Nano fluorine-aluminum high energy release fuel and preparation method thereof

A technology of nano-aluminum and fluorine-aluminum, which is applied in the field of high-energy-release fuel and its preparation, and can solve problems such as the thickness of the fluorine-containing shell and the impact on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

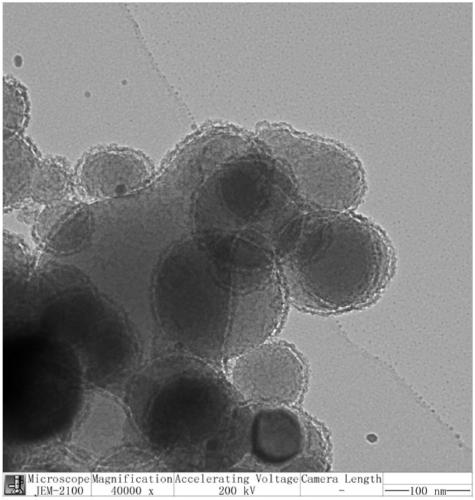

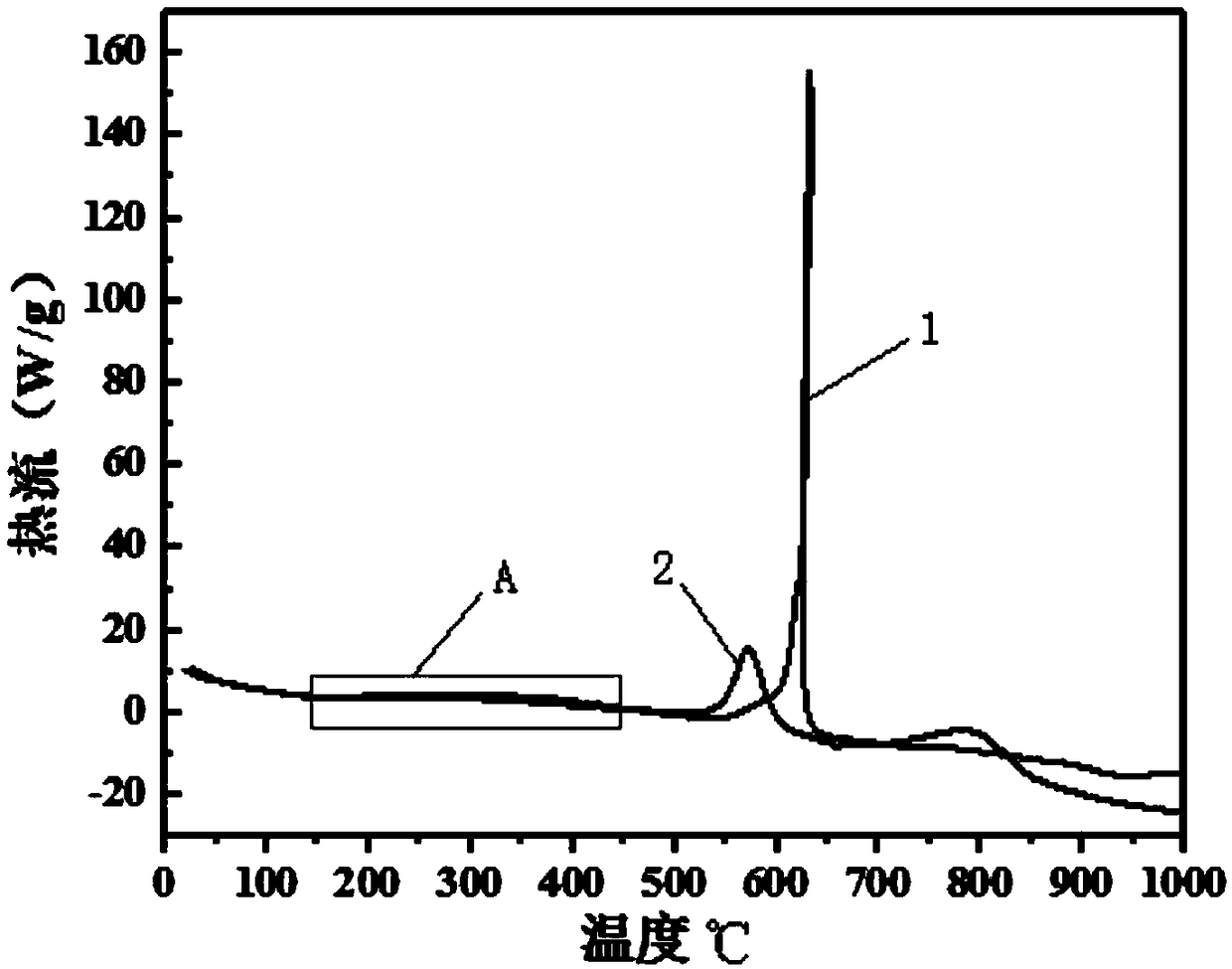

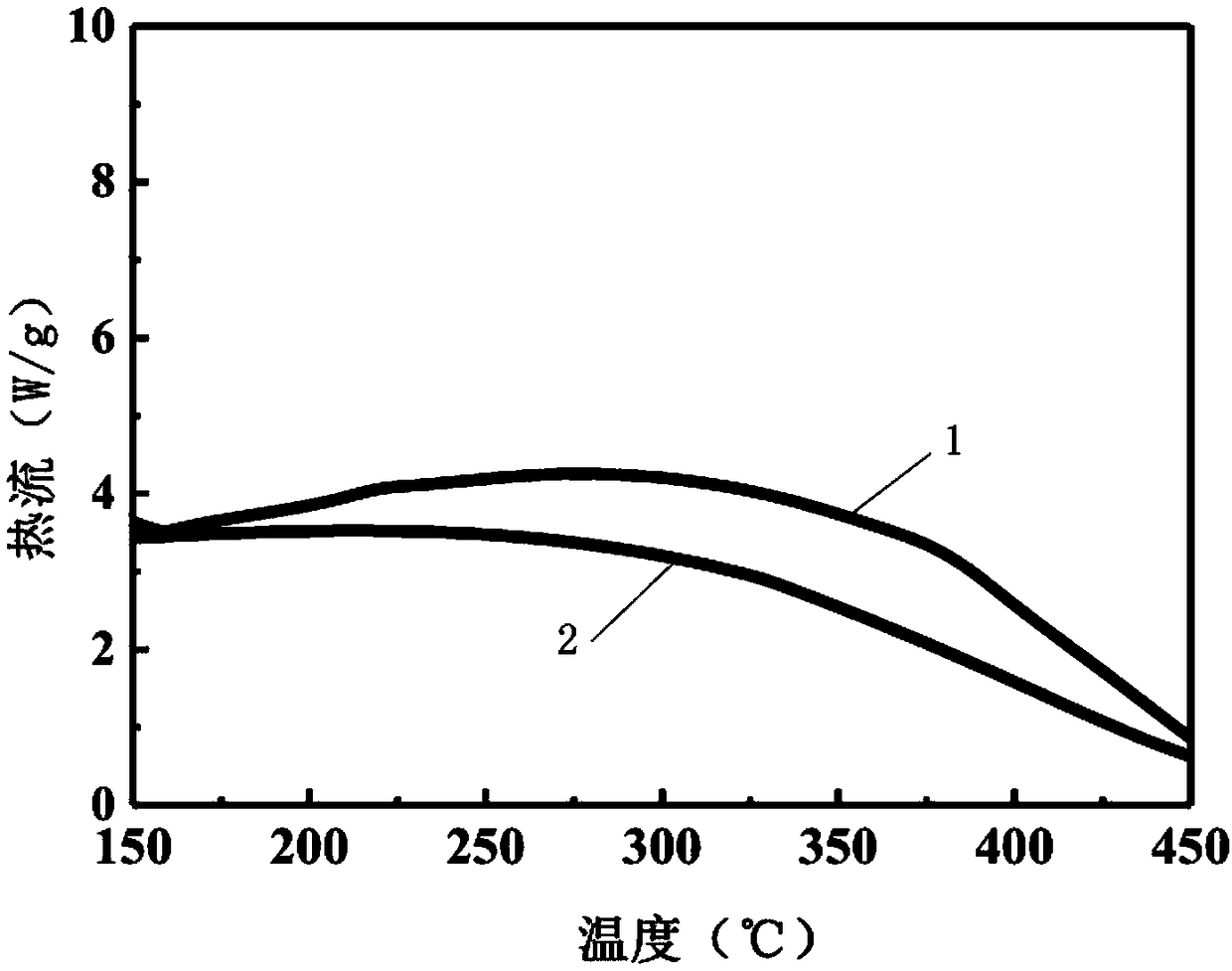

[0037] Embodiment 1: The nano-aluminum fluoride high-energy-release fuel of this embodiment is composed of a nano-aluminum core and a shell layer from which the oxide film has been removed; the nano-aluminum core is treated with HF solution to obtain a nano-aluminum core from which the oxide film has been removed, and simultaneously generates Al 2 f 1.5 (OH) 1.5 0.375H 2 O aluminum source, then Al 2 f 1.5 (OH) 1.5 0.375H 2 The aluminum perfluorocarboxylate cross-linked network formed by the reaction of O aluminum source and perfluorocarboxylic acid acts as the shell layer.

[0038] The beneficial effects of this specific embodiment are: 1. This specific embodiment is a perfluorocarboxylate aluminum cross-linked network to establish a polymer-like coating layer and an active aluminum core to directly contact to form a nano-fluorine-aluminum composite structure. The specific reaction mechanism As follows: (1) HF solution etches the oxide layer on the surface of aluminum po...

specific Embodiment approach 2

[0041] Specific embodiment two: the preparation method of a kind of nano-aluminum fluoride high energy release fuel of the present embodiment is to carry out according to the following steps:

[0042] 1. Mix the HF solution with a mass percentage of 1% to 10% and the solvent to obtain a mixed solution;

[0043] The volume ratio of the 1%-10% HF solution to the solvent in the mass percentage is 1:(0.5-2);

[0044] 2. Add nano-aluminum powder to the mixed solution, and stir at room temperature for 3 minutes to 10 minutes to obtain a mixed solution containing aluminum powder;

[0045] The mass percentage described in step 1 is that the volume of the HF solution of 1%~10% and the mass ratio of nano-aluminum powder described in step 2 are 10mL:(1~3)g;

[0046] 3. Add a perfluorocarboxylic acid solution with a concentration of 5g / L to 20g / L to the mixed solution containing aluminum powder, and stir at room temperature for 2h to 8h to obtain a crude product;

[0047] The solvent in...

specific Embodiment approach 3

[0050] Embodiment 3: This embodiment is different from Embodiment 2 in that: the solvent described in step 1 is N,N-dimethylformamide, dimethylacetamide or dimethyl sulfoxide. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com