Single pipe free telescopic structure of high-temperature air preheater

A technology of air preheater and telescopic structure, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., and can solve the problems of difficult replacement, jamming and incomplete sealing of sealing ring and stuffing box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

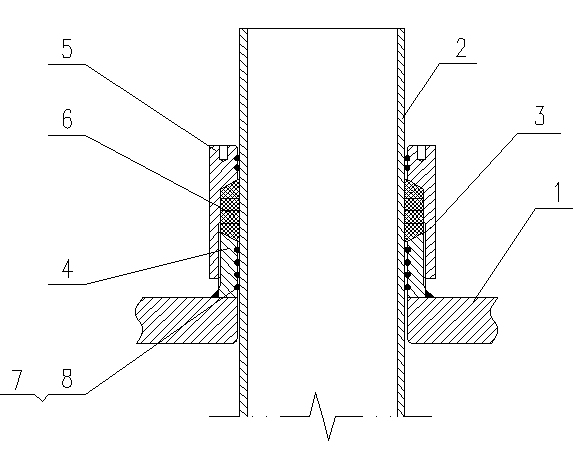

[0008] like figure 1 As shown, the high-temperature air preheater has a single-tube free telescopic structure, including a tube plate 1 and a heat exchange tube 2. The heat exchange tube 2 is vertically connected to the tube plate 1, and a seal is set between the heat exchange tube 2 and the tube plate 1 System 3, sealing system 3 includes packing top block 4, stuffing box 5, packing 6, packing top block 4, stuffing box 5 are respectively set outside the heat exchange tube 2, packing top block 4 is welded on the tube sheet 1, stuffing box 5 is screwed on the filler top block 4, the filler 6 is filled between the filler top block 4 and the stuffing box 5, and at least one installation groove 7 is set on the surface of the filler top block 4 in contact with the heat exchange tube 2, and the stuffing box 5 At least one installation groove 7 is provided on the surface in contact with the heat exchange tube 2 , and sealing rings 8 are respectively arranged in the installation groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com