Method for directly preparing metallic iron and aluminum concentrate by using aluminum high-iron red mud as raw materials

A technology of high-speed iron red mud and metal iron, applied in the direction of improving process efficiency, etc., can solve problems such as land occupation, environmental pollution, hidden safety hazards, waste of resources, etc., and achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

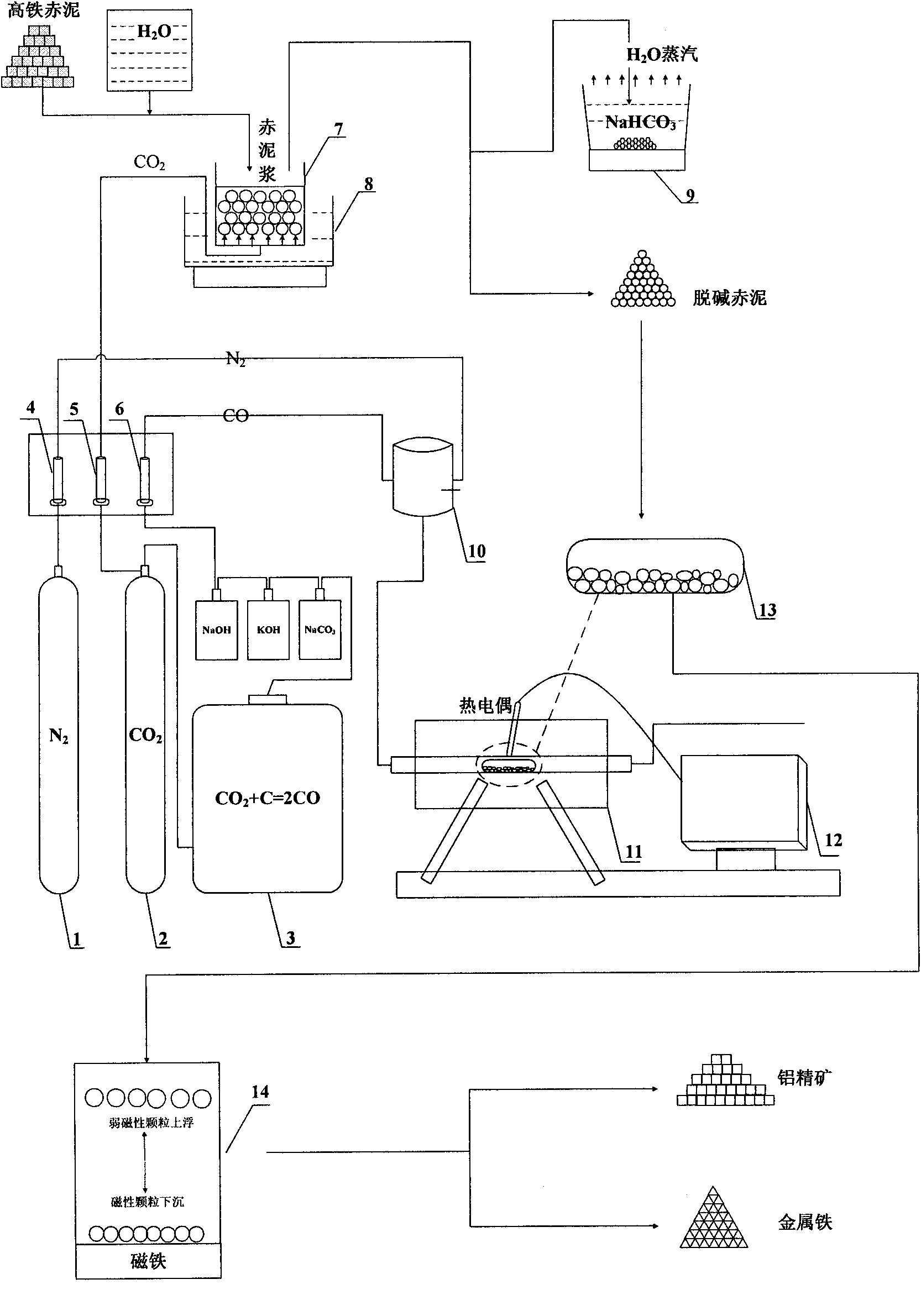

[0037] The content of implementation of the present invention is that wet red mud 100g (TFe=27.22%, Al 2 o 3 =27.26%, Na 2 O=8.18%) carry out recycling treatment according to the process of the present invention.

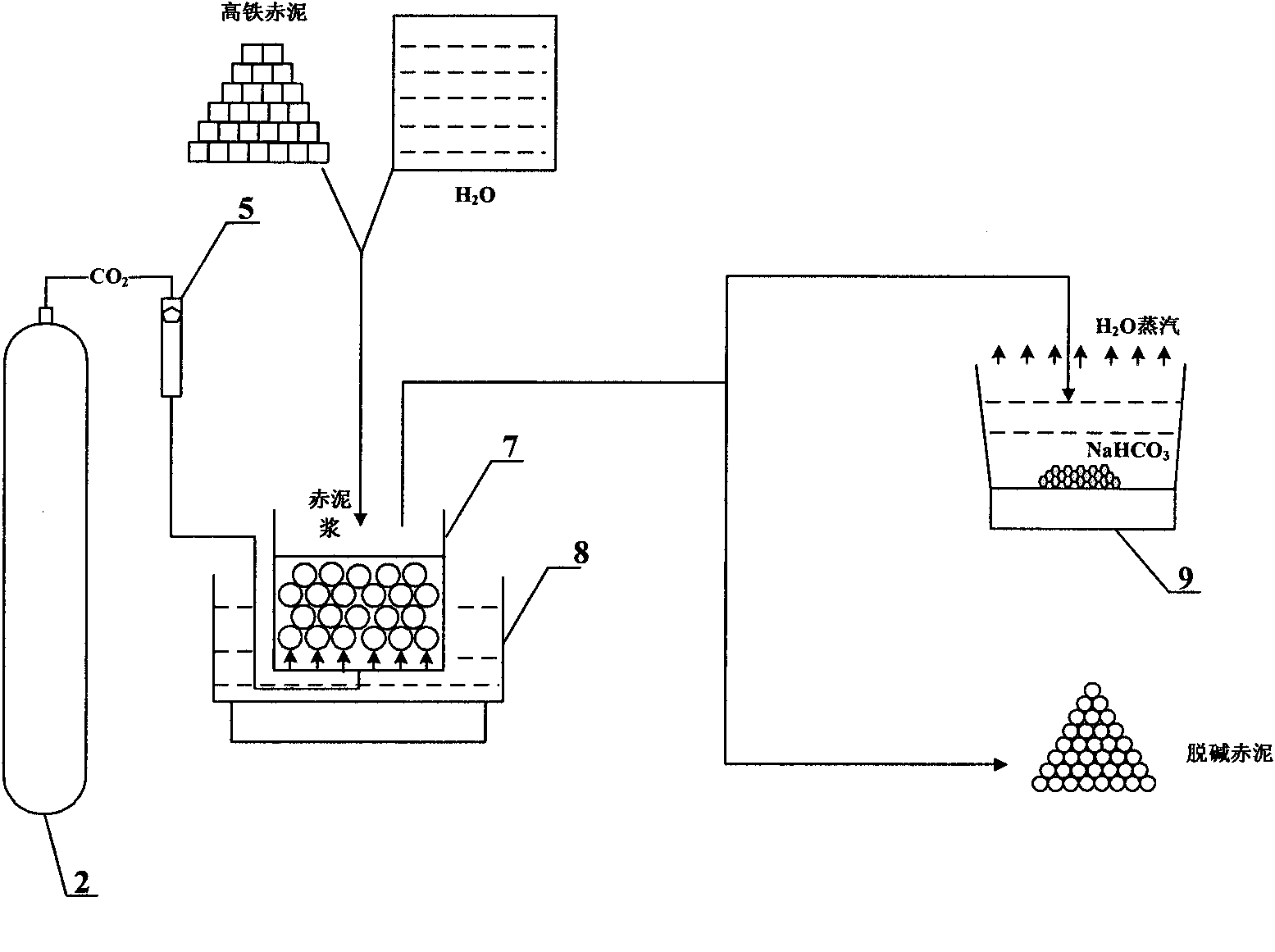

[0038] (1) Use of greenhouse gas CO 2 Dealkalization technology for dealkalization of high-iron wet red mud

[0039]Put 100g of high-iron wet red mud into 250ml of clean water and introduce CO 2 The gas is stirred into a suspension, and the solution changes from strongly alkaline (PH=11) to neutral (PH≈6~7), that is, most of the sodium in the red mud is converted into NaHCO 3 , and then the suspension is left to stand, the solid precipitates to the lower part of the container, and the precipitate is separated from the solution to obtain the solid precipitate dealkalized red mud and NaHCO 3 solution.

[0040] Parameter control of dealkalization process:

[0041] 1) dealkalization temperature: 50~70℃;

[0042] 2) dealkalization CO 2 Flow rate: 0.5~1L / min;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com