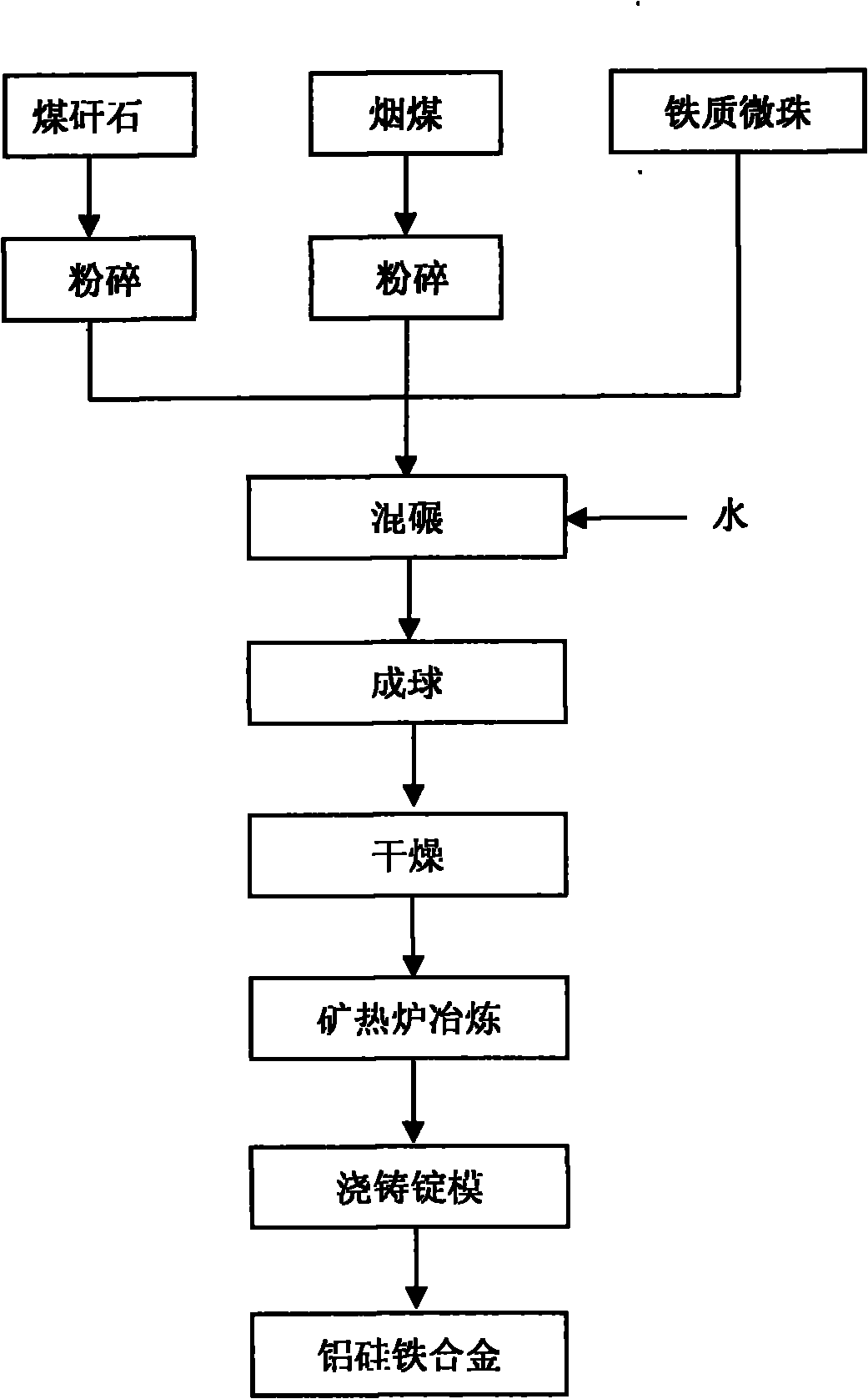

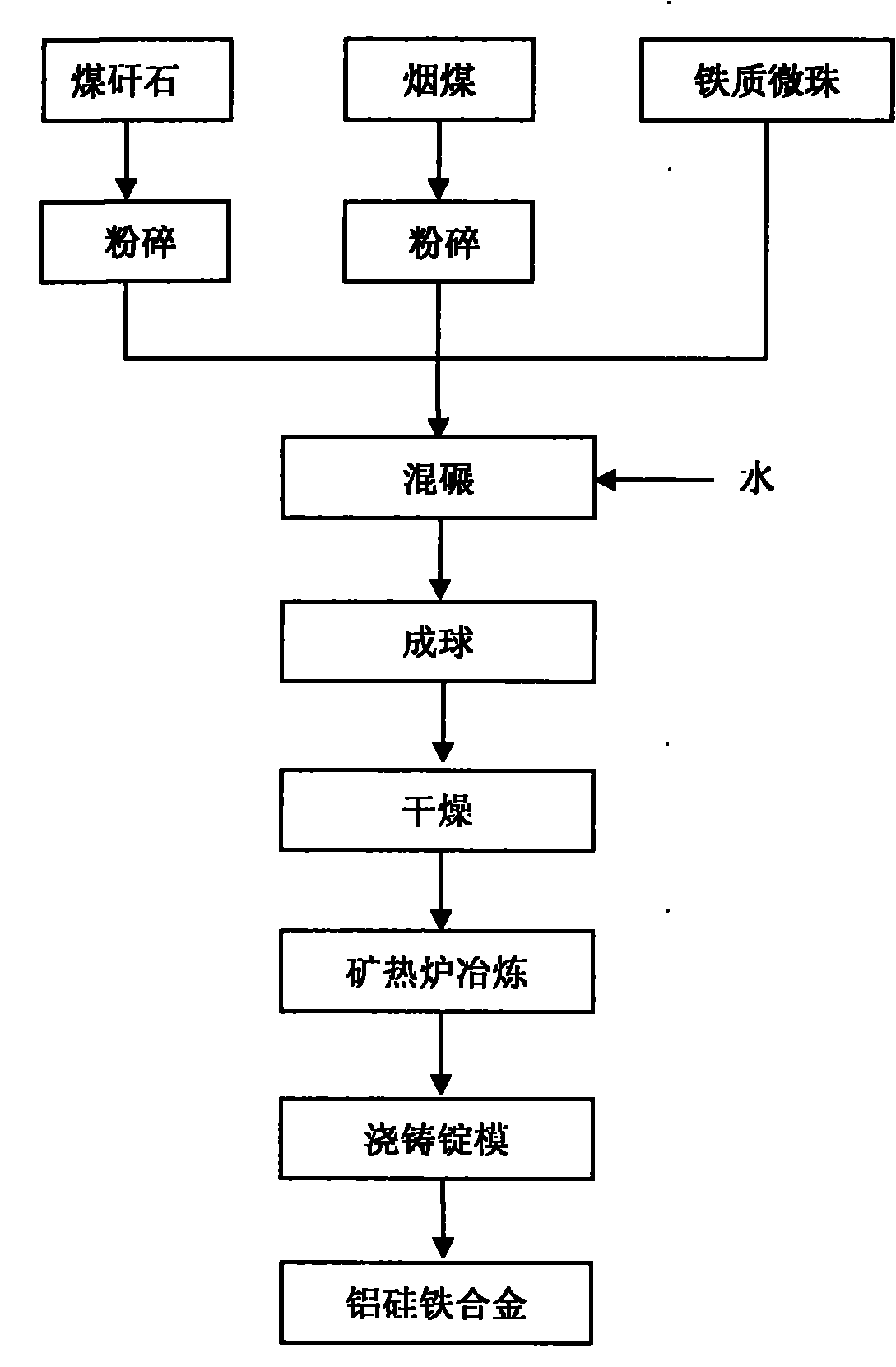

Method for preparing aluminum-silicon-ferrum alloy from coal gangue

A technology of coal gangue and ferroalloy, which is applied in the field of preparing aluminum-silicon-ferroalloy by using coal gangue, can solve the problems of large amount of natural bauxite, uneven feeding materials, slow reaction speed, etc., and achieves short sintering time, fast reduction, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Proceed as follows:

[0031] ① Raw material selection of coal gangue content Al 2 o 3 42.93%, SiO 2 51.92%, Fe 2 o 3 The reducing agent is selected from bituminous coal with low ash content, high fixed carbon content and good caking property. The coal gangue and bituminous coal are crushed, the crushed particle size of coal gangue is below 0.2mm, and the crushed bituminous coal particle size is below 2mm.

[0032] ②Select the content of Al in fly ash iron microbeads 2 o 3 15.4%, SiO 2 25.5%, Fe 2 o 3 It is 55.1%, and it is sent into the mixing mill together with the above-mentioned pulverized materials, and an appropriate amount of water is added for mixing and rolling.

[0033] ③ After uniform mixing and grinding, the material is sent to the ball press machine to form balls, and the ball forming pressure is 8Mpa.

[0034] ④The pellets coming out of the briquetting machine enter the drying kiln for drying at 160°C for 1 hour.

[0035] ⑤ The dried pellets are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com