High-temperature seal assembly

A high-temperature sealing and component technology, applied in the direction of engine sealing, engine components, furnace types, etc., can solve the problems of burning and deformation of stainless steel sealing curtains, affecting the normal operation of cold wires, and damaging uploading tools, etc., to improve service life, The effect of enhancing thermal insulation performance and reducing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

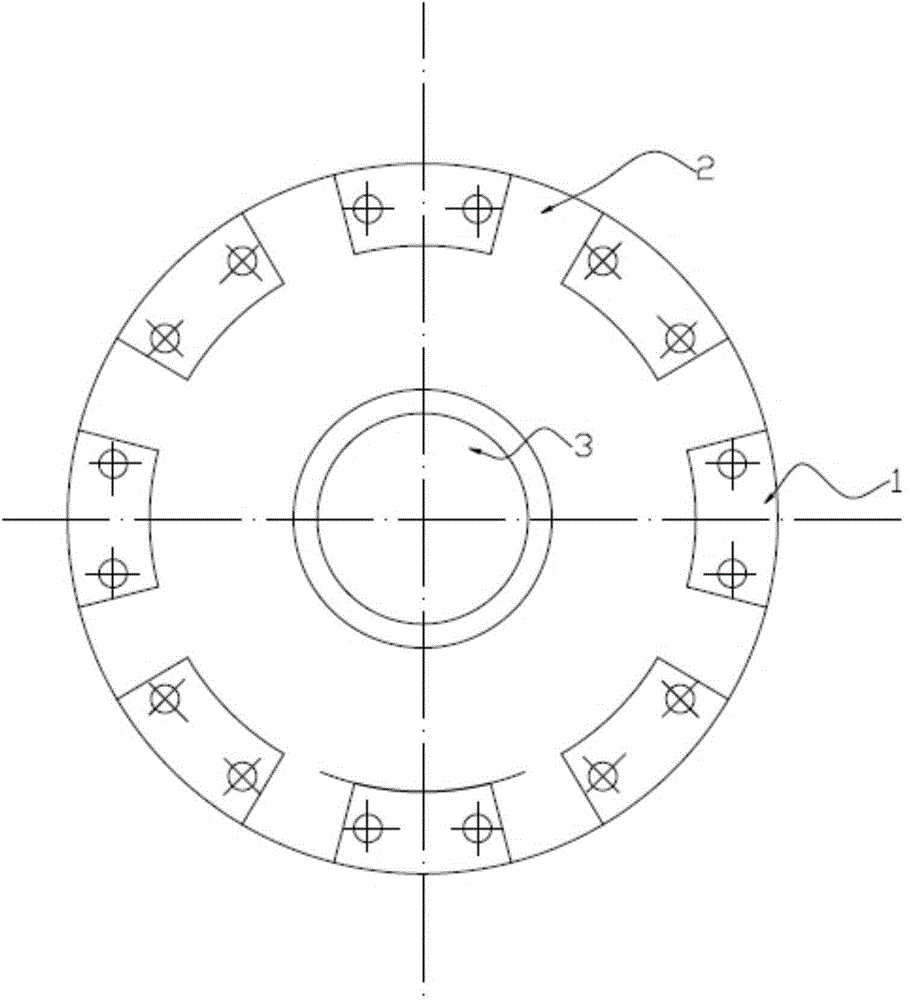

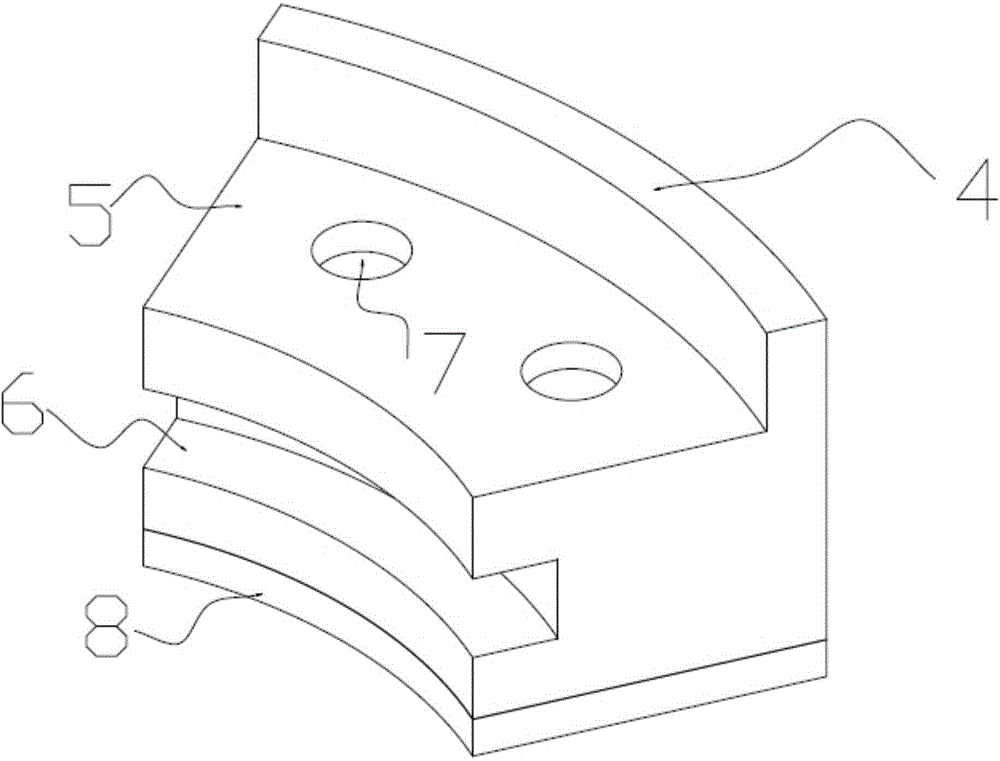

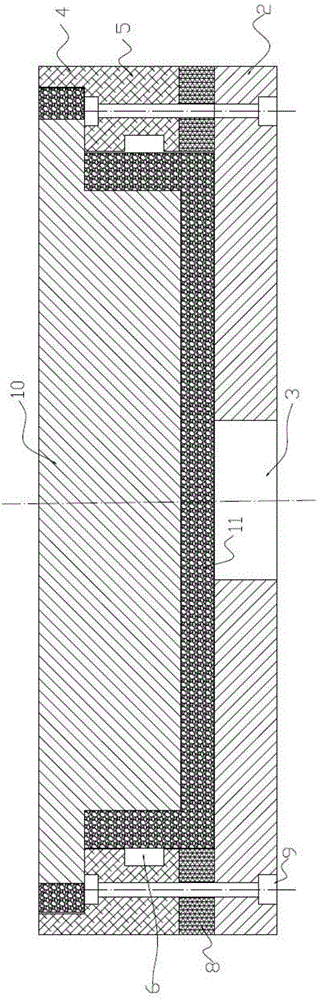

[0017] like figure 1 , image 3 A high temperature sealing assembly shown includes a bottom plate 2 and a sealing block 1 . The bottom plate 2 is a circular heat insulation plate, and the bottom plate 2 is used to close the annealing furnace. A circular through-hole 3 is arranged at the center of the base plate 2, and the inside of the through-hole 3 communicates with the annealing furnace. Eight sealing blocks 1 are also arranged on the surface of the bottom plate 2, and the shape of the sealing block 1 includes a circular arc with the same diameter as the bottom plate 2 and a circular arc with a diameter smaller than the bottom plate 2, and two sections passing through the center of the circular arc. Side composition. The eight sealing blocks 1 are evenly arranged on the largest diameter of the bottom plate 2 and fixed on the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com