Partition board waterproof and anti-seepage joint structure and construction method thereof

A technology of partition board and wall board, applied in the direction of walls, building components, building structures, etc., can solve the problems of low strength, weak connection, gaps, etc., to improve the splicing strength, safe and reliable construction, and improve the overall performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

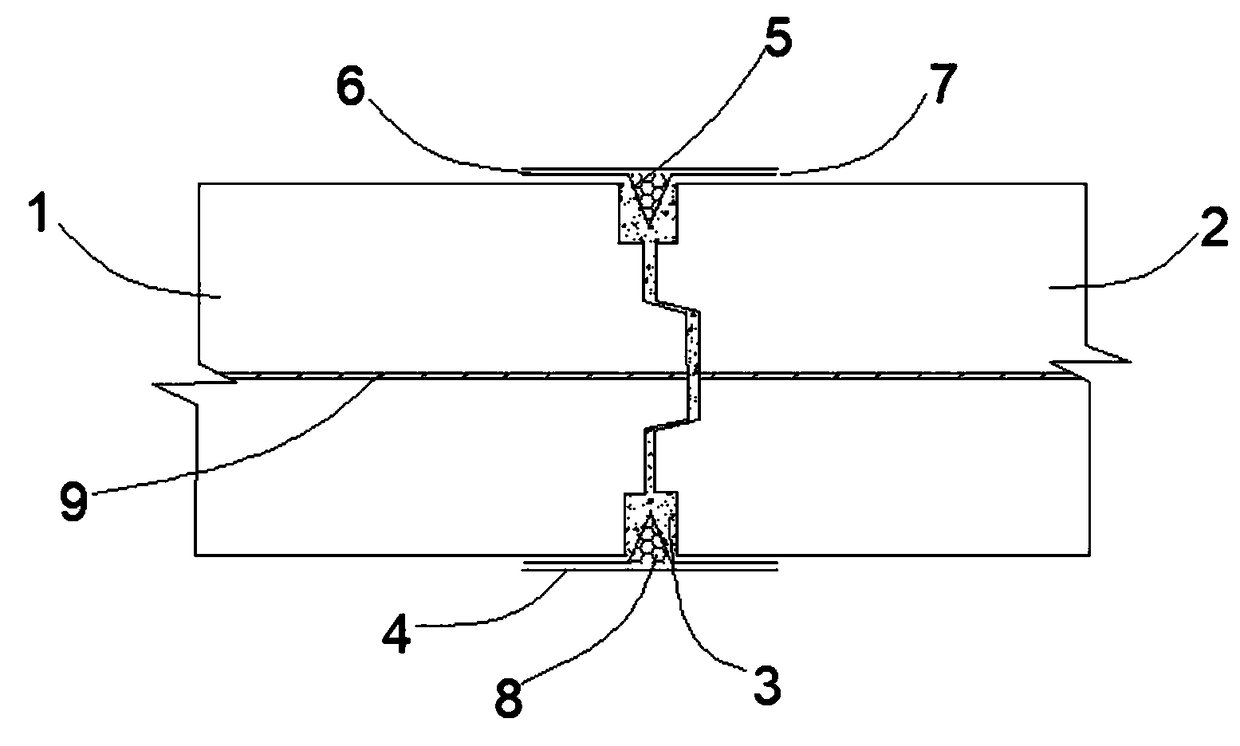

[0025] Such as figure 1 As shown, a waterproof and anti-seepage joint structure of a partition wall according to the present invention includes a left wall panel 1 and a right wall panel 2, and a vertical joint is formed between the left wall panel 1 and the right wall panel 2 structure, the joint structure also includes a caulking mortar layer 3, a water stop board and an anti-crack fiber grid belt layer 4, and the caulking mortar layer 3 is filled in the joint structure; the water stop board includes The V-shaped plate 5, the first horizontal plate 6 and the second horizontal plate 7, the first horizontal plate 6 is connected transversely with one end of the V-shaped plate 5, and the second horizontal plate 6 is transversely connected with the other end of the V-shaped plate 5 connected, and the angled tip of the V-shaped plate 5 is pre-embedded in the joint structure, and the first horizontal plate 6 and the second horizontal plate 7 are symmetrically laid on the left wall ...

Embodiment 2

[0035] The caulking agent in the caulking agent layer 8 is made of the following raw materials in parts by weight: 130 parts of trifunctional polyether polyol, 45 parts of isocyanate, 40 parts of propane butane, 1 part of composite catalyst, 1 part of chlorinated paraffin part and 0.5 part of Si-C type silicone oil foam stabilizer. The composite catalyst is formed by mixing dibutyltin dilaurate and 2,2-bismorpholino diethyl ether in a mass ratio of 1:2.

[0036] All the other parameters and preparation process are the same as in Example 1.

Embodiment 3

[0038] The caulking agent in the caulking agent layer 8 is made of the following raw materials in parts by weight: 150 parts of trifunctional polyether polyol, 65 parts of isocyanate, 50 parts of propylene butane, 5 parts of composite catalyst, 3 parts of chlorinated paraffin and 2 parts of Si-C silicone oil foam stabilizer. The composite catalyst is formed by mixing dibutyltin dilaurate and 2,2-bismorpholino diethyl ether at a mass ratio of 1:1.

[0039] All the other parameters and preparation process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com