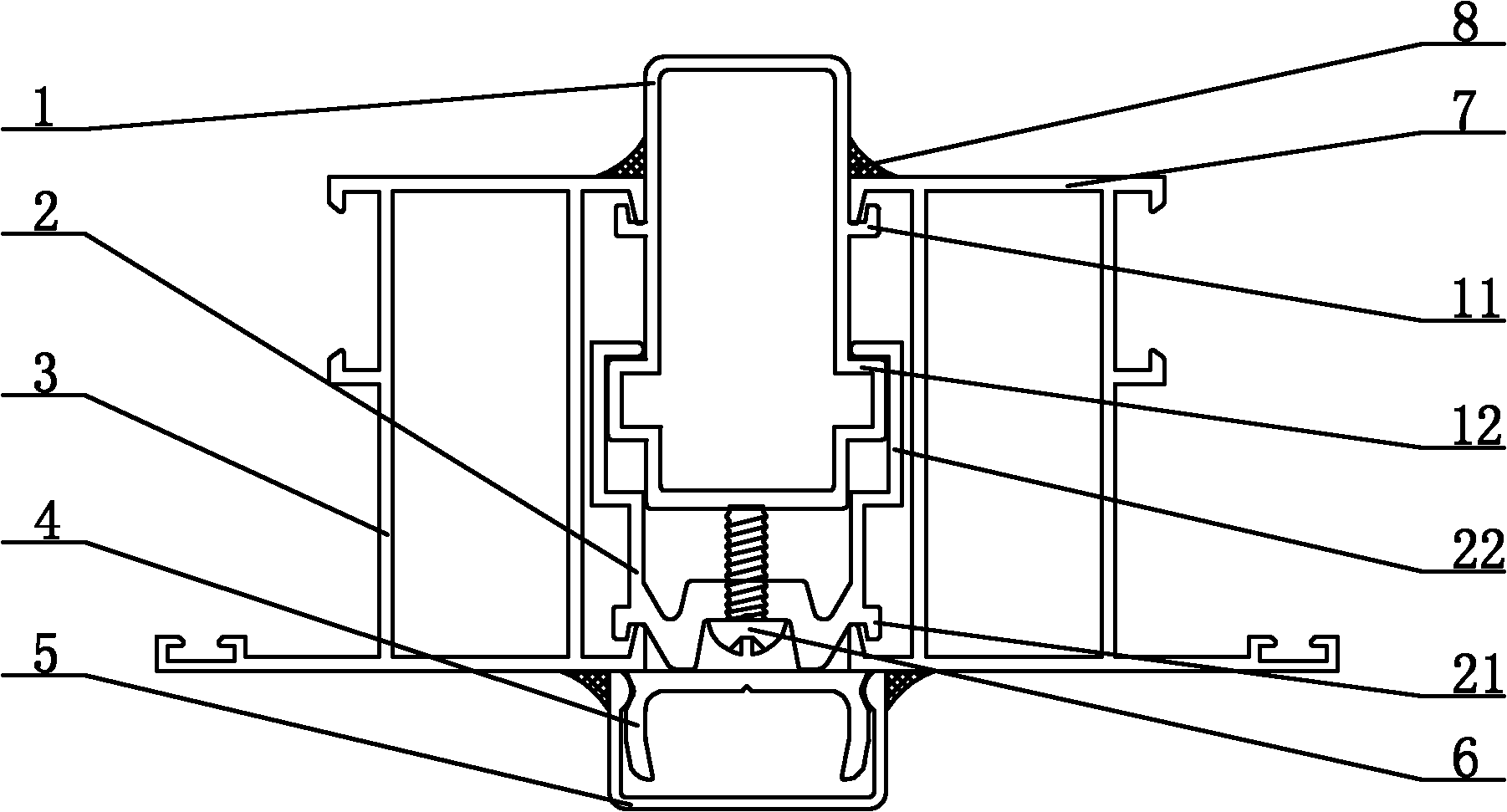

[0015] like figure 2 As shown, the main body of the composite non-broken bridge pipe joint structure is the pipe joint 9, which mainly includes the pipe joint insert 1 and the pipe joint kit 2 which are parallel to each other and plugged together. Alloy pipe material, the middle and lower parts on both sides of the pipe splitting insert 1 protrude outwards to form a symmetrical insert slider 12, and the middle and upper parts of the two sides of the pipe splitting insert 1 are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com