Crystal annealing device in growth furnace

An annealing device and growth furnace technology, applied in crystal growth, post-processing details, post-processing, etc., can solve problems such as long annealing time, high annealing temperature, release and resolution of crystal internal stress, etc., and achieve low production cost , reduce internal stress, reduce the effect of internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

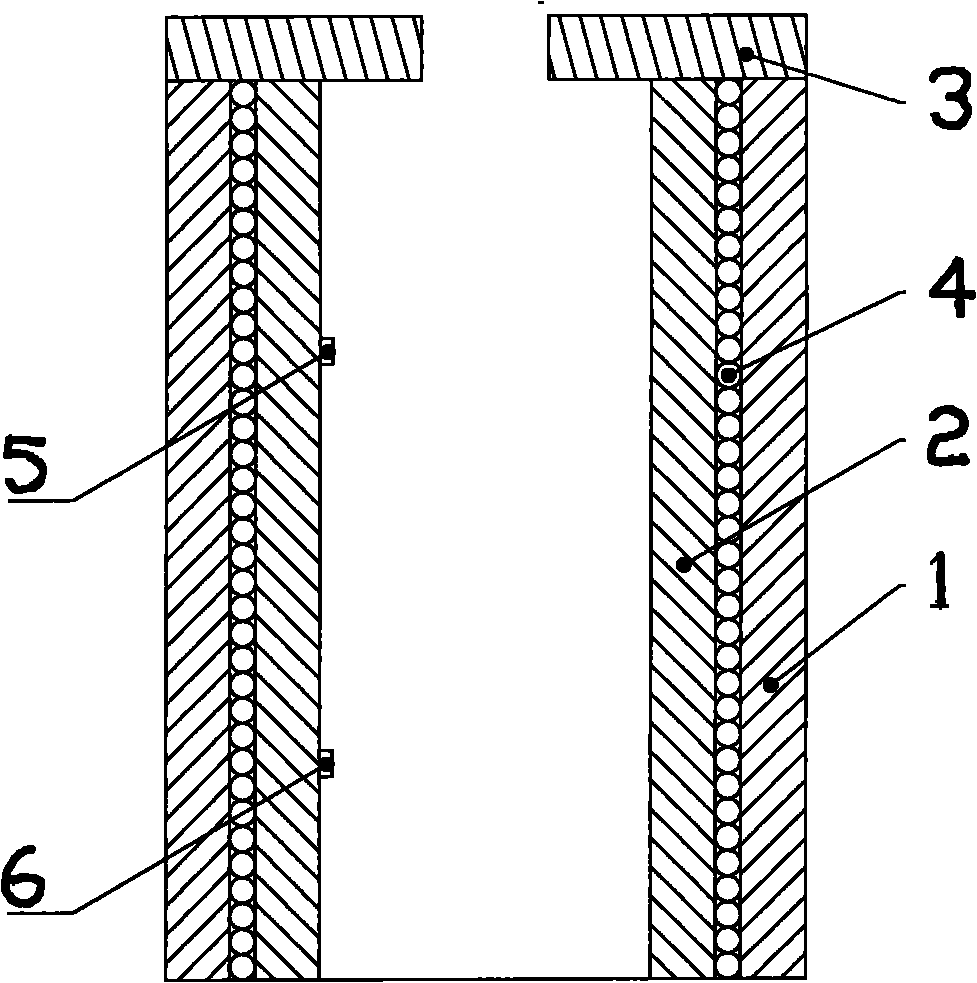

[0012] Example 1: Laser crystal growth of neodymium-doped yttrium aluminum garnet

[0013] It adopts domestic DJL-600 type single crystal growth furnace, 50KW thyristor intermediate frequency induction power heating, double platinum rhodium (Pt / Rh30-Pt / Rh10) thermocouple, British Euro 818 temperature regulator.

[0014] Technical parameters used for crystal growth: 1) Seed crystal orientation: a-axis; 2) Growth atmosphere and pressure: N 2 , 50KPa; 3) Pulling rate: 0.5~1.0m / h; 4) Rotation rate: 10~15rpm; 5) The inner cavity height of the rear heater: 160~200mm; 6) Annealing rate: 10~15K / h( >1200°c), 30~50K / h (<1200°C).

[0015] Use Grade shallow iridium crucible, and made of Al 2 O 3 Tube, Pt radiant tube, Pt baffle plate and other components of the after-heating chamber. By adjusting the relative position of the crucible and the induction coil and the heating wire power in the upper heat preservation cover, the gas-liquid temperature difference on both sides of the melt surface ca...

Embodiment 2

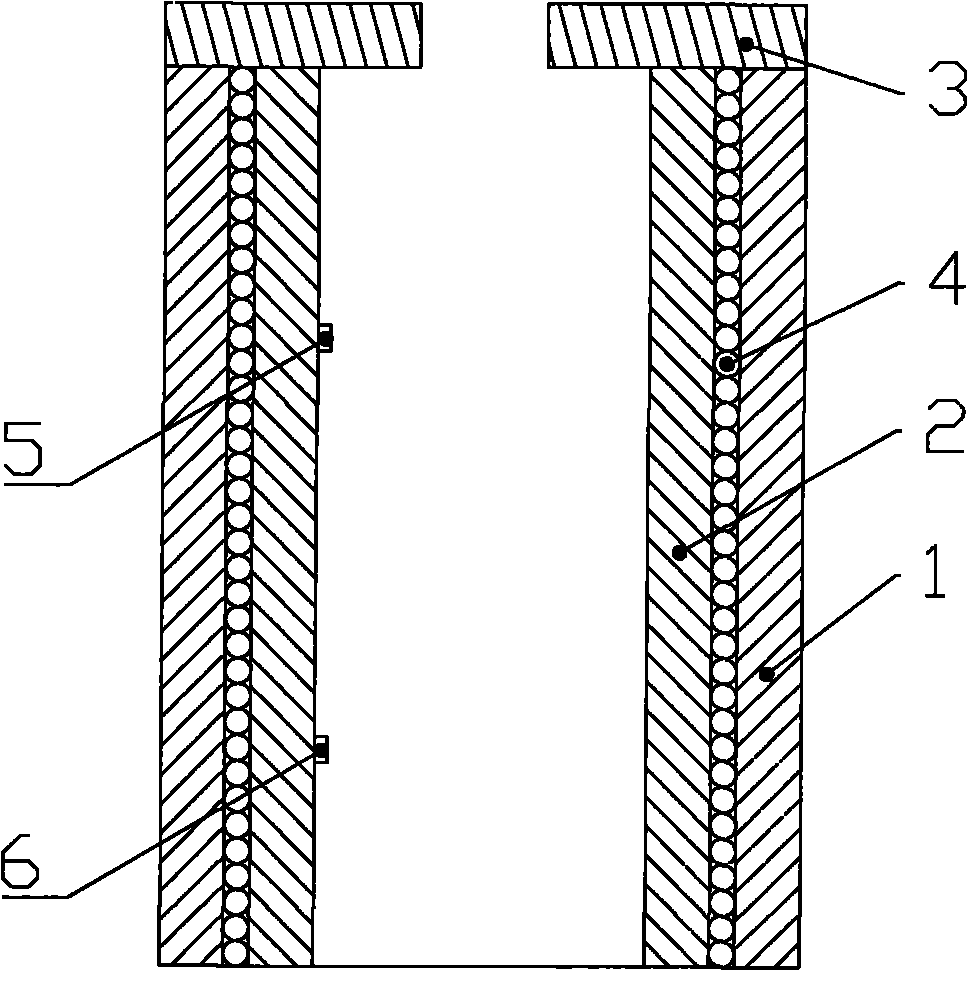

[0016] Example 2: Scintillation crystal growth of cerium-doped yttrium lutetium silicate

[0017] It adopts domestic DJL-600 type single crystal growth furnace, 50KW thyristor intermediate frequency induction power heating, double platinum rhodium (Pt / Rh30-Pt / Rh10) thermocouple, British Euro 818 temperature regulator.

[0018] Technical parameters used for crystal growth: 1) Seed crystal orientation: a-axis; 2) Growth atmosphere and pressure: N 2 , 50KPa; 3) Pulling rate: 0.5~1.0m / h; 4) Rotation rate: 10~15rpm; 5) The inner cavity height of the rear heater: 160~200mm; 6) Annealing rate: 10~15K / h( >1200°c), 30~50K / h (<1200°C).

[0019] Use Grade shallow iridium crucible, and made of Al 2 O 3 Tube, Pt radiant tube, Pt baffle plate and other components of the after-heating chamber. By adjusting the relative position of the crucible and the induction coil and the heating wire power in the upper heat preservation cover, the gas-liquid temperature difference on both sides of the melt sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com