Particlepowder body material level detection device

A detection device, technology of powder and granular body, applied in the direction of measurement device, liquid/fluid solid measurement, liquid level indicator for physical variable measurement, etc. , to achieve the effect of online cleaning, avoiding material accumulation, and round and smooth shape design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

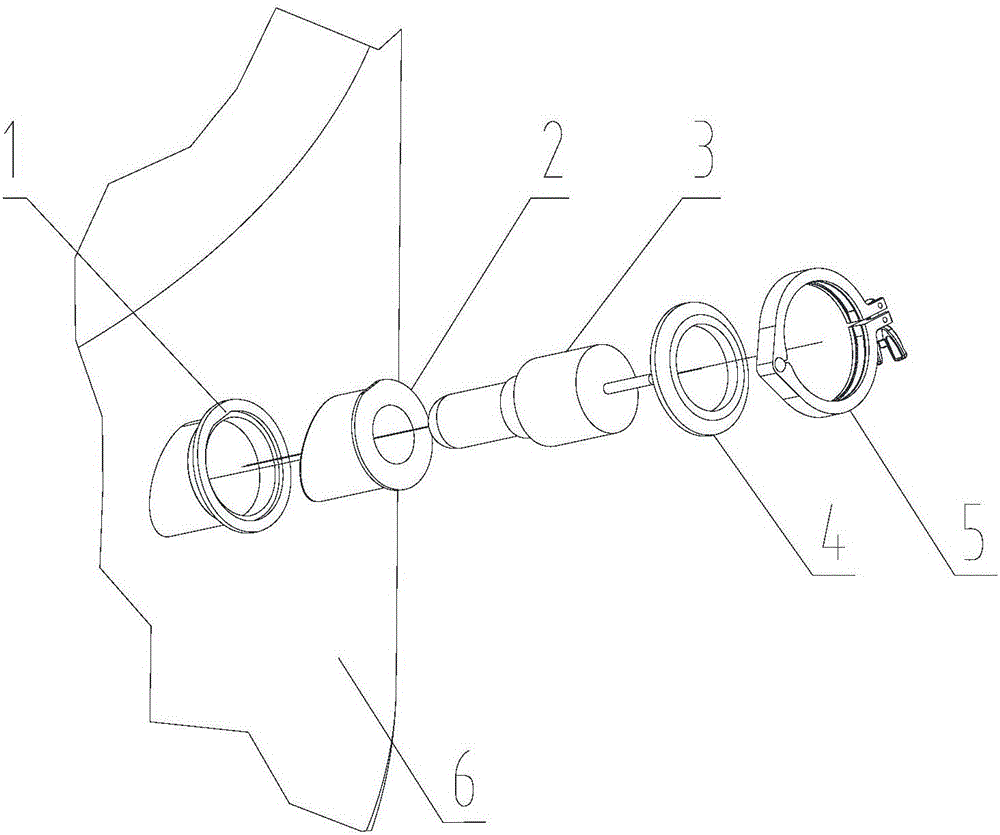

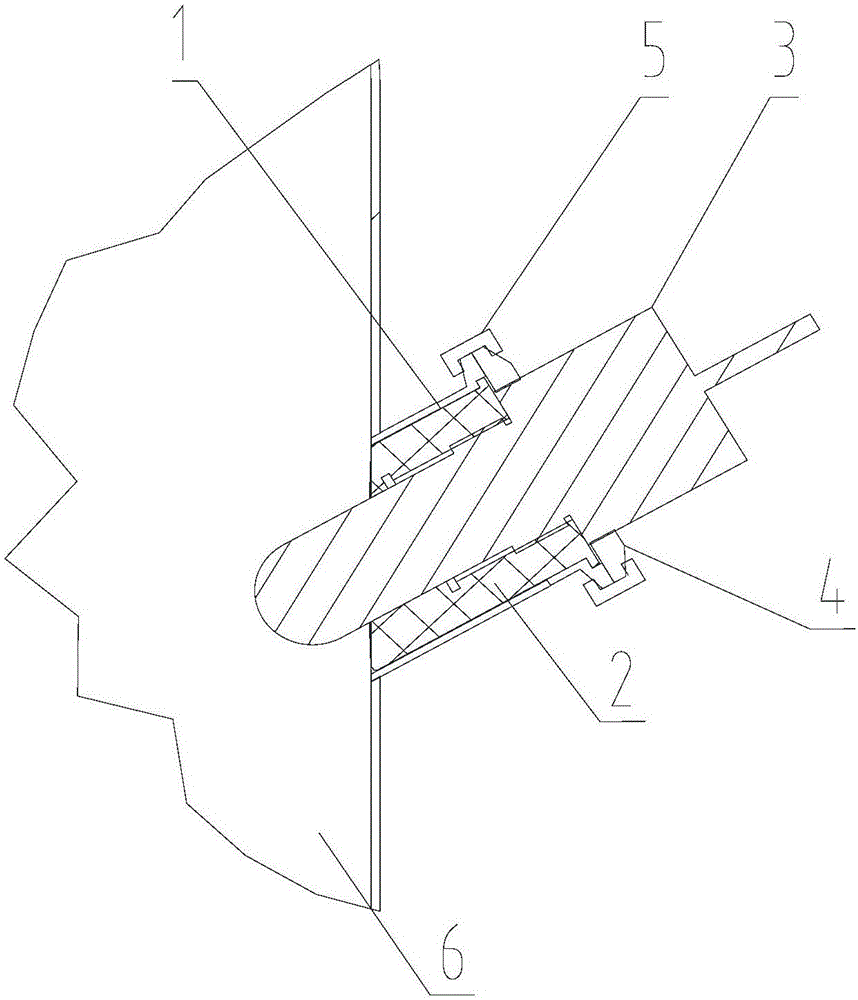

[0020] see figure 1 and figure 2 , The material level detection device for powder or granular body of the present invention includes a clamp lower end 1 , a threaded seal 2 , a capacitive level gauge 3 , a clamp upper end 4 and a clamp 5 .

[0021] The lower end 1 of the hoop is obliquely welded to the periphery of the side wall hole of the tank body 6 and has a central hole.

[0022] The threaded seal 2 is tightly inserted into the center hole of the lower end 1 of the clamp, and is provided with a threaded hole. The lower end of the threaded seal 2 is an arc inclined surface, which fits with the arc surface of the side wall of the tank body 6 to ensure smooth blanking without accumulation.

[0023] The capacitive level gauge 3 is screwed into the threaded hole, and is threadedly connected with the thread seal 2 . At the same time, the lower end of the capacitive leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com