Solid wood round table processing technology

A processing technology, a round table technology, applied in the field of invention, can solve the problems of lack of water resistance and wear resistance, unable to meet the desktop strength, not paying attention to wood selection, etc., to increase the desktop strength, connect stable, and avoid the plank breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

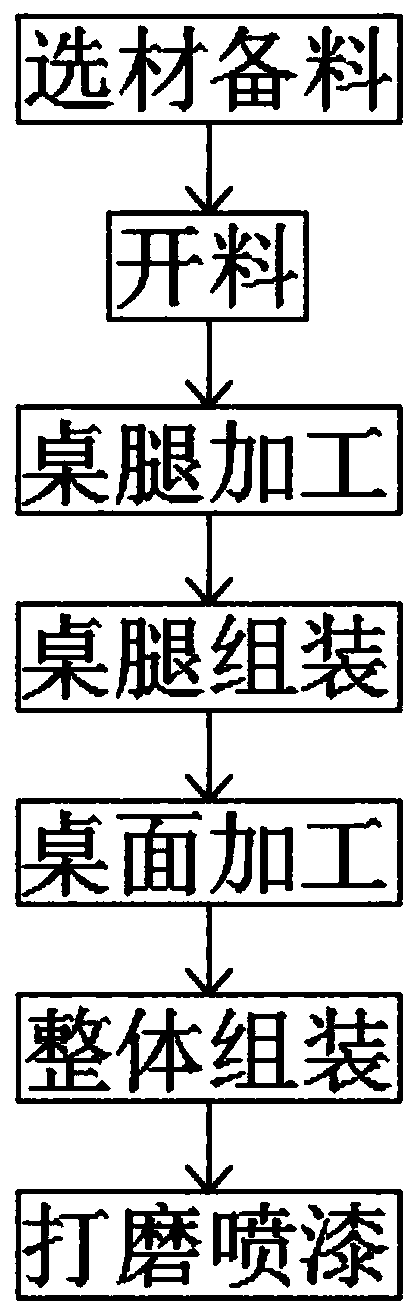

Method used

Image

Examples

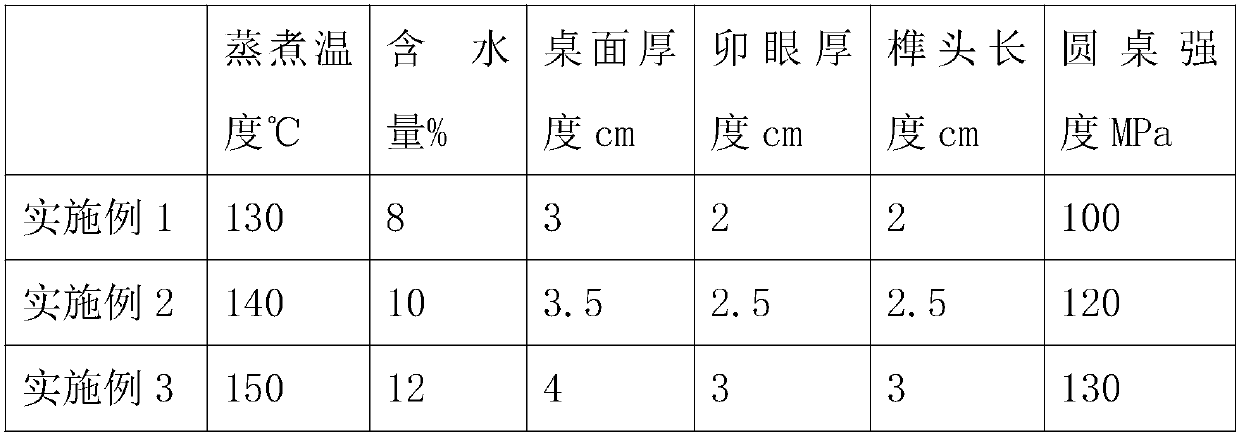

Embodiment 1

[0028] (1) Material selection and preparation: select wood with no white bark in the heartwood, place it in a wood cooking tank for cooking and sterilization, and the cooking and sterilization temperature is 130°C, and then put it in a wood drying box for drying, the drying temperature is 80°C, and it is dried to Out of the box with a moisture content of 8%;

[0029] (2) Cutting: Place the dried wood in step (1) on the cutting machine for cutting. First, the tabletop and outriggers of the round table are set out according to the size of 1:1 to draw the drawing, and the drawing is pasted on the cut wood. Cutting, the thickness of the tabletop is 3cm, and then finishing, decomposing the wooden board;

[0030] (3) Processing of table legs: In step (2), draw a semi-transparent tenon structure on both sides of the wooden board cut according to the ratio of the outriggers, and use a table saw to drill out the mortise according to the marked line. The thickness of the mortise is 2cm....

Embodiment 2

[0036] (1) Material selection and preparation: select wood with no white bark in the heartwood, place it in a wood cooking tank for cooking and sterilization, and the cooking and sterilization temperature is 140°C, and then put it in a wood drying box for drying, the drying temperature is 85°C, and it is dried to After the water content is 10%, leave the box for later use;

[0037] (2) Cutting: Place the dried wood in step (1) on the cutting machine for cutting. First, the tabletop and outriggers of the round table are set out according to the size of 1:1 to draw the drawing, and the drawing is pasted on the cut wood. Cutting, the thickness of the tabletop is 3.5cm, and then finishing, decomposing the wooden board;

[0038] (3) Processing of table legs: In step (2), draw a semi-transparent tenon structure diagram on both sides of the wooden board cut according to the ratio of the outriggers, and use a table saw to drill out the mortise according to the marked line. The thickne...

Embodiment 3

[0044] (1) Material selection and preparation: select wood with no white bark in the heartwood, place it in a wood cooking tank for cooking and sterilization, the cooking and sterilization temperature is 150°C, and then put it in a wood drying box for drying, the drying temperature is 90°C, and it is dried to After the water content is 12%, it is ready to leave the box;

[0045] (2) Cutting: Place the dried wood in step (1) on the cutting machine for cutting. First, the tabletop and outriggers of the round table are set out according to the size of 1:1 to draw the drawing, and the drawing is pasted on the cut wood. Cutting, the thickness of the tabletop is 4cm, and then finishing, decomposing the wooden board;

[0046] (3) Processing of table legs: In step (2), draw a semi-transparent tenon structure diagram on both sides of the wooden board cut according to the ratio of the outriggers, and use a table saw to drill out the mortise according to the marked line. The thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com