Plasma spraying zinc-aluminum high-strength steel as well as preparation method and application thereof

A high-strength steel and plasma technology, applied in coating, fusion spraying, metal material coating technology, etc., can solve the problems of short service life, ineffective effect, high maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

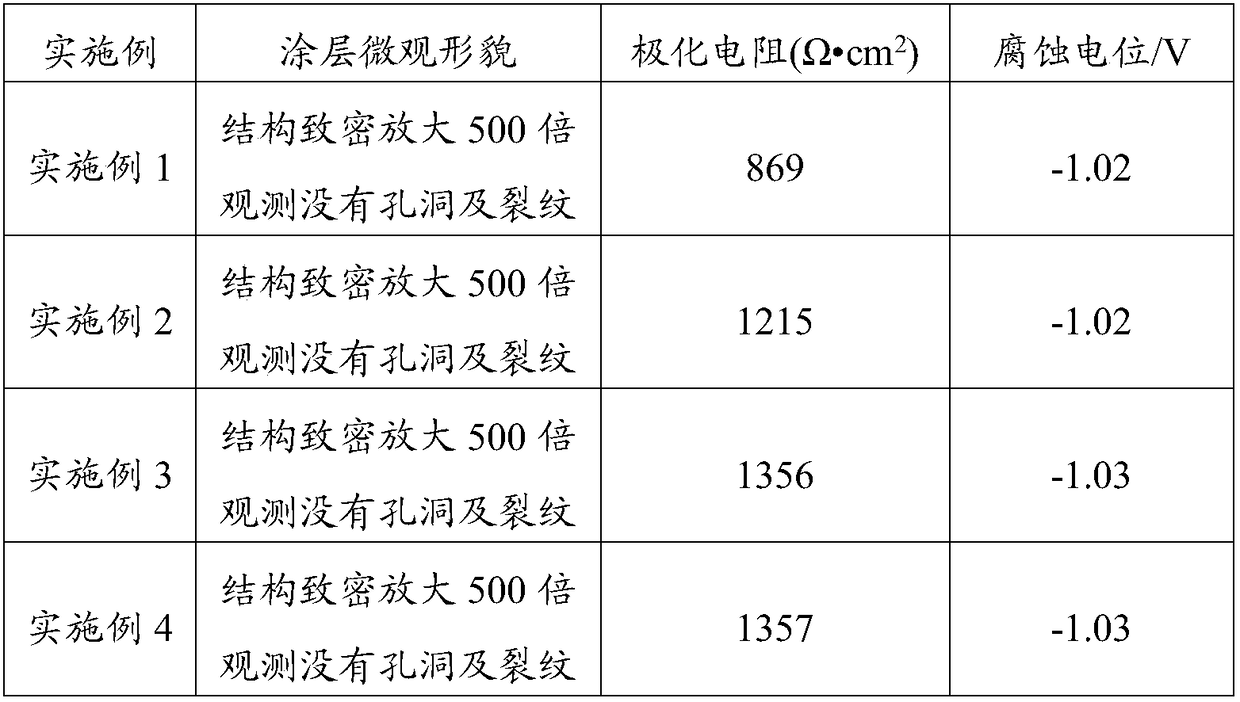

Examples

preparation example Construction

[0019] The invention provides a method for preparing zinc-aluminum high-strength steel by plasma spraying, comprising the following steps:

[0020] Ball milling zinc powder, aluminum powder and rare earth metal powder to obtain composite metal powder; the mass ratio of the zinc powder, aluminum powder and rare earth metal powder is (84-87): (13-14.5): (0.2-0.6) ;

[0021] Perform pretreatment and shot blasting on the surface of high-strength steel in sequence to obtain high-strength steel substrate;

[0022] The composite metal powder is sprayed on the surface of the high-strength steel substrate by a plasma spraying method, and a zinc-aluminum coating is formed on the surface of the high-strength steel substrate to obtain a plasma-sprayed zinc-aluminum high-strength steel.

[0023] In the present invention, zinc powder, aluminum powder and rare earth metal powder are ball milled to obtain composite metal powder; the mass ratio of the zinc powder, aluminum powder and rare ear...

Embodiment 1

[0040] According to the mass ratio of zinc powder, aluminum powder and cerium metal powder is 86:13.8:0.2, zinc powder, aluminum powder and cerium metal powder are mixed, add n-butanol and stearic acid (the amount of zinc powder, aluminum powder and cerium metal powder The mass ratio of the total mass to n-butanol and stearic acid is 1:2:2), under the protection of argon, ball mill at a speed of 350r / min for 10h, and vacuum-dry the obtained slurry at 60°C to obtain a composite metal pink;

[0041] Use 180#, 240#, 320#, 600#, 800#, 1200#, 2000# silicon carbide sandpaper to polish the surface of BR1500HS high-strength steel in sequence, and use 10wt.% NaOH solution as alkaline washing solution to polish at 50°C The steel is subjected to alkali washing for 2 hours, and the alkali-washed steel is rinsed with deionized water, and 6wt.% HCl solution is used as the pickling liquid, and the water-washed steel is acid-washed at room temperature for 30 minutes, and the pickled steel is ...

Embodiment 2

[0044] The plasma-sprayed zinc-aluminum high-strength steel was prepared according to the method of Example 1, except that the ball milling time was 14 hours, and the spraying distance was 85 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com