Aluminum alloy and alloy sheet thereof as well as preparation method of alloy sheet

A technology of aluminum alloy sheet and alloy sheet, which is applied in the field of high-strength corrosion-resistant Al-Mg alloy and sheet products to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

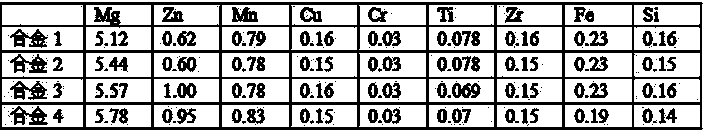

Examples

Embodiment 1

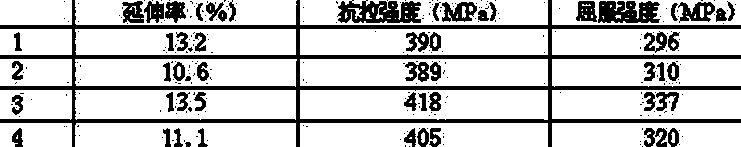

[0026] The above four alloys were heated from room temperature to 440°C at a heating rate of 30°C / hour, kept for 5 hours, continued to be heated to 510°C, kept for 10 hours, and then cooled to room temperature with the furnace. The alloy is heated to 500°C for 2 hours and then rolled. The total deformation of hot rolling is 90%. The hot-rolled alloy is held at 375°C for 75 minutes for recrystallization annealing, followed by cold deformation with a deformation of 15%, and then 2% pre-stretching to obtain the alloy in the H321 state (cold work hardening state), measured The mechanical properties of the alloy are shown in Table 2.

[0027] Table 2 Mechanical properties of the measured alloys in the rolling direction (L-direction)

[0028]

[0029] Compared with existing reference alloys, the alloy prepared according to the invention has more excellent strength in the work-hardened state.

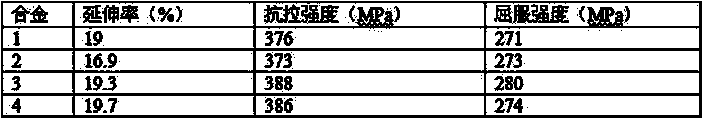

Embodiment 2

[0031] The above four alloys were heated from room temperature to 500°C for 13 hours, and then cooled to room temperature with the furnace. The alloy is heated to 480°C for 2 hours to carry out hot rolling with a total deformation of 95%. The hot-rolled alloy was held at 350°C for 90 minutes for recrystallization annealing, and then cold-rolled with a deformation of 10%. Stabilization annealing and 2% pre-stretching were carried out at 250°C for 1 hour to obtain a H131 state alloy sheet (stabilized state). The prepared plates were kept at 100°C for 7 days for sensitization experiments. The mass loss of the alloy after stabilization and sensitization was measured according to the ASTM G67 standard, and the exfoliation corrosion resistance of the alloy was measured according to the ASTM G66 standard. The measured mechanical properties and corrosion resistance of the alloy are shown in Table 3 and Table 4.

[0032] Table 3 Mechanical properties of alloy rolling direction (L-d...

Embodiment 3

[0039] After melting and casting No. 3 alloy, the alloy was heated from room temperature to 440°C at a heating rate of 30°C / hour, kept for 6 hours, continued to be heated to 510°C, kept for 13 hours, and then cooled to room temperature with the furnace. The starting temperature of the alloy is 520°C, and the total deformation is 92%. The hot-rolled alloy was recrystallized and annealed at 400°C for 60 minutes, and cold-rolled at room temperature with a deformation of 5%. Stabilization annealing and 2% pre-stretching are carried out at 180-275°C for 1 hour. The H131 state (stabilization treatment state) alloy plate was kept at 100°C for 7 days for sensitization experiment. The intergranular corrosion performance of the alloy after stabilization and sensitization at different temperatures was determined according to the ASTM G67 standard, and the exfoliation corrosion resistance of the alloy was measured according to the ASTM G66 standard. The corrosion properties of the measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com