Special attachment joint for introducing ammonia gas and ammonia water

A special connection and ammonia water technology, which is applied in the direction of pipes/pipe joints/fittings, connections with fluid cut-off devices, passing components, etc., can solve problems such as ammonia gas leakage, and achieve safe use, simple structure, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

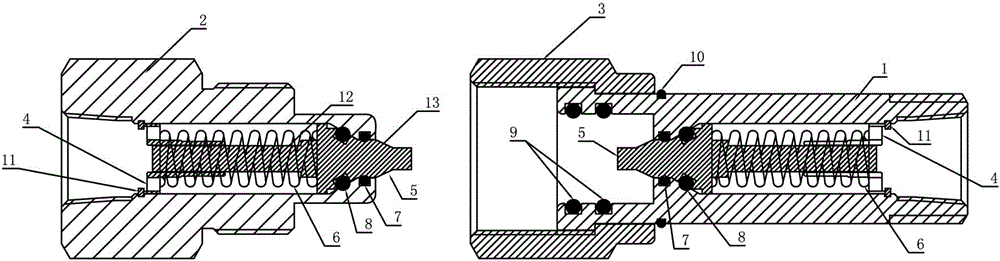

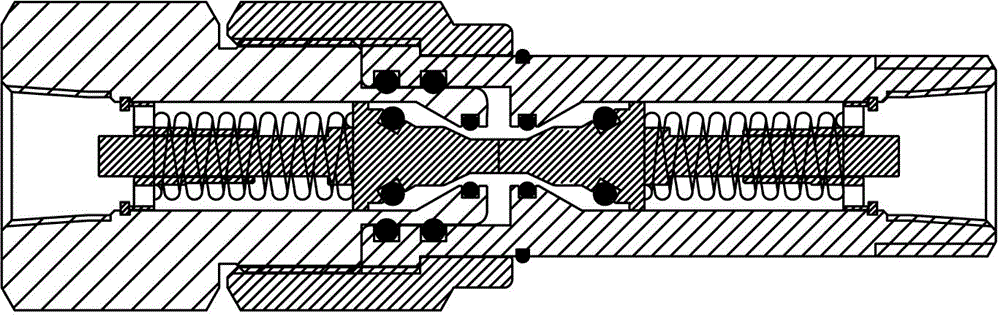

[0041] like figure 1 As shown, the present invention includes a male body 2 , a female body 1 , an outer ring 3 , a valve core 5 , a spring 6 , and seals 7 , 8 , and 9 .

[0042] The outer ring 3 is set on the front end of the female body 1, and the outer ring 3 cooperates with the male body 2 inserted into the female body 1 through threads, so as to fasten and lock the male body 2 and the female body 1;

[0043] The outer wall surface of the main body 1 of the female head is provided with a retaining spring 10, which is used to cooperate with the outer ring 3 to realize the stop of the outer ring 3;

[0044] Each of the male body 2 and the female body 1 has an air guide channel, and the two air guide channels have the same shape;

[0045] An O-shaped seal 7 is provided at the opening positions of the two air guiding channels;

[0046] The female head main body 1 is also provided with a connecting channel communicating with the front end of the air guide channel;

[0047] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com