Etching solution with satin-like silky effect and process for manufacturing mobile phone glass rear cabinet with etching solution

A technology of etching solution and satin, which is applied in the direction of telephone structure, branch equipment, electrical components, etc., can solve the problem of inability to achieve tactile effect, and achieve the effect of easy operation, obvious effect, simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

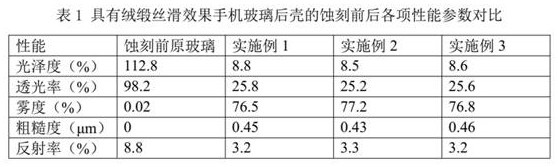

Embodiment 1

[0021] The etching solution with velvet silky effect is composed of the following raw materials in mass fraction: 10% NH 4 HF 2 , 5% KHF 2 , 6% HF, 16% H 3 PO 4 , 9% C 6 h 8 o 7 , 1% K 2 HPO 4 , 6% K 2 SO 4 , 0.8% ZnCl 2 , 0.2% sodium alkylbenzene sulfonate, 0.2% polyacrylamide, 7% polyvinyl alcohol, 3% glycerin, 36.8% H 2 O.

[0022] The manufacturing process of the mobile phone glass rear case of the etchant having the silky effect of velvet satin, comprising the following steps:

[0023] (1) Weigh the calculated amount of NH 4 HF 2 、KHF 2 , HF, H 3 PO 4 、C 6 h 8 o 7 、K 2 HPO 4 、K 2 SO 4 , ZnCl 2 , sodium alkylbenzene sulfonate, polyacrylamide, polyvinyl alcohol, glycerin, H 2 O, configure etching solution, stir evenly until the etching solution is in a uniform transparent solution state, let stand and mature for 36 hours, and place the etching solution in the etching solution pool.

[0024] (2) Cover and protect the non-etching side of the origina...

Embodiment 2

[0028] The etching solution with velvet silky effect is composed of the following raw materials in mass fraction: 8% NH 4 HF 2 , 6% KHF 2 , 7% HF, 16% H 3 PO 4 , 10% C 6 h 8 o 7 , 1.5% K 2 HPO 4 , 8% K 2 SO 4 , 1.5% ZnCl 2 , 0.2% sodium alkylbenzene sulfonate, 0.5% polyacrylamide, 8% polyvinyl alcohol, 5.5% glycerin, 27.8% H 2 O.

[0029] The manufacturing process of the mobile phone glass rear case of the etchant having the silky effect of velvet satin, comprising the following steps:

[0030] (1) Weigh the calculated amount of NH 4 HF 2 、KHF 2 , HF, H 3 PO4 、C 6 h 8 o 7 、K 2 HPO 4 、K 2 SO 4 , ZnCl 2 , sodium alkylbenzene sulfonate, polyacrylamide, polyvinyl alcohol, glycerin, H 2 O, configure etching solution, stir evenly until the etching solution is in a uniform transparent solution state, let stand and mature for 48 hours, and place the etching solution in the etching solution pool.

[0031] (2) Cover and protect the non-etching side of the origi...

Embodiment 3

[0035] The etching solution with velvet silky effect is composed of the following raw materials in mass fraction: 9% NH 4 HF 2 , 6% KHF 2 , 6.5% HF, 18% H 3 PO 4 , 9.5% C 6 h 8 o 7 , 1.2% K 2 HPO 4 , 7.5% K 2 SO 4 , 1.2% ZnCl 2 , 0.5% sodium alkylbenzene sulfonate, 0.3% polyacrylamide, 7.5% polyvinyl alcohol, 6% glycerin, 25.8% H 2 O.

[0036] The manufacturing process of the mobile phone glass rear case of the etchant having the silky effect of velvet satin, comprising the following steps:

[0037] (1) Weigh the calculated amount of NH 4 HF 2 、KHF 2 , HF, H 3 PO 4 、C 6 h 8 o 7 、K 2 HPO 4 、K 2 SO 4 , ZnCl 2 , sodium alkylbenzene sulfonate, polyacrylamide, polyvinyl alcohol, glycerin, H 2 O, configure etching solution, stir evenly until the etching solution is in a uniform transparent solution state, let stand and mature for 42 hours, and place the etching solution in the etching solution pool.

[0038] (2) Cover and protect the non-etching side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com