Bonding glue and manufacturing method of seamless clothes

An adhesive and seamless technology, which is applied to the production of adhesive adhesive and seamless garments, can solve the problems of water seepage and cold air infiltration of clothing, reduce the waterproof and cold-proof effect of clothing, etc. , the effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

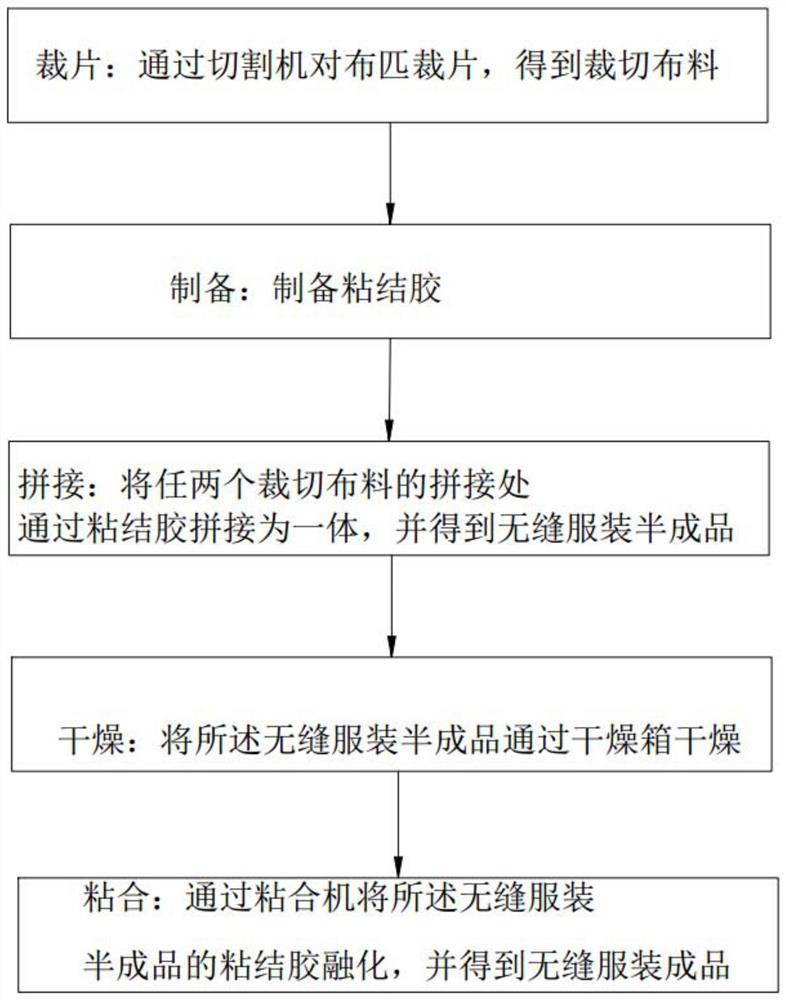

[0031] Such as figure 1 and figure 2 As shown, the present embodiment provides a method for making a seamless garment, comprising the steps of:

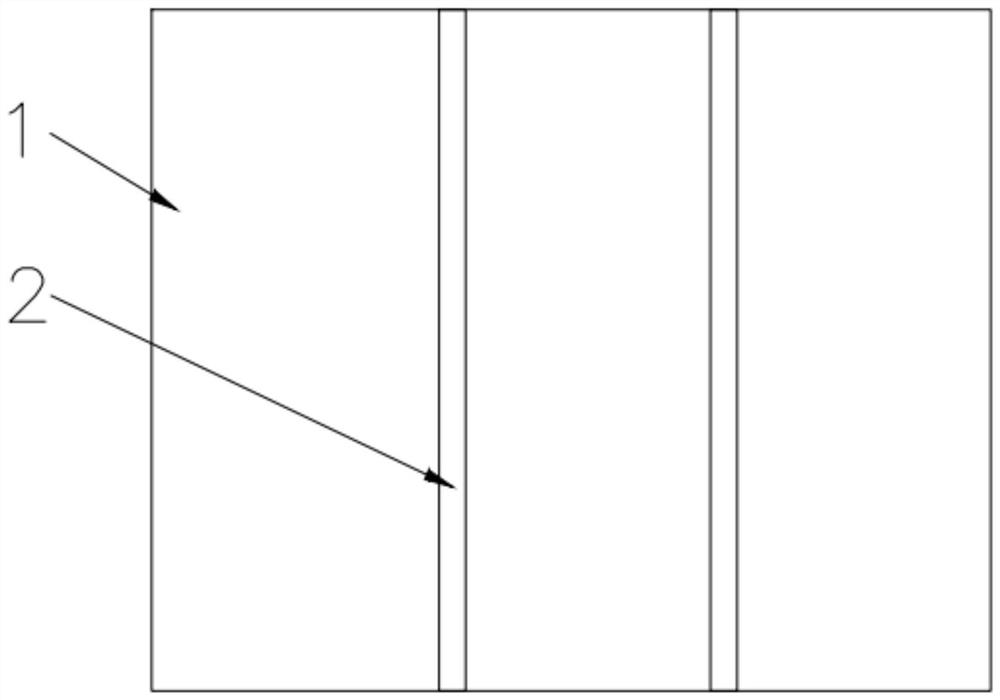

[0032] Cutting pieces: the mass per unit area of the cloth is 80g / m2 through an ultrasonic cutting machine 2 Cloth cut pieces, to obtain two pieces of cut cloth 1 size of 100mmx100mm sample;

[0033] Preparation: Fully mix the raw materials of adhesive 2 to make adhesive 2 and store it at room temperature for later use;

[0034] Splicing: splicing the splicing parts of the two cut fabrics 1 through adhesive glue 2 to obtain a semi-finished seamless garment. The sample size of the semi-finished seamless garment is 160mmx100mm;

[0035] Drying: The semi-finished seamless garment is dried in a drying oven; the drying temperature in the drying step is 45° C., and the drying time in the drying step is 12 minutes.

[0036] Bonding: Melt the bonding glue 2 of the semi-finished seamless garment by using a hot-press bonding machine wit...

Embodiment 2

[0039] This embodiment provides a method for making a seamless garment, comprising the following steps:

[0040] Cutting pieces: the mass per unit area of the cloth is 50g / m2 by ultrasonic cutting machine 2 Cloth cutting pieces, to obtain two pieces of cut fabric 1 size of 90mmx100mm sample;

[0041] Preparation: Fully mix the raw materials of adhesive 2 to make adhesive 2 and store it at room temperature for later use;

[0042] Splicing: Splicing the splicing parts of any two cut fabrics 1 through adhesive glue 2 to obtain a semi-finished seamless garment. The sample size of the semi-finished seamless garment is 170mmx100mm;

[0043] Drying: the semi-finished seamless garment is dried in a drying oven; the drying temperature in the drying step is 50° C., and the drying time in the drying step is 20 minutes.

[0044] Bonding: Melt the adhesive glue 2 of the semi-finished seamless garment by using a hot-press bonding machine with a hot-pressing temperature of 750°C, and the...

Embodiment 3

[0047] This embodiment provides a method for making a seamless garment, comprising the following steps:

[0048] Cutting pieces: the mass per unit area of the cloth is 80g / m2 through an ultrasonic cutting machine 2 The cloth cut piece, obtains two cut cloth 1 the sample that size is 100mmx100mm;

[0049] Preparation: Fully mix the raw materials of adhesive 2 to make adhesive 2 and store it at room temperature for later use;

[0050] Splicing: splicing the splicing parts of any two cut fabrics 1 through adhesive glue 2 to obtain a semi-finished seamless garment. The sample size of the semi-finished seamless garment is 180mmx100mm;

[0051]Drying: The semi-finished seamless garment is dried in a drying oven; the drying temperature in the drying step is 47° C., and the drying time in the drying step is 20 minutes.

[0052] Bonding: Melt the bonding glue 2 of the semi-finished seamless garment through a hot-press bonding machine with a temperature of 800°C, and then cool it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com