Solar cell module and preparation method thereof

A technology of solar cells and components, applied in the field of solar energy, can solve the problems of reducing power generation efficiency, shortening service life, and low overall strength, and achieve the effects of prolonging safety, increasing power generation efficiency, and beautifying appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

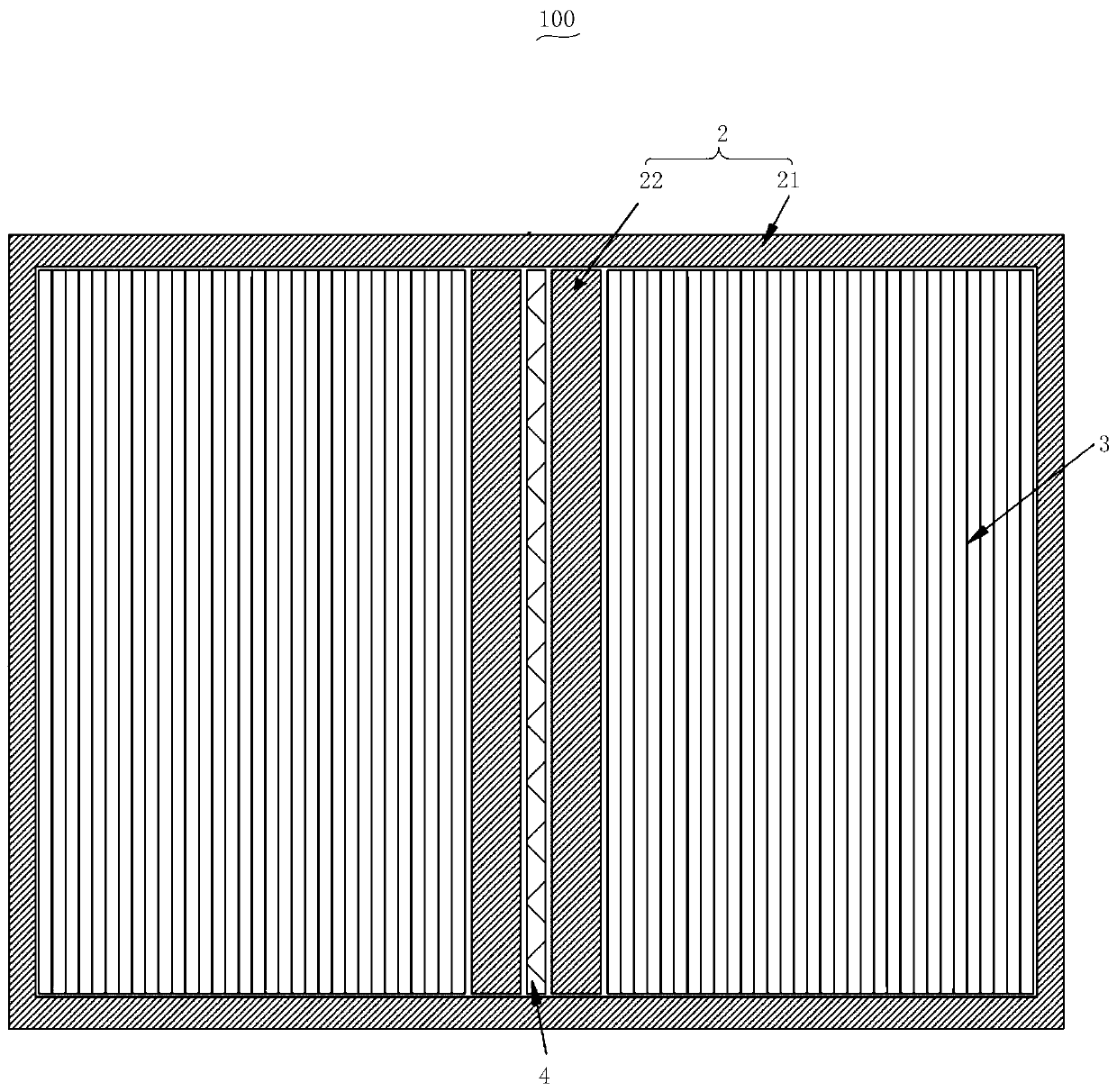

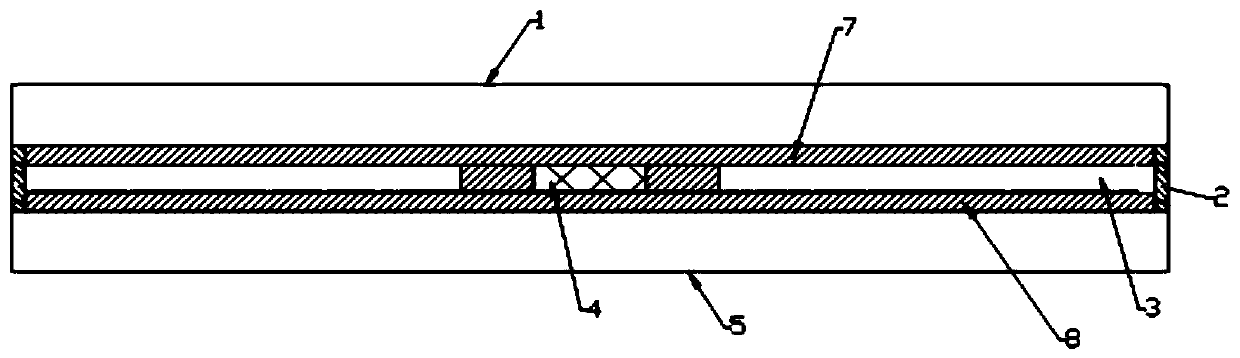

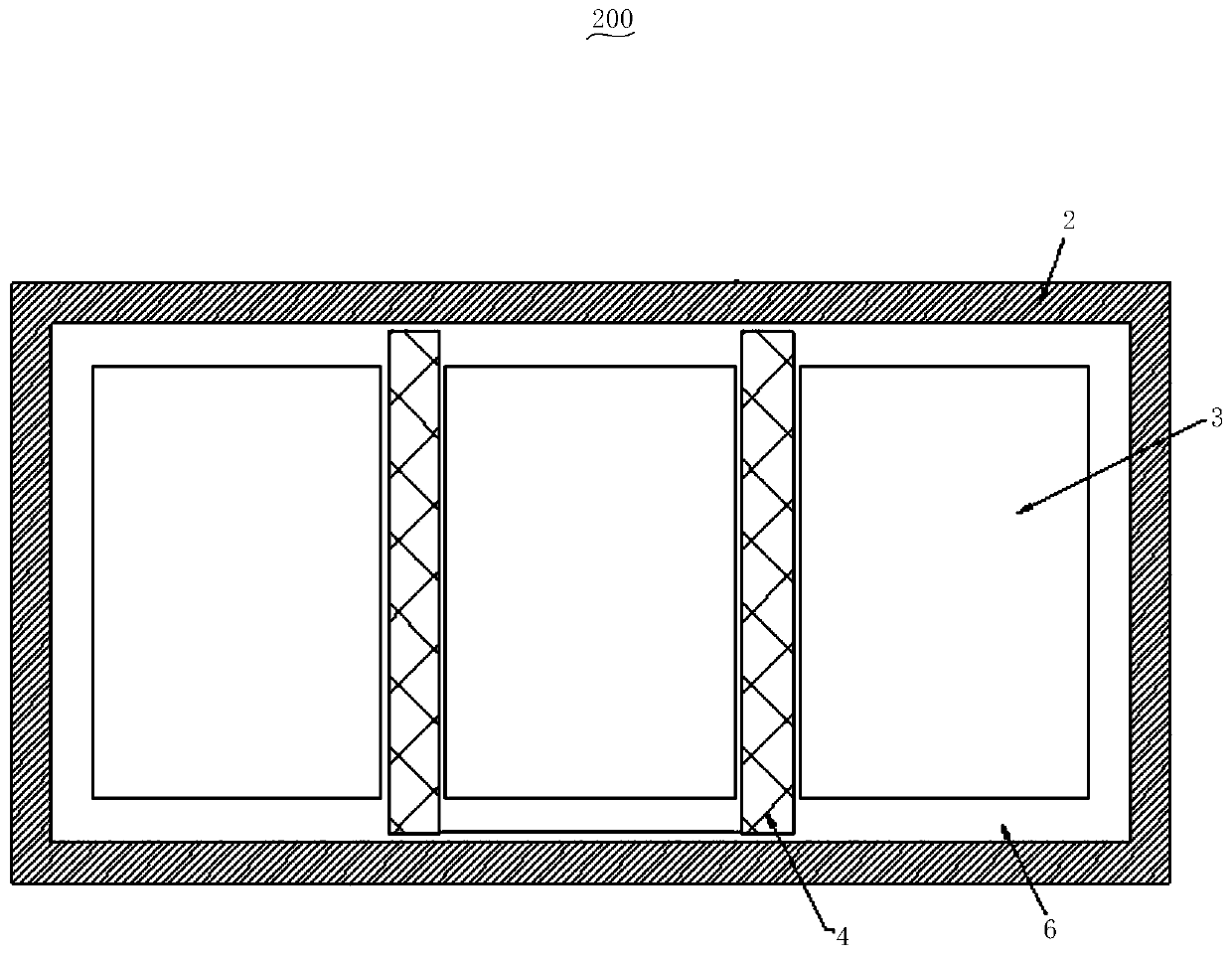

[0085] In the preparation method of the above-mentioned solar cell module, the performance and strength of resisting water vapor attack can be improved by setting the water vapor barrier 2 and the isolation glue 4 . Install the water vapor barrier 2 before stacking the front plate 1 and the back plate 5, and avoid setting the water vapor barrier after lamination, which can further improve the bonding tightness between the front plate 1, the back plate 5 and the water vapor barrier 2, and at the same time avoid stacking The subsequent installation of the water vapor barrier 2 may cause processing defects, which can also reduce the difficulty of processing and reduce the processing steps.

[0086] Another embodiment discloses A1, a method for preparing a solar cell module. The solar cell module includes: a front plate; a back plate, arranged opposite to the front plate; a water vapor barrier, interposed between the front plate and the back plate, and the water vapor barrier and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com