Oxygen gun opening nitrogen sealing device

An oxygen muzzle and nitrogen sealing technology, which is used in the manufacture of converters and other directions, can solve the problems of high temperature flue gas and dust leakage, poor nitrogen sealing effect, and no treatment, so as to achieve reliable sealing, reduce energy consumption, and improve sealing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

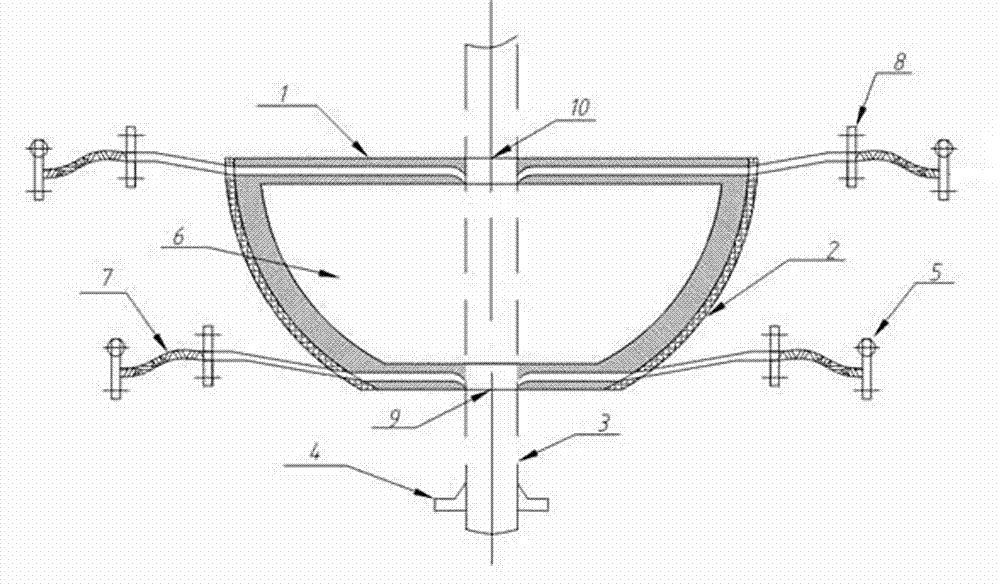

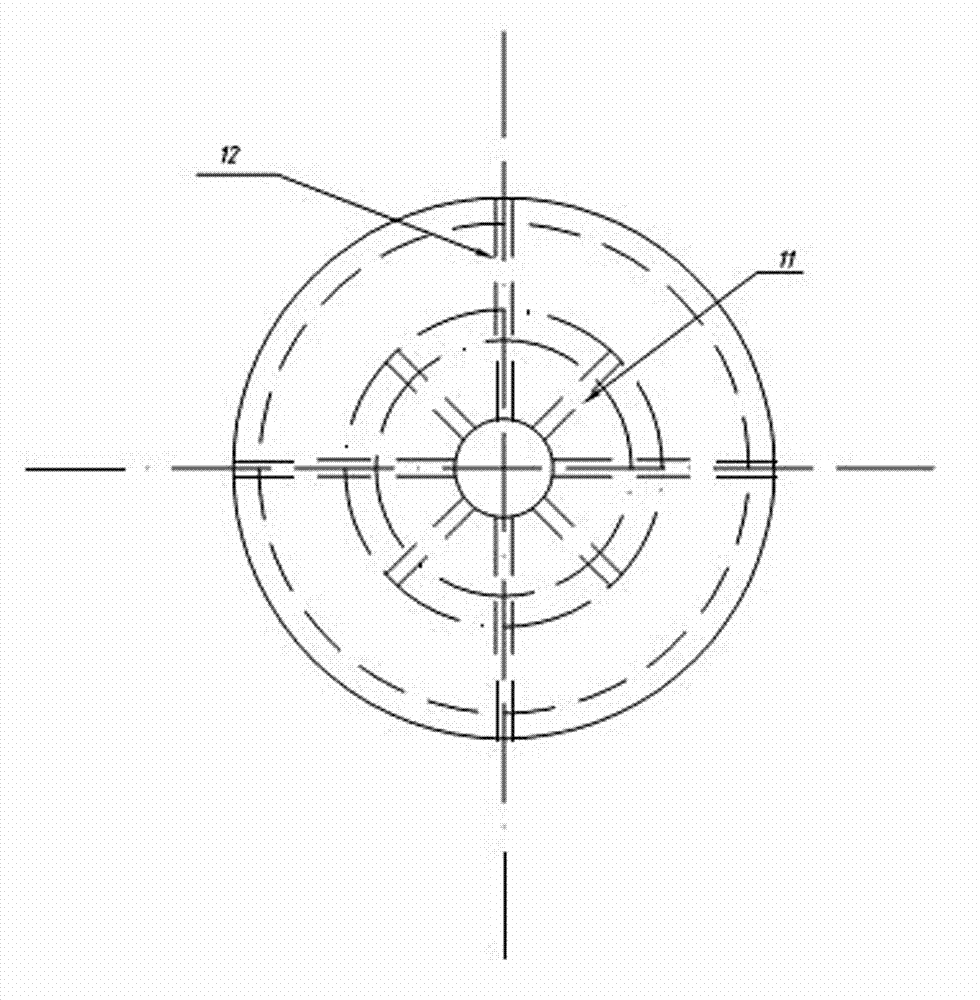

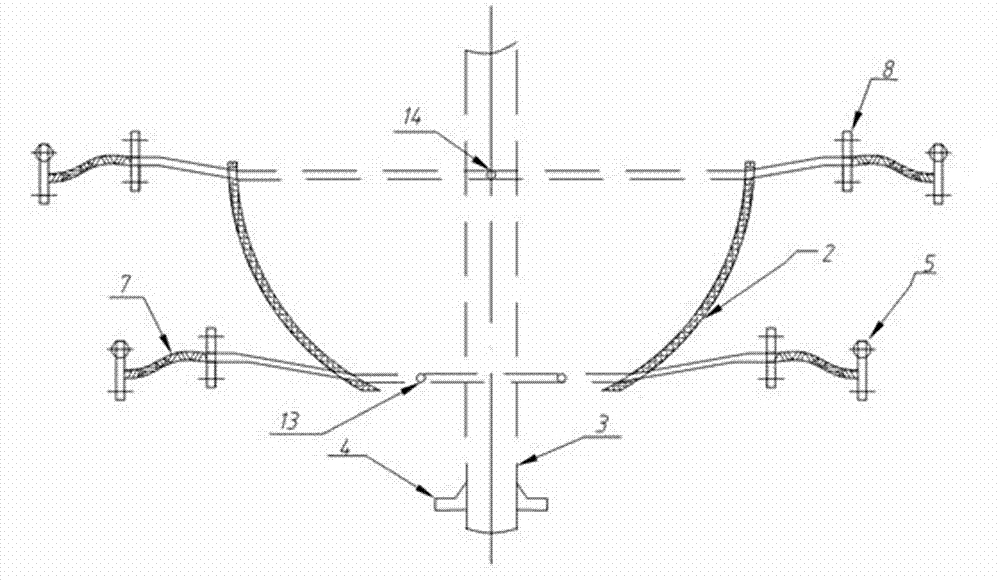

[0024] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1 to Figure 3 As shown, a nitrogen sealing device for an oxygen muzzle of the present invention includes a nitrogen sealing plug 1 and a nitrogen sealing seat 2, the nitrogen sealing plug 1 includes an upper large mouth end and a lower small opening end, and the outer surface of the nitrogen sealing plug 1 and the nitrogen sealing seat The inner surface of 2 forms a matching sealing surface. The nitrogen sealing seat 2 is provided with an oxygen gun port, the nitrogen sealing plug 1 is set on the oxygen lance 3, and the lower part of the nitrogen sealing plug 1 is provided with a nitrogen sealing round hole Ⅰ9. Hole I9 communicates with a plurality of nitrogen channels I11, nitrogen sealing round hole II10 is arranged on the upper part of nitrogen sealing plug 1, nitrogen sealing round hole II10 communicates with multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com