Method for smelting low-silicon low-aluminum high-boron martensitic stainless steel

A technology of martensitic stainless steel and smelting method, which is applied in the field of iron and steel smelting, can solve problems such as the difficulty in controlling the content of Si, Al and B in martensitic stainless steel, achieve good mechanical properties and durable performance, low production cost, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

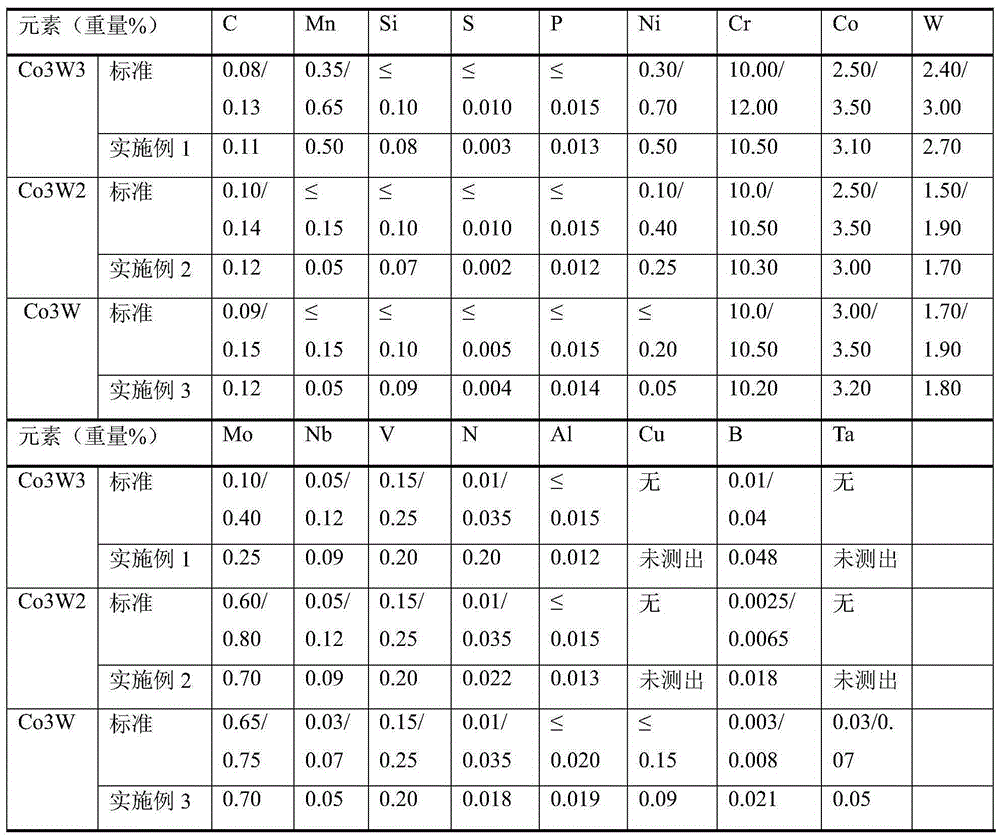

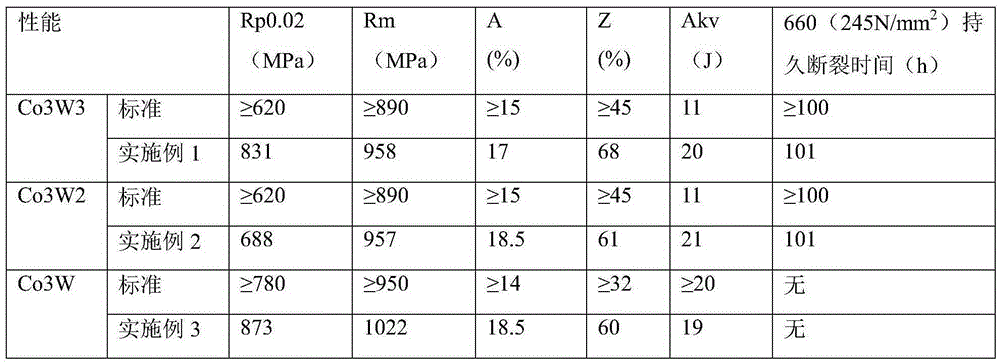

Embodiment 1

[0054] This embodiment is used to illustrate the smelting method of Co3W3 steel.

[0055] (1) The ingredients are returned from Benxi Steel, raw steel (including Ni, W, Mo, Co, P≤0.006), high-carbon ferrochrome (required P≤0.015%), N-Cr alloy, Fe-B alloy, Fe- Composed of Nb alloy and Fe-V alloy, the ratio of the ingredients makes the content of each element except P, Cr and Al basically meet the requirements of Co3W3. In the control charge: the content of P is about 0.008% by weight, and the content of Cr is about 0.008% by weight. 10.50% by weight, Al is not specially compounded; the weight of the charge is about 42 tons.

[0056] (2) In the electric arc furnace: a) melt the furnace material, and take samples for full analysis; b) control the temperature of molten steel at about 1550°C, blow oxygen to decarburize and adjust the composition (mainly adjust Cr to 10.5% by weight, W to 2.7 % by weight and Co to 3.1% by weight), the content of carbon at the end point is 0.45% by ...

Embodiment 2

[0063] This embodiment is used to illustrate the smelting method of Co3W2 steel.

[0064] (1) The ingredients are returned from Benxi Steel, raw steel (including Ni, W, Mo, Co, P≤0.006), high-carbon ferrochrome (required P≤0.015%), N-Cr alloy, Fe-B alloy, Fe- Composed of Nb alloy and Fe-V alloy, the ratio of the ingredients makes the content of each element except P, Cr and Al basically meet the requirements of Co3W2. In the control charge: the content of P is about 0.007% by weight, and the content of Cr is about 0.007% by weight. 10.30% by weight, Al is not specially compounded; the weight of the charge is about 42.5 tons.

[0065](2) In the electric arc furnace: a) melt the charge, and take samples for full analysis; b) control the temperature of molten steel at about 1530°C, blow oxygen to decarburize and adjust the composition (mainly adjust Cr to 10.3% by weight, W to 1.7 % by weight and Co to 3.0% by weight), the content of carbon at the end point is 0.40% by weight of...

Embodiment 3

[0072] This example is used to illustrate the smelting method of Co3W steel.

[0073] (1) The ingredients are returned from Benxi Steel, raw steel (including Ni, W, Mo, Co, P≤0.006), high-carbon ferrochrome (required P≤0.015%), N-Cr alloy, Fe-B alloy, Fe- Composed of Nb alloy and Fe-V alloy, the ratio of the ingredients makes the content of each element except P, Cr and Al basically meet the requirements of Co3W2. In the control charge: the content of P is about 0.009% by weight, and the content of Cr is about 0.009% by weight. 10.20% by weight, Al is not specially compounded; the weight of the charge is about 41.5 tons.

[0074] (2) In the electric arc furnace: a) melt the furnace material, and take samples for full analysis; b) control the temperature of molten steel at about 1580°C, blow oxygen to decarburize and adjust the composition (mainly adjust Cr to 10.20 wt%, W to 1.80 % by weight and Co to 3.20% by weight), the content of carbon at the end point is 0.50% by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com