Process to yarn making non-knot twist contecting and thread rolling device using said method

A technology of knotless splicing and splicer, which is applied in spinning machines, splicing devices, textiles and papermaking, etc. It can solve splicing strength with exposed hairiness in the splicing area, exposed hairiness in the splicing area, instability, etc. problems, to achieve the effect of uniform yarn fiber wrapping thickness, improve appearance, and increase splicing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

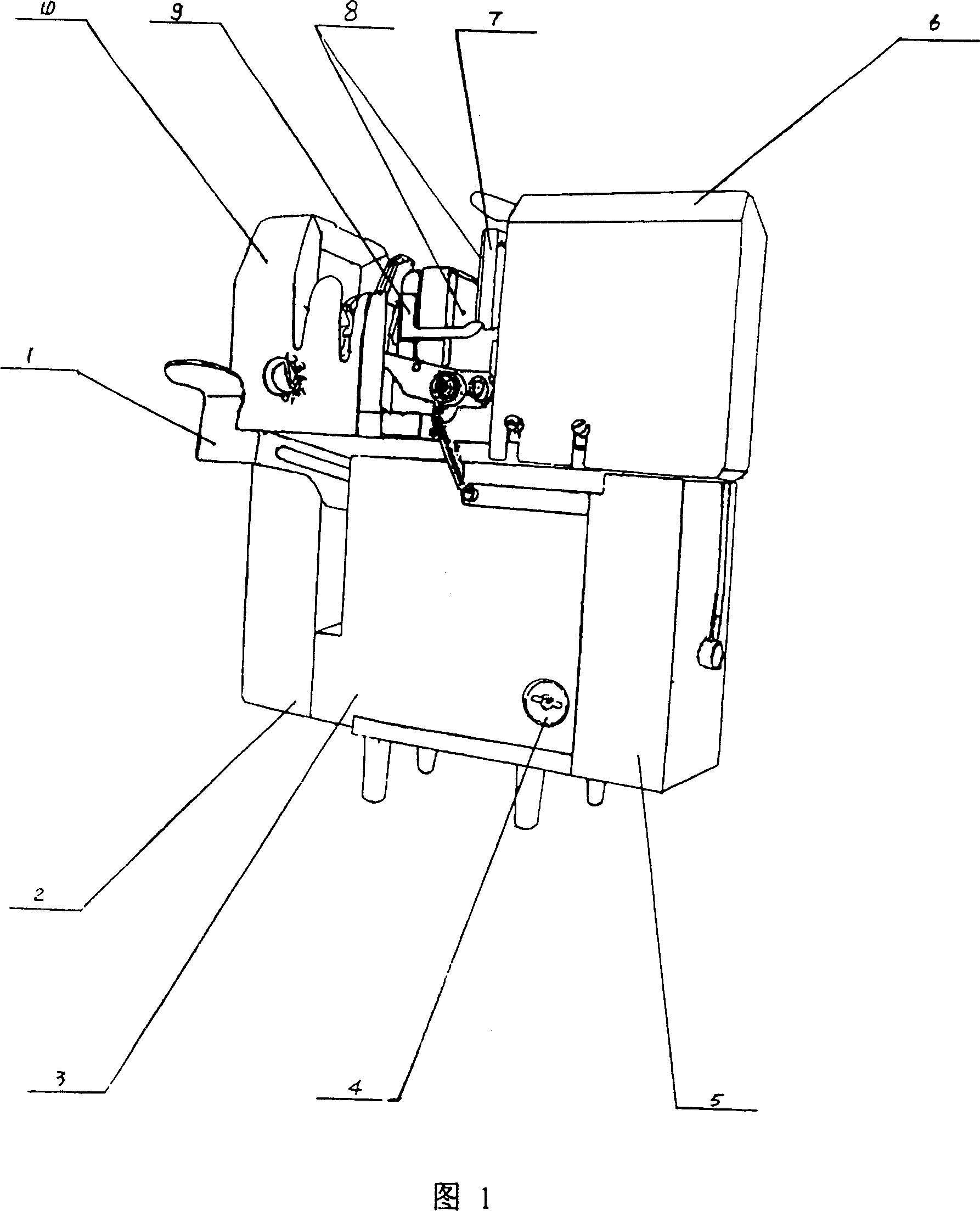

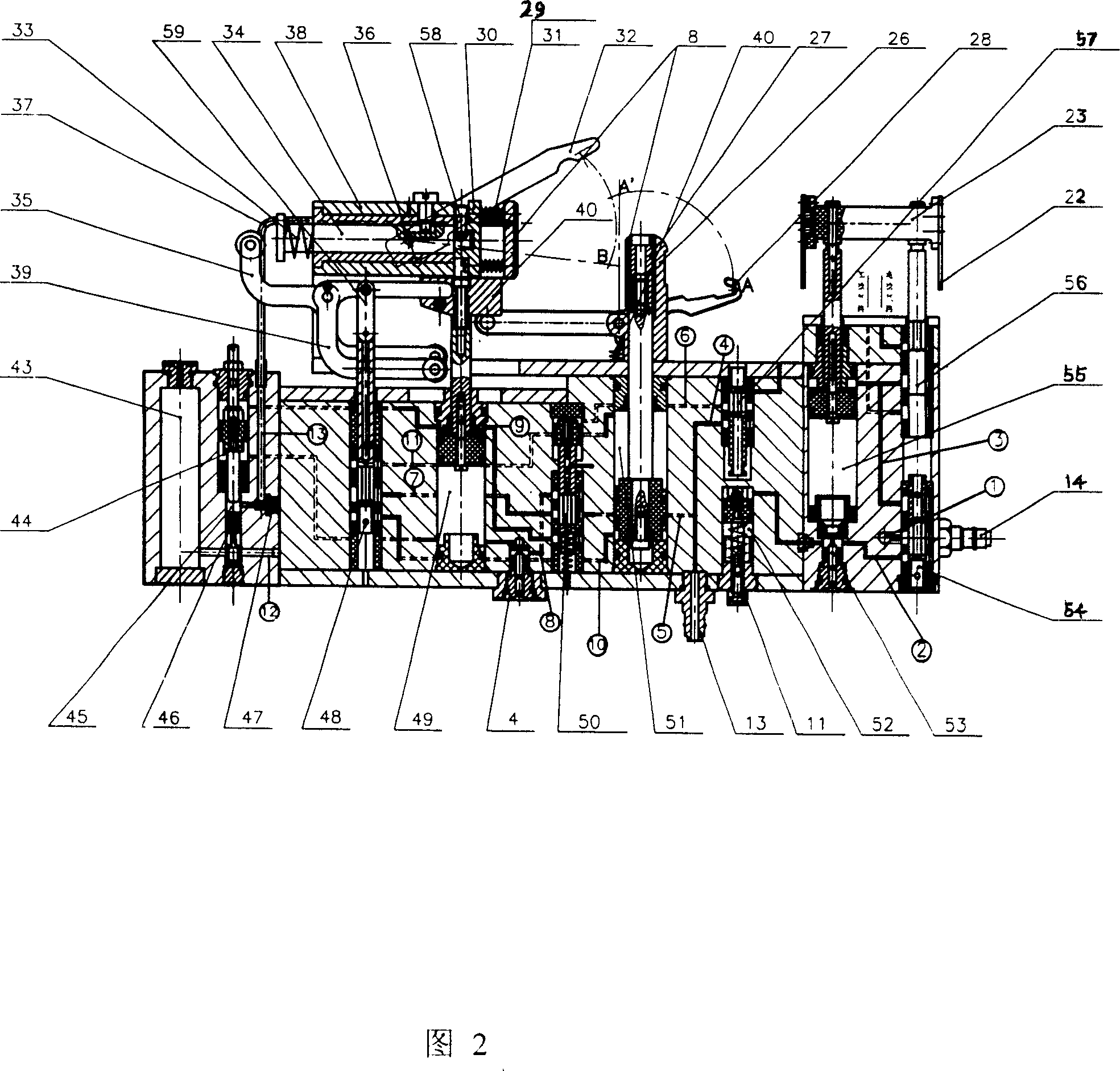

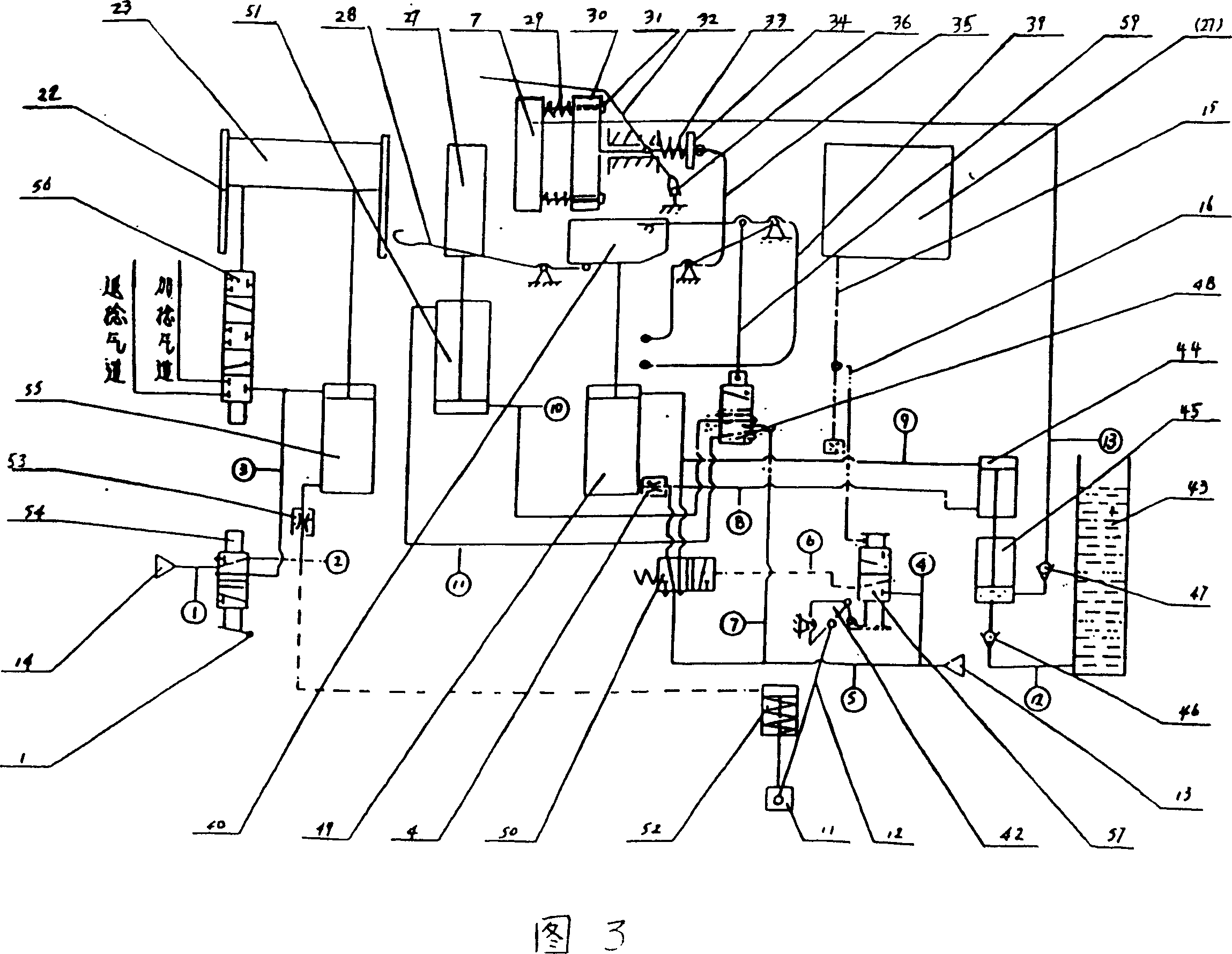

[0023] A kind of method of carrying out knotless splicing to yarn of the present invention is realized like this, and its steps are:

[0024] The first step is to fix the yarn on the air twister, press the manual trigger 1 of the air twister, and the cylinder piston of the air twister starts to work downward under the action of compressed air, and completes the yarn cutting and yarn pressing actions;

[0025] In the second step, after the above-mentioned actions are completed, compressed air enters the untwisting tube 25 to form a high-speed airflow, and the broken ends of the yarn are blown into the untwisting chamber (not shown in the figure), and the rubber vibrating plate in the untwisting chamber is blown to make a high-speed airflow. Frequency oscillation, so that the broken yarn is untwisted into cotton wool, and the untwisting is completed;

[0026] In the third step, the compressed air enters the splicing cavity through the twisting air channel to form a high-speed ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com