Method for refining high carbon molten steel by using low aluminum steel casting residue

A casting slag and low-aluminum steel technology, which is applied in the direction of improving process efficiency and recycling materials, etc., to achieve good slagging condition, fast slagging speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

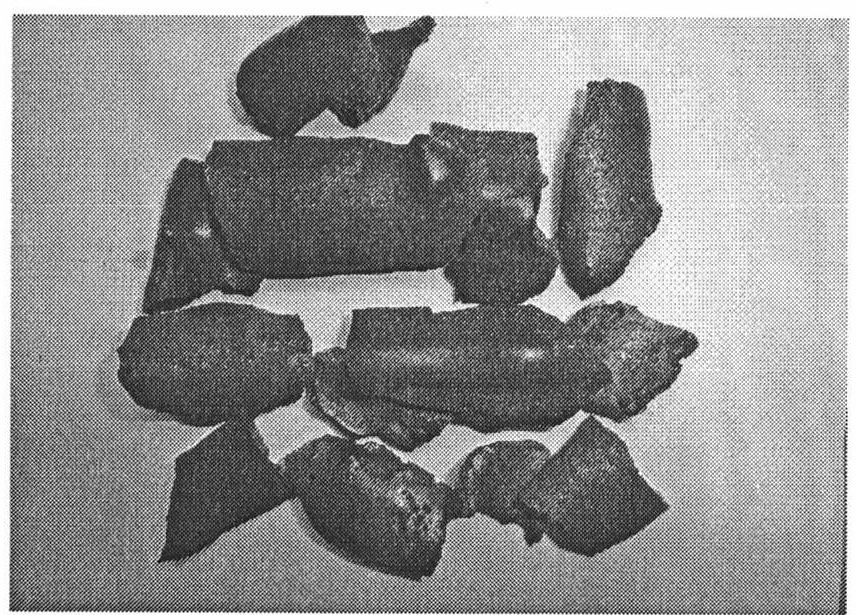

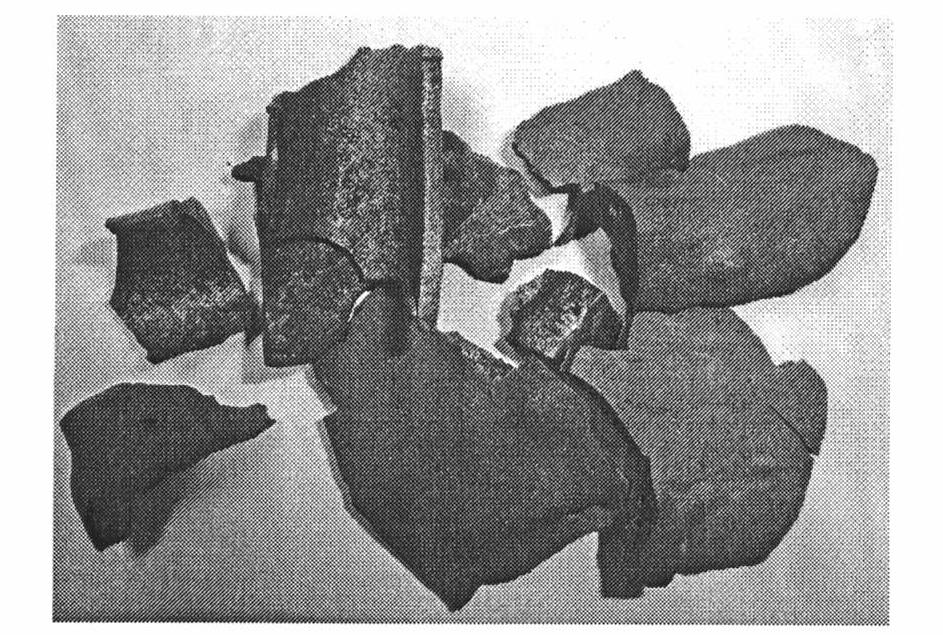

Image

Examples

Embodiment 1

[0026] A method for refining high-carbon molten steel with low-aluminum steel casting slag, the steps of which are as follows:

[0027] 1) Preparation of refining slag:

[0028] a) collecting Al≤0.0040% aluminum and steel casting slag with a basicity of 2.0, 2.5, 2.8, 3.2, 4.5;

[0029] b) Crushing the collected Al≤0.0040% aluminum and steel casting slag, with a particle size of ≤5 mm;

[0030] c) Grinding: adding hydrated lime while grinding, the alkalinity of the mixture after adding hydrated lime is 4.5, and the particle size of the grinding is ≤2 mm;

[0031] d) Add water glass water inorganic binder, its addition is Al≤0.0040% 2% of the total amount of aluminum steel casting residue and slaked lime, and stir evenly;

[0032] e) making balls, the diameter of which can be controlled within the range of 5 to 25 millimeters to any size;

[0033] f) Baking, the baking temperature is 80-85°C, the baking time is 175-180 minutes, and the refining slag is ready for use;

[003...

Embodiment 2

[0037] A method for refining high-carbon molten steel with low-aluminum steel casting slag, the steps of which are as follows:

[0038] 1) Preparation of refining slag:

[0039] a) collecting Al≤0.0040% aluminum and steel casting slag with basicity of 2.0, 2.8, 3.2, 3.6, 4.3;

[0040] b) Crushing the collected Al≤0.0040% aluminum and steel casting slag, with a particle size of ≤5 mm;

[0041] c) Grinding: adding slaked lime while grinding, the alkalinity of the mixture after adding slaked lime is 4.8, and the particle size of the grinding is ≤2mm;

[0042] d) adding sodium chloride / magnesium chloride / calcium chloride inorganic binder, the amount of which is 2.5% of the total amount of Al≤0.0040% aluminum steel casting residue and slaked lime, and stirring evenly;

[0043] e) making balls, the diameter of which can be controlled within the range of 5 to 25 millimeters to any size;

[0044] f) Baking, the baking temperature is 95-100°C, the baking time is 150-165 minutes, and...

Embodiment 3

[0048] A method for refining high-carbon molten steel with low-aluminum steel casting slag, the steps of which are as follows:

[0049] 1) Preparation of refining slag:

[0050] a) collecting Al≤0.0040% aluminum and steel casting slag with basicity of 2.2, 2.5, 3.0, 3.8, 4.3;

[0051] b) Crushing the collected aluminum-free steel casting slag, the particle size of which is ≤5 mm;

[0052] c) Grinding: adding slaked lime while grinding, the alkalinity of the mixture after adding slaked lime is 5.0, and the particle size of the grinding is ≤2mm;

[0053] d) adding coal tar organic binder, the amount of which is 3.0% of the total amount of Al≤0.0040% aluminum steel casting residue and slaked lime, and stirring evenly;

[0054] e) making balls, the diameter of which can be controlled within the range of 5 to 25 millimeters to any size;

[0055] f) Baking, the baking temperature is 105-110°C, the baking time is 100-105 minutes, and the refining slag is ready for use;

[0056] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com