Patents

Literature

58results about How to "Achieve secondary sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

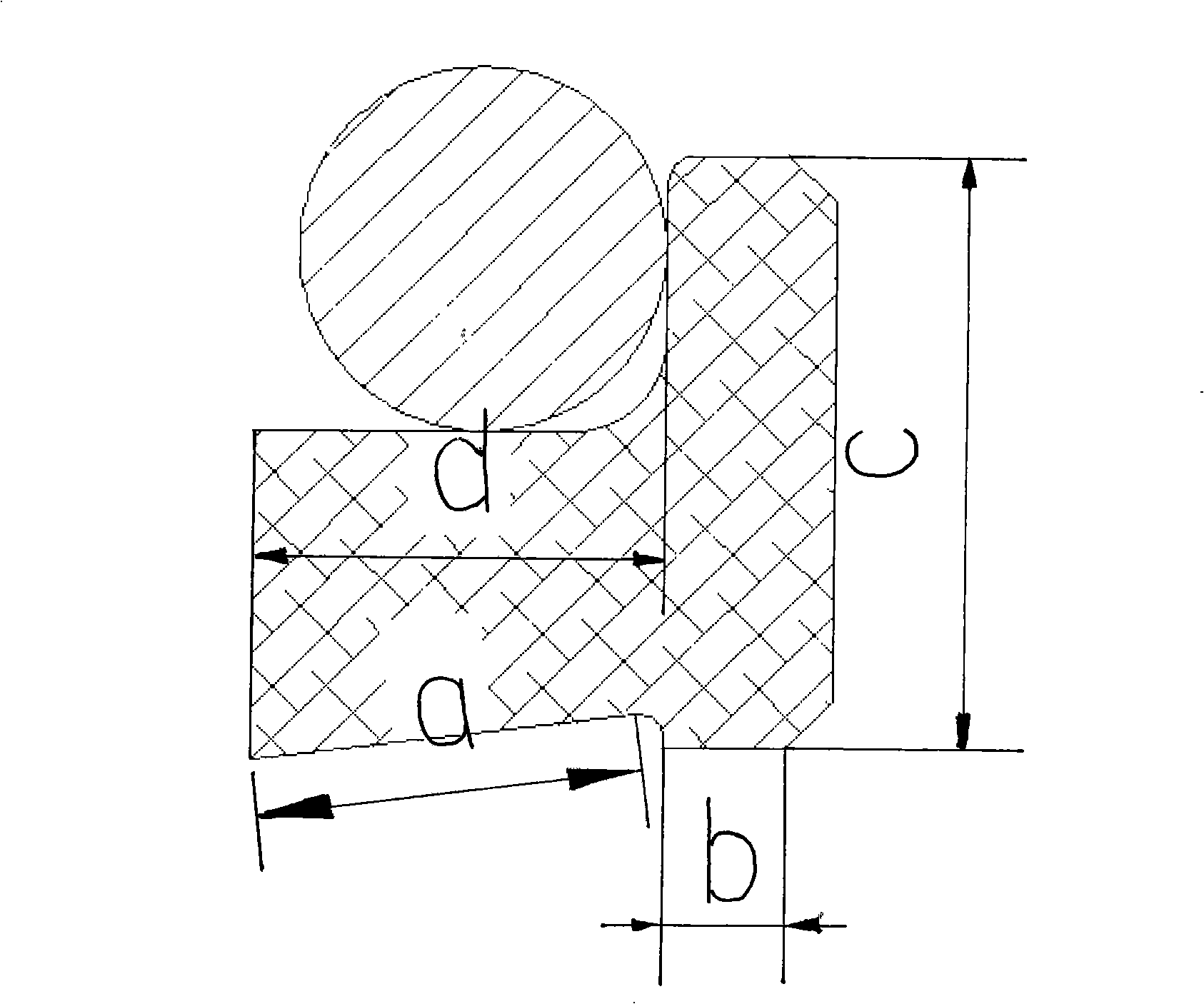

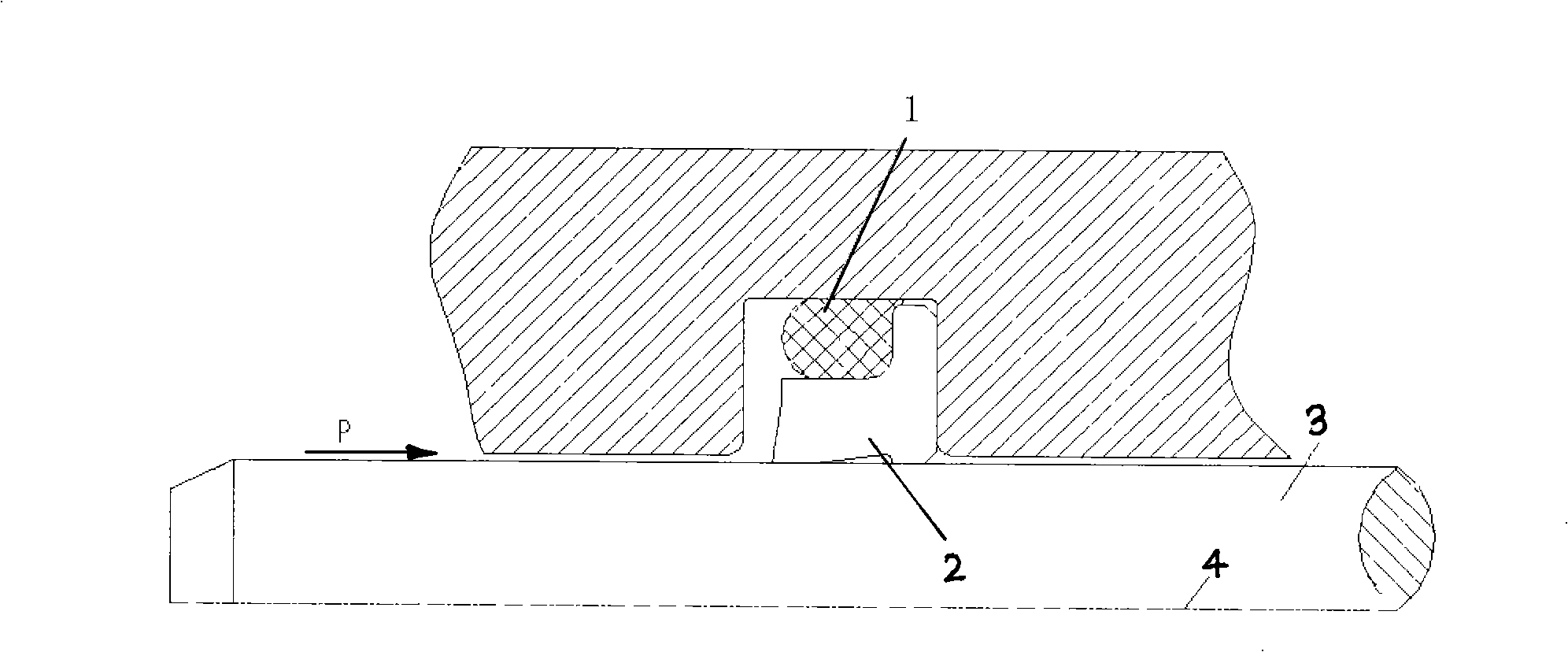

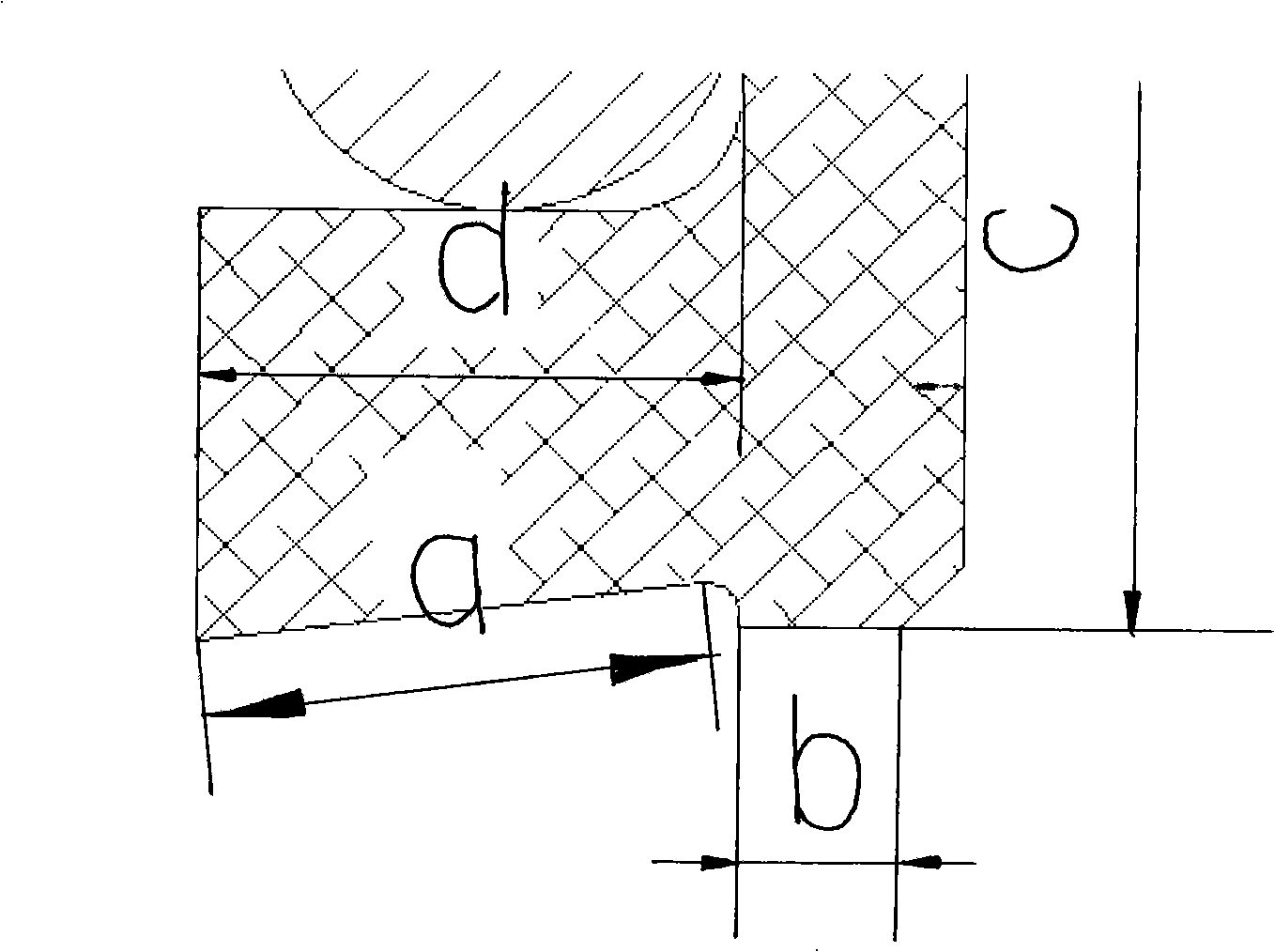

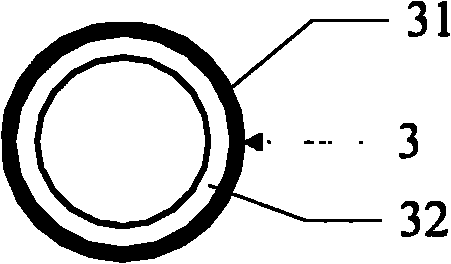

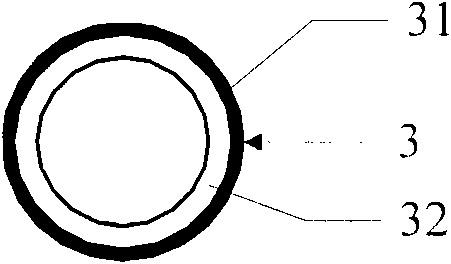

L-shaped slip-ring sealed ring

InactiveCN101338819AImprove wear resistanceImprove creep resistanceEngine sealsPiston ringsEngineeringHigh pressure

The present invention discloses an L-shaped slip ring sealing ring, which is composed of an O-shaped ring and an L-shaped slip ring; wherein, the lip of the L-shaped slip ring, which is contacted with a main shaft, is composed of a straight section and an oblique section; the included angle between the oblique section and the axial line is between 6 degrees and 8 degrees. The L-shaped slip ring sealing ring, which is particularly applicable to the sealing of a large-diameter piston rod, has good abrasion-resisting, creep-resisting and high-pressure-resisting properties and has more persistent elastic property and prominent anti-aging property.

Owner:GUANGZHOU MECHANICAL ENG RES INST

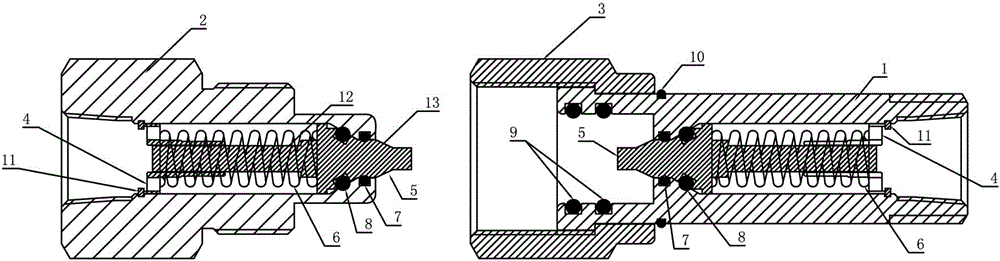

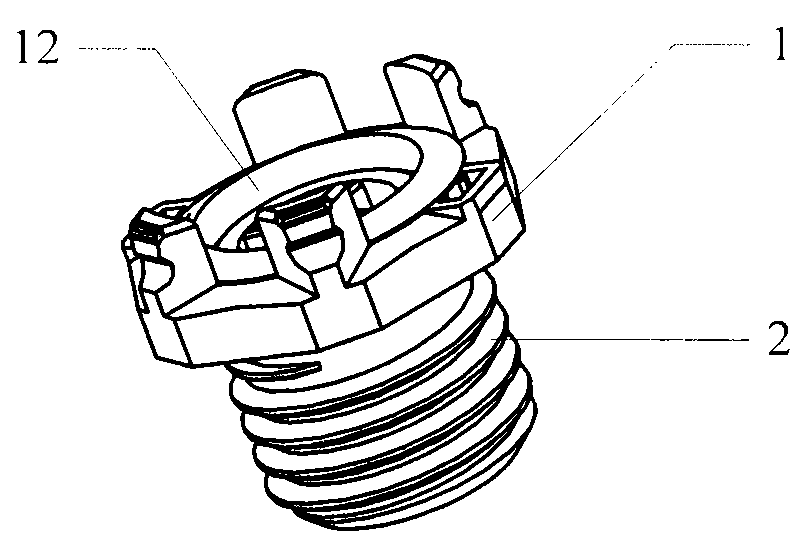

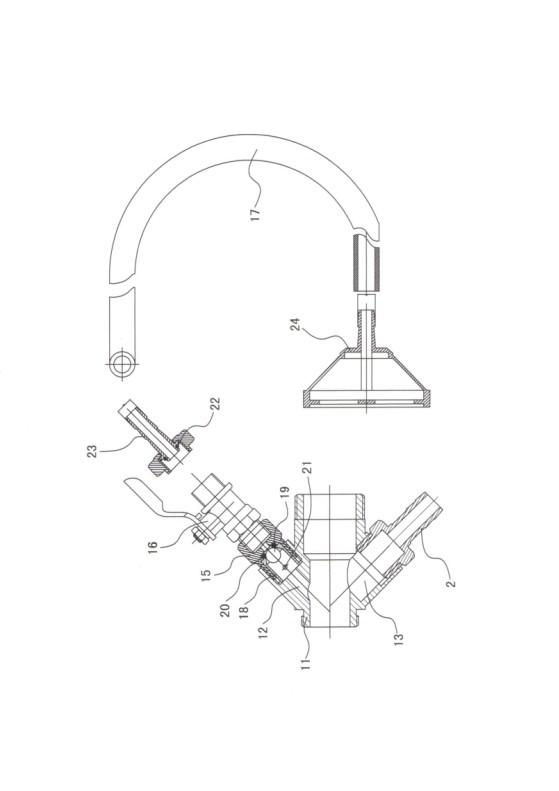

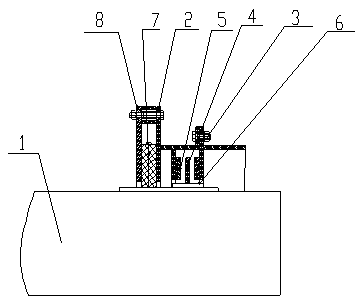

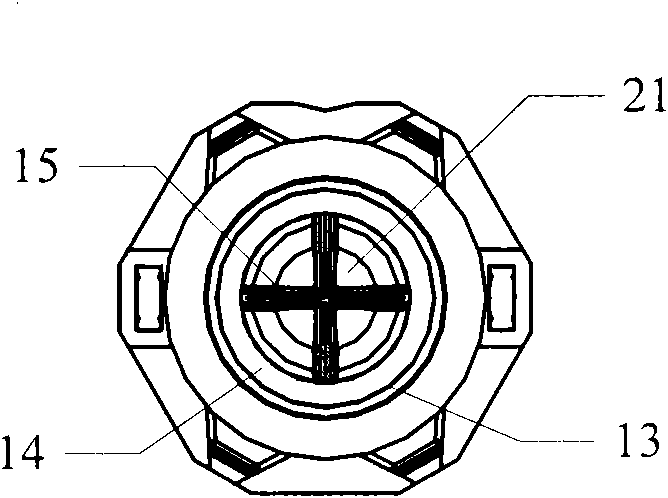

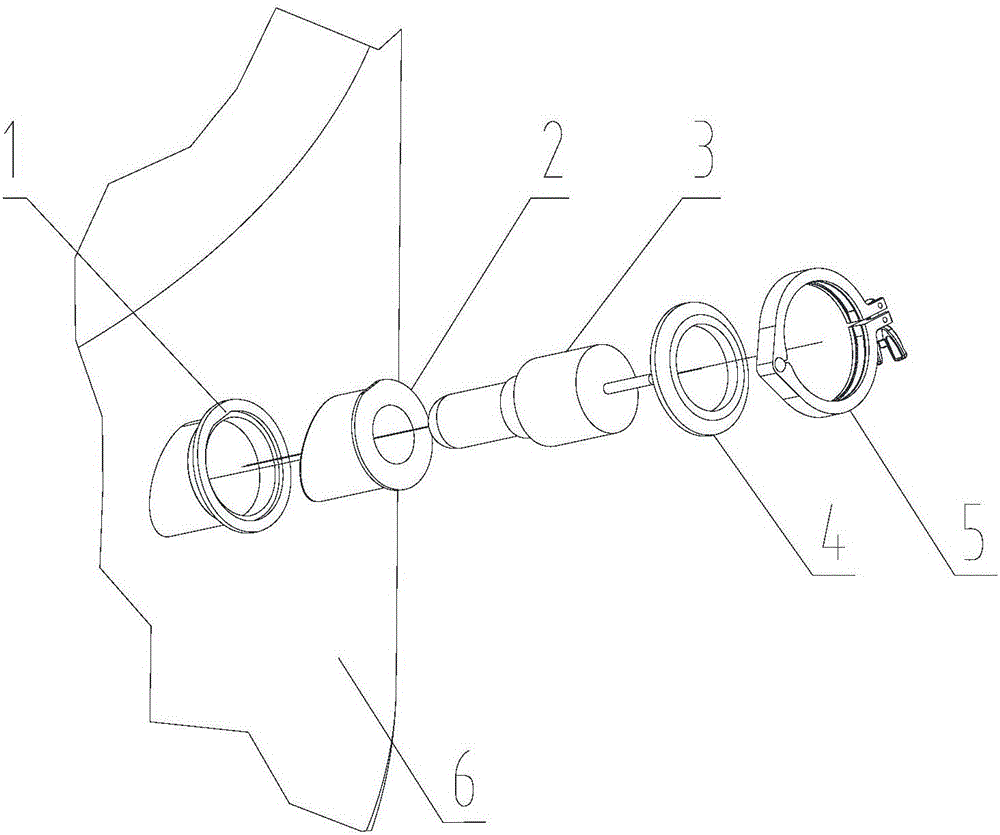

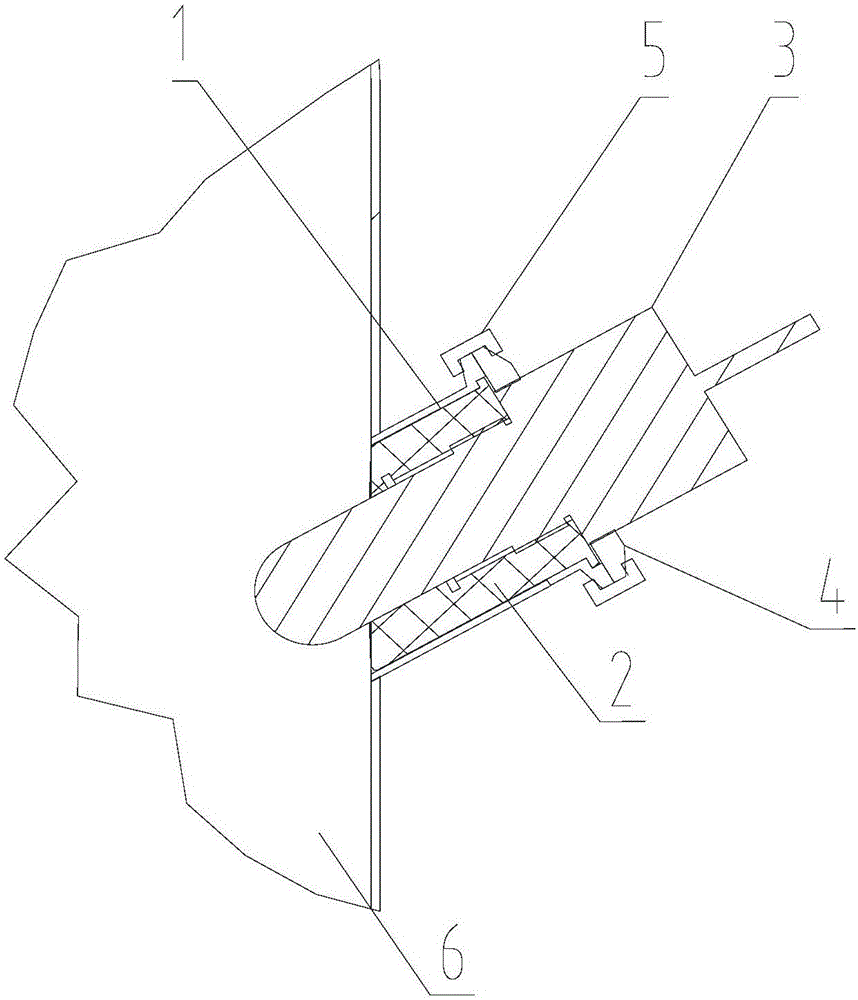

Special attachment joint for introducing ammonia gas and ammonia water

InactiveCN104879587AEasy to useSimple structureJoints with fluid cut-off meansAmmonia storageEngineering

The invention discloses a special attachment joint for introducing ammonia gas and ammonia water. The special attachment joint comprises a male main body, a female main body, an outer ring, a valve core, a spring and a sealing element. The outer ring sleeves the front end of the female main body and is matched with the male main body inserted into the female main body by use of threads, and therefore, the male main body and the female main body can be fastened and locked; a gas guide channel is formed in the male main body and the female main body, and the two gas guide channels are the same in shape; a valve core is mounted in each of the two gas guide channels by use of a guide part and a spring; the front end of the valve core extends out of the opening of the gas guide channel. The special attachment joint is simple in structure and reasonable in design; the male main body and the female main body are sealed twice no matter in a disconnected state and a connected state, and an ammonia storage tank can be used more safely.

Owner:张燕梅

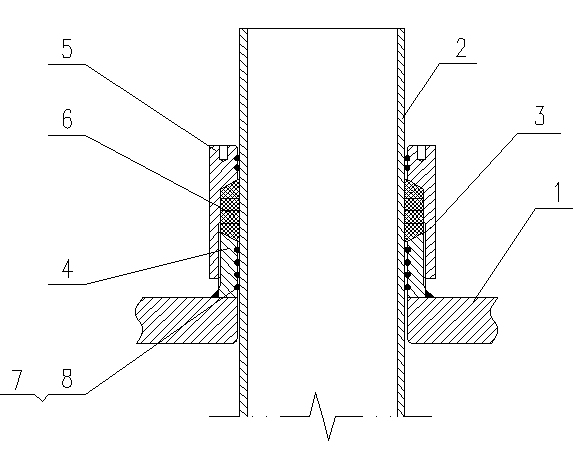

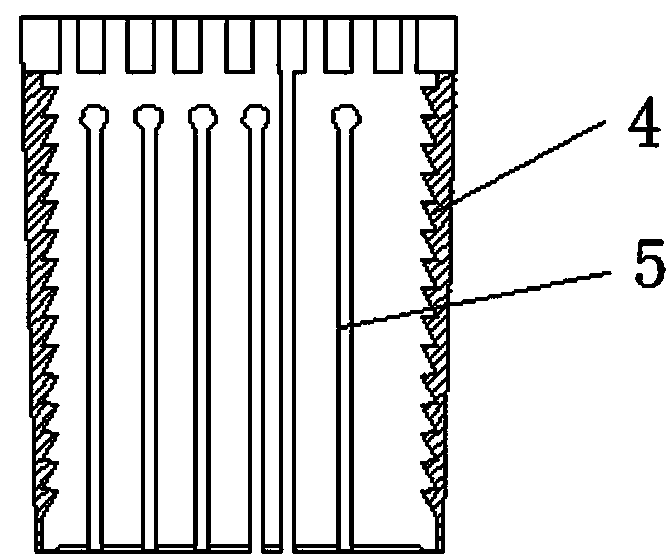

Single pipe free telescopic structure of high-temperature air preheater

A single pipe free telescopic structure of a high-temperature air preheater relates to a high-temperature air preheater, belongs to the field of connection modes between a heating pipe and a tubular plate and comprises the tubular plate and a heat exchanging plate vertically connected on the tubular plate; a sealing system is arranged between the heat exchanging plate and the tubular plate and comprises a filling top block, a filling box and fillings; the filling top block and the filling box are respectively sleeved outside the heat exchanging pipe, the filling top block is welded on the tubular plate, the filling box is in thread connection on the filling top block, and the fillings are filed between the filling top block and the filling box; at least one installation groove is arranged on the contact face between the filling top block and the heat exchanging pipe, and at least one installation groove is arranged on the contact face between the filling box and the heat exchanging pipe; and seal rings are respectively arranged in the installation grooves of the filling top block and the filling box. The single pipe free telescopic structure of the high-temperature air preheater avoids the incomplete sealing or blocking phenomena easily caused by the connection structure between a pipe fitting and the tubular plate, and solves the problem of difficulty in replacement of the seal rings and the filling box at the same time.

Owner:金沙 +2

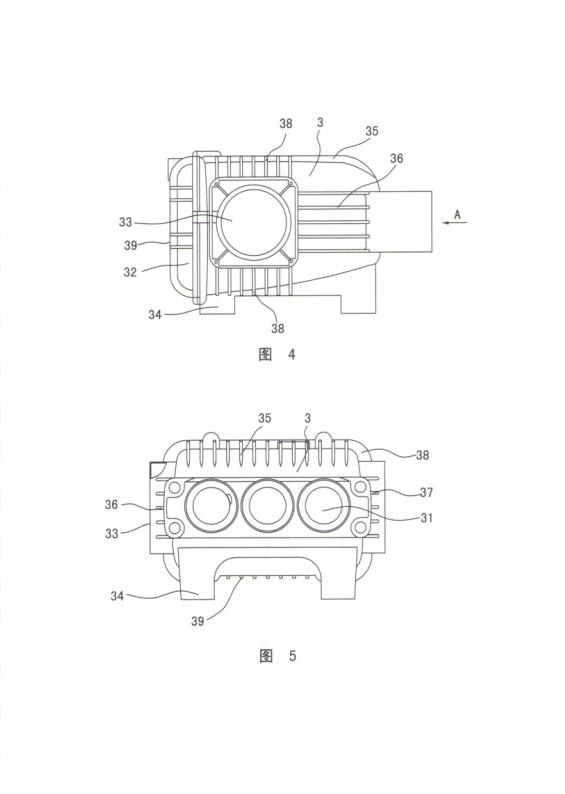

Two-way inflation pump

InactiveCN103485999AIngenious designImprove efficiencyPositive displacement pump componentsPumpsPistonEngineering

The invention relates to a two-way inflation pump comprising a barrel. A working chamber is arranged in the barrel, a first one-way air outlet valve communicated with the working chamber to allow air to be discharged from the working chamber is arranged at one end of the barrel, a cover is arranged at the other end of the barrel, a first one-way air inlet valve communicated with the working chamber to allow air to be guided into the working chamber is arranged on the cover, and a push-pull tube is arranged in the middle of the cover penetratingly. One end, extending into the barrel, of the push-pull tube is connected with a piston by which the working chamber is divided into a front working chamber and a rear working chamber. A cavity communicated with the atmosphere through the push-pull tube is formed in the piston. A second one-way air inlet valve, allowing air to be guided into the rear working chamber when the piston is pulled back, is arranged between the cavity and the rear working chamber. The other end of the push-pull tube is combined with a handle. A second one-way air outlet valve, which is communicated with the front working chamber and allows air to be discharged from the front working chamber when the piston is pulled back, is arranged on one side of the wall of the barrel. Inflation can be performed during reciprocation of the piston, and use efficiency is high.

Owner:JUNHONG PLASTIC PROD CO LTD

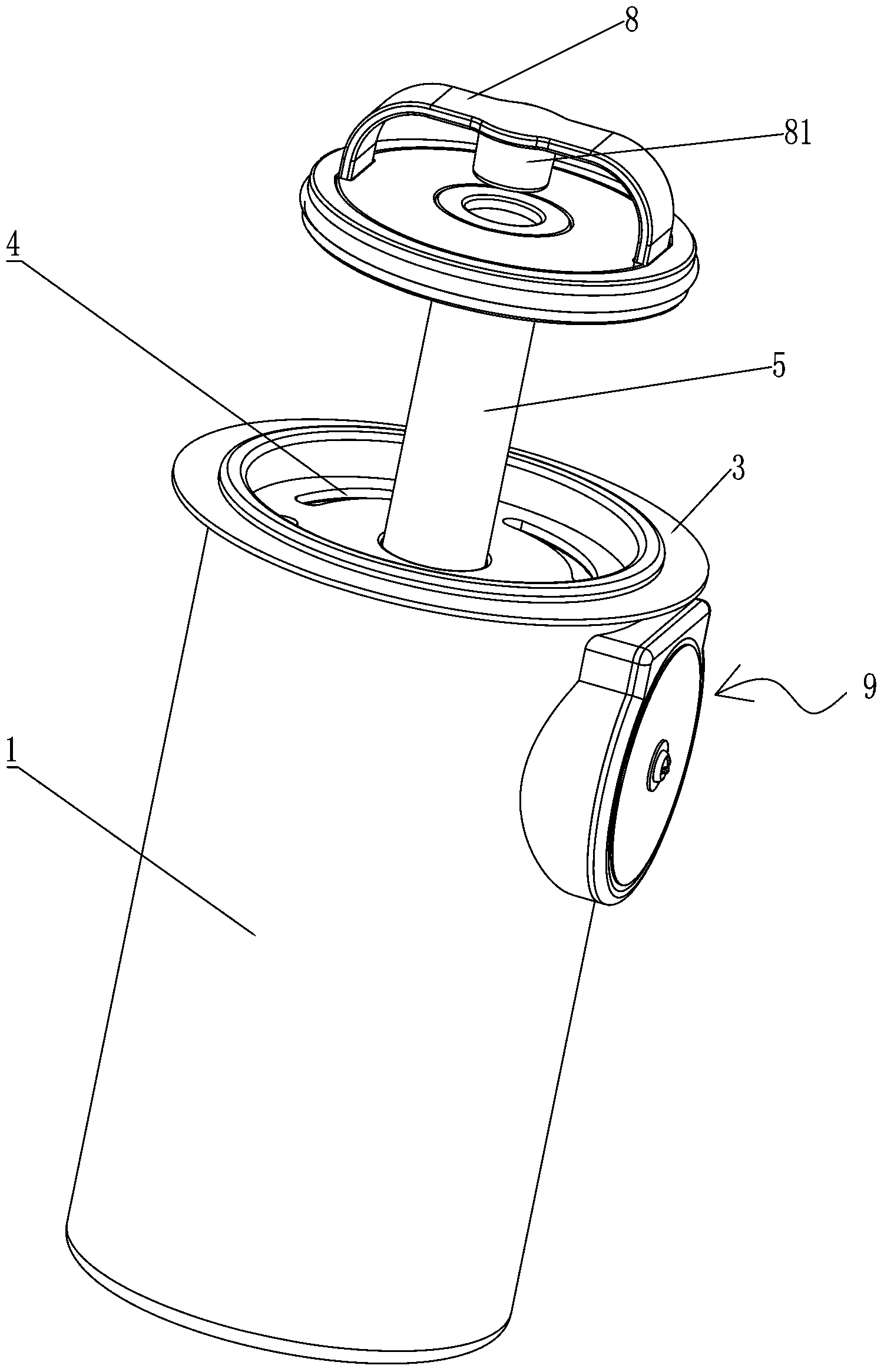

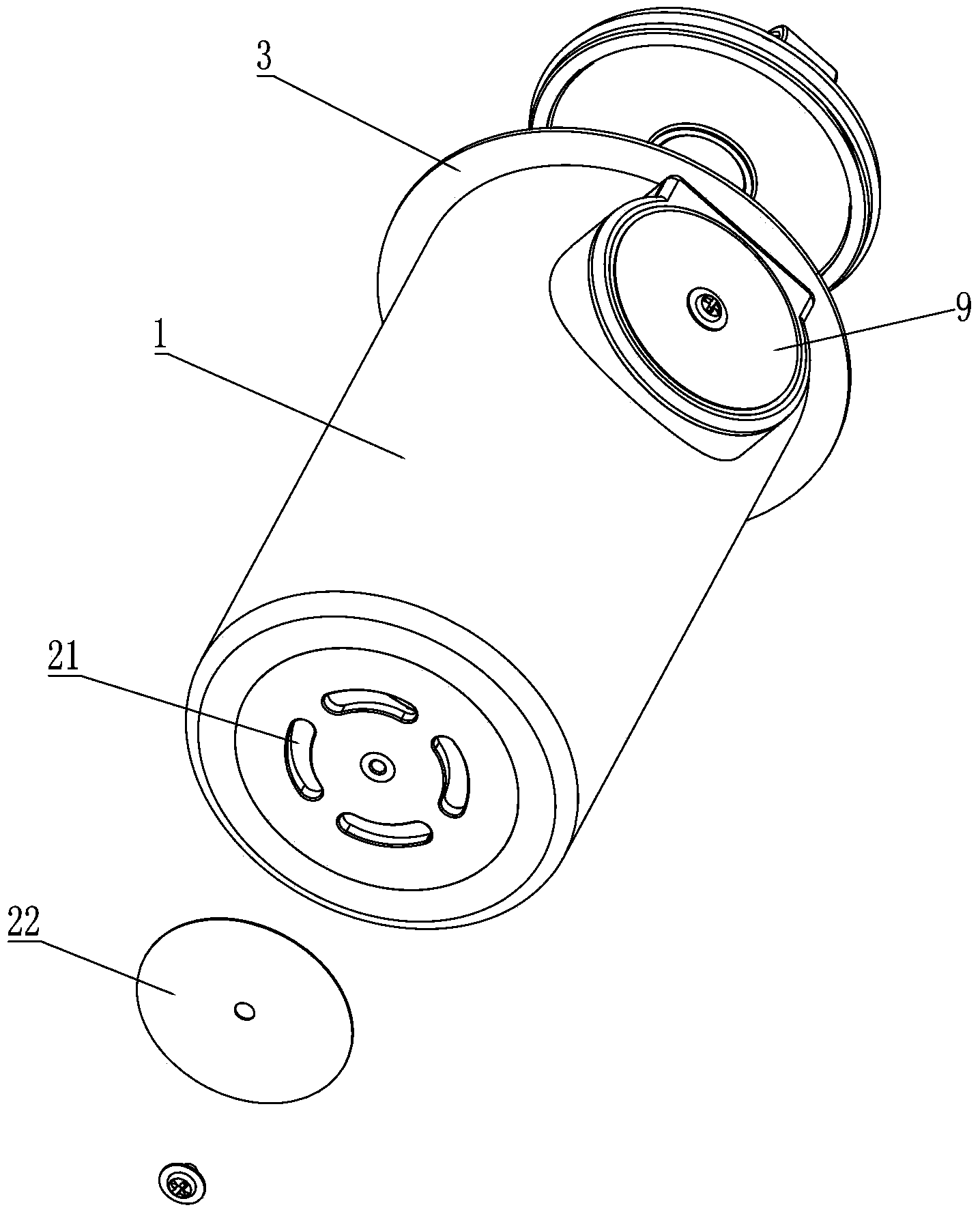

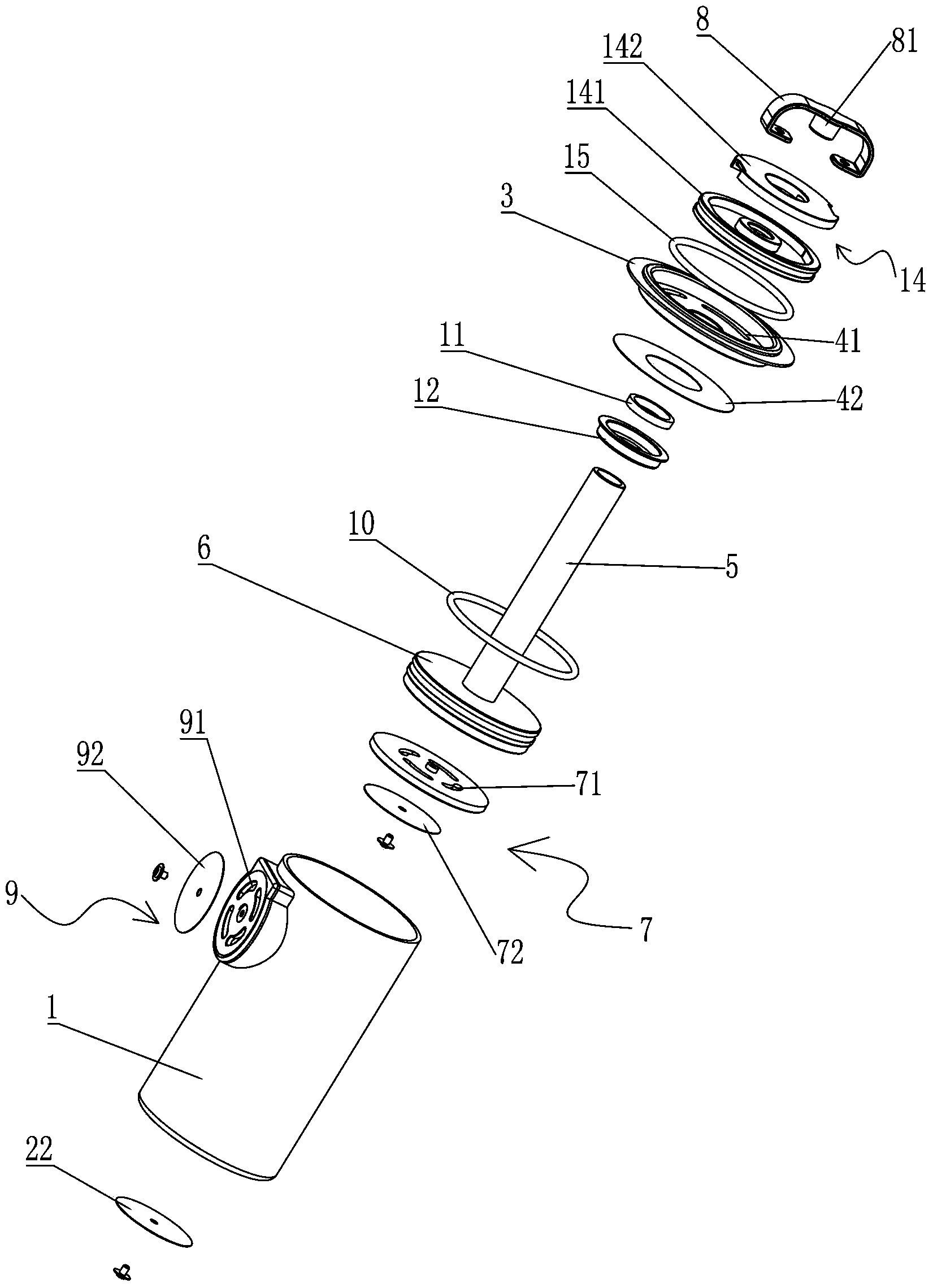

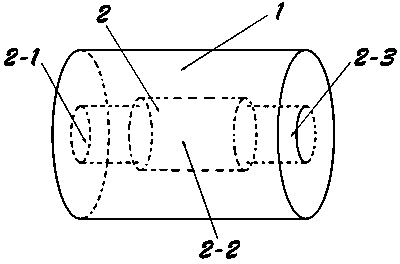

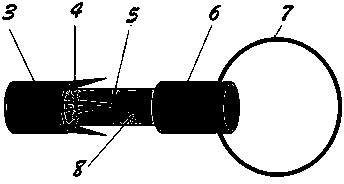

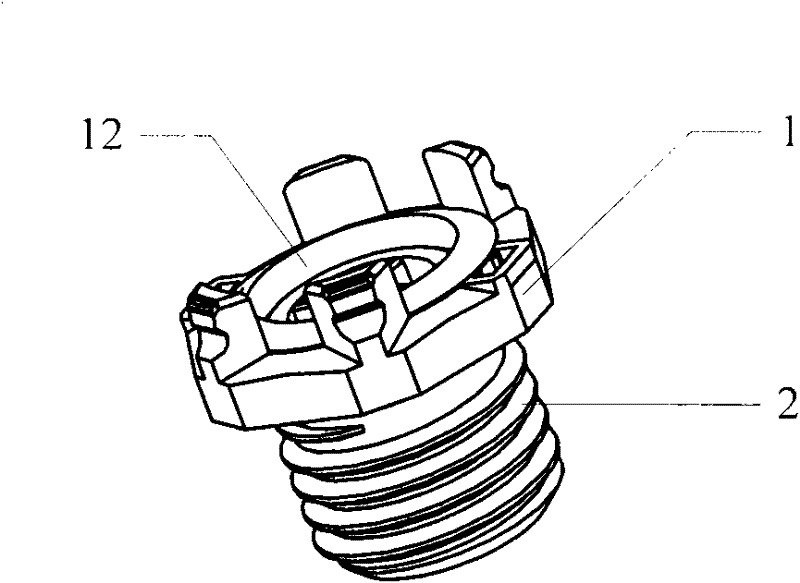

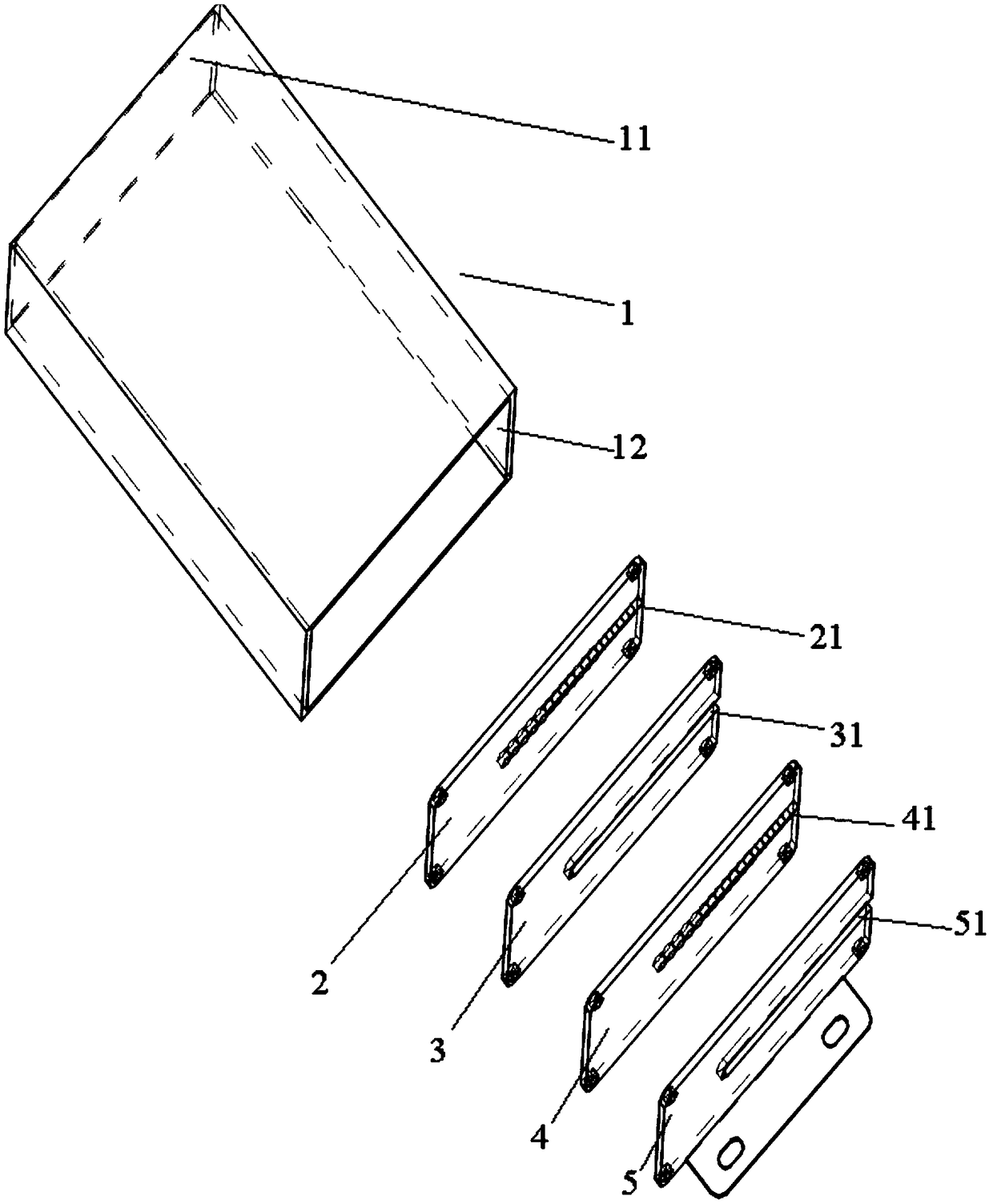

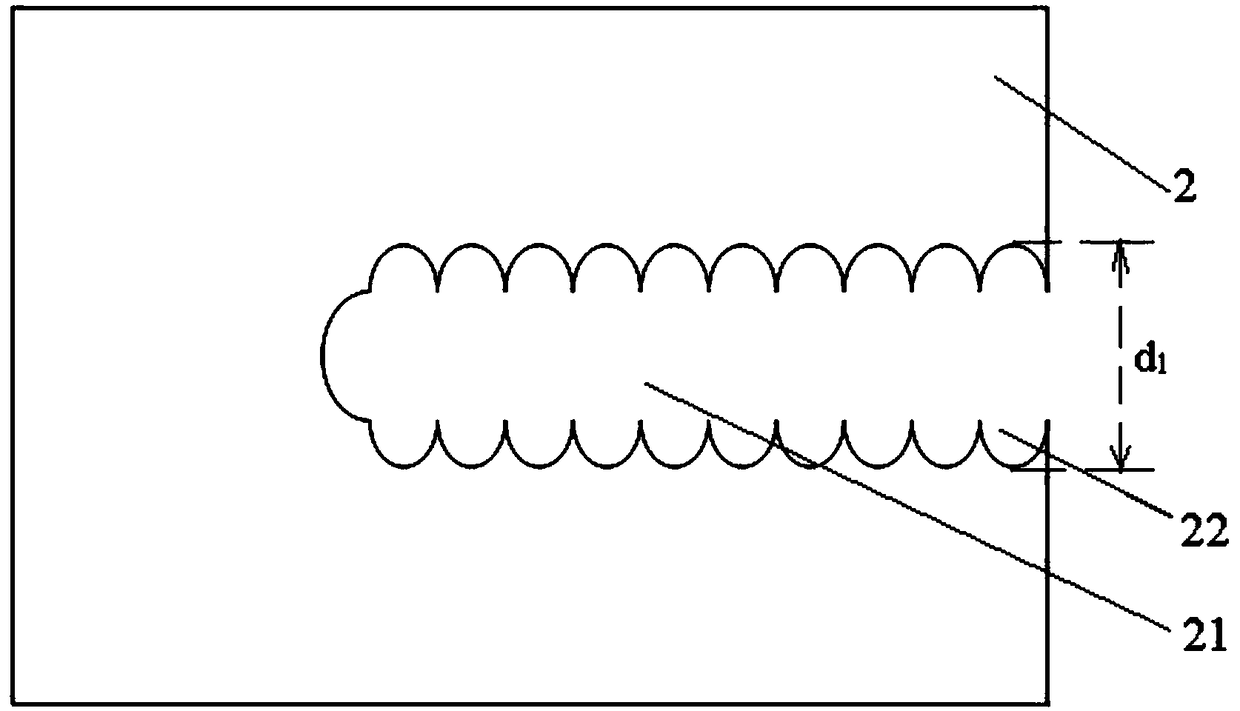

Red wine cork capable of being removed fast

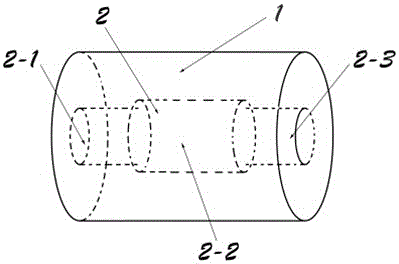

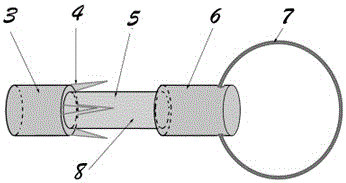

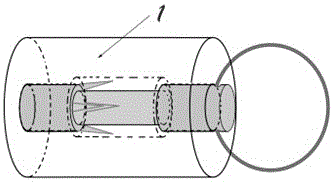

ActiveCN104354976AAchieve secondary sealingClosuresClosure using stoppersInterference fitEngineering

The invention provides a red wine cork capable of being removed fast and aims to provide a cork which can be removed fast without a corkscrew and can realize secondary sealing. The red wine cork comprises a cork body (1), wherein the cork body (1) is provided with a through hole (2) penetrating through the cork body (1); a pull rod (8) is arranged in the through hole (2); the diameter of the middle part (2-2) of the through hole is greater than those of the front end (2-1) and the rear end (2-3) of the through hole; the pull rod (8) comprises a front cork (3), a rear cork (6) and a connecting rod (5) for connecting the front cork (3) with the rear cork (6); a pull handle (7) is arranged on the rear cork (6); an elastic piece is arranged at the joint of the front cork (3) and the connecting rod (5); at least one of the front cork (3) and the rear cork (6) is in interference fit with the through hole (2). The red wine cork provided by the invention is used as a wine cork.

Owner:枣庄市亚太石榴酒有限公司

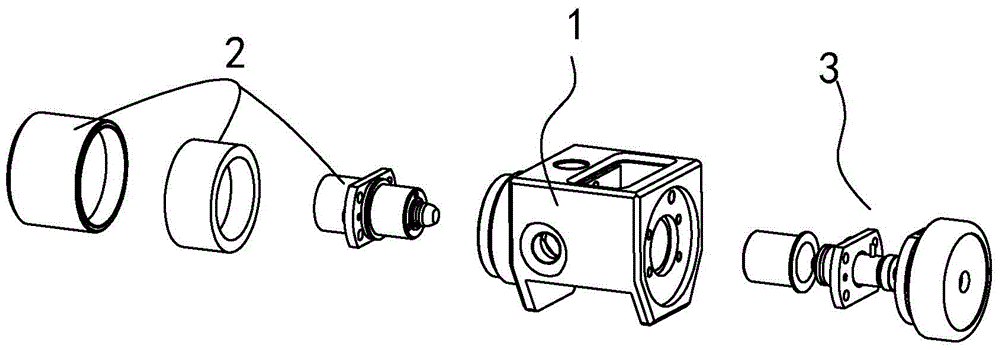

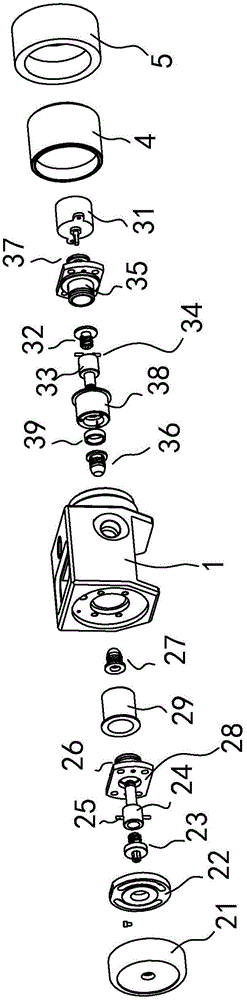

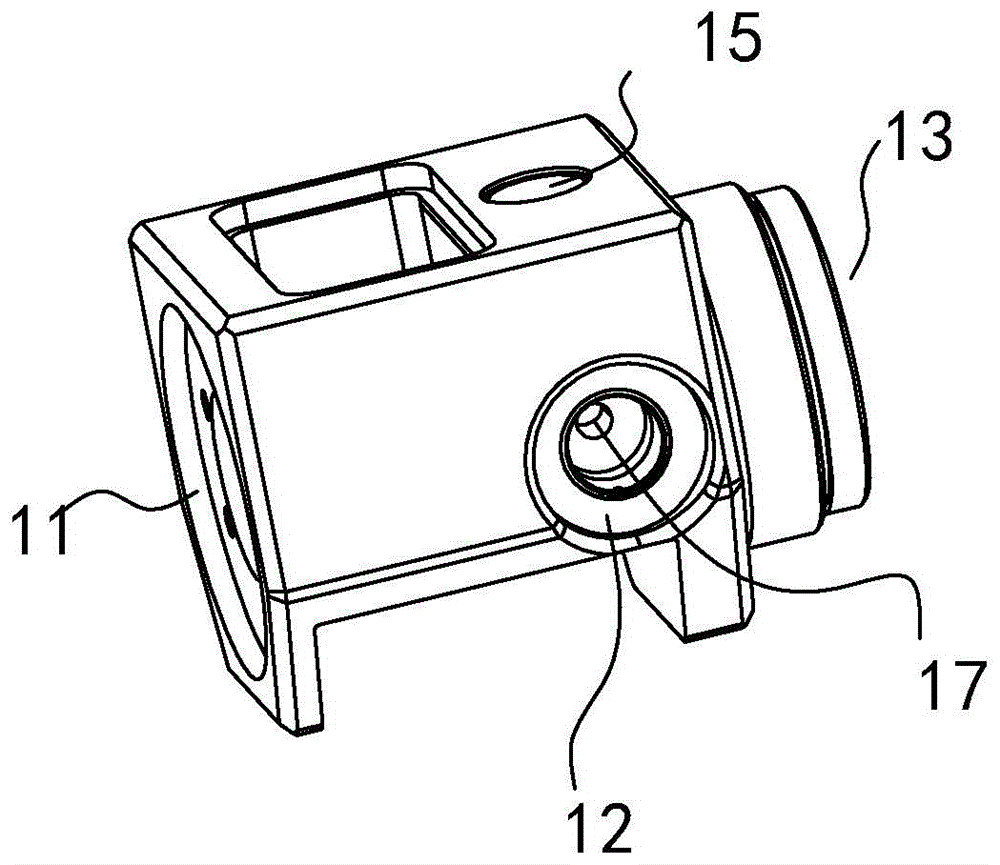

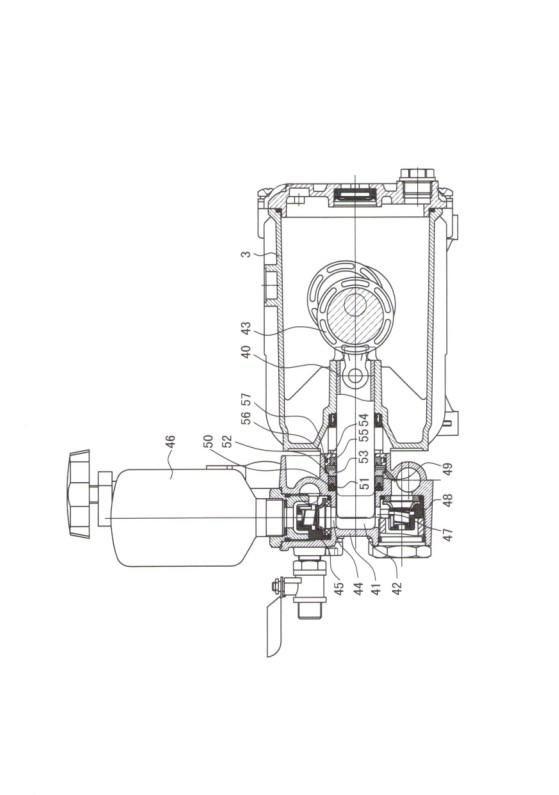

Bathroom cold and hot water constant-temperature device

InactiveCN104565496AReduce volumeIncrease the lengthOperating means/releasing devices for valvesMultiple way valvesWater channelWarm water

The invention discloses a bathroom cold and hot water constant-temperature device. The bathroom cold and hot water constant-temperature device comprises a valve core, a manual adjusting knob, a motor adjusting knob, a control circuit board and a power supply, wherein the four sides of the valve core are provided with a manual adjusting knob mounting hole, a cold water interface, a motor adjusting knob mounting hole and a hot water interface in sequence; the upper part of the valve core is provided with a warm water outlet; a power supply accommodating groove is formed in the lower part of the valve core; a mixed channel, a cold water channel, a hot water channel and a warm water channel are formed inside the valve core; the manual adjusting knob mounting hole is communicated with the motor adjusting knob mounting hole through the mixing channel; the cold water interface is communicated with the mixing channel through the cold water channel; the hot water interface is communicated with the motor adjusting knob mounting hole through the hot water channel; the manual adjusting knob mounting hole is communicated with the warm water outlet through the warm water channel. By adopting the bathroom cold and hot water constant-temperature device, the technical problems of cold and hot water sealing and flow adjustment can be solved.

Owner:SHAOXING DAYOU ELECTROMECHANICAL

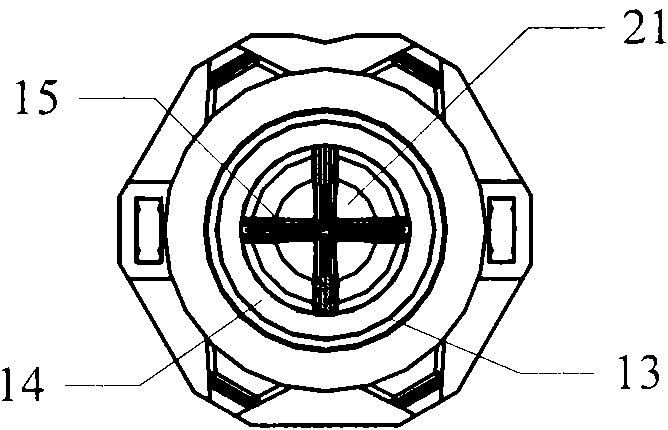

Waterproof vent valve and encapsulation method thereof

ActiveCN101868131AAchieve secondary sealingCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringScrew cap

The invention discloses a waterproof vent valve, which comprises a screw cap, a screw stem, a waterproof vent film and an insert with a hole. The insert can be embedded in the screw cap to contain the waterproof vent film and seal the waterproof vent film in the screw cap. After the scheme is adopted, the invention closely encapsulates the waterproof vent film and a plastic valve together through the simple inset structure and realizes secondary sealing through further hot melting.

Owner:东莞市维赛实业有限公司

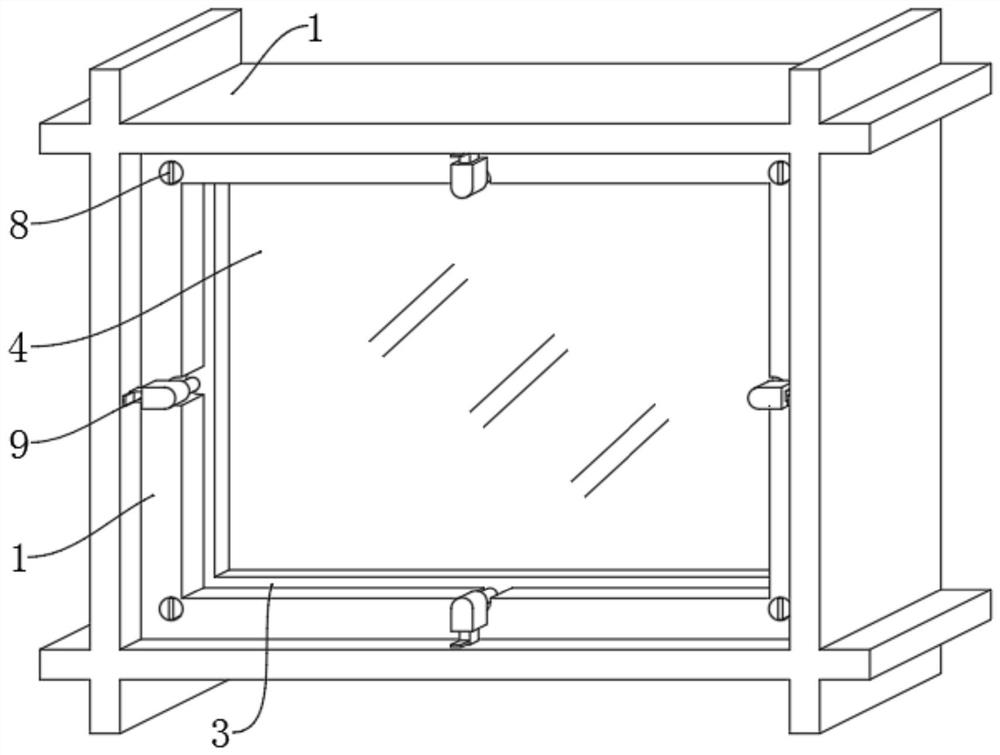

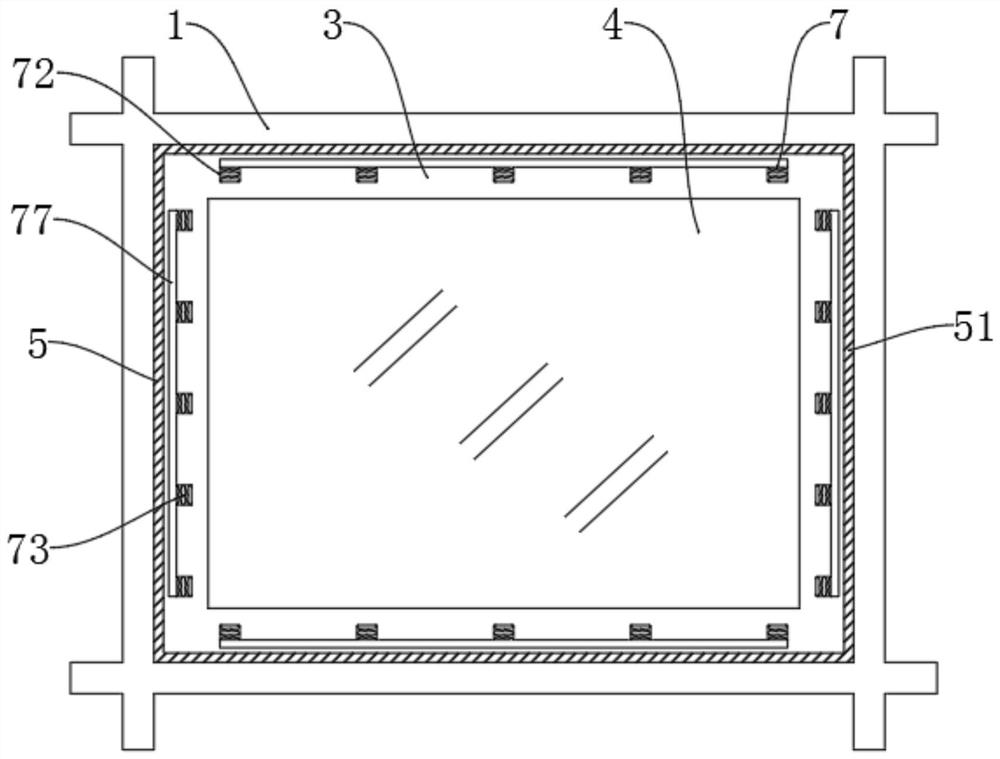

Anti-falling high-sealing glass curtain wall mounting structure

The invention provides an anti-falling high-sealing glass curtain wall mounting structure, and belongs to the technical field of glass curtain walls. The anti-falling high-sealing glass curtain wall mounting structure comprises a curtain wall steel structure, wherein the inner side of the curtain wall steel structure is fixedly connected with a mounting square frame; an outer sealing structure is arranged between a curtain wall frame and the curtain wall steel structure; an inner sealing structure is arranged between the curtain wall frame and the mounting square frame; the curtain wall steel structure is connected with the curtain wall frame through a connecting assembly; and the mounting square frame is connected with the curtain wall frame through a side reinforcing structure. The anti-falling high-sealing glass curtain wall mounting structure solves the problems that during mounting of a glass curtain wall, glass is compressed by a metal plate on the steel structure, the steel structure and the metal plate are locked through bolts, during construction, more than three workers are required to operate, construction is complicated, the personnel cost is high, the mounting efficiency of the glass curtain wall is greatly reduced, meanwhile, the glass curtain wall is sealed by injecting sealant generally, the sealant easily falls off after being used for a long time, the sealing effect is poor, and water seepage easily occurs.

Owner:江苏致一建设工程有限公司

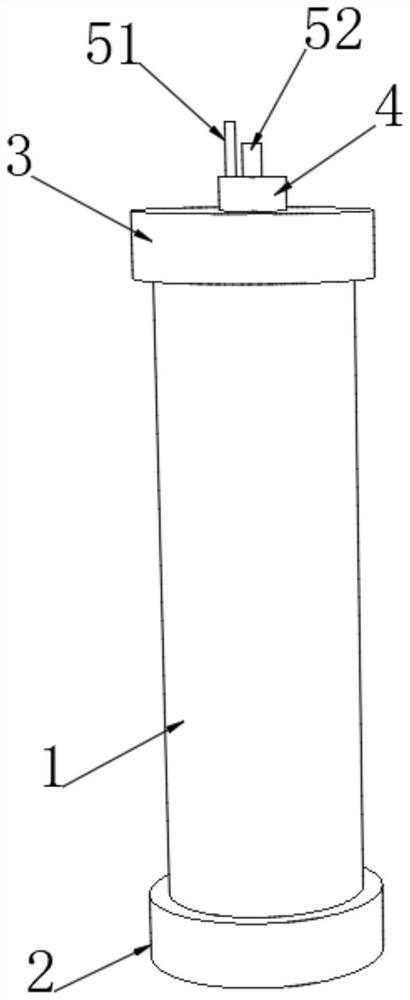

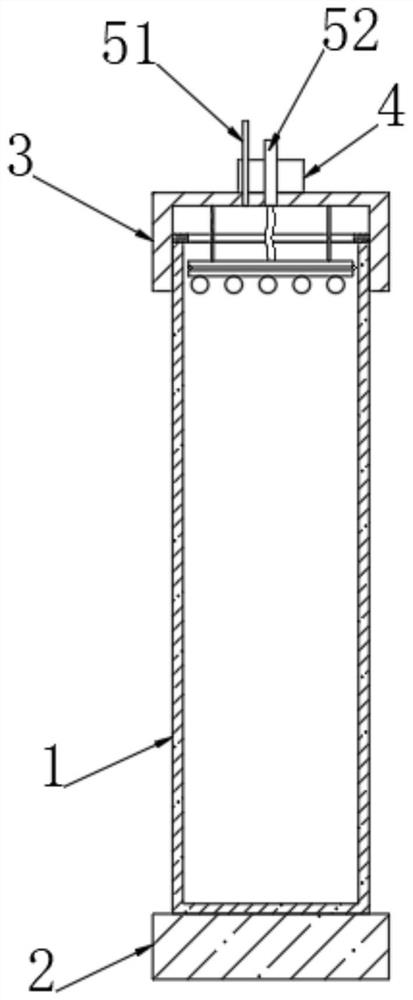

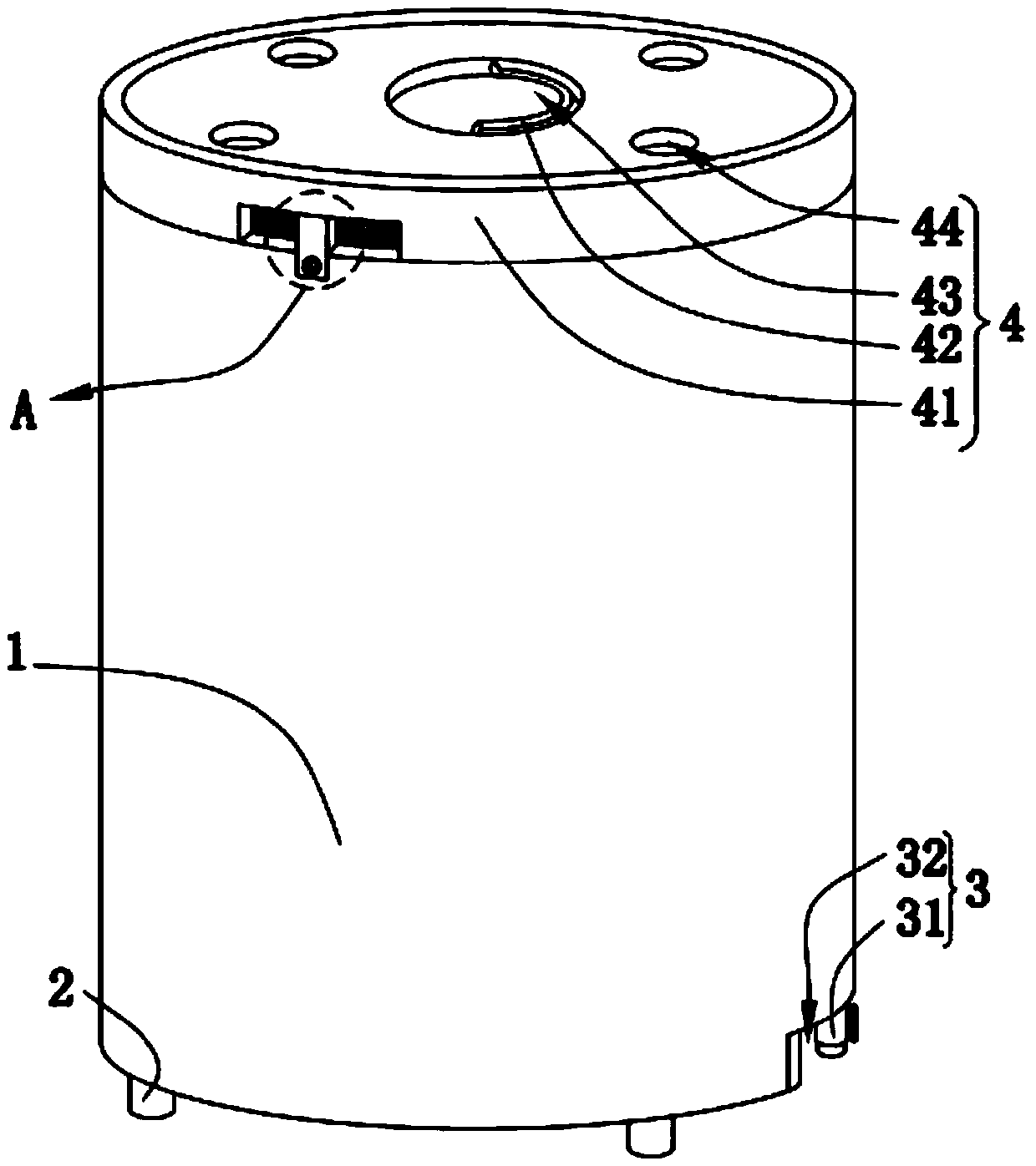

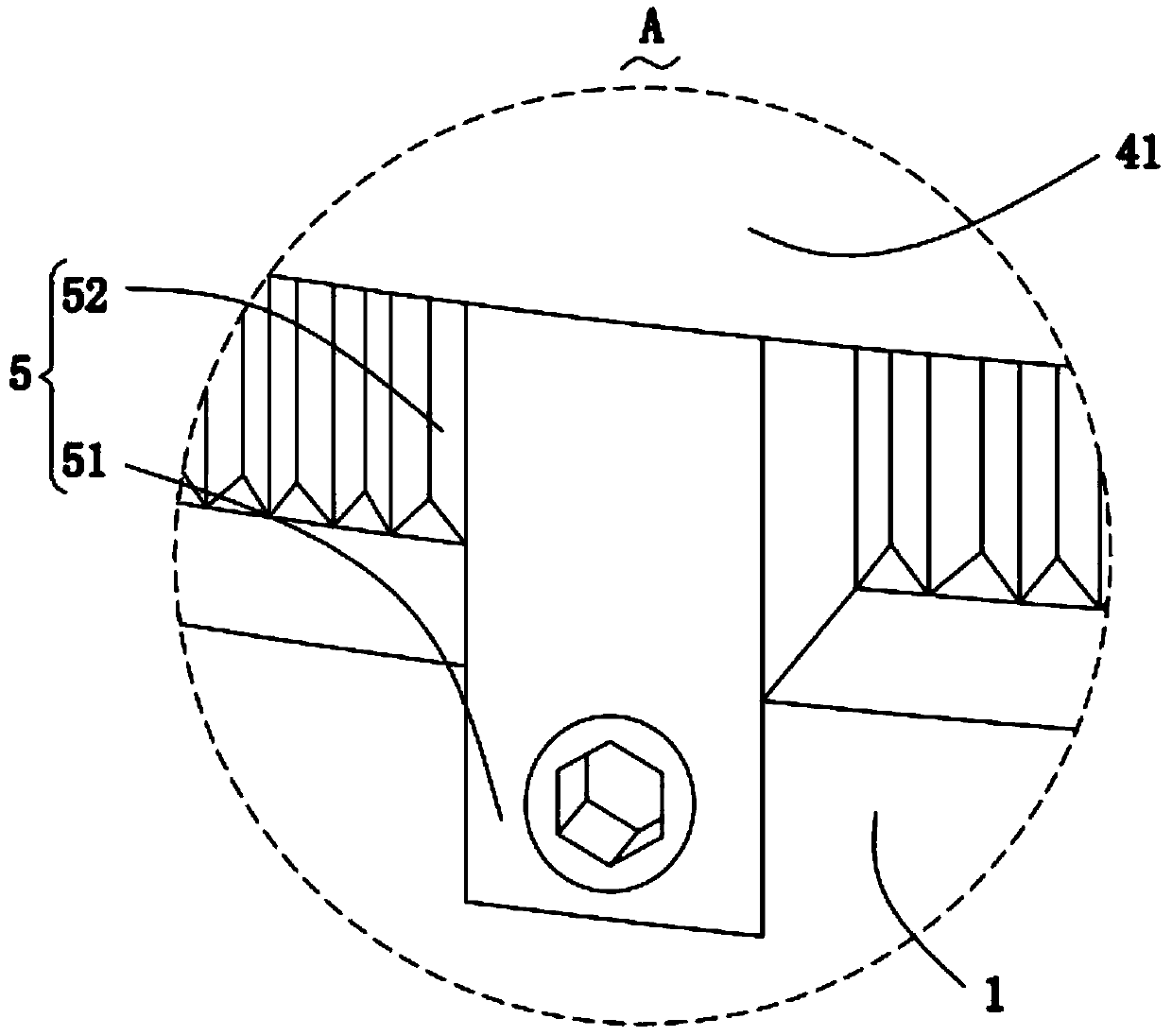

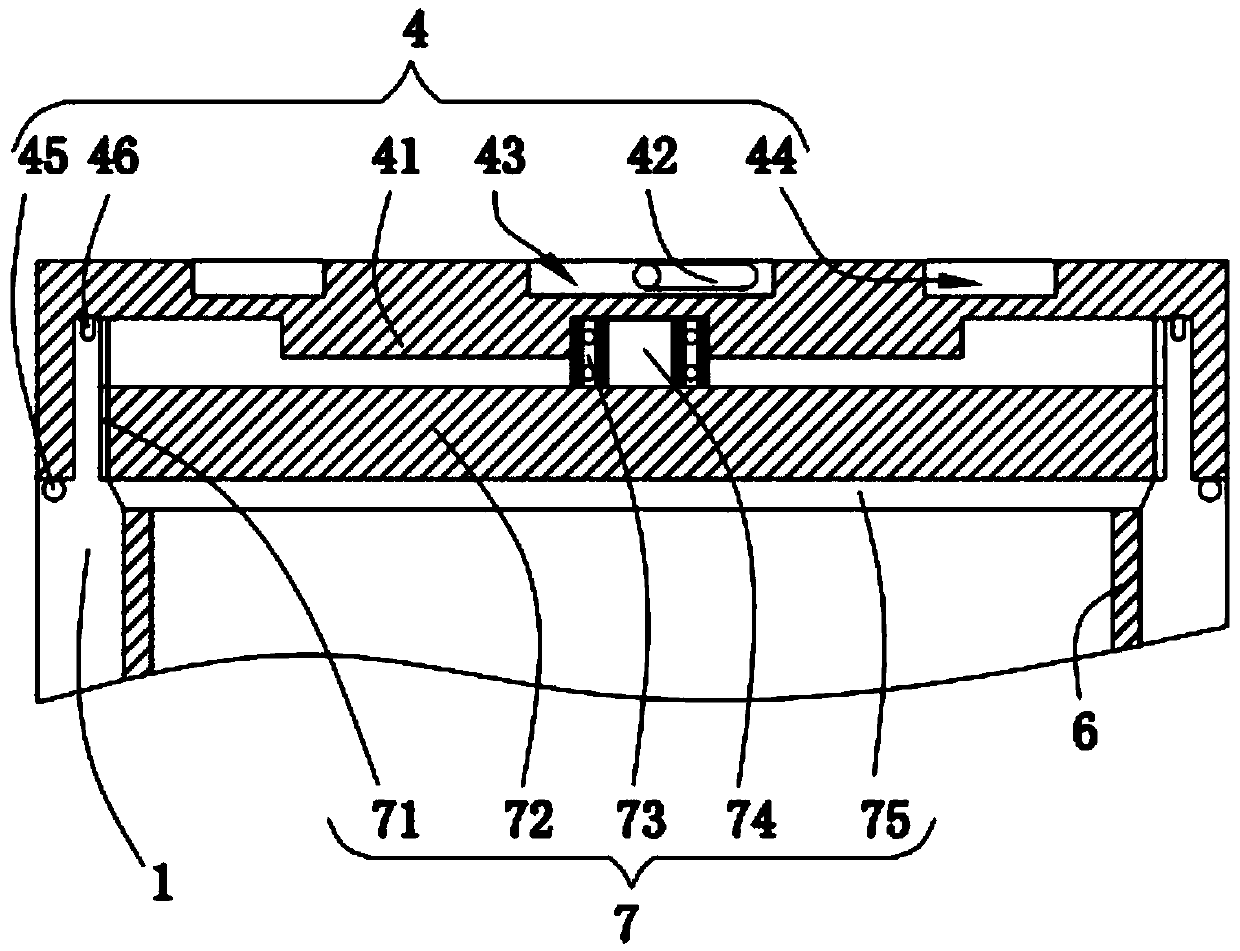

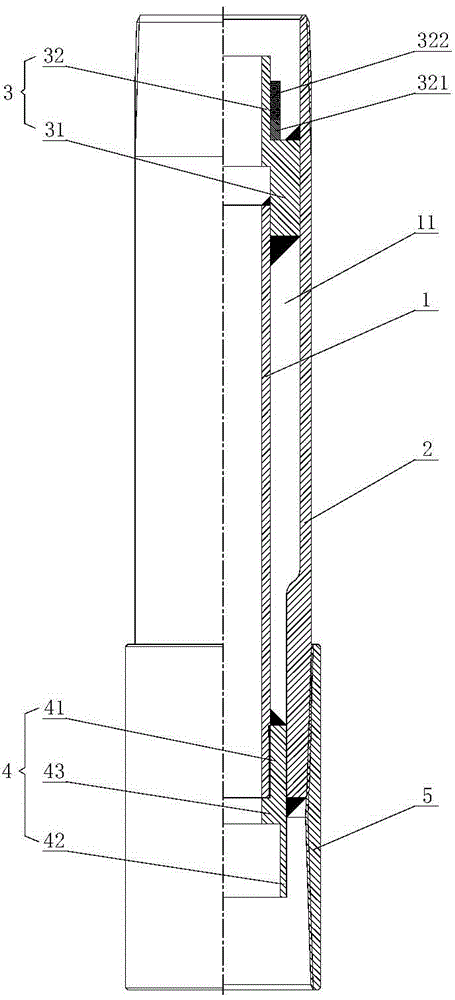

Sample storage device for geological mineral exploration

ActiveCN114476378APrevent oxidationAvoid the problem of uneven distribution of moisture contentPackaging under vacuum/special atmosphereSealingResearch dataEngineering

The invention discloses a sample storage device for geological mineral exploration and belongs to the field of sample storage, after flowing samples are stored, the interior of the sample storage device for geological mineral exploration can be vacuumized, the samples are effectively prevented from being oxidized, meanwhile, through the arrangement of a secondary sealing plate, the secondary sealing plate is inflated firstly, and then the flowing samples are stored in the sample storage device for geological mineral exploration. The pre-falling cushion balls fall off from the secondary sealing plate, then deflation is carried out, the secondary sealing plate is moved into the shell, the pre-falling cushion balls form an air cushion layer on the liquid level of the sample as the secondary sealing plate approaches the liquid level of the sample, and when the pre-falling cushion balls make contact with the surface of the secondary sealing plate, inflation continues to be carried out, so that the secondary sealing plate is tightly attached to the inner wall of the shell; compared with the prior art, the effect of adaptively setting the sealing position according to the sample amount can be realized, so that the wall hanging phenomenon is greatly reduced, the problem of non-uniform water content distribution of the sample is effectively avoided, and the accuracy of research data is further improved.

Owner:孙彩虹

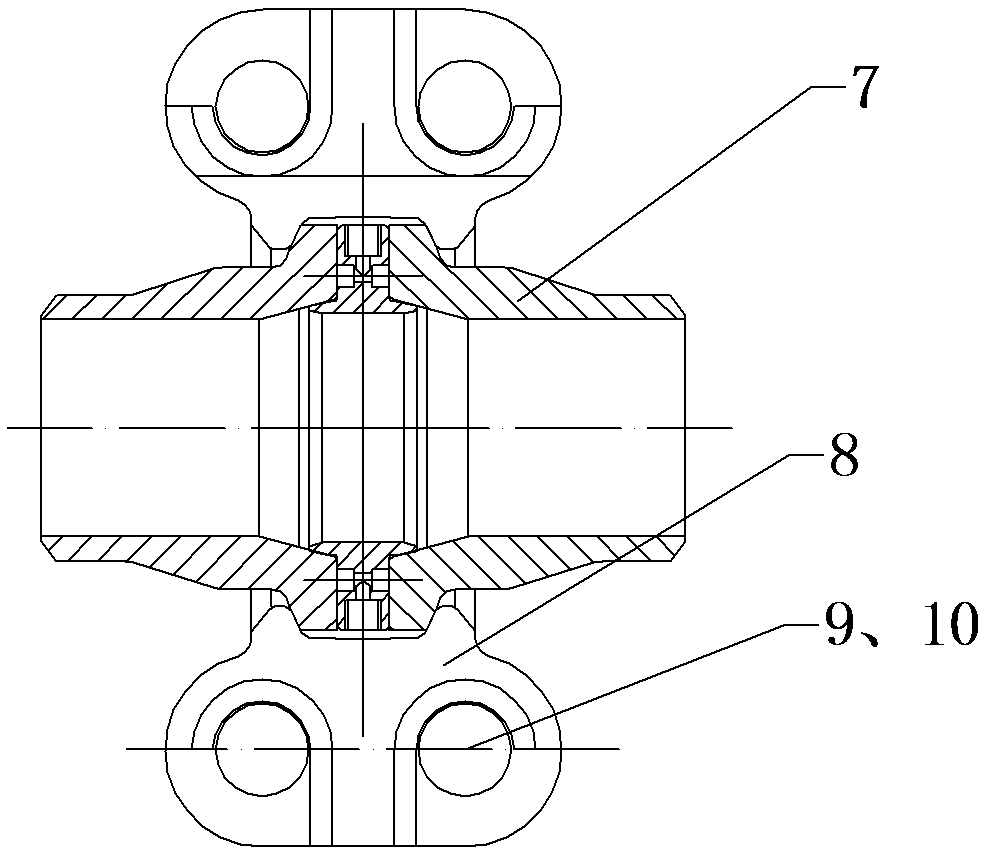

Oxygen gun opening nitrogen sealing device

InactiveCN103882179AImprove the sealing effectReliable sealingManufacturing convertersChemistryNitrogen gas

The invention relates to equipment belonging to the field of converter steelmaking, and in particular relates to an oxygen gun opening nitrogen sealing device. The nitrogen sealing device comprises a nitrogen sealing plug and a nitrogen sealing base, wherein the nitrogen sealing plug comprises an upper big-port end and a lower small-port end; matched sealing surfaces are formed by the outer surface of the nitrogen sealing plug and the inner surface of the nitrogen sealing base; an oxygen gun opening is formed in the nitrogen sealing base; an oxygen gun is sleeved with the nitrogen sealing plug; a nitrogen sealing round hole I is formed in the lower part of the nitrogen sealing plug; the nitrogen sealing round hole I is communicated with a plurality of nitrogen channels I; a nitrogen sealing round hole II is formed in the upper part of the nitrogen sealing plug; the nitrogen sealing round hole II is communicated with a plurality of nitrogen channels II; a conical cavity is formed in the nitrogen sealing plug. The nitrogen sealing device disclosed by the invention has the advantages of being capable of sealing twice and decompressing high-pressure smoke, and good in sealing effect.

Owner:JIGANG GRP

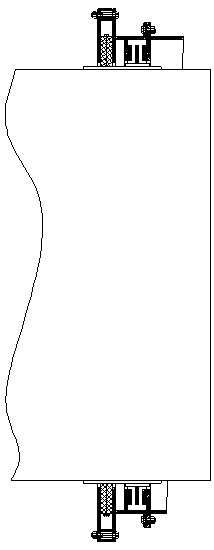

Chemical liquid transportation storage tank

PendingCN108674802AEasy to addAchieve recyclingRemovable lids/coversSealingCompound (substance)Environmental engineering

The invention relates to the field of warehousing and transportation, in particular to a chemical liquid transportation storage tank comprising a storage tank, a base, a drainage structure, a sealingstructure, a limiting structure and a leak-proof structure; the bottom end of the storage tank is provided with a base used for handling; the bottom end of the storage tank is provided with the drainage structure used for draining chemical liquid; the top end of the storage tank is provided with the sealing structure used for sealing, and the bottom end of the sealing structure is provided with the leak-proof structure which abuts against the storage tank; and the limiting structure used for limiting is arranged between the storage tank and the sealing structure. According to the chemical liquid transportation storage tank, the storage tank is removably connected to the sealing structure, thereby facilitating adding of the chemical liquid into the storage tank, and the recycling use of thestorage tank is achieved; the leak-proof structure is arranged between the sealing structure and the storage tank, so that the secondary seal of the storage tank is achieved, and the safety performance of handling and storage is improved; the bottom end of the storage tank is provided with the base, thereby facilitating handling of the storage tank through a forklift, and meanwhile a plurality ofstorage tanks are easy to stack through cooperation of the sealing structure.

Owner:安庆泽远化工有限公司

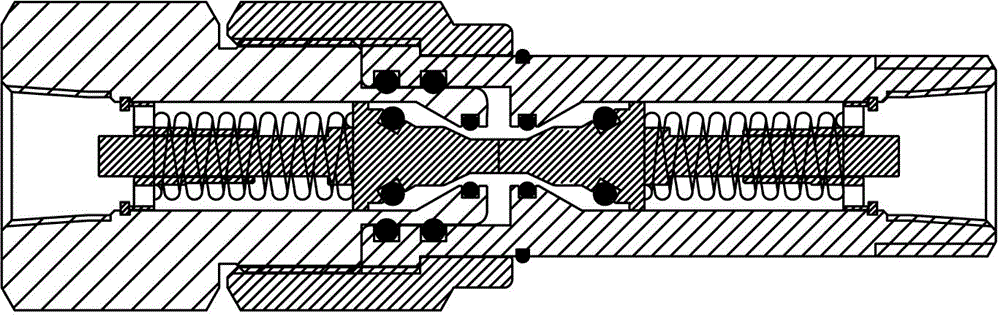

Vacuum heat insulation pipe

InactiveCN104948118AAchieve secondary sealingReduce hot spot lossDrilling rodsFluid removalCouplingEngineering

The invention provides a vacuum heat insulation pipe. The vacuum heat insulation pipe comprises an internal pipe and an external pipe, wherein the internal pipe is arranged in the external pipe in a penetrating mode, a supporting ring is connected between one end of the internal pipe and one end of the external pipe, a compression ring is connected between the other end of the internal pipe and the other end of the external pipe, and the outer side of the other end of the external pipe is connected with a coupling. In the process of continuously injecting steam for a long term, by means of the vacuum heat insulation pipe, the heat loss at the coupling position of the vacuum heat insulation pipe can be effectively reduced, and the goal of improving the heavy oil reservoir employing degree is achieved.

Owner:PETROCHINA CO LTD

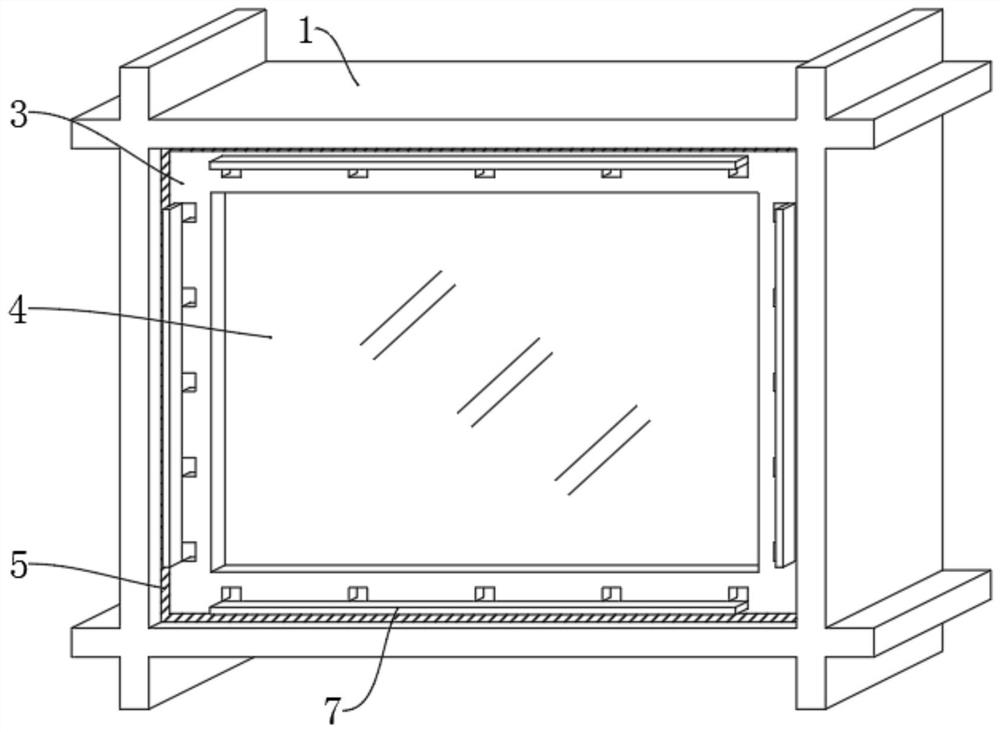

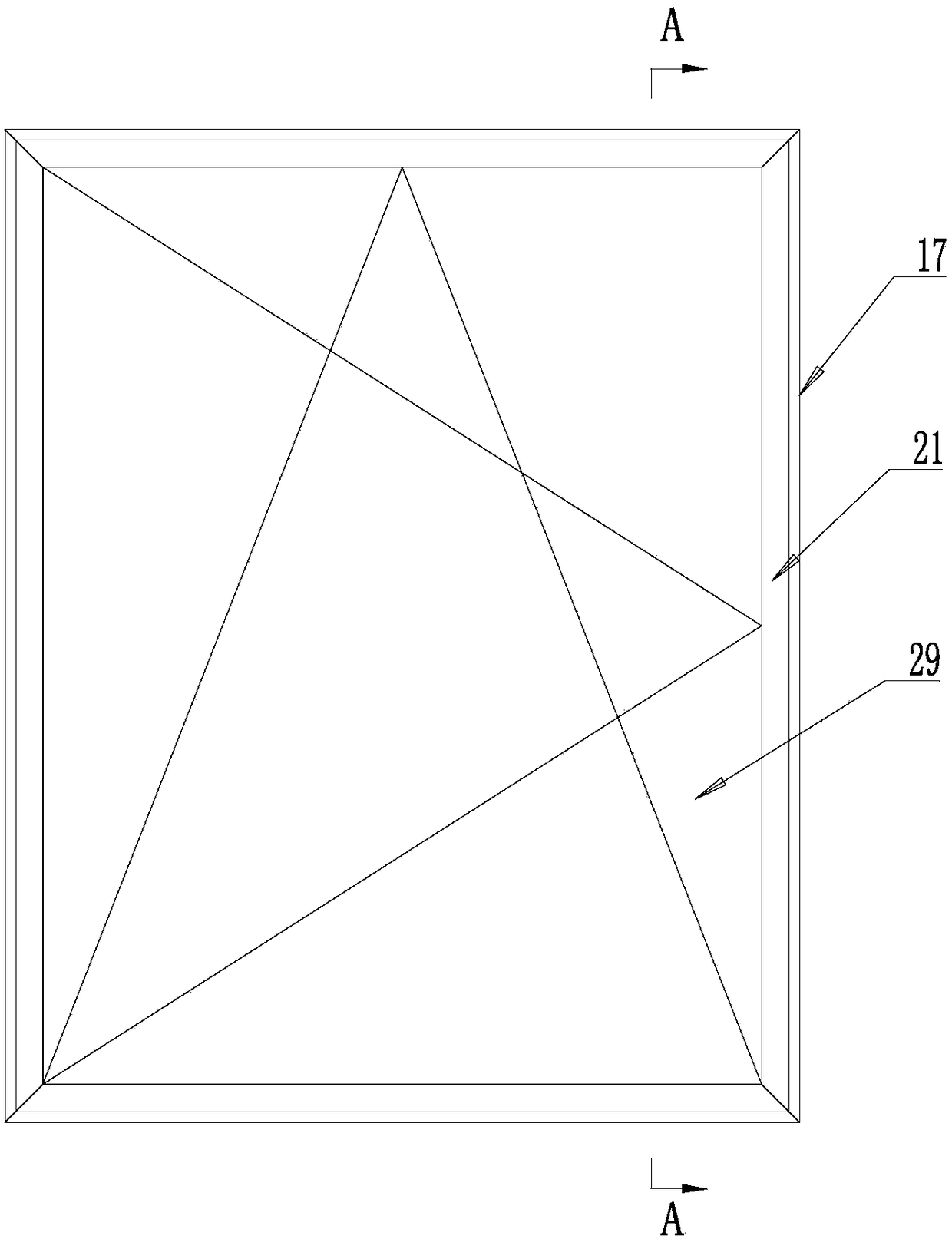

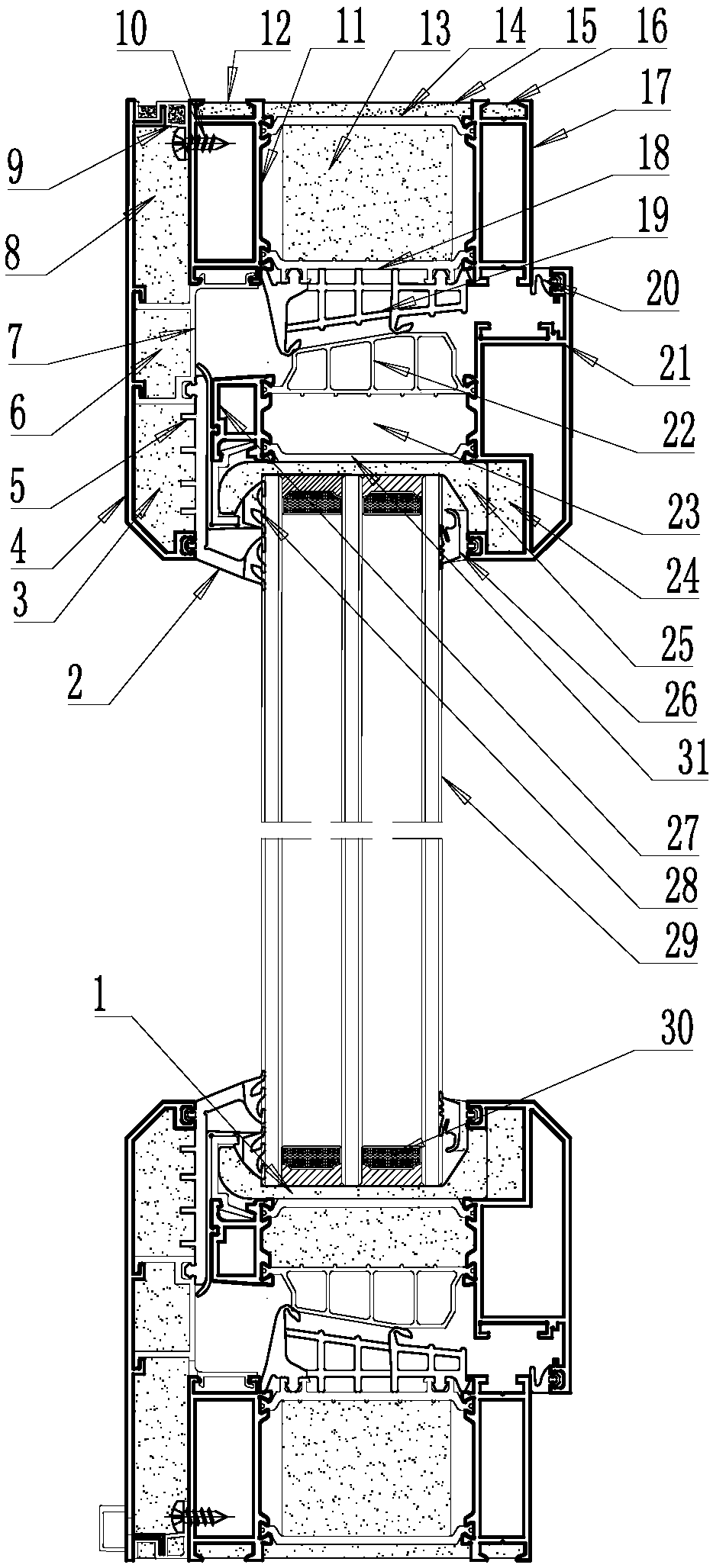

Novel energy-saving passive window

InactiveCN108316816AImprove sealingGood energy saving effectSealing arrangementsUnits with parallel planesSash windowExtreme Cold

The invention relates to a novel energy-saving passive window, and belongs to the technical field of building energy saving. The novel energy-saving passive window comprises an inner window frame, wherein a window sash; hollow glass is arranged in the window sash; a window sash sealing strip is arranged between the inner window frame and the window sash; an outer window frame is arranged on the outer sides of the inner window frame and the window sash; the inner edge of the outer window frame is flush with the inner edge of the window sash; secondary frame sealing rubber strip is arranged between the outer window frame and the hollow glass; a gasket is filled in a connecting gap of the window sash and the hollow glass; a glass edge sealing rubber strip is arranged between one side, surrounding the hollow glass, of the window sash, and the hollow glass. The novel energy-saving passive window meets the requirement, on a passive window, of a passive building in an extreme cold state, is good in heat-preservation effect, and is energy-saving and environmentally friendly.

Owner:山东铝业有限公司

Multifunctional spray sterilizer

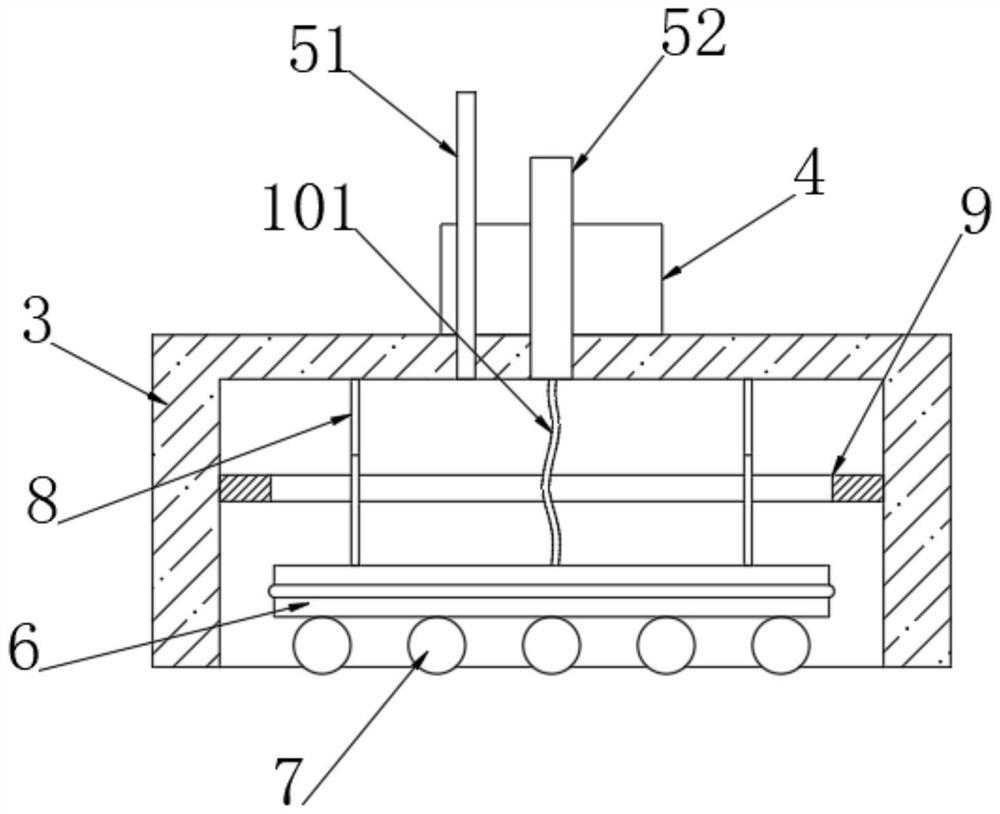

ActiveCN102485276AEasy to moveInhibit sheddingLighting and heating apparatusAtomized substancesAgricultural engineeringGasoline

A multifunctional spray sterilizer comprises a frame; the frame is provided with a gasoline engine, which drives a plunger pump through a crankcase; the plunger pump is provided with a relief valve, a water inlet, a liquid inlet and a water outlet; the water inlet is connected with a water tank through a leather hose; the liquid inlet is connected with an imbibition apparatus; the water outlet is connected with a spray gun through a high pressure output tube; the imbibition apparatus is characterized by comprising an imbibition joint connected to a medical liquor inlet; the imbibition joint is provided with an imbibition port and a backwater port; the imbibition port is connected with an imbibition valve; the imbibition valve is connected with an imbibition switch; the imbibition switch is connected with an imbibition rubber hose; a head of the imbibition rubber hose enters the medical liquor; and the backwater port is connected with the backwater rubber hose through a backwater joint. The scheme employs spray for disinfection and has advantages of uniform spraying, large area, high disinfection efficiency, safety, health, no damage on human body, low energy consumption and low cost.

Owner:FUSITE CO LTD

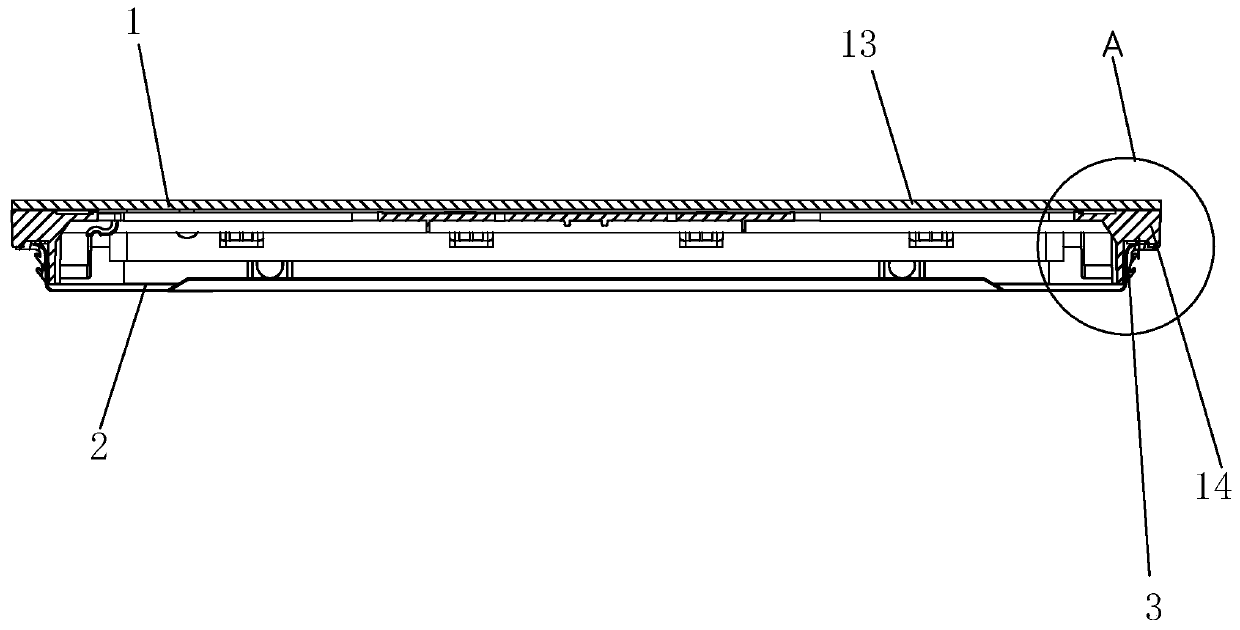

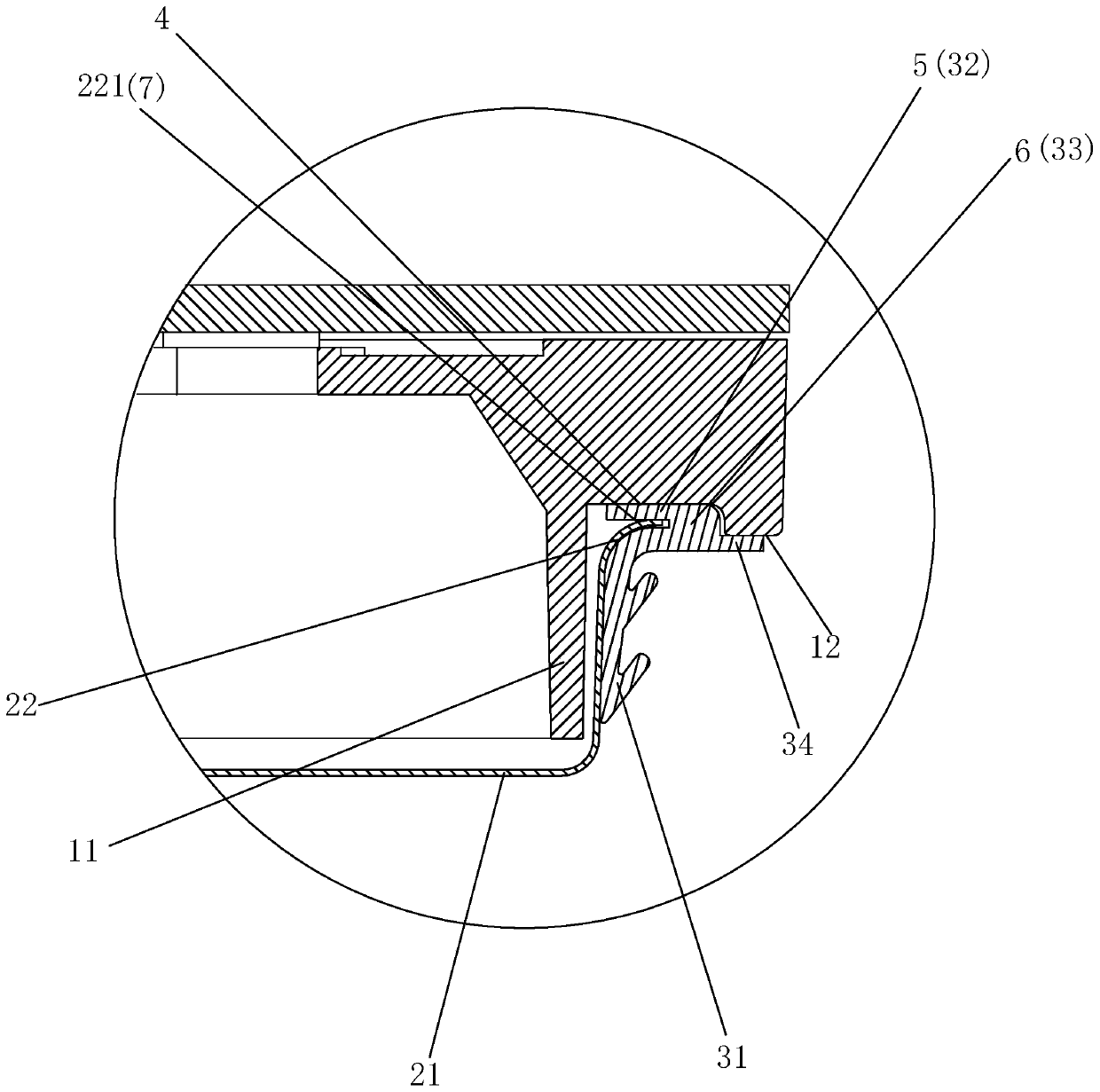

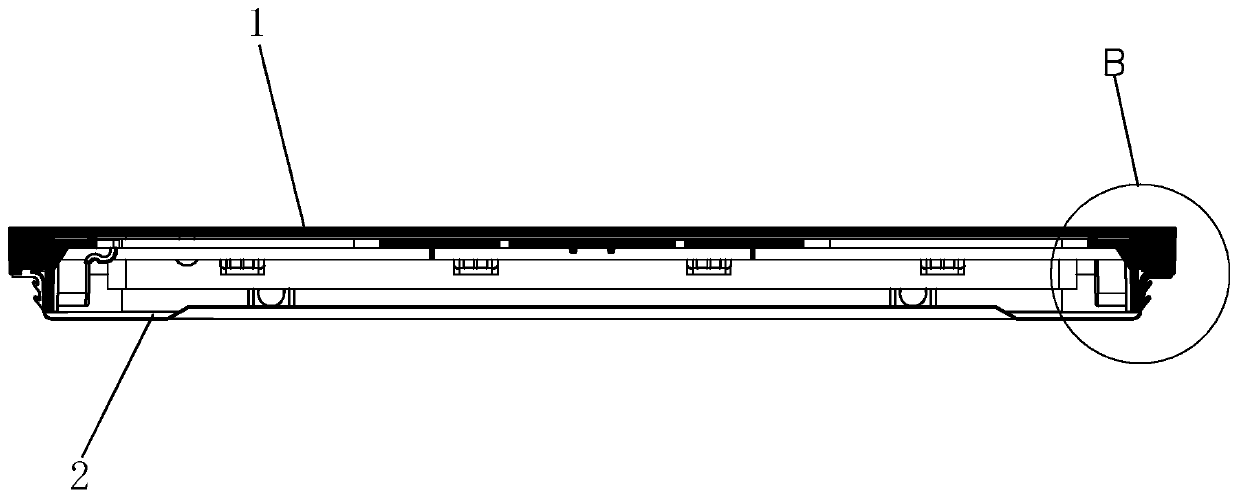

Door for cleaning machine and assembly method of door

PendingCN110123236ASimple structureSimple structural designTableware washing/rinsing machine detailsSurface plate

The invention provides a door for a cleaning machine and an assembly method of the door. The door comprises a face plate, a door decoration cover and a door sealing strip, wherein the face plate is provided with a decorative inner frame, a clamping groove is formed between the decorative inner frame and the face plate, the door decoration cover is provided with a door decoration cover body and a door decoration cover outer edge which corresponds to the clamping groove, and the door decoration cover outer edge is provided with an inner side face. A first sealing groove is formed between the inner side face of the decoration cover outer edge and the face plate, and a second sealing groove is formed between the tail end of the decoration cover outer edge and the face plate; the door sealing strip comprises an outer ring body, a first sealing part and a second sealing part, the outer ring body sleeves the outer side of the door decoration cover body, the outer ring body extends to form thesecond sealing part, a wrapping groove is formed between the first sealing part and the outer ring body, the decoration cover outer edge is clamped into the wrapping groove, the first sealing part iscompressed into the first sealing groove, and the second sealing part is located in the second sealing groove. The transverse and longitudinal movement, relative to the door body, of the door sealingstrip is limited, the structure is stable, and the sealing effect is good.

Owner:ZHEJIANG ZEPPELIN INTELLIGENT TECH CO LTD

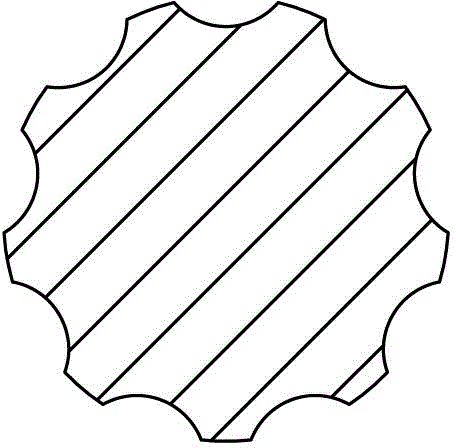

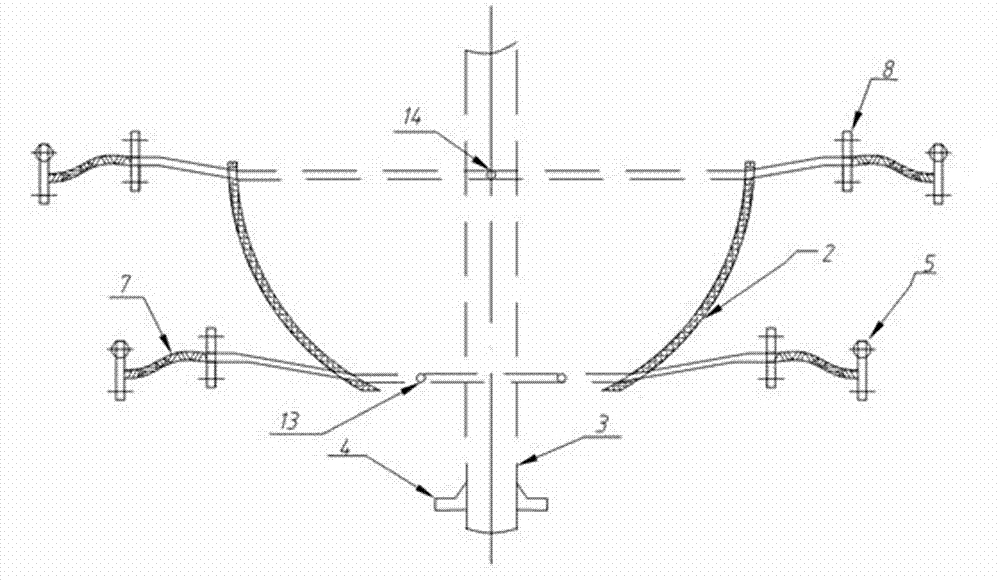

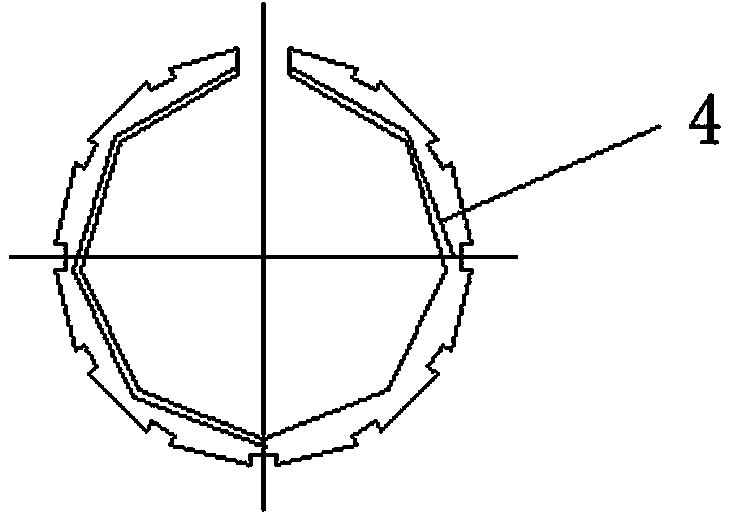

Pipe connector sealing ring

PendingCN108150746AAchieve secondary sealingAvoid maintenance stopsSleeve/socket jointsFlanged jointsEconomic benefitsEngineering

The invention discloses a pipe connector sealing ring. The pipe connector sealing ring comprises an annular rib part extending in the radial direction and an annular lip part extending in the axial direction; the two sides of the rib part are each provided with an annular sealing groove; the sealing grooves on the two sides are mutually communicated; a plurality of glue injecting holes are formedin the circumferential direction of the rib part; the sealing grooves are communicated with the glue injecting holes; and the outer ends of the glue injecting holes are provided with a glue injector connector. According to the pipe connector sealing ring, by arranging a reserved standby sealing cavity and the glue injecting connector; after a sealing piece leaks, sealing glue is injected in from the glue injecting connector so that the standby sealing cavity can be filled with the sealing glue, and secondary sealing on a pipe connector is achieved. Due to secondary sealing, system shutdown overhauling caused by leaking of a certain sealing piece is avoided, the cost for replacing the system sealing piece is reduced, and besides, the extra high cost generated due to system shutdown overhauling is saved; and very high economic benefits are achieved.

Owner:天津斯林力克密封科技有限公司

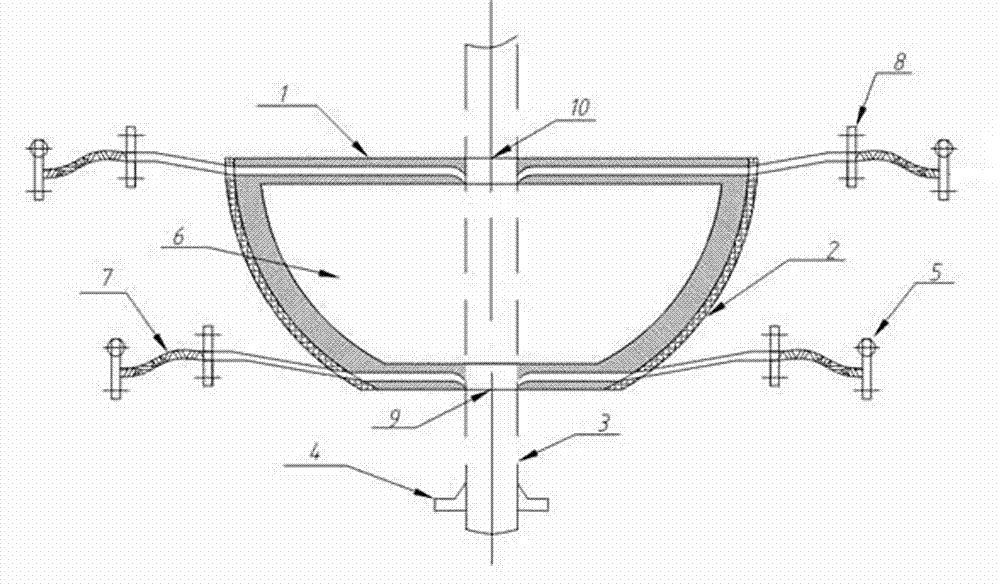

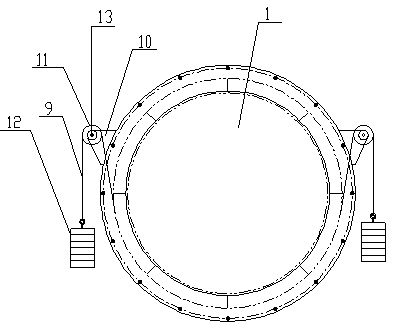

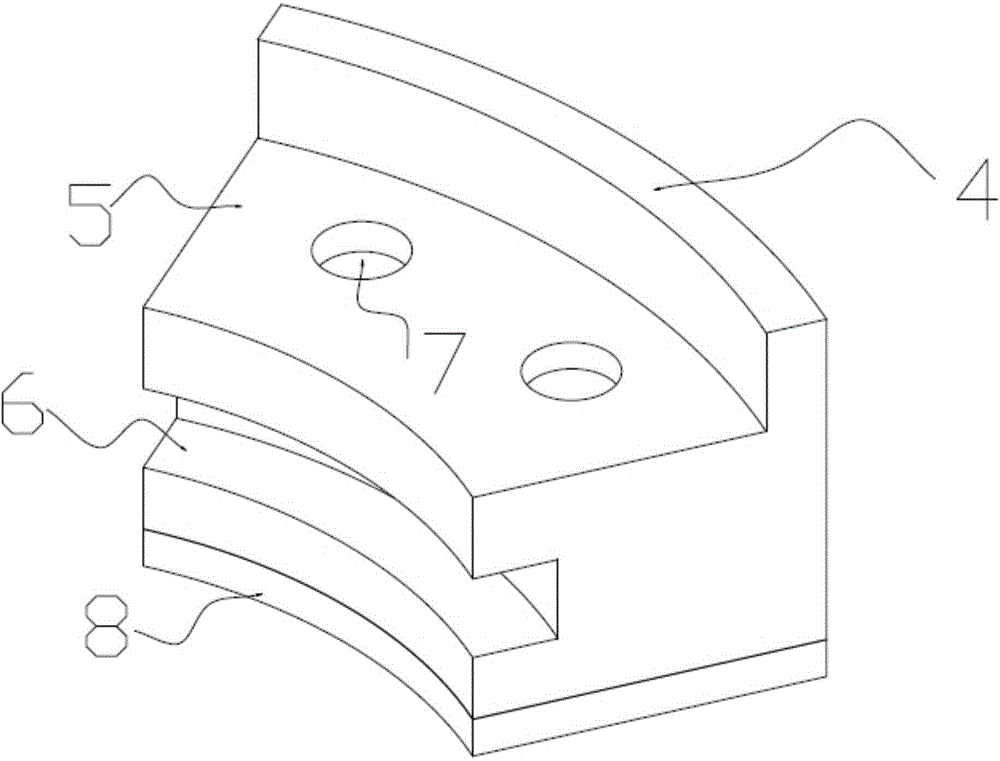

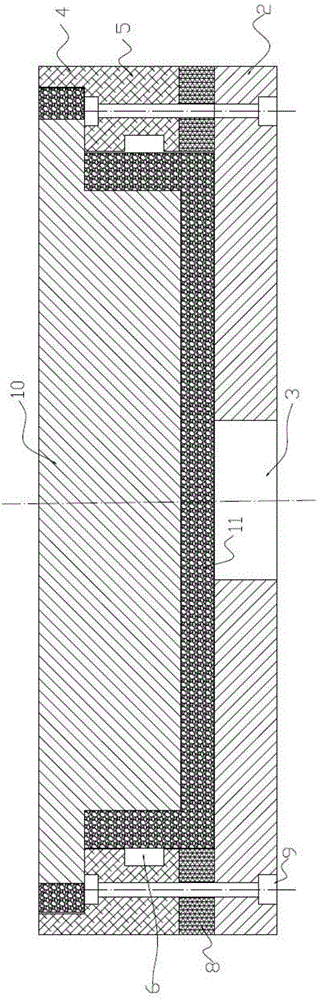

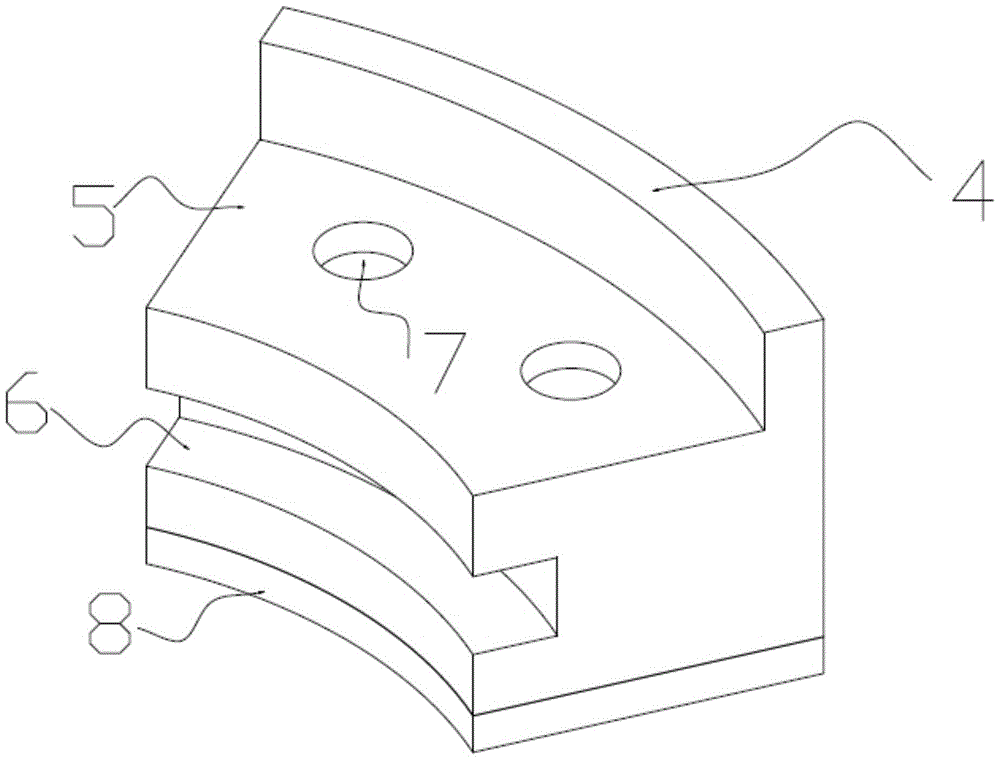

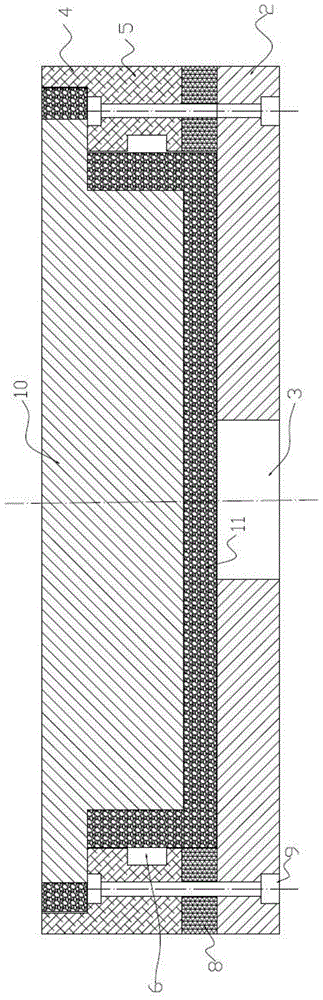

Specialized combined type sealing device for incinerator

The invention provides a specialized combined type sealing device for an incinerator. The specialized combined type sealing device for the incinerator comprises a rotary kiln, a labyrinth sealing partand a graphite block sealing part, wherein the labyrinth sealing part and the graphite block sealing part are arranged at the two ends of a kiln body of the rotary kiln; the labyrinth sealing part comprises a support, a flange, a sealing ring, a friction plate and a sliding key; the support is arranged on the rotary kiln; the flange is arranged on the support; the sealing ring is arranged at theleft side of the flange; the friction plate is arranged at the left side of the sealing ring; labyrinth sealing is formed by the flange, the sealing ring and the friction plate; and the sliding key isarranged at the lower end of the sealing ring. The specialized combined type sealing device for the incinerator has the beneficial effects that the specialized combined type sealing device for the incinerator has a good sealing effect and a stable performance and is simple in structure by adopting rotary kiln feeding and discharging combined type sealing; gas leakage and dust leakage are avoided;the working efficiency of the rotary kiln is improved; the secondary pollution is reduced; the environmental protection requirements are satisfied; and the cost is saved.

Owner:JIANGSU HAIJIAN

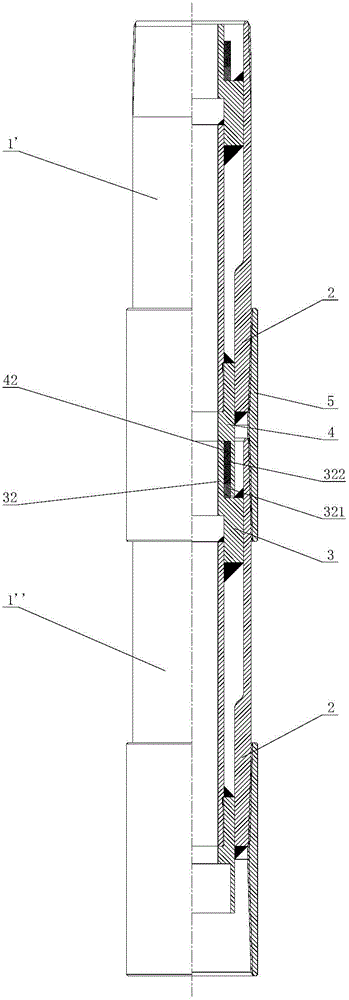

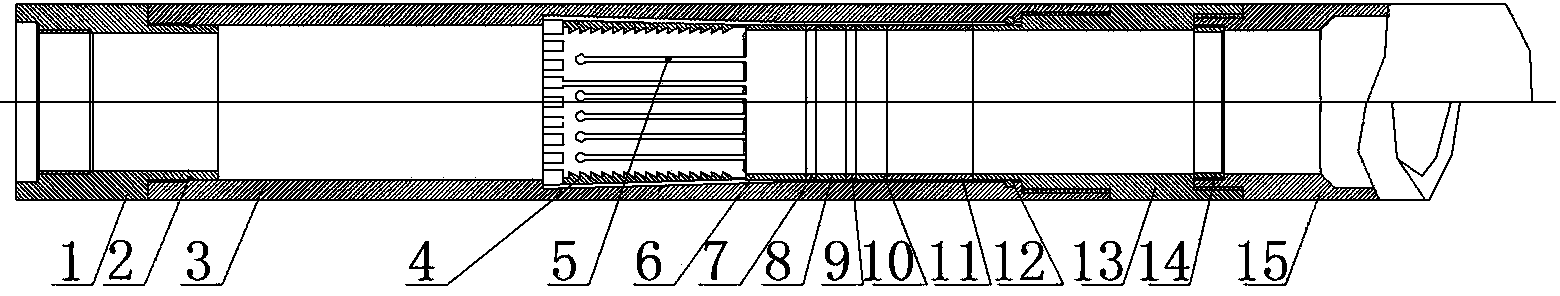

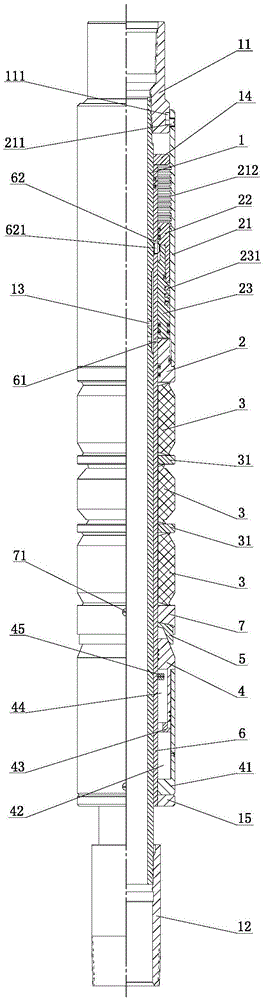

Multifunctional bushing self-sealing repair and connection device

InactiveCN103643914AAchieve secondary sealingImprove sealingBorehole/well accessoriesUpper jointUltimate tensile strength

The invention relates to the technical field of oil filed oil well repair tools and particularly relates to a multifunctional bushing self-sealing repair and connection device. The repair and connection device comprises a grappling component and a sealing component. The grappling component comprises an upper joint, a guiding shoe, an outer cylinder and a connection cylinder which are arranged between the upper joint and the guiding shoe successively and a slip connected internally with the outer cylinder. Locating keys on the inner wall of the outer cylinder are snapped in grooves of the slip, and a milling ring is arranged at the connection position of the connection cylinder and the guiding shoe. According to the device, the structure is used, so that the inner drift diameter is kept unchanged; meanwhile, the primary seal is achieved through lead rings, and the secondary seal is achieved through cementing well cementation, so that the device is good in seal performance, convenient to operate and use and capable of effectively improving the repair and connection strength and prolonging the service life. Besides, the device has the advantages of being reasonable in design, simple in structure, low in manufacture cost and the like.

Owner:JIANGSU JUNXINYI GASOLINEEUM MACHINERY

Waterproof vent valve and encapsulation method thereof

ActiveCN101868131BAchieve secondary sealingCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention discloses a waterproof vent valve, which comprises a screw cap, a screw stem, a waterproof vent film and an insert with a hole. The insert can be embedded in the screw cap to contain the waterproof vent film and seal the waterproof vent film in the screw cap. After the scheme is adopted, the invention closely encapsulates the waterproof vent film and a plastic valve together throughthe simple inset structure and realizes secondary sealing through further hot melting.

Owner:东莞市维赛实业有限公司

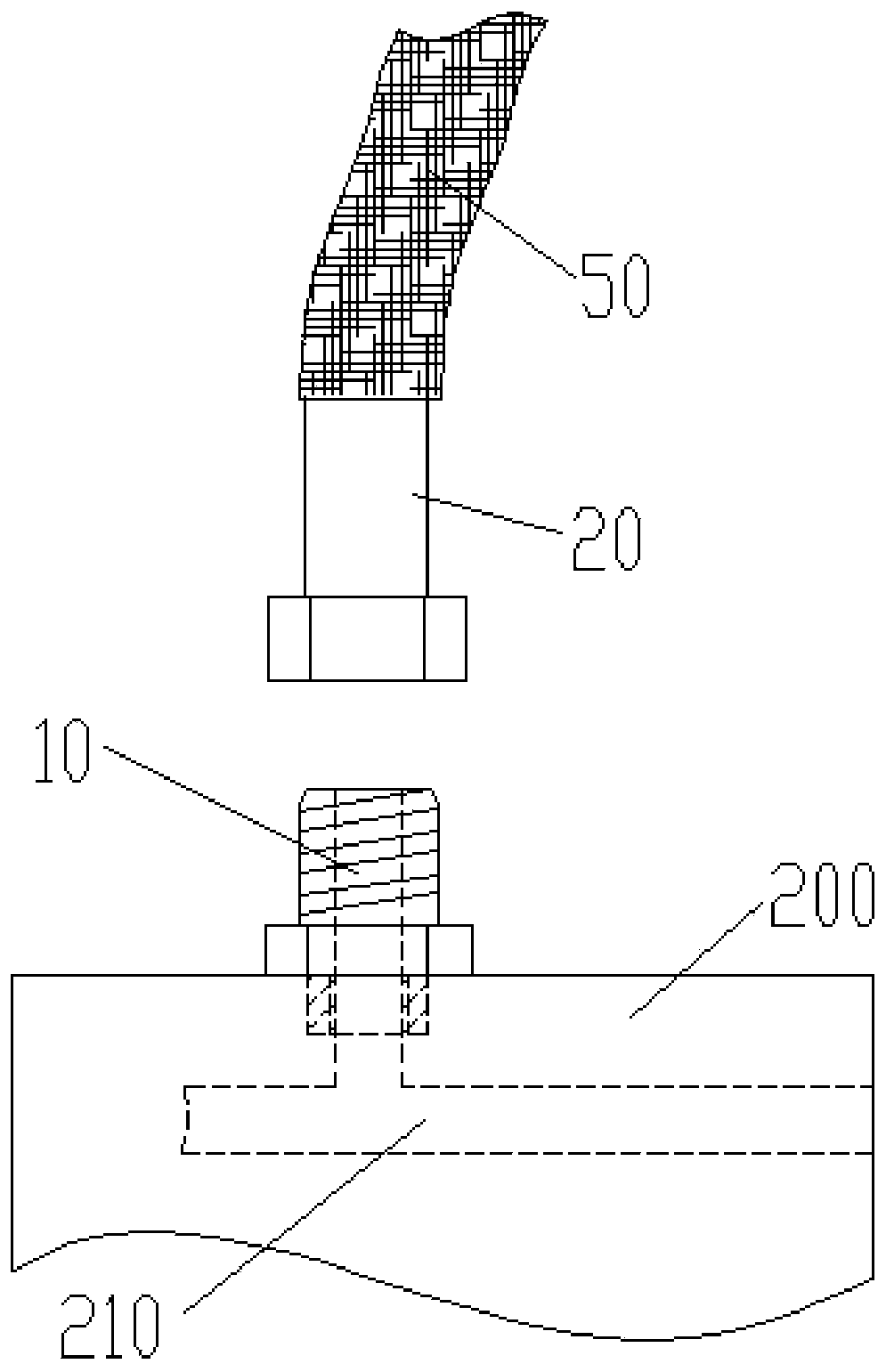

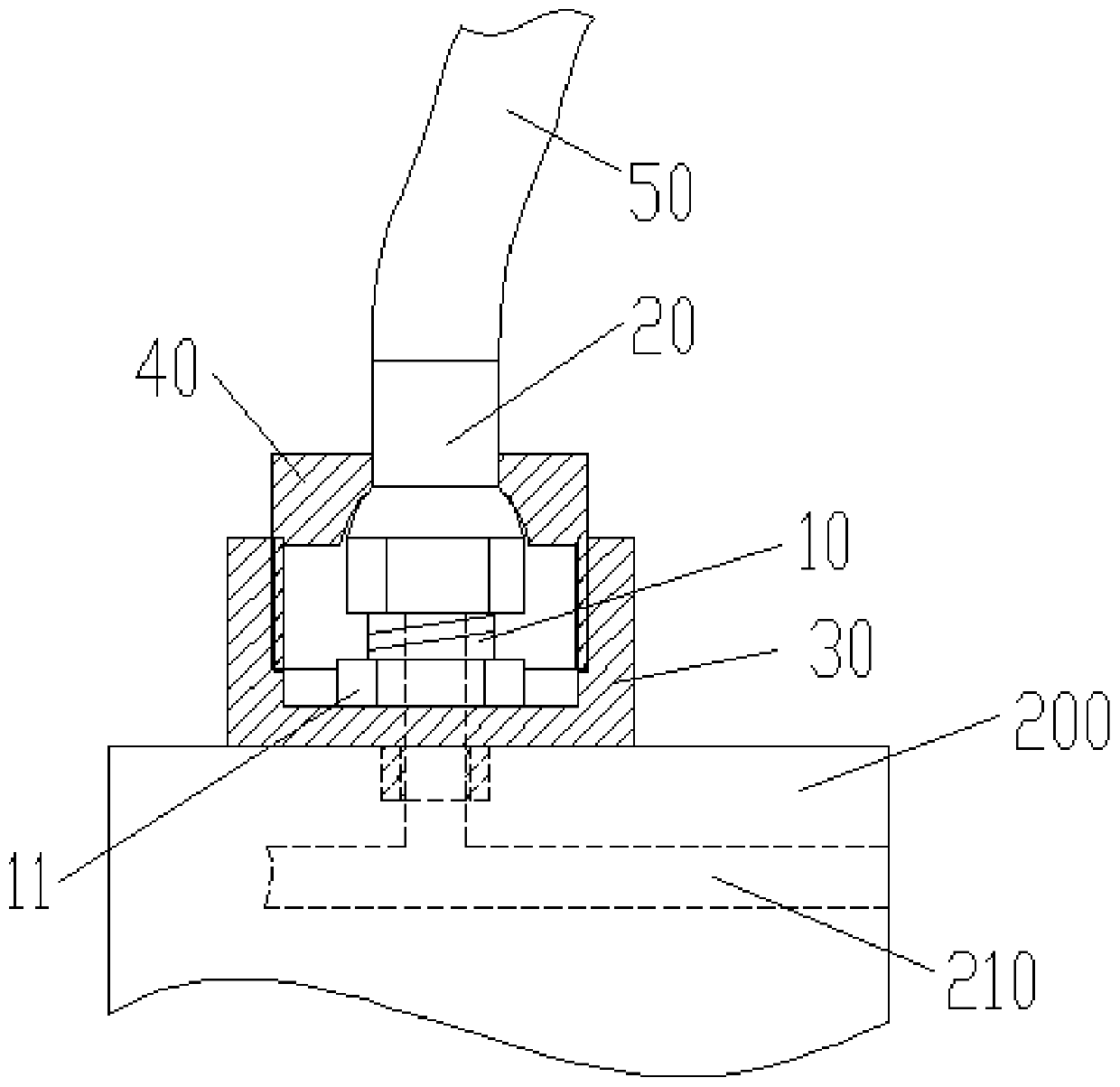

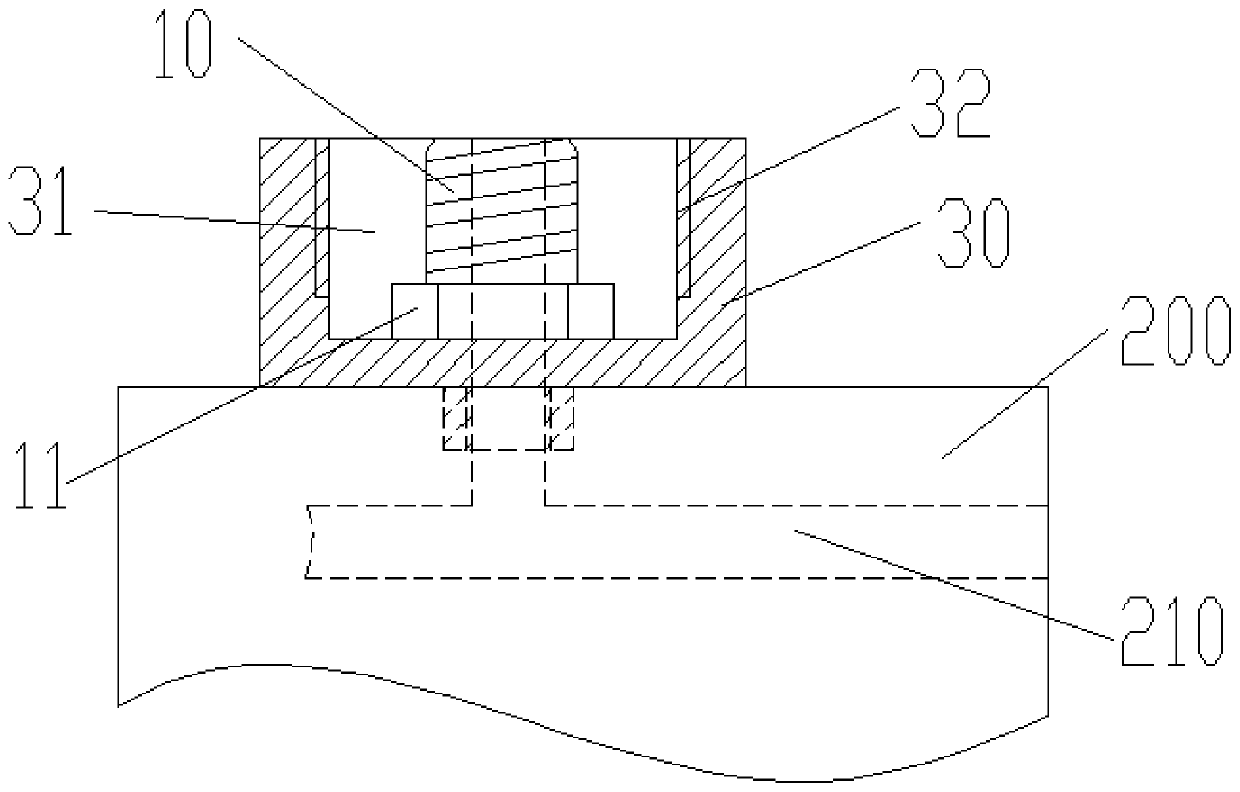

Particlepowder body material level detection device

ActiveCN106813750AAchieve secondary sealingStrong adhesionLevel indicators by physical variable measurementCapacitanceEngineering

The invention discloses a particle powder body material level detection device. The deviceiswelded in atilted mode on the hole circumferences on the side wall of a tank body, and onthe bottom head of a clamp openedwith a center hole; the device is insertedclosely in thecenter hole of the bottom head of the clamp, and in a threaded sealing piece opened with a threaded hole; the device is spun in the threaded hole, and passes through the capacitance material level gage of the side wall hole; the threaded sealing piece is pressedon the top head of the clampwithin the bottom head of the clamp; the bottom head of the clamp and the top head of the clampare tightly clamped togetherin a sleeving mode. The material level detection device can detect accurately under the bad environment of material high viscosity and high vibrations, and is convenient for assembly line cleaning.

Owner:SHANGHAI HAN OU PHARMA EQUIP CO LTD

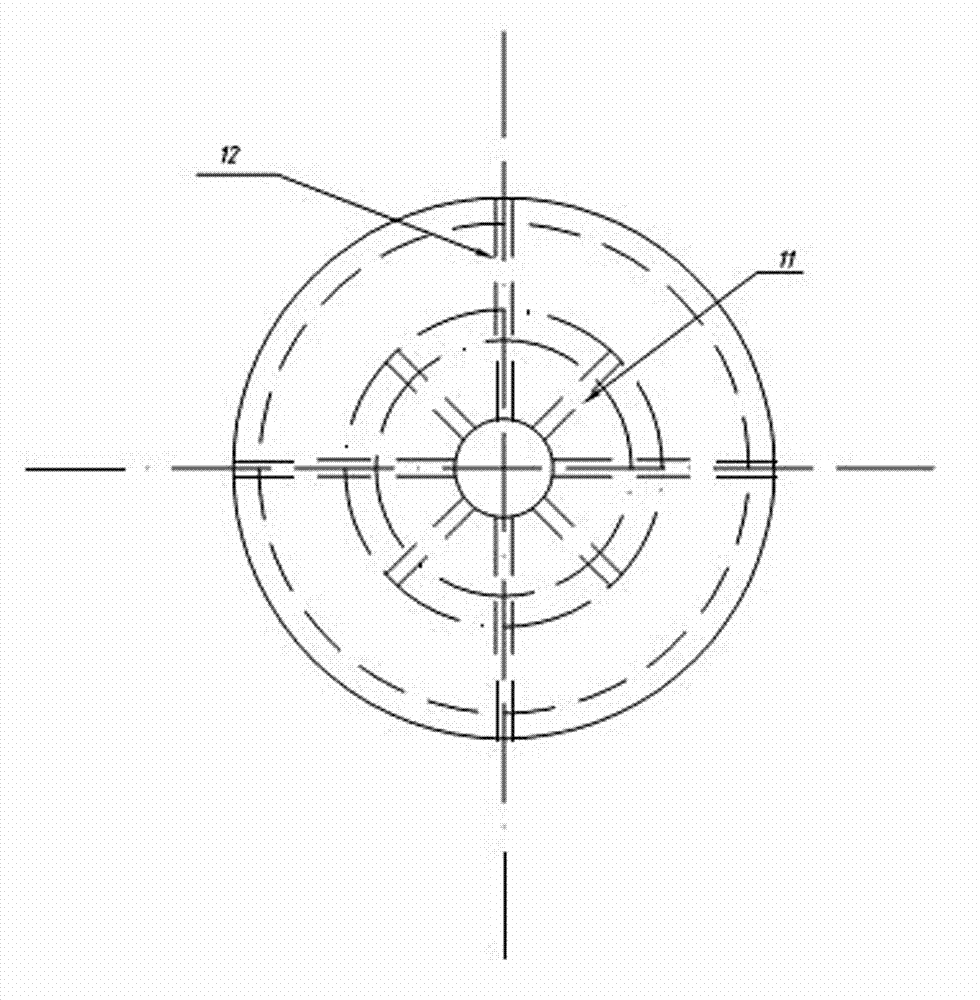

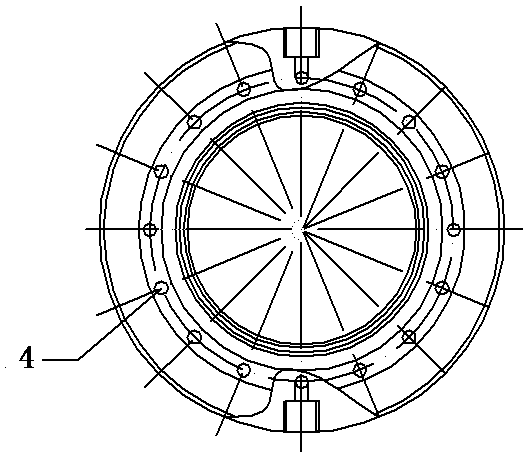

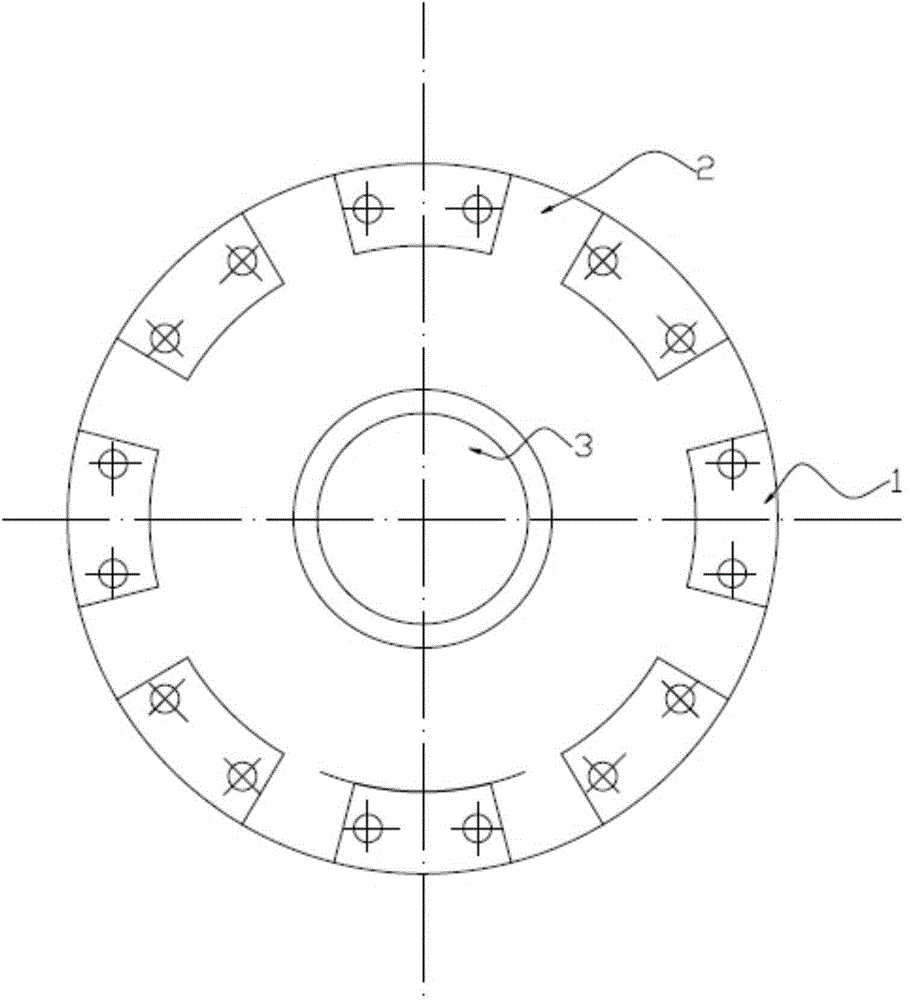

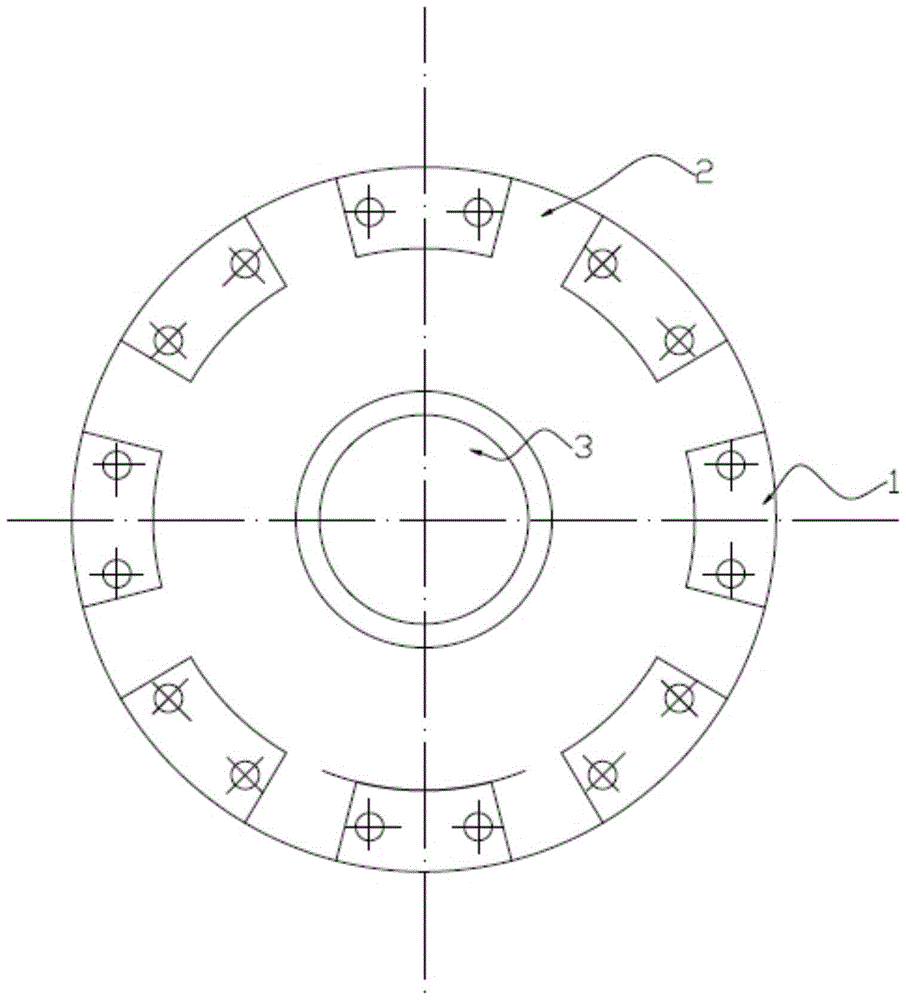

High-temperature seal assembly

The invention provides a high-temperature seal assembly. The high-temperature seal assembly comprises a base plate and a plurality of seal blocks. The base plate is a round isolation plate, a round through hole is formed in the circle center of the base plate, the seal blocks are arranged on the base plate along the circumference, the seal blocks are composed of seal block bodies and backing plates, the seal block bodies are ceramic fiber specially-shaped folding blocks, the backing plates are specially-shaped fiber backing plates, the specially-shaped fiber backing plates make contact with the base plate, the seal blocks are fixedly arranged on the base plate, a round baffle is further arranged on the base plate, and the baffle is connected with the seal blocks internally and is in clearance fit with the seal blocks. According to the high-temperature seal assembly, existing heat-resistant seal materials are replaced by the seal blocks formed by the ceramic fiber specially-shaped folding blocks and the specially-shaped fiber backing plates, therefore, expenditures can be cut down, cost can be reduced, meanwhile, the service life of equipment can be prolonged, and losses, caused by equipment replacement and the like, in manpower, material resource, yield and the like are reduced accordingly.

Owner:天津太钢天管不锈钢有限公司

Self-locking sealing pipeline connecting device

PendingCN114776900AImprove sealingAvoid loose phenomenonJoints with sealing surfacesRubber matScrew thread

The invention discloses a self-locking sealing pipeline connecting device which comprises a connecting pipe and pipelines arranged on the two sides of the connecting pipe, convex rings are fixedly arranged on the two sides in the connecting pipe, each convex ring is composed of a gradually-shrinking ring and a gradually-expanding ring, an embedding groove is formed in the circumference of the inner wall of each gradually-expanding ring, and a rubber pad is fixedly arranged in each embedding groove. The pipeline connecting device relates to the technical field of pipeline connection and is compact in structure, the connecting cap is screwed to the connecting pipe, so that the connecting cap pushes the pipeline to abut against the rubber pad of the gradually-expanding ring, primary sealing is achieved, meanwhile, the connecting cap enables the pressing ring to be embedded into the annular groove, and therefore the sealing effect of the pipeline is improved. And due to the arrangement of the locking structure, the phenomenon that the threads are loosened due to the fact that the connecting cap rotates due to external factors can be avoided, and convenience is brought to use of people.

Owner:禧阅航空技术(上海)有限公司

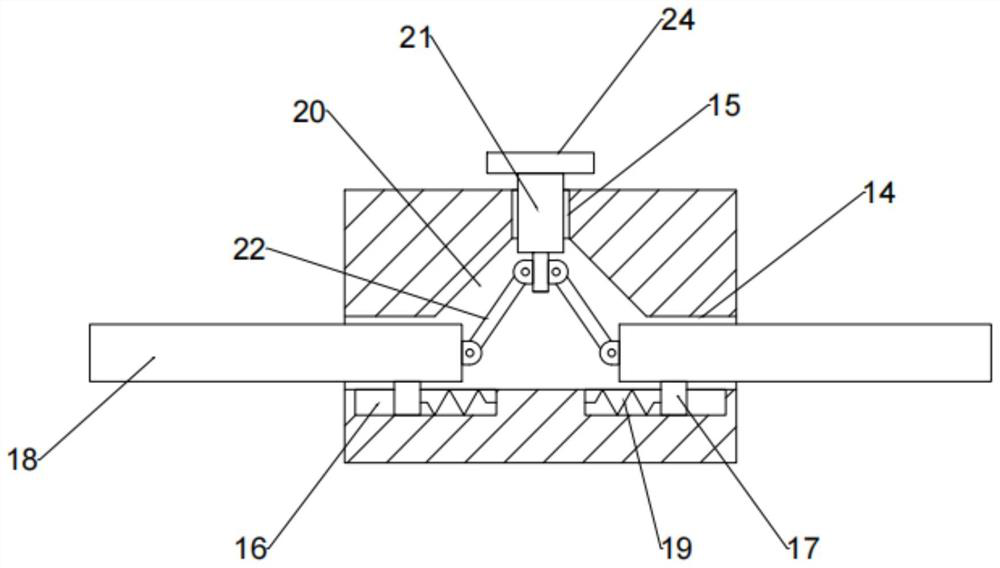

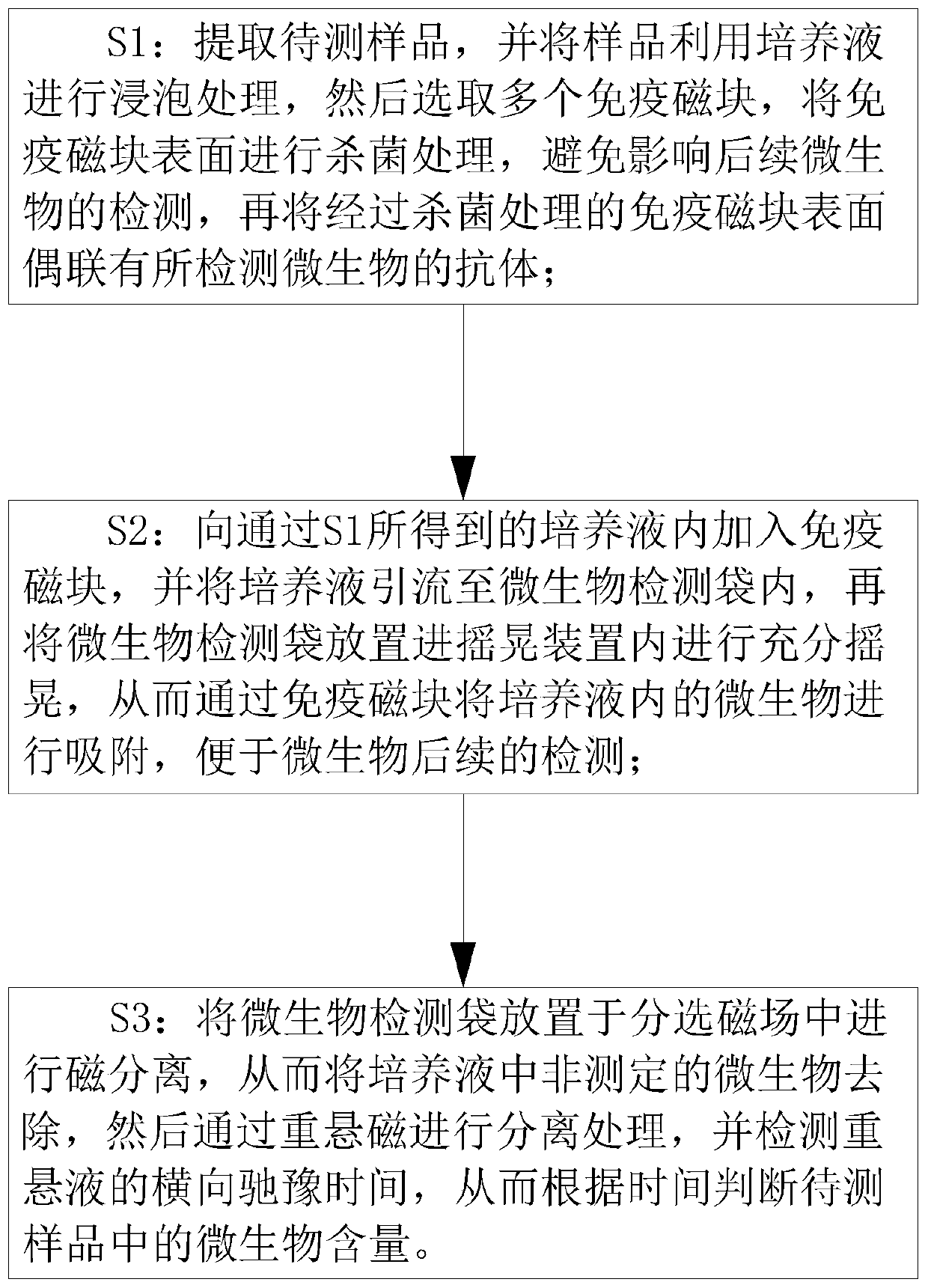

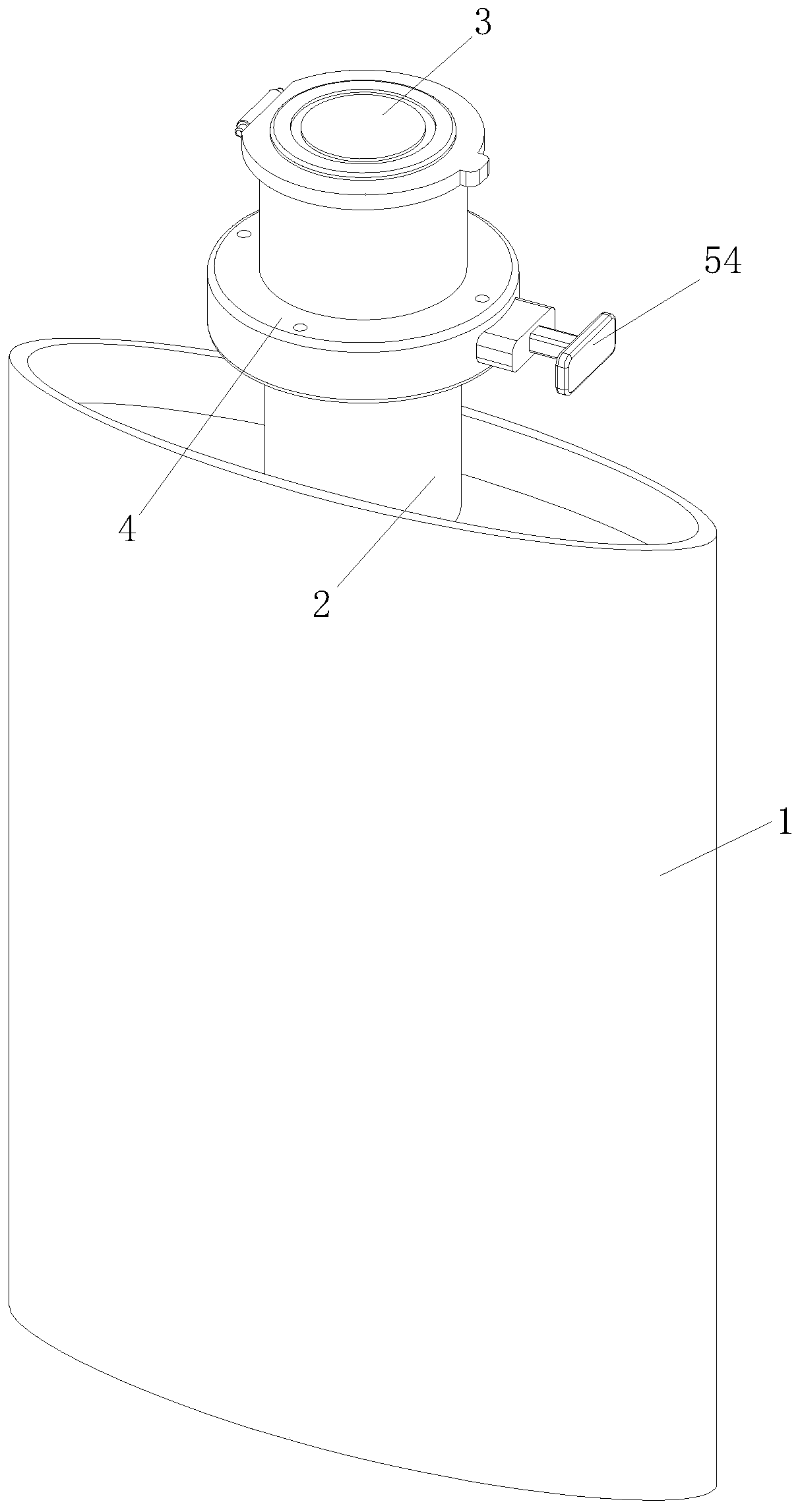

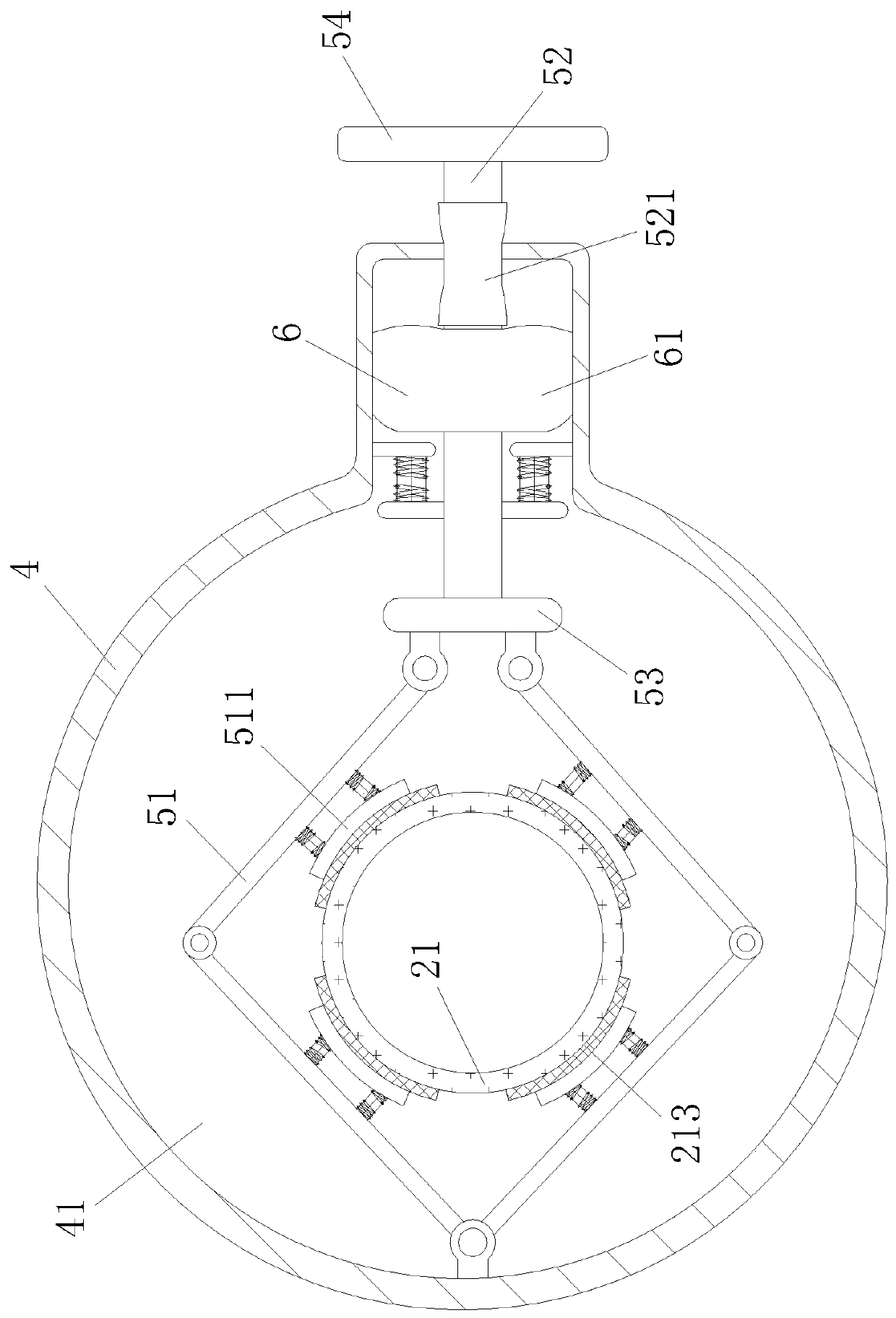

Microbiological detection bag and detection method

InactiveCN111413494AAchieve secondary sealingAvoid infectionChemicalsMaterial analysisBiotechnologyMicroorganism

The invention belongs to the technical field of microbiological detection, and particularly relates to a microbiological detection bag and a detection method. The microbiological detection bag comprises a storage bag, a conveying pipe, an end cover and a clamping ring, wherein the outer side wall of the conveying pipe is sleeved with the clamping ring, a cavity is formed in the clamping ring, andthe cavity is communicated with the inner side wall of the material conveying pipe; a locking unit is mounted in the cavity; the locking unit comprises a hinge rod, a push rod, a fixing plate and a pressing plate. Through cooperation of the storage bag, the conveying pipe, the end cover and the clamping ring, secondary sealing of the detection bag is achieved, and microbial infection is avoided; in the resetting process of the hinged rod, the hinged rod extrudes the inner tube, so that the inner tube is elastically deformed until being sealed after being pressed, secondary sealing of the detection bag is realized, cross infection between bacteria on hands and microorganisms in a culture solution when a worker opens and closes the detection bag is effectively avoided, and the accuracy of microbiological detection is guaranteed.

Owner:林振山

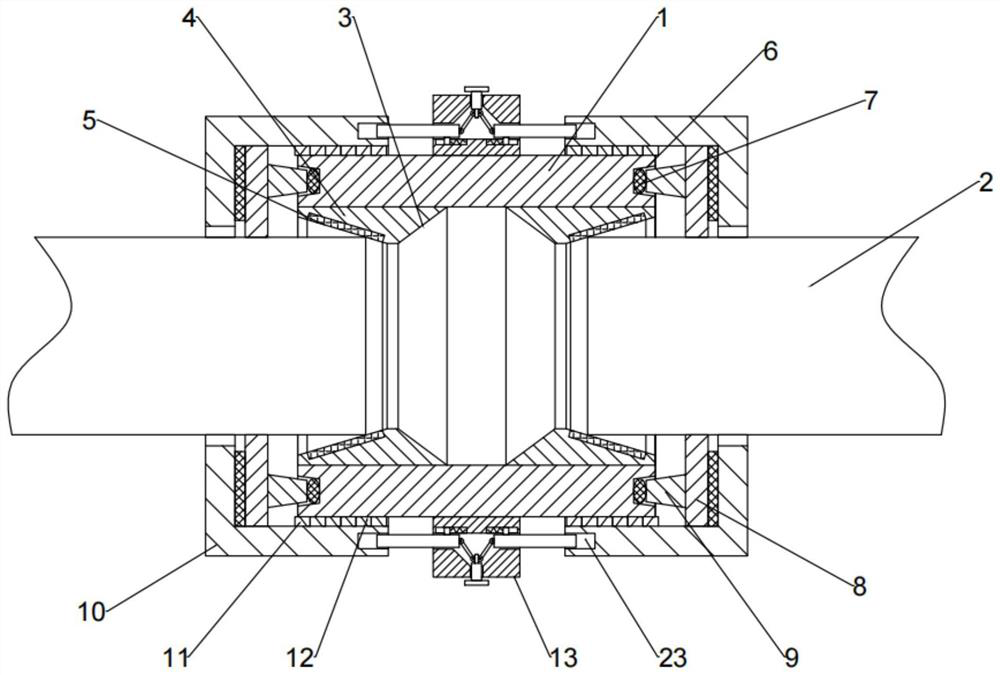

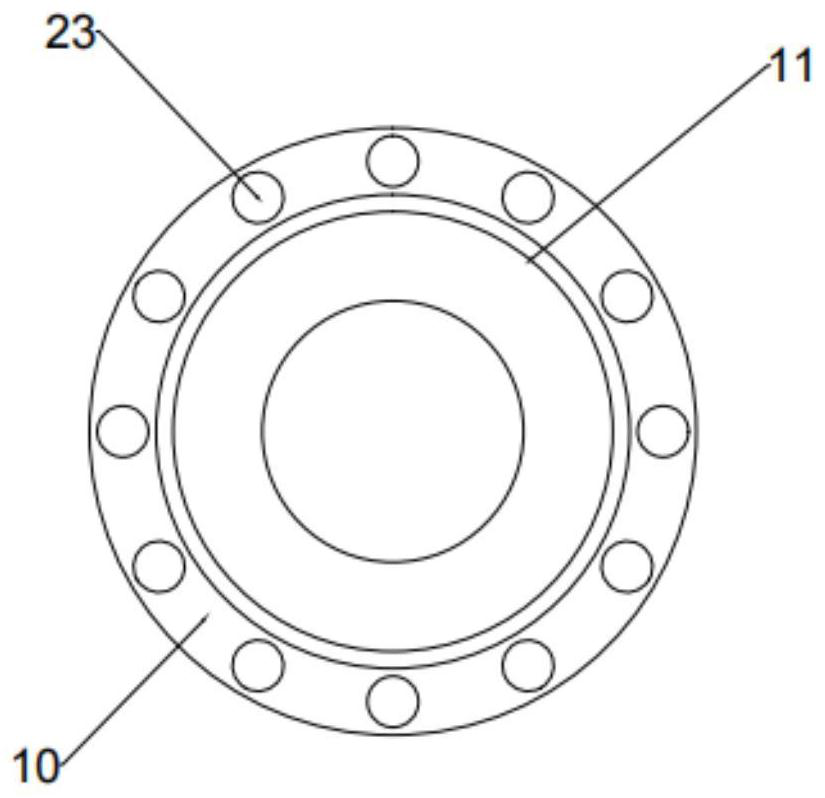

Hot and cold double acting packer

ActiveCN103806861BAchieve secondary sealingImprove the effect of layered gas injectionSealing/packingUpper jointRoom temperature

A cold and hot double-acting packer comprises a plurality of liquid outlet holes formed in an inner central pipe sleeved with an outer central pipe, and a liquid inlet hole is formed in the outer central pipe sleeved with a piston, a steel bushing is connected with the upper end of the piston, the upper end of the steel bushing is connected with an upper joint, and a locking piece sleeve and a snap ring sleeve are clamped between the steel bushing and the outer central pipe; a plurality of rubber sleeves are nested on the outer central pipe and located at the lower end of the piston, and distance rings are arranged between every two rubber sleeves; an expansion cone is nested on the outer central pipe and located at the lower ends of the plurality of rubber sleeves, the lower end of the expansion cone is connected with a cylinder, and an accommodating cavity is formed among the cylinder body, the expansion cone and the outer central pipe and filled with an expansion fluid; and a sealing rubber sleeve is clamped between the plurality of rubber sleeves and the expansion cone. The cold and hot double-acting packer can perform pressure set by aid of the ground at the room temperature and achieve secondary sealing through hot expansion of the fluid at a high temperature for steam injection, the oil jacket annulus sealing reliability is high, and the oil reservoir production degree is increased.

Owner:PETROCHINA CO LTD

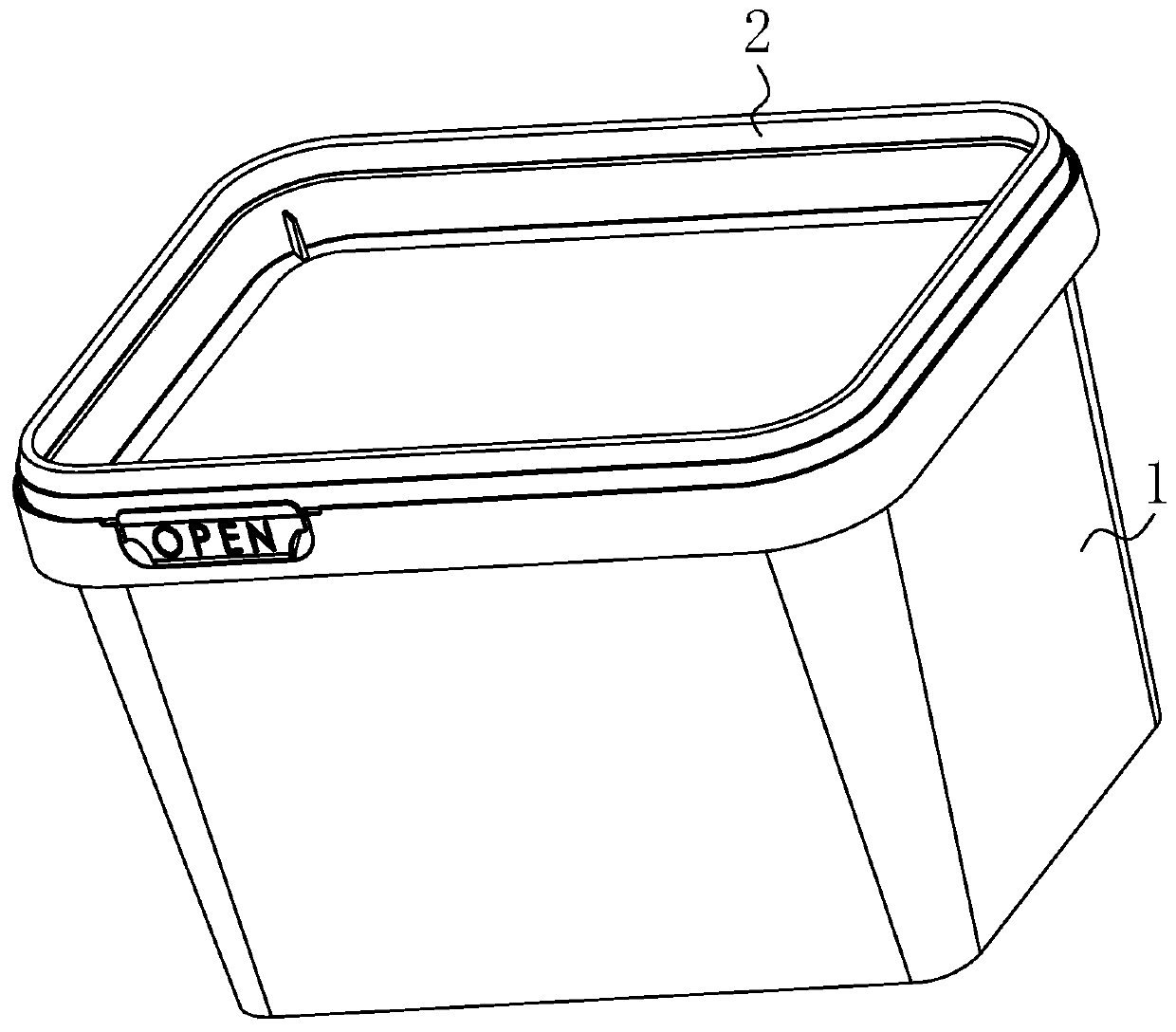

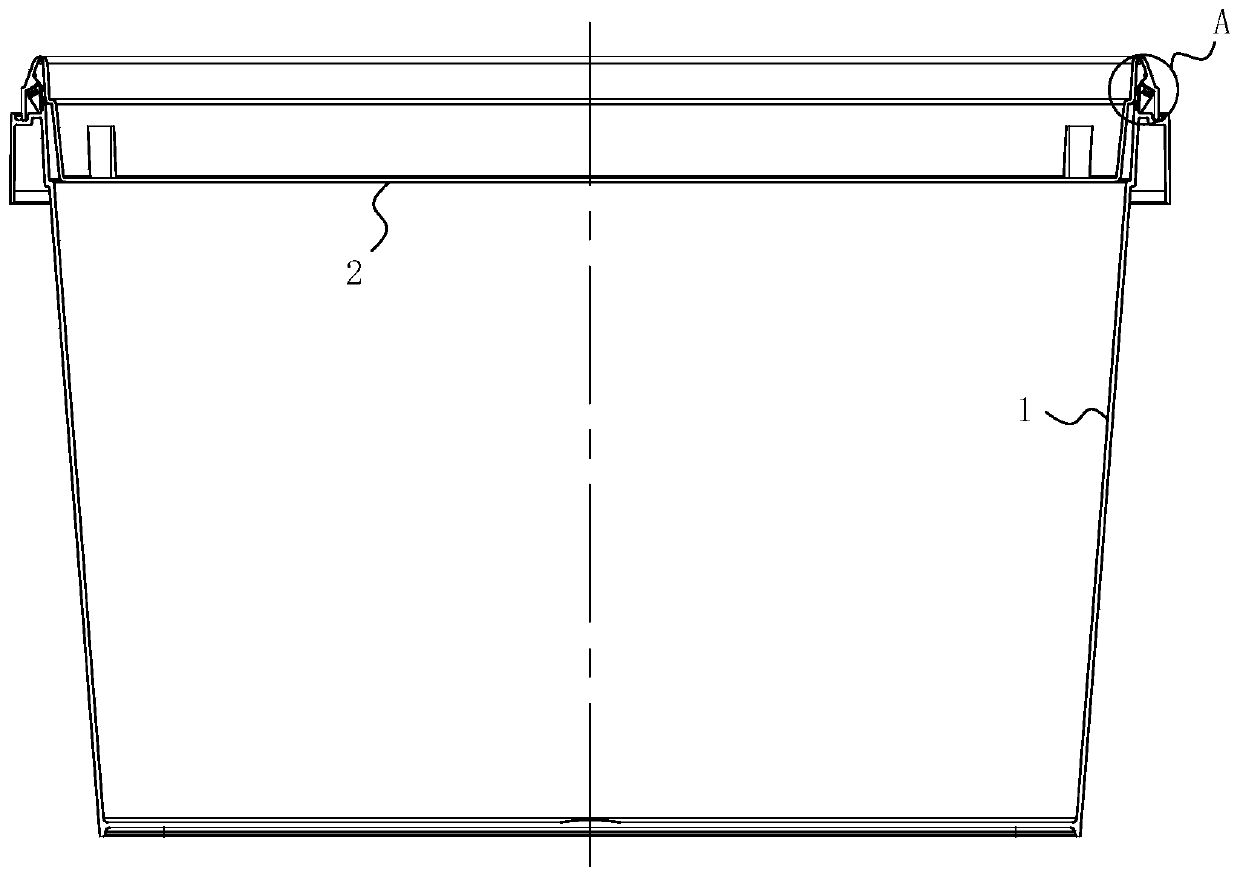

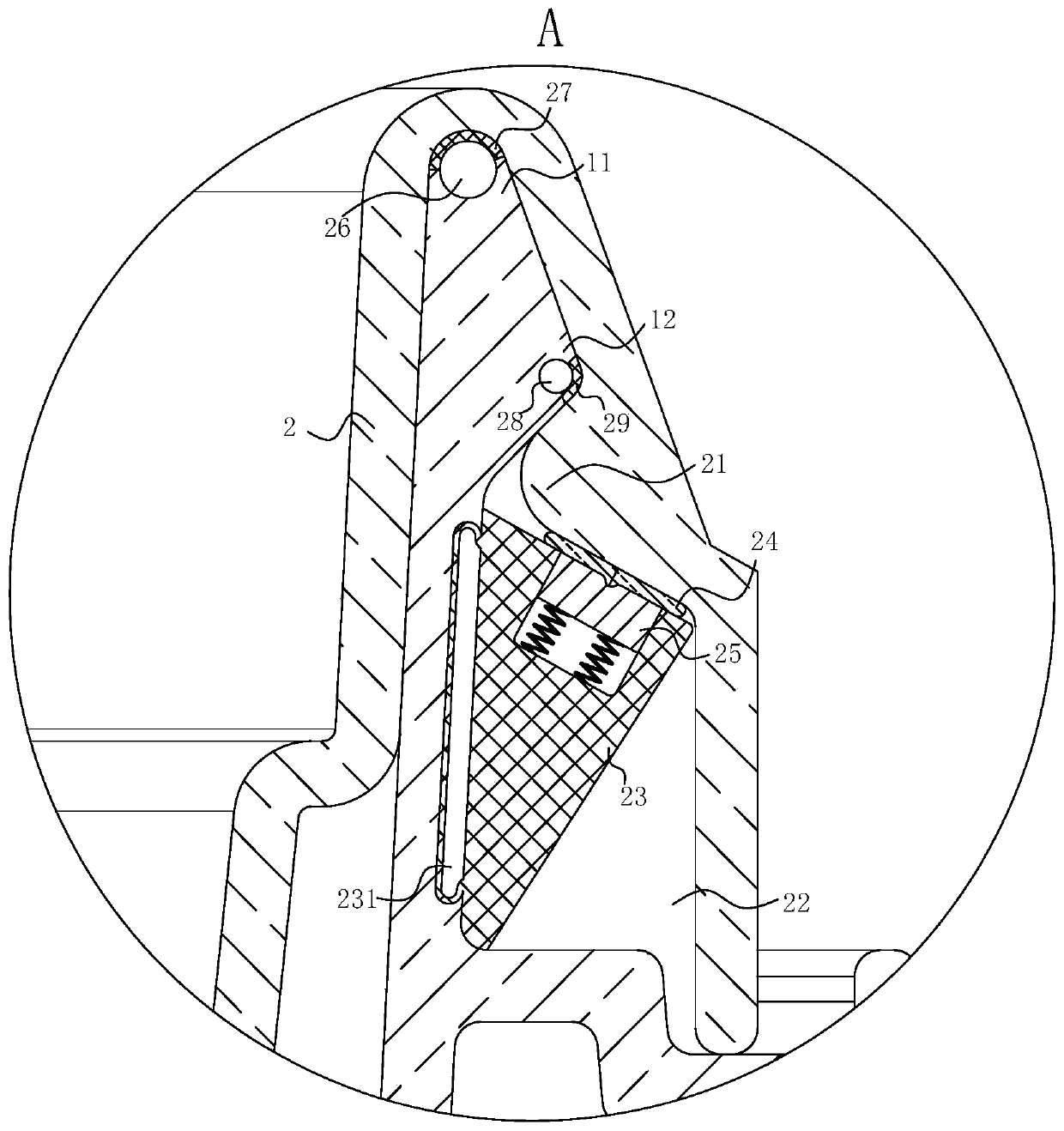

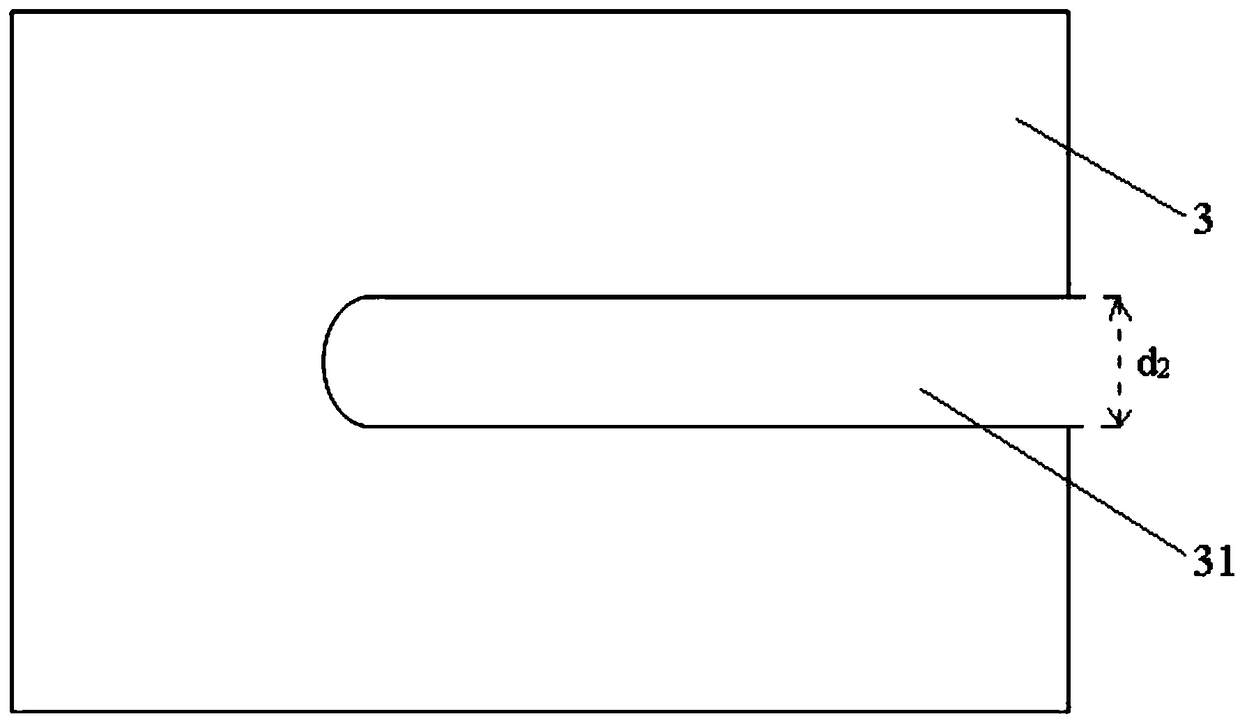

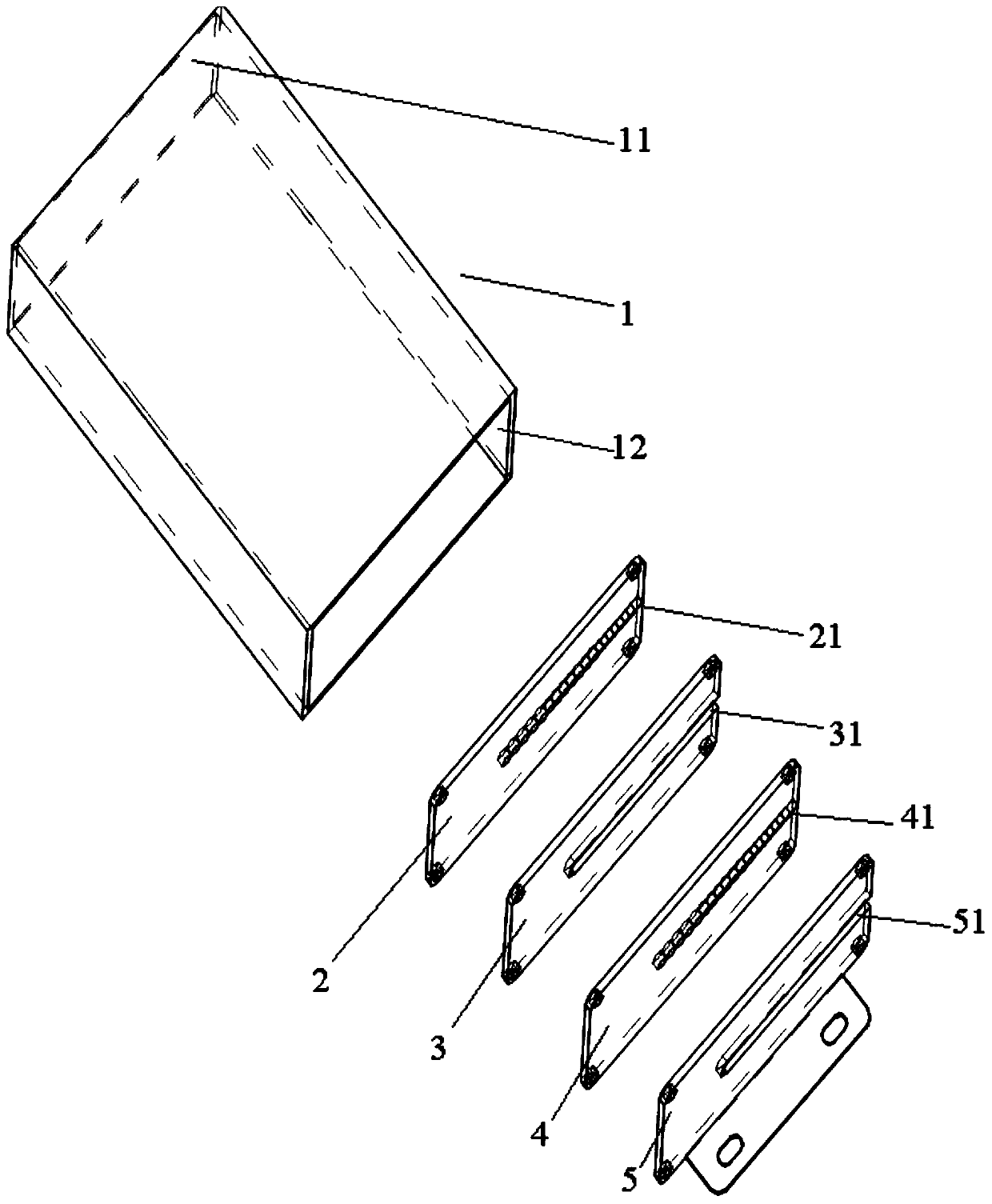

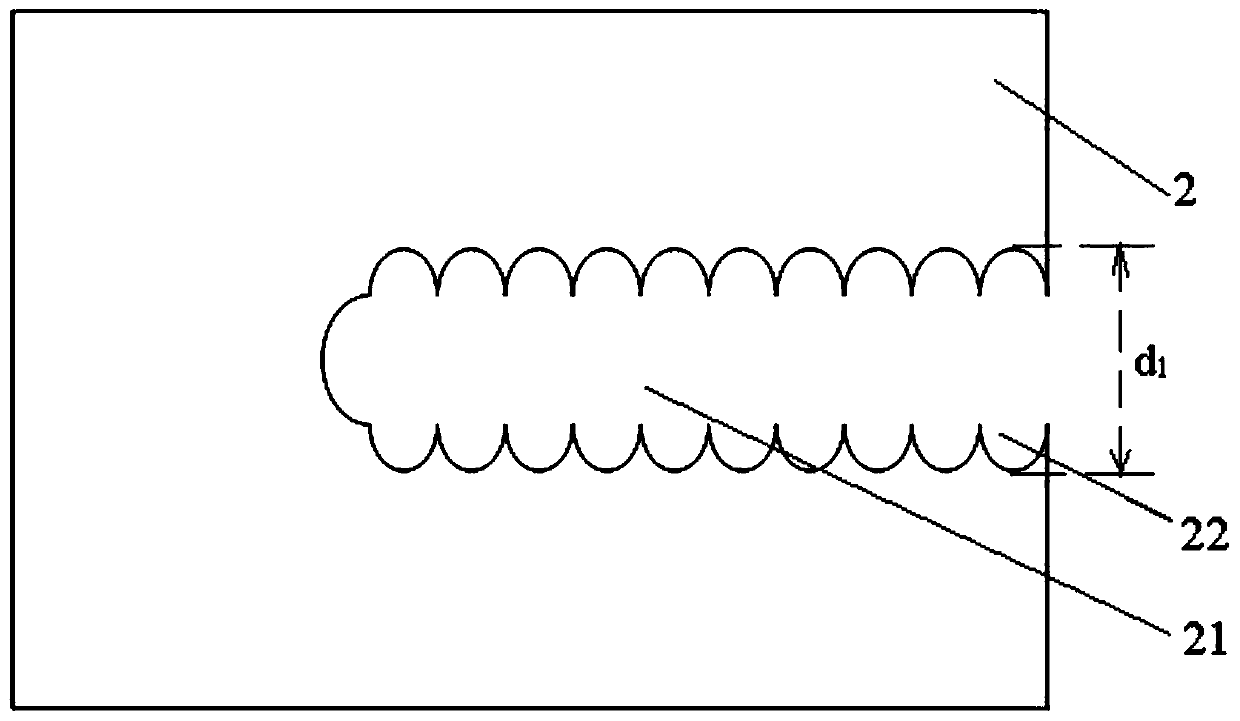

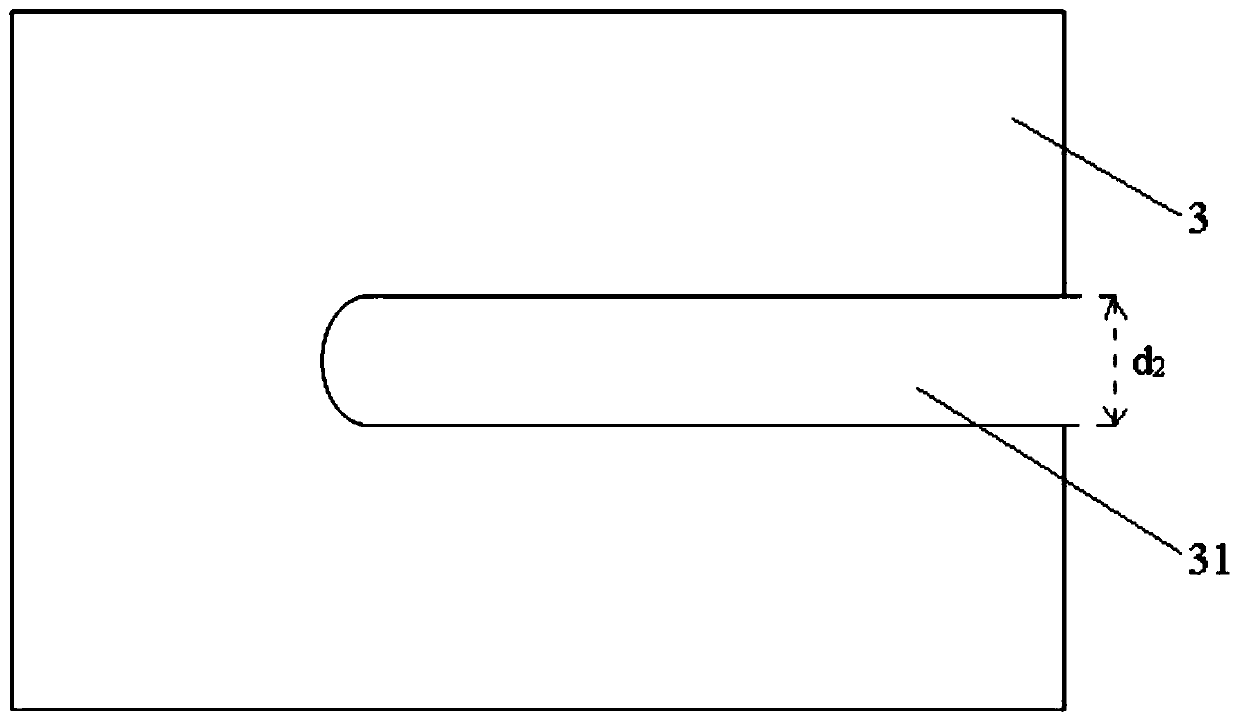

Blister packaging box

Owner:汕头市柏优环保科技有限公司

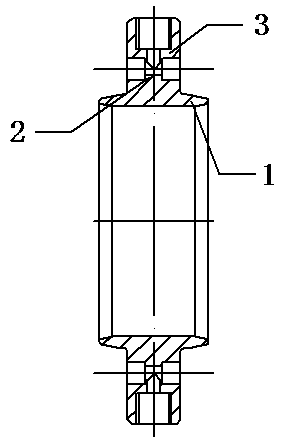

A fast-opening red wine cork

ActiveCN104354976BAchieve secondary sealingClosuresClosure using stoppersInterference fitEngineering

The invention provides a red wine cork capable of being removed fast and aims to provide a cork which can be removed fast without a corkscrew and can realize secondary sealing. The red wine cork comprises a cork body (1), wherein the cork body (1) is provided with a through hole (2) penetrating through the cork body (1); a pull rod (8) is arranged in the through hole (2); the diameter of the middle part (2-2) of the through hole is greater than those of the front end (2-1) and the rear end (2-3) of the through hole; the pull rod (8) comprises a front cork (3), a rear cork (6) and a connecting rod (5) for connecting the front cork (3) with the rear cork (6); a pull handle (7) is arranged on the rear cork (6); an elastic piece is arranged at the joint of the front cork (3) and the connecting rod (5); at least one of the front cork (3) and the rear cork (6) is in interference fit with the through hole (2). The red wine cork provided by the invention is used as a wine cork.

Owner:枣庄市亚太石榴酒有限公司

A high temperature sealing component

The invention provides a high-temperature seal assembly. The high-temperature seal assembly comprises a base plate and a plurality of seal blocks. The base plate is a round isolation plate, a round through hole is formed in the circle center of the base plate, the seal blocks are arranged on the base plate along the circumference, the seal blocks are composed of seal block bodies and backing plates, the seal block bodies are ceramic fiber specially-shaped folding blocks, the backing plates are specially-shaped fiber backing plates, the specially-shaped fiber backing plates make contact with the base plate, the seal blocks are fixedly arranged on the base plate, a round baffle is further arranged on the base plate, and the baffle is connected with the seal blocks internally and is in clearance fit with the seal blocks. According to the high-temperature seal assembly, existing heat-resistant seal materials are replaced by the seal blocks formed by the ceramic fiber specially-shaped folding blocks and the specially-shaped fiber backing plates, therefore, expenditures can be cut down, cost can be reduced, meanwhile, the service life of equipment can be prolonged, and losses, caused by equipment replacement and the like, in manpower, material resource, yield and the like are reduced accordingly.

Owner:天津太钢天管不锈钢有限公司

Waterproof electrical control box

ActiveCN108925068ASimple structureFunctionalHermetically-sealed casingsElectrical controlEngineering

The invention relates to a waterproof electrical control box, comprising a controller box body, a first sealing piece, a lining board, a second sealing piece and a baffle, wherein the baffle, the second sealing piece, the lining board and the first sealing piece are sequentially stacked from outside to inside and fastened at an opening of the controller box body by virtue of fastening screws. In the waterproof electrical control box provided by the invention, wiring ducts with open ends consistent in orientation are utilized, arranged wiring harnesses can be rapidly arranged in the wiring ducts at one time, and waterproof gaskets arranged at intervals are utilized for realizing secondary sealing on the controller box body, so that waterproof performance of the waterproof electrical controlbox is improved.

Owner:湖北省应急智能装备创新中心有限公司

A waterproof electrical control box

ActiveCN108925068BSimple structureFunctionalHermetically-sealed casingsClassical mechanicsElectrical control

The invention relates to a waterproof electrical control box, comprising a controller box body, a first sealing piece, a lining board, a second sealing piece and a baffle, wherein the baffle, the second sealing piece, the lining board and the first sealing piece are sequentially stacked from outside to inside and fastened at an opening of the controller box body by virtue of fastening screws. In the waterproof electrical control box provided by the invention, wiring ducts with open ends consistent in orientation are utilized, arranged wiring harnesses can be rapidly arranged in the wiring ducts at one time, and waterproof gaskets arranged at intervals are utilized for realizing secondary sealing on the controller box body, so that waterproof performance of the waterproof electrical controlbox is improved.

Owner:湖北省应急智能装备创新中心有限公司

Pipe connection mechanism

ActiveCN108223933BGuaranteed tightnessMake sure it fits in placeScrew threaded jointsEngineeringScrew thread

The invention provides a pipeline connecting mechanism, which comprises an outer joint, a pipe joint, an inner joint and a pressing sleeve. The pressing sleeve is interworked with the inner joint so as to jointly form a sealed chamber; the outer joint is arranged in the inner joint, partially downwards stretches out relative to the inner joint, and is connected with a pipeline on an equipment body; the pipe joint is arranged in the pressing sleeve, and upwards partially stretches out relative to the pressing sleeve; a rubber pipe is connected onto a part, stretching out of the pressing sleeve,of the pipe joint; and the outer joint and the pipe joint are connected and fixed in a screw thread way. According to the pipeline connecting mechanism provided by the invention, through the reasonable structure arrangement, a sealing effect is ensured when the equipment body outwards conveys a medium through the rubber pipe, so that the occurrence of equipment field safety accidents caused by medium leakage and seepage is avoided.

Owner:SHANGHAI ZHONGLIN FEEDWATER MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com