Method for preparing LPSO (Long Period stacking ordered) phase enhanced magnesium alloy gradient material

A gradient material and magnesium alloy technology, applied in the field of intermetallic compound preparation, achieves the effects of simple operation, stable quality, improved service life and service environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

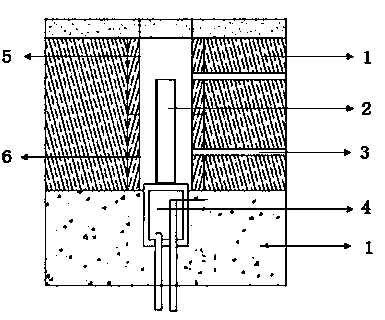

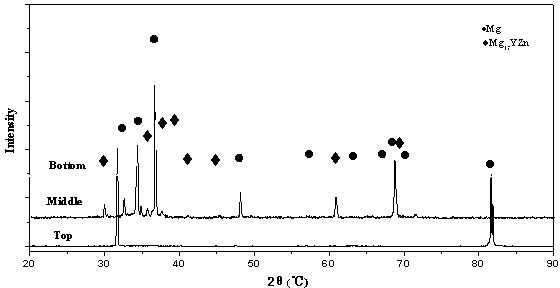

[0023] The method for preparing the LPSO phase-reinforced magnesium alloy gradient material, its specific steps are as follows:

[0024] (1) First, pure magnesium and pure yttrium are mixed and processed to prepare Mg-Y alloy blocks, and then pure magnesium blocks, pure zinc blocks, and Mg-Y alloy blocks are stacked in order from bottom to top, among which Mg, Y, Zn The atomic number ratio is 57:1.5:1, and the purity of pure magnesium, pure yttrium, and pure zinc is over 99.98%;

[0025] (2) Divide the superimposed metal block prepared in step (1) into two parts, the upper part and the lower part, and heat the two parts at the same time to 350 ° C for 30 minutes to remove water vapor, then pass in protective gas and heat up at a rate of 10 ° C / min The melting rate was increased to 720°C for 1 hour, and the protective gas was Ar gas;

[0026] (3) After completing step (2) smelting process, stop the heating of the lower part and pass cooling water to cool the lower part, adju...

Embodiment 2

[0029] The method for preparing the LPSO phase-reinforced magnesium alloy gradient material, its specific steps are as follows:

[0030] (1) First, pure magnesium and pure yttrium are mixed and processed to prepare Mg-Y alloy blocks, and then pure magnesium blocks, pure zinc blocks, and Mg-Y alloy blocks are stacked in order from bottom to top, among which Mg, Y, Zn The atomic number ratio is 79:3:2, and the purity of pure magnesium, pure yttrium, and pure zinc is over 99.98%;

[0031] (2) Divide the superimposed metal block prepared in step (1) into two parts, the upper part and the lower part, and heat the two parts at the same time to 400 °C, keep it warm, remove water vapor for 10 minutes, and then pass in protective gas and heat up at 10 °C / min Melting at 780°C for 1 hour, the protective gas is SF 6 and CO 2 mixed gas;

[0032] (3) After completing the smelting process of step (2), stop the heating of the lower part and pass in cooling water to cool the lower part, and...

Embodiment 3

[0034] The method for preparing the LPSO phase-reinforced magnesium alloy gradient material, its specific steps are as follows:

[0035] (1) First, pure magnesium and pure yttrium are mixed and processed to prepare Mg-Y alloy blocks, and then pure magnesium blocks, pure zinc blocks, and Mg-Y alloy blocks are stacked in order from bottom to top, among which Mg, Y, Zn The atomic number ratio is 21:1.3:1, and the purity of pure magnesium, pure yttrium, and pure zinc is over 99.98%;

[0036] (2) Divide the superimposed metal block prepared in step (1) into two parts, the upper part and the lower part, and heat the two parts at the same time to 300 °C and keep it warm for 50 minutes to remove water vapor, then pass in protective gas and heat up at a rate of 5 °C / min Melting at 700°C for 3 hours, in which the protective gas is Ar gas;

[0037] (3) After completing the melting process of step (2), stop the heating of the lower part and pass in cooling water to cool the lower part, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com