L-shaped slip-ring sealed ring

A slip ring seal and slip ring technology, which is applied in the direction of engine seals, piston rings, mechanical equipment, etc., can solve the problems of poor performance of seal rings such as wear resistance, high temperature resistance and high pressure, and achieve superior aging resistance and possible The effect of reducing the resistance and reducing the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

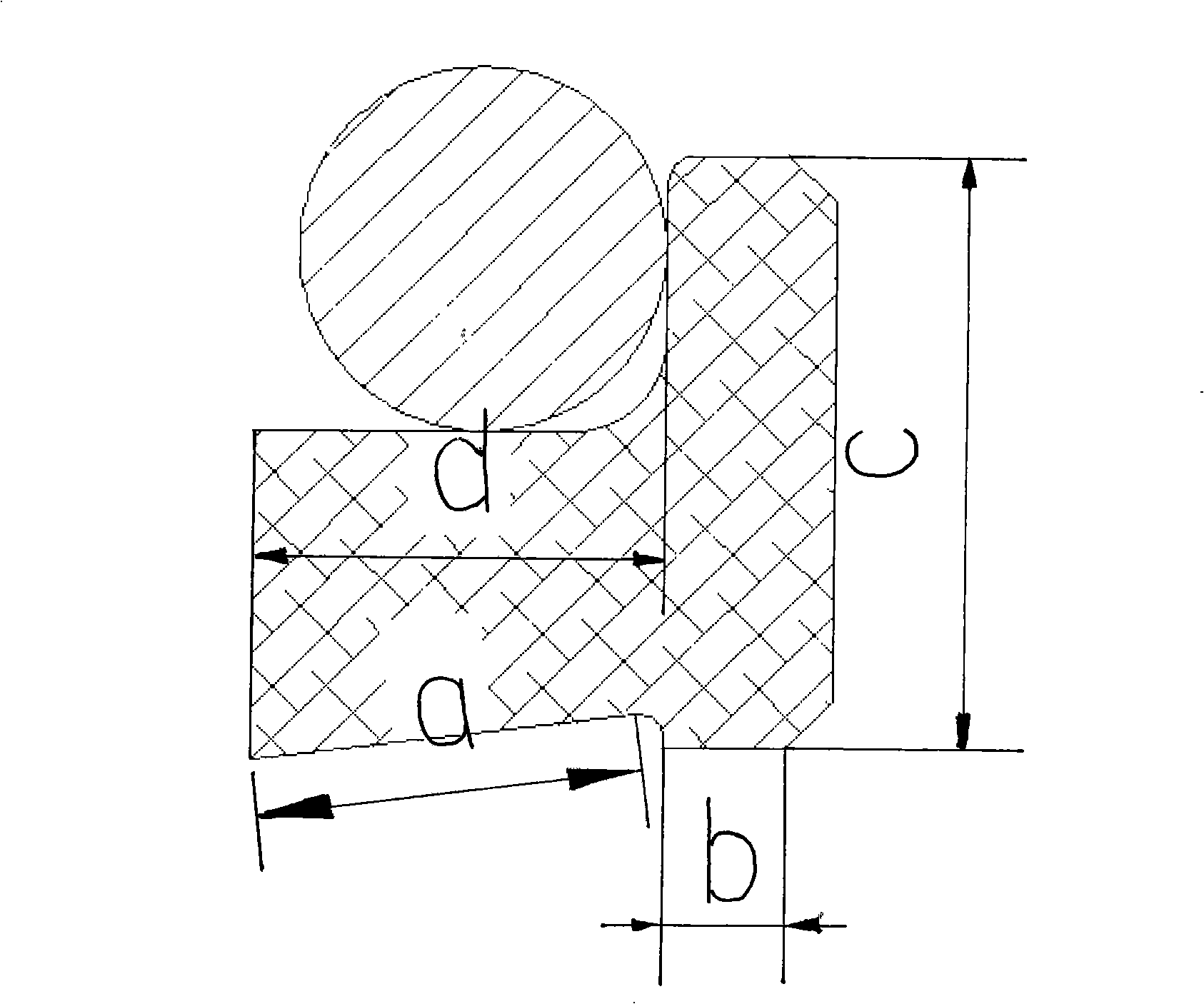

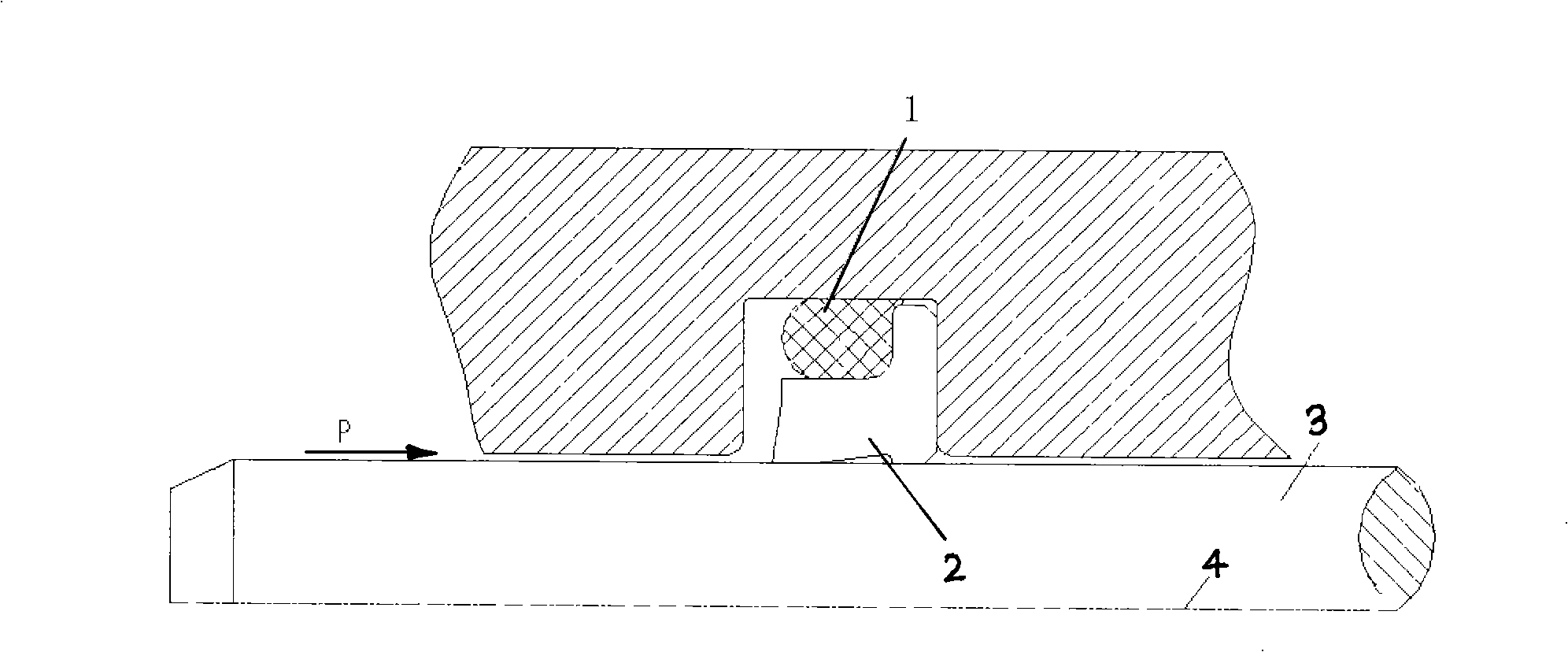

[0025] like figure 1 As shown, the L-shaped slip ring and the O-ring are in a natural state, and the contact section d of the L-shaped slip ring and the O-ring must match the cross-sectional diameter of the O-ring, where d must be greater than the cross-sectional diameter of the O-ring to avoid O-ring O-ring extrusion occurs at the top; the length c of the back pressure side of the L-shaped slip ring is close to the depth of the groove, which is also to avoid serious extrusion of the O-ring as much as possible.

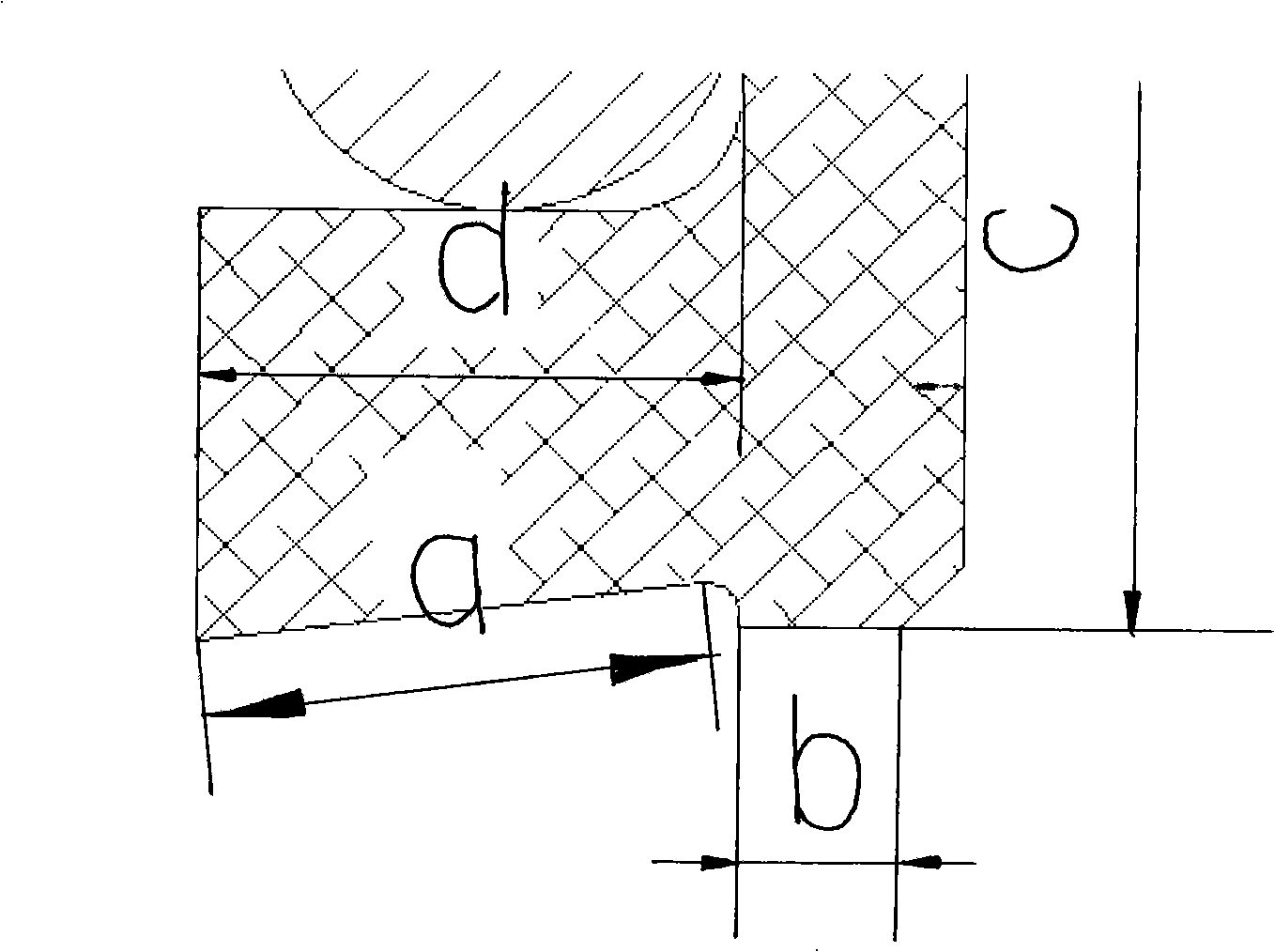

[0026] like Figure 4 As shown, in the compression process, the L-shaped slip ring is slightly inclined inward, and the force and moment on the slip ring after oil pressure are not easy to twist and turn over. After the L-shaped slip ring is squeezed by the piston rod and the O-ring, the inclined surface is slightly deformed, but its wedge-shaped structure reduces the contact area, thus increasing the normal contact stress, and the contact stress value in the middle ...

Embodiment 2

[0032] The raw materials of the O-ring are calculated in parts by weight: 100 parts of hydrogenated nitrile rubber HNBR with 34% ACN content, 6.0 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of styrenated diphenylamine, methyl mercaptan benzimidazole 0.3 parts of zinc, 40 parts of fast extruded carbon black, 10 parts of high wear-resistant carbon black, 3 parts of N, N'-m-phenylbismaleimide, 2,5-dimethyl-2,5-bis 3.5 parts of (tert-butylperoxy)hexane.

[0033] The raw materials of the L-shaped slip ring are calculated in parts by weight: 65 parts of PTFE, and 35 parts of bronze powder.

[0034] Structural size parameters: the angle between the slope of the L-shaped slip ring and the shaft is 8°, a=9.1, b=13.5, c=10.9 d=10.4, the nominal size of the L-shaped slip ring (inner diameter*outer diameter*width) is 950 *990*19, the size specification of O-ring is 970*12.

[0035] The L-shaped slip ring sealing ring of this embodiment is suitable for hot rolling, cold rol...

Embodiment 3

[0037] The raw materials of the O-ring are calculated in parts by weight: 34% ACN content hydrogenated nitrile rubber HNBR 100 parts, zinc oxide 5.0 parts, stearic acid 1.0 parts, styrenated diphenylamine 1.1 parts, methyl mercaptan benzimidazole 0.4 parts of zinc, 35 parts of fast extruded carbon black, 15 parts of high wear-resistant carbon black, 2 parts of N, N'-m-phenylbismaleimide, 2,5-dimethyl-2,5-bis (tert-butylperoxy) hexane 4 parts.

[0038] The raw materials of the L-shaped slip ring are calculated in parts by weight: 60 parts of PTFE, 40 parts of bronze powder.

[0039] Structural dimension parameters: the angle between the slope of the L-shaped slip ring and the shaft is 7°, a=9.1, b=13.5, c=10.9 d=10.4, the nominal size of the L-shaped slip ring (inner diameter*outer diameter*width) is 900 *940*19, the size specification of O-ring is 920*12.

[0040] The L-shaped slip ring sealing ring in this embodiment is suitable for hot rolling and cold rolling, and the AGC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com