High temperature thermistor and manufacturing method thereof

A kind of thermistor and heating technology, applied in the field of high temperature thermistor and its manufacturing, can solve the problems of unsatisfactory safety, etc., and achieve the effect of improving the withstand voltage capability, fine and uniform grain size, and dense ceramic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

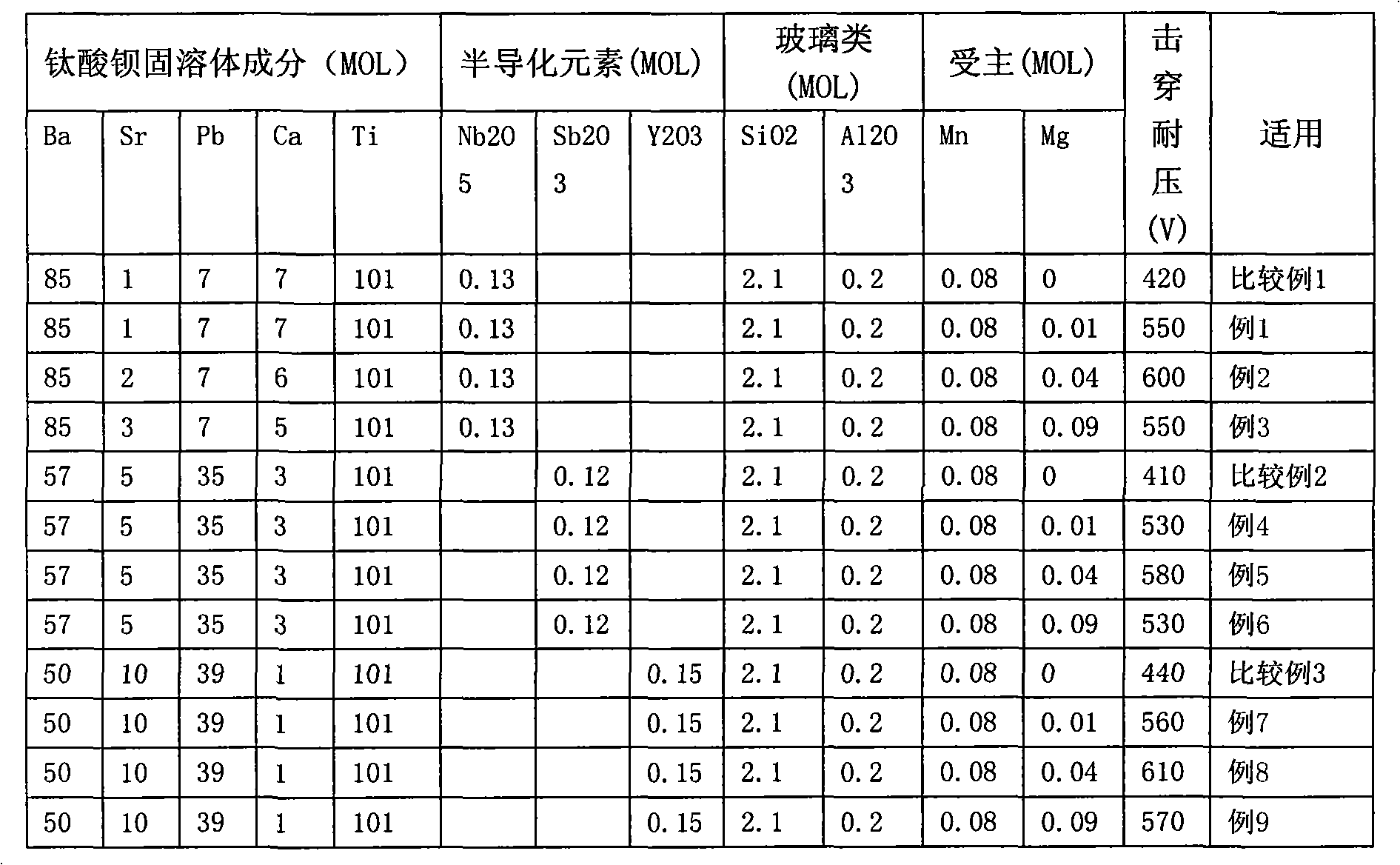

[0012] Example 1, take 85mol barium titanate, 7mol lead titanate, 7mol calcium titanate, 1mol strontium titanate, 0.13mol niobium oxide, 2.1mol silicon oxide, 1mol titanium oxide, 0.2mol aluminum oxide, 0.08mol manganese dioxide and 0.01 mol magnesium oxide is mixed with water in a ball mill, and the material is dried, lightly burned at 1050°C for 2 hours, and then crushed in a ball mill, added with a PVA binder solution with a powder weight ratio of 8%, granulated, and pressed Chip machine molding, and sintering at 1290 ° C for 30 minutes to become semiconducting ceramics, after grinding, spraying Al electrodes, to get 32 × 12 × 2.4mm thermistor chip products.

[0013] Example 2, take 85mol barium titanate, 7%mol lead titanate, 6mol calcium titanate, 2mol strontium titanate, 0.13%mol niobium oxide, 2.1%mol silicon oxide, 1%mol titanium oxide, 0.2%mol aluminum oxide, 0.08% mol of manganese dioxide and 0.04% mol of magnesium oxide are mixed with water in a ball mill, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com