Modified red mud, modification method thereof and catalyst applicable to direct coal liquefaction

A modifier and catalyst technology, applied in the field of comprehensive treatment of red mud, can solve problems such as unsatisfactory utilization effect of red mud, and achieve the effect of cheap and efficient catalyst, solving utilization problems and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

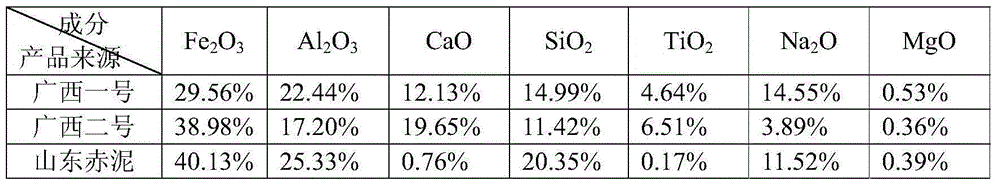

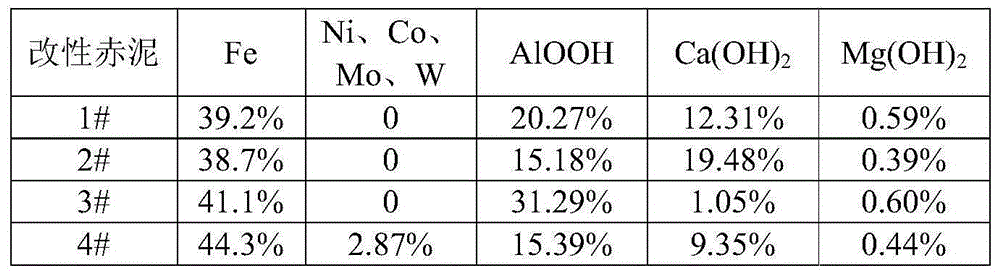

[0051] Take 100g of Guangxi No. 1 red mud, add 400g of deionized water, stir evenly, slowly add sulfuric acid solution with a mass concentration of 50%, until the pH value of the slurry is less than 0.5 and does not rise anymore, transfer the slurry to a centrifuge for centrifugation Filter to collect the acidic filtrate.

[0052] To this acidic filtrate was added 78.5 g FeSO 4 ·7H 2 O, after stirring and dissolving, slowly add 2wt% ammonia solution dropwise, and feed air at the same time until the pH value of the solution remains constant at 8.0, filter the slurry, and wash the filter cake until the conductivity of the filtrate is less than 1000 μm / cm. Place in a 120-degree drying oven to dry for 12 hours, grind to less than 50um, and prepare 1# modified red mud catalyst.

Embodiment 2

[0054] The implementation method is similar to Example 1, the difference is that the Guangxi No. 2 red mud is used, and 45.8g FeSO is added in the acidic filtrate 4 ·7H 2 O, the modified red mud catalyst number is 2#.

Embodiment 3

[0056] The implementation method is similar to Example 1, the difference is that Shandong red mud is used, and 23.6g FeSO is added in the acidic filtrate 4 ·7H 2 O, the number of the modified red mud catalyst is 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com