Production method of ultra-low-aluminum high-purity industrial pure iron

A technology of industrial pure iron and production method, which is applied in the field of iron and steel smelting, can solve the problems of reducing the purity of industrial pure iron, reducing the cleanliness of pure iron, and increasing the cost of deoxidized alloys, so as to achieve the effect of improving purity and avoiding the increase of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1— Embodiment 7

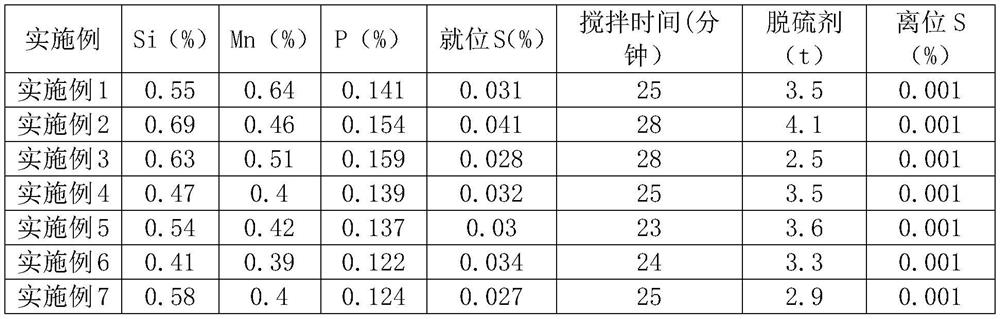

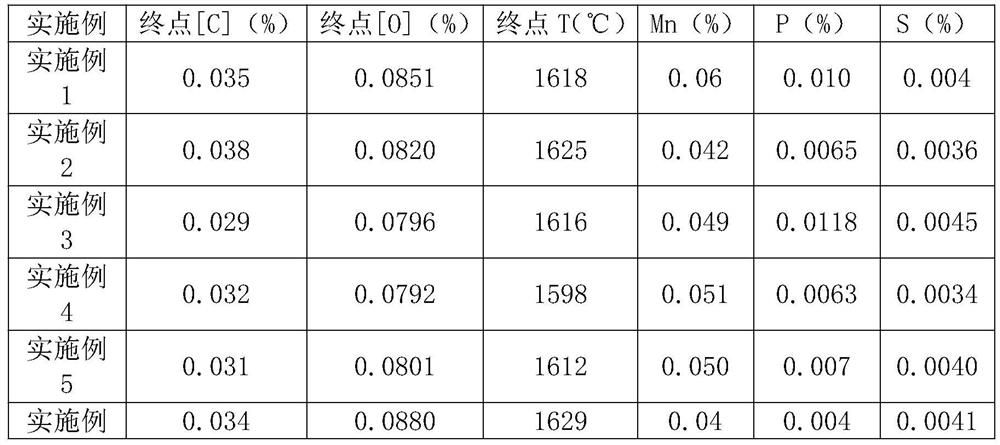

[0028] The molten iron is pre-desulfurized by KR, the amount of desulfurizer is determined according to the sulfur content of the molten iron, the stirring time is 23-28 minutes, and the sulfur content is reduced to 0.001% after treatment. In order to promote the dephosphorization and demanganization of molten steel, the converter adopts double slag method for smelting, the end temperature of blowing is controlled to be less than 1630°C, the carbon content is less than 0.035%, and the oxygen content is greater than 0.075%. %; The content of P in tapping molten steel is less than 0.010%, and the content of Mn is less than 0.06%. The steel slag and molten steel are not deoxidized during the tapping process, and the slag is refined in LF to adjust the ladle slag alkalinity to 5-7; the bottom of the ladle is blown with argon to promote the reaction of steel slag, and the content of P and Mn in the steel is further reduced. RH vacuum deep decarburization, after decarburization, alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com