Patents

Literature

43results about How to "Improve hydrogen absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of ultra fine manganese dioxide

InactiveCN1513767AImprove hydrogen absorption performanceSmall particlesManganese oxides/hydroxidesHydrogenManganese

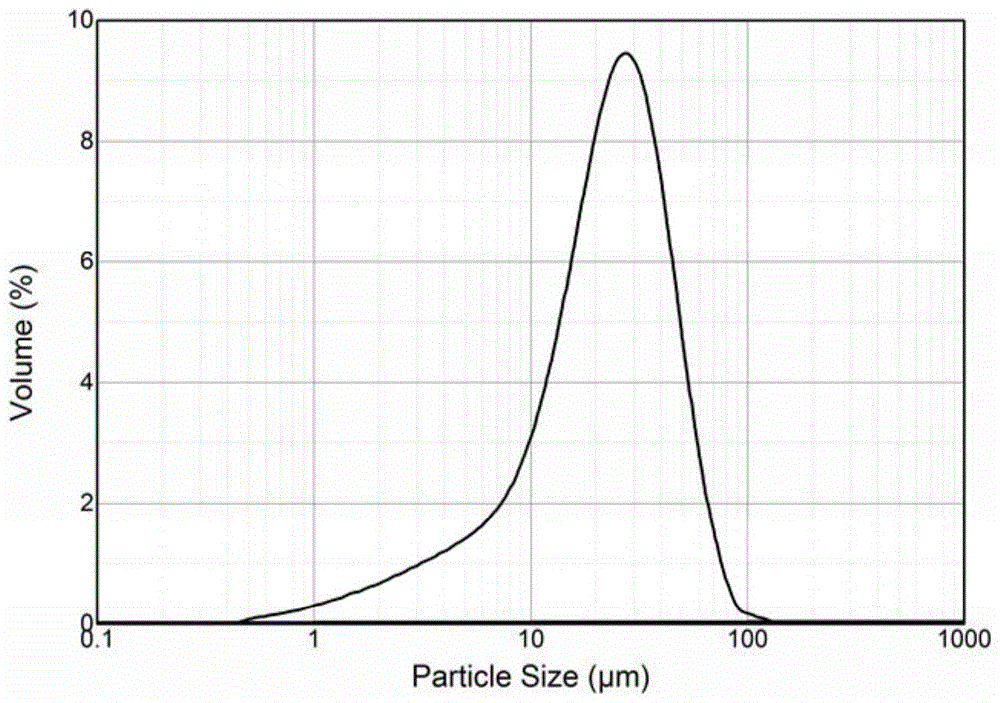

A process for preparing superfine MnO2 includes adding surfactant to soluble Mn salt to form microemulsion, adding alkali to generate manganese hydroxide, oxidizing, dewatering, and calcining. Its advantages are small diameter (50 nm), high specific surface area (100 sq.m / g) and high hydrogen absorbing effect in ZnMn battery.

Owner:章浩龙

Catalytic agent for preparing p-aminophenol by using nitrobenzene catalytic hydrogenation and preparation method thereof

InactiveCN102658125AHigh activityHigh selectivityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonP-Aminophenol

The invention relates to a novel catalytic agent for preparing p-aminophenol by using nitrobenzene catalytic hydrogenation and a preparation method thereof. The catalytic agent enables active carbon to serve as a carrier, enables Pt to serve as a main catalytic agent and enables MoS2 to serve as an auxiliary catalytic agent. The preparation step of the catalytic agent comprises (1) preparing Pt / C catalytic agent, namely enabling the Pt to be loaded on the activated carbon through an infusion process; and (2) restoring the auxiliary catalytic agent MoS2 through steeping and roasting under certain H2, loading on the Pt / C, and finally obtaining the catalytic agent for preparing the p-aminophenol. The catalytic agent for synthesizing the p-aminophenol is high in productivity and high in selectivity, and the catalytic agent is good in stability. After 23 times of circulation, the catalytic agent keeps good activity, yield coefficient of the p-aminophenol is above 83%, and the catalytic agent has good industrial application prospect.

Owner:ANHUI UNIV OF SCI & TECH

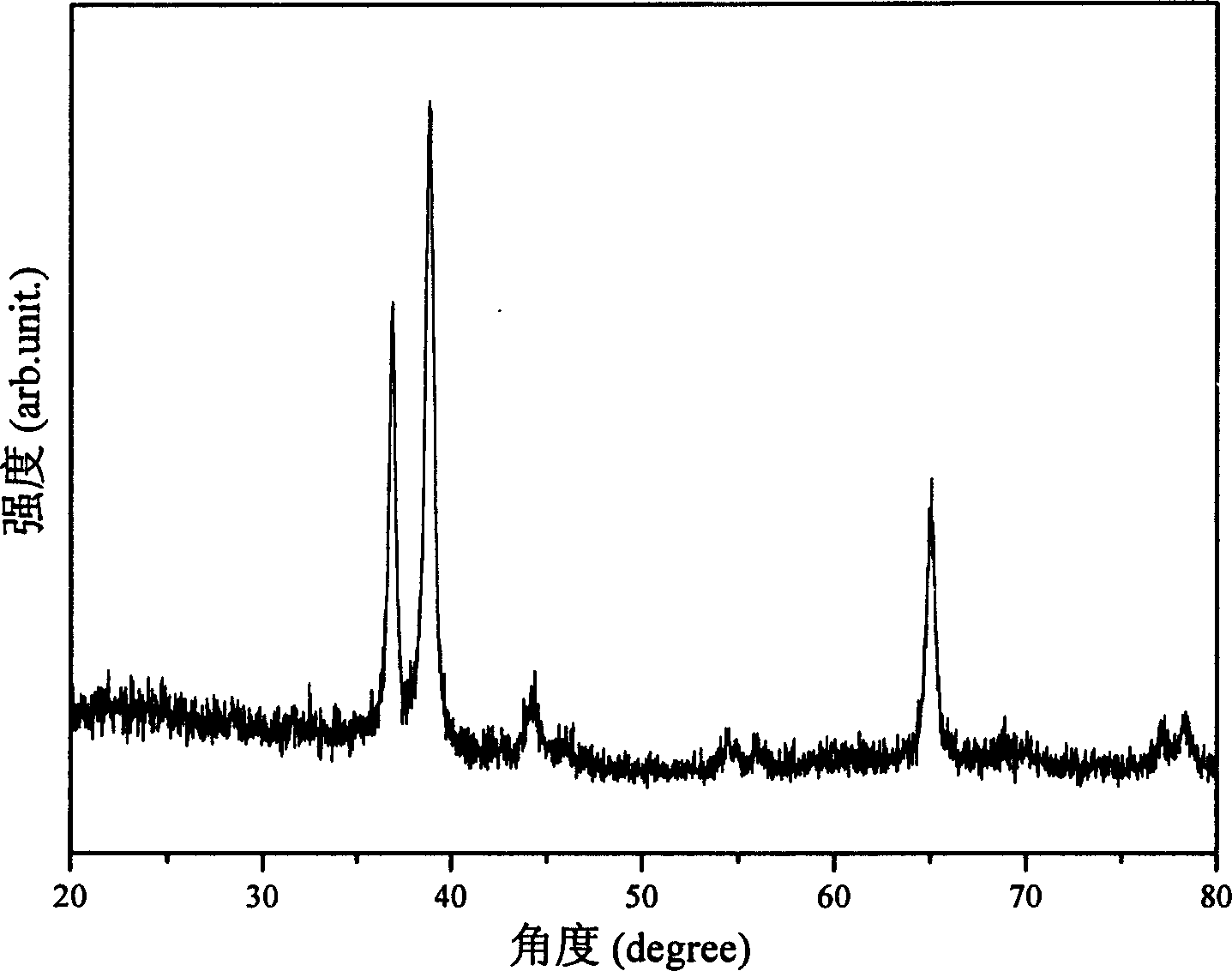

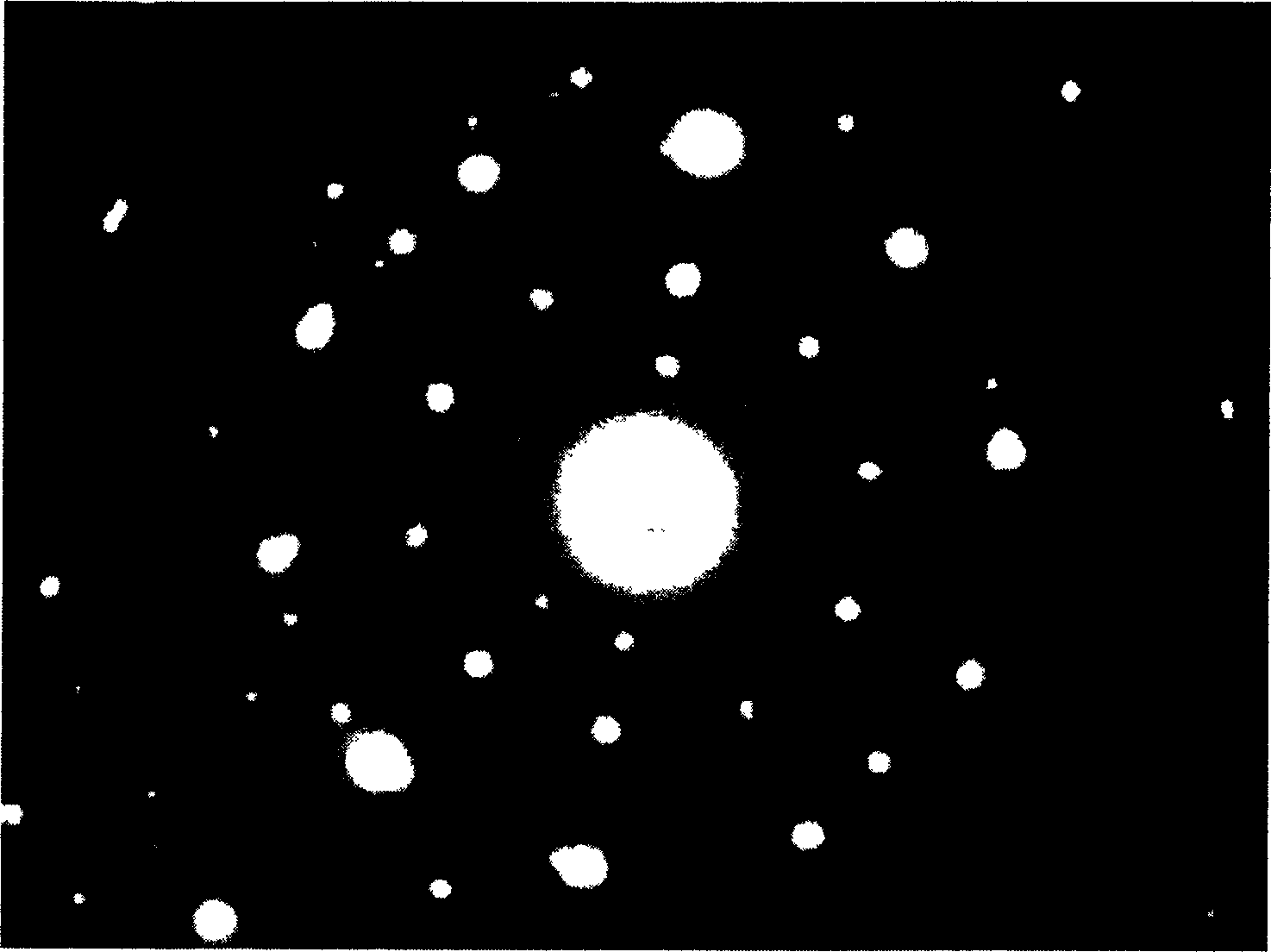

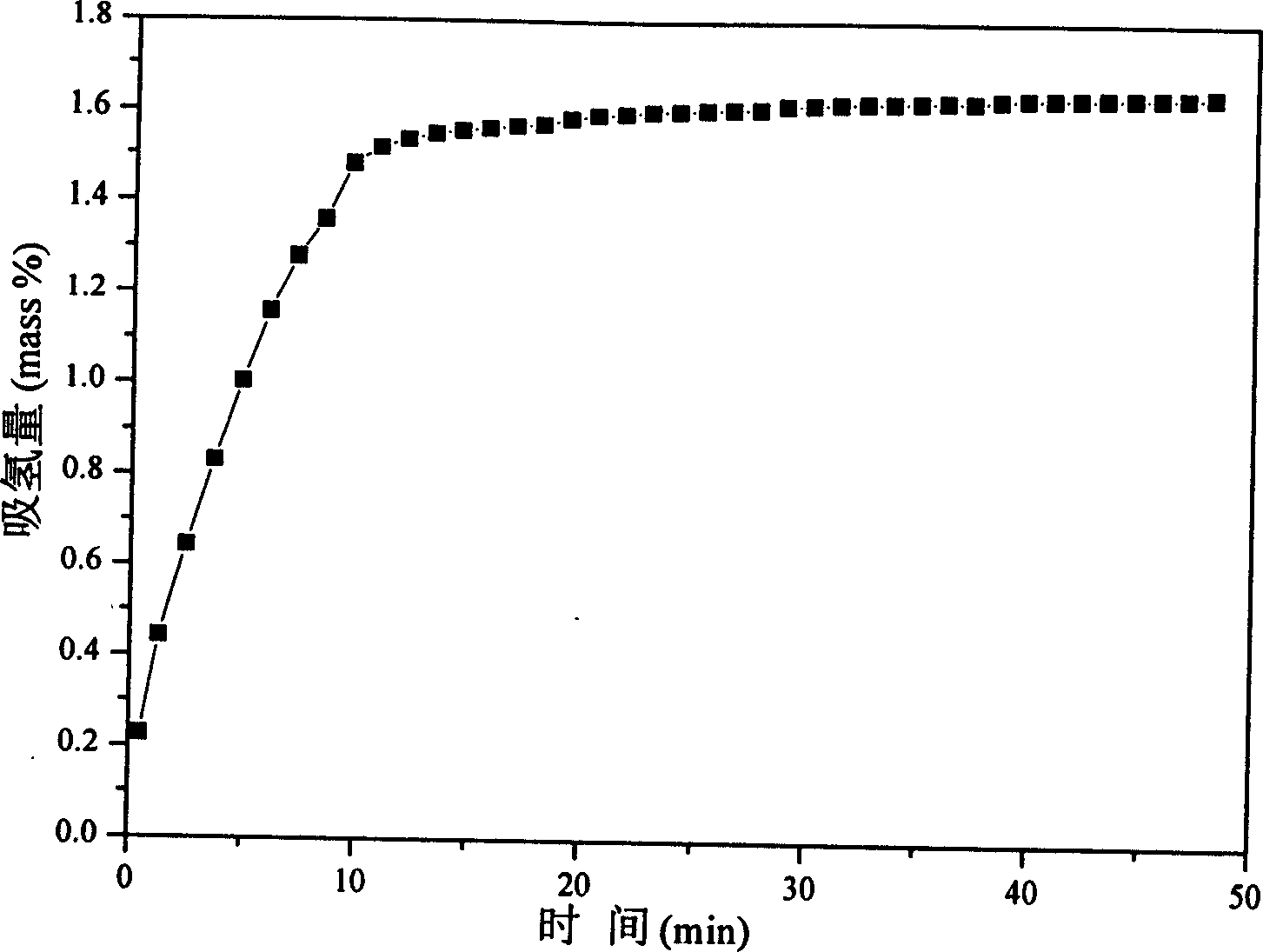

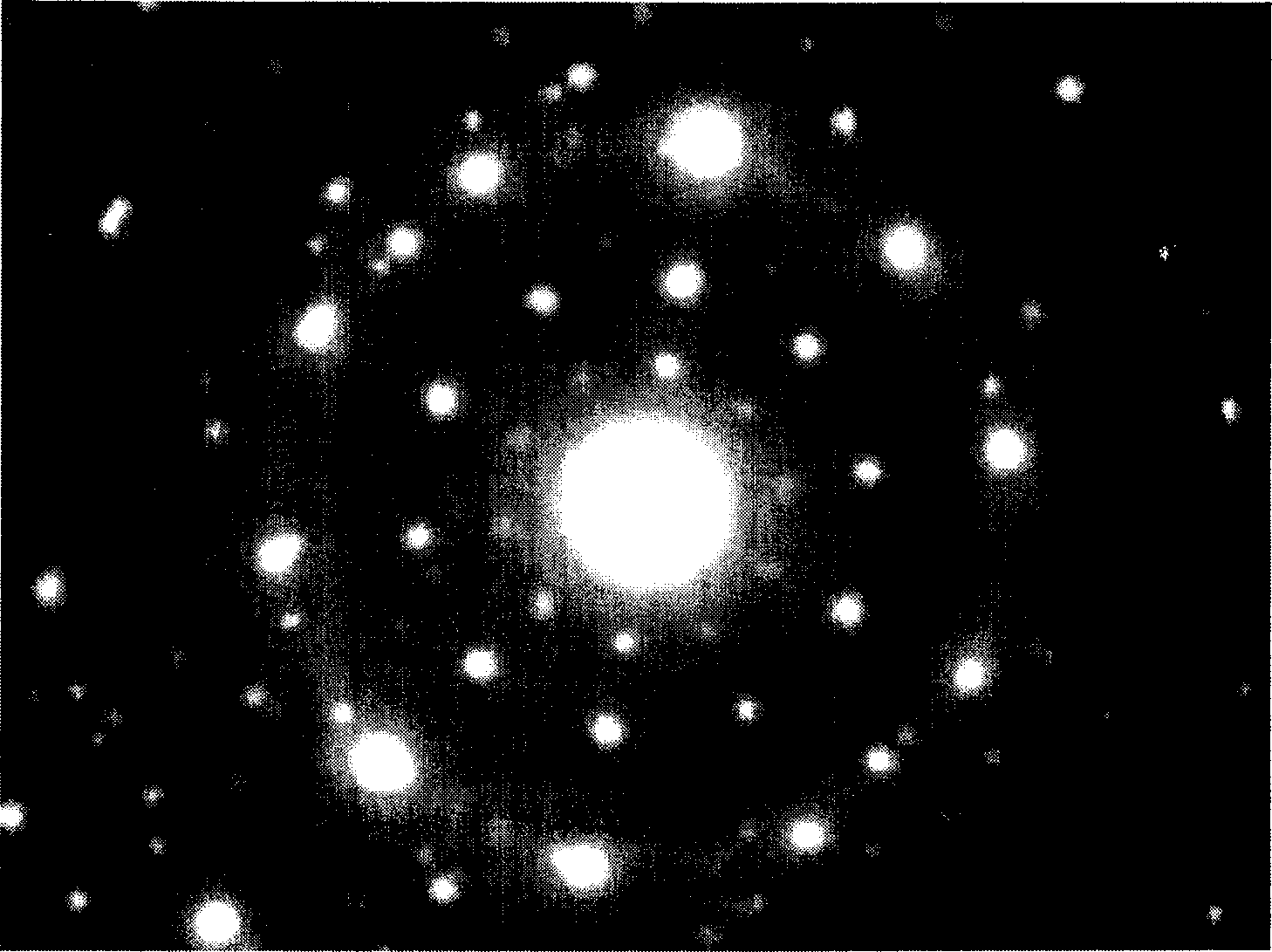

Regular icosahedron titanium-base quasi-crystal material with hydrogen-storage function and its preparing method

InactiveCN1709564AStrong ability to form quasicrystalsEasy to operateOther chemical processesHigh energyTitanium

The invention provides a kind of single icosahedron quasicrystal material with hydrogen storing function. Its component is Ti100-x-y-zZrxNiyCuz, thereinto, 10 < x < 45, 5 < y < 20, 1 < z < 10. the forming ability of the alloy quasicrystal is strong, and the formed quasicrystal material is single icosahedron structure. It is thermodynamics is stable, and has good hydrogen storing function. It can be applied in gaseous state hydrogen storing material and battery cathode material; meantime, it provides a kind of producing method of the material: according to the count of the component formula of the quasicrystal material, choose powders of Ti, Zr, Ni, and Cu of 100 holes per cm2 chemical purity, encase them in the ball milling pot of the high energy ball mill, the ball material rate is 20 : 1, ball mill for 100 - 200 hours under the protection of argon, seal the ball milled alloy powders in the quartz tube, have heat processing at 1 í‡ 10-3 Pa, the heat processing temperature is 480 - 650 Deg. C, the time is 0.5 - 6 hours. Its craft is simple, the operational ability is strong, and it is easy to be industrialized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

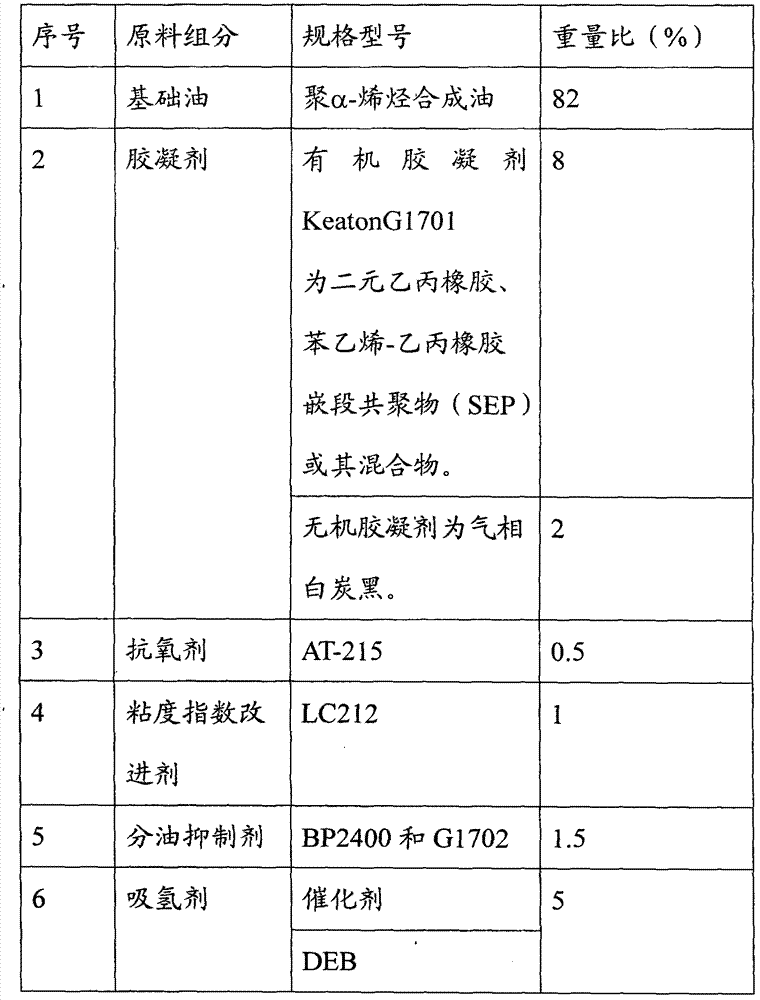

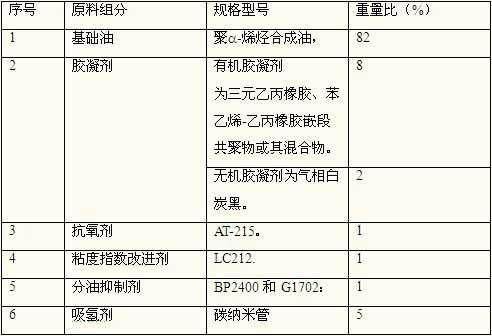

Hydrogen absorption fiber paste for optical fiber composite overhead ground wire (OPGW) optical cable and manufacture method thereof

InactiveCN102778735AGood high and low temperature performanceDrop point highFibre mechanical structuresFiberAntioxidant

The invention relates to hydrogen absorption fiber paste for an optical fiber composite overhead ground wire (OPGW) optical cable. The hydrogen absorption fiber paste comprises, by weight, 75-85% of base oil, 6-10% of gelatinizing agent, 0.3-0.6% of antioxidant, 0.8-1% of viscosity index improver, 1.5-2% of oil distribution inhibitor and 2-5% of hydrogen absorption agent. The base oil is polyalpha-olefin synthesis oil, and the gelatinizing agent is a composite of an organic gelatinizing agent and an inorganic gelatinizing agent. The hydrogen absorption fiber paste has the advantages of adopting the polyalpha-olefin synthesis oil as the base oil so as to enable the fiber paste to have good high-low-temperature performance; improving the stability of a glue body by adding an appropriate amount of silicon-containing (inorganic) glue body into a silicon-free (organic) glue body; having good hydrogen absorption performance by adding an efficient hydrogen absorption agent, removing hydrogen caused by incompatibility of the fiber paste and stainless steel and caused in welding process, reducing defects in optical fiber lattice and loss of optical fiber, and improving transmission performance of the optical fiber.

Owner:JIANGSU NANFANG COMM TECH

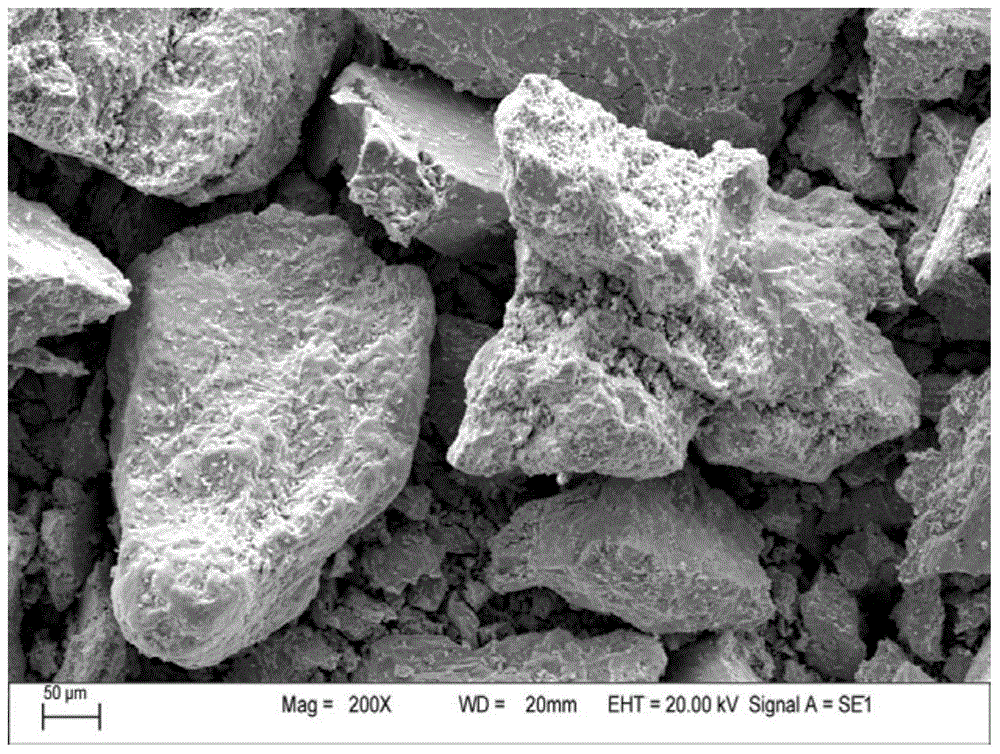

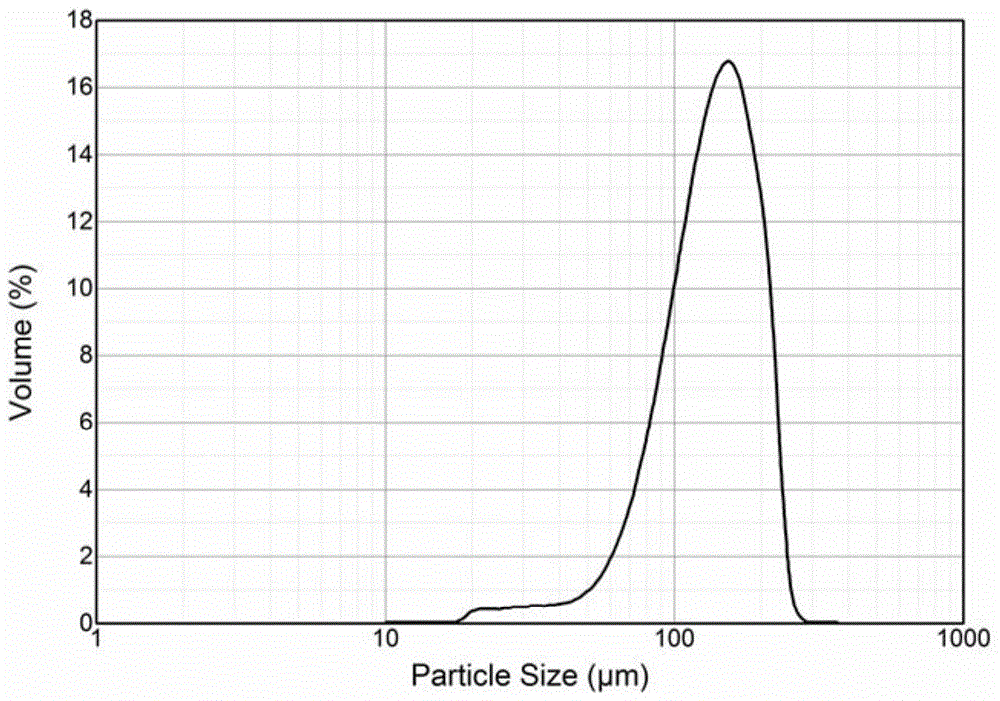

Preparation method of hydrogen absorption component

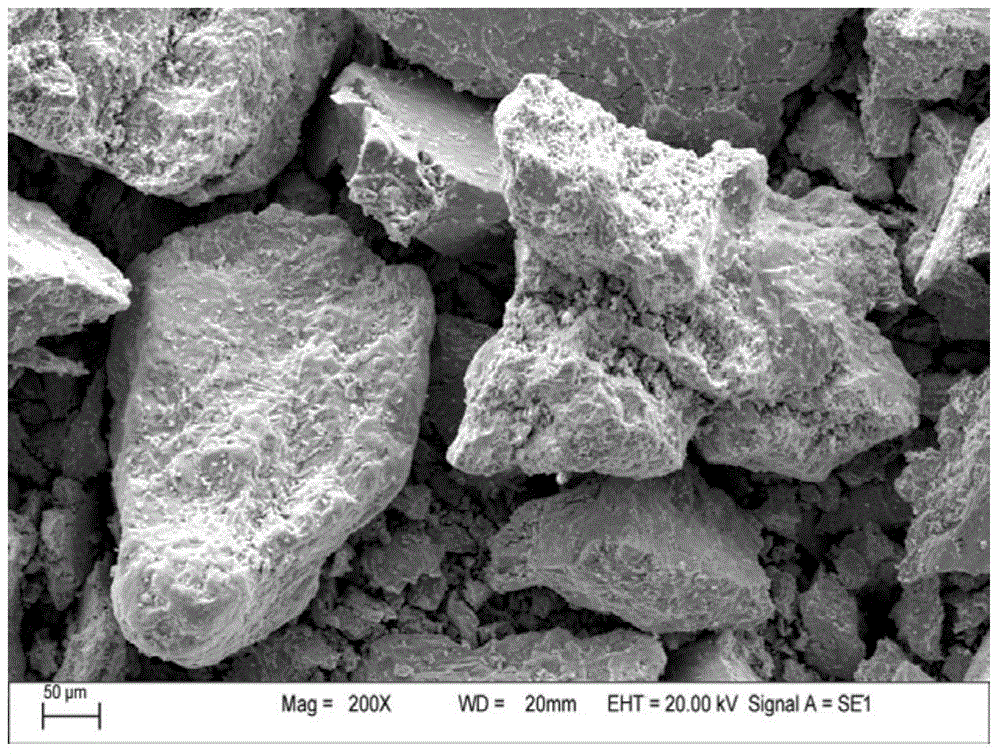

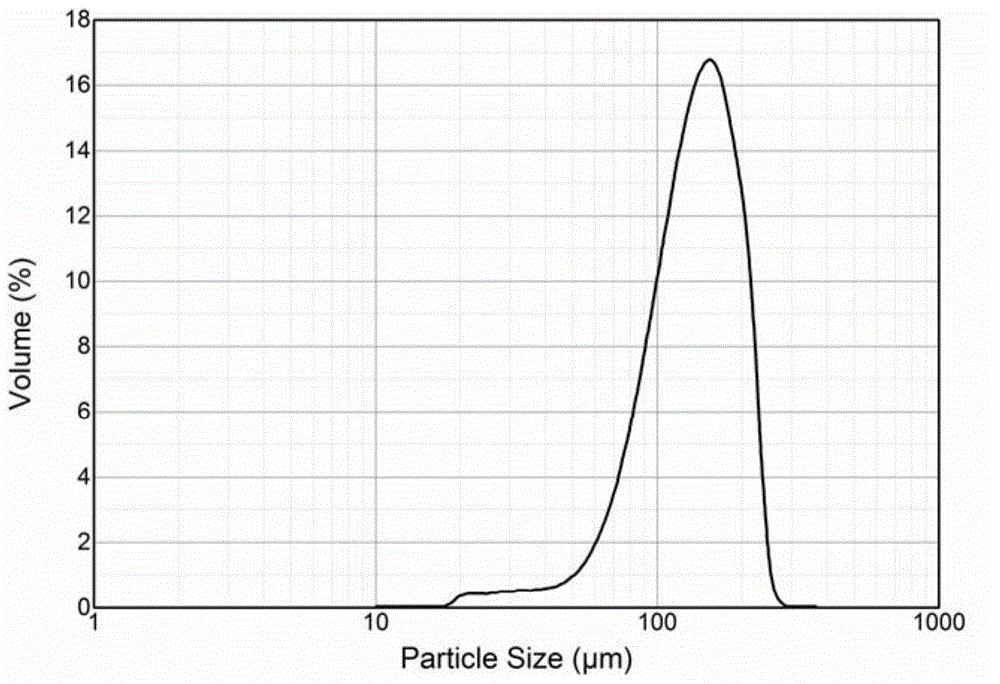

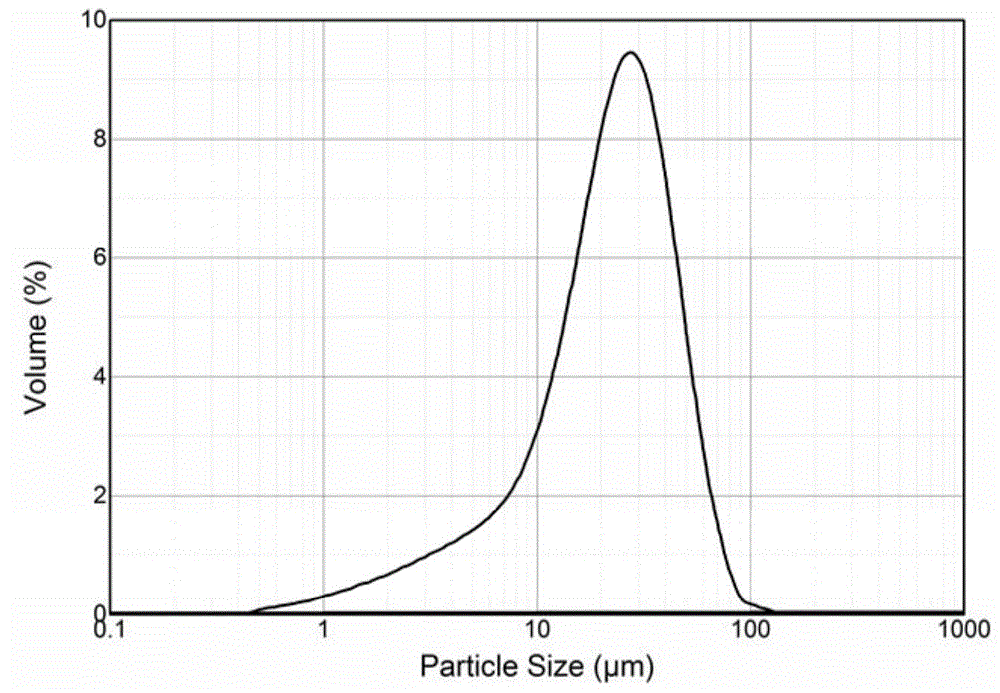

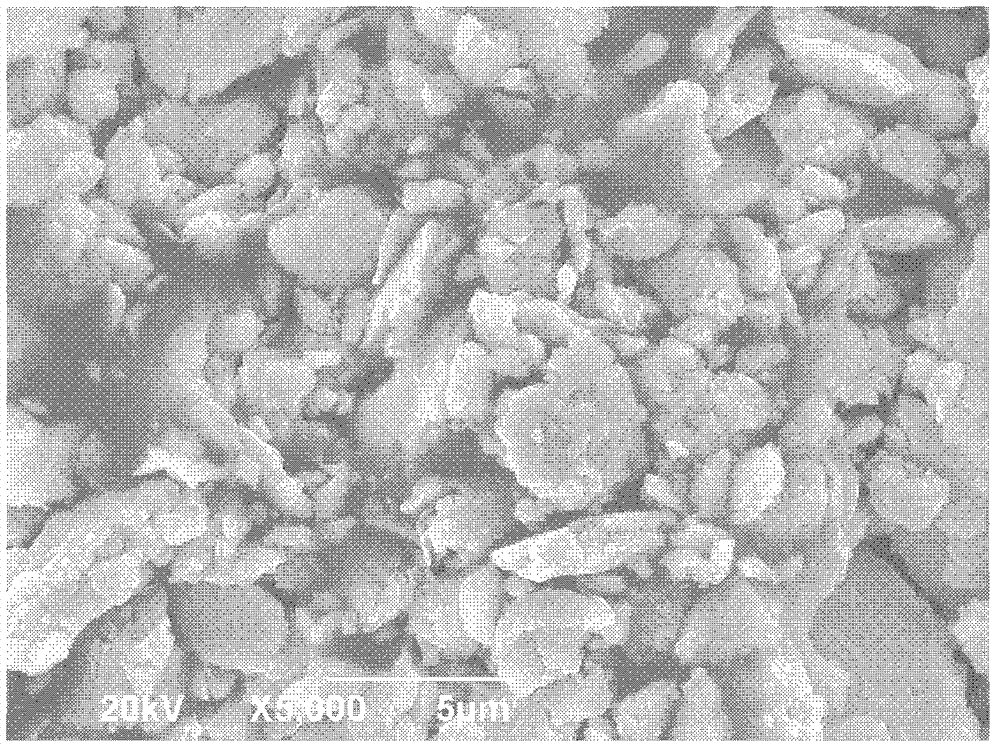

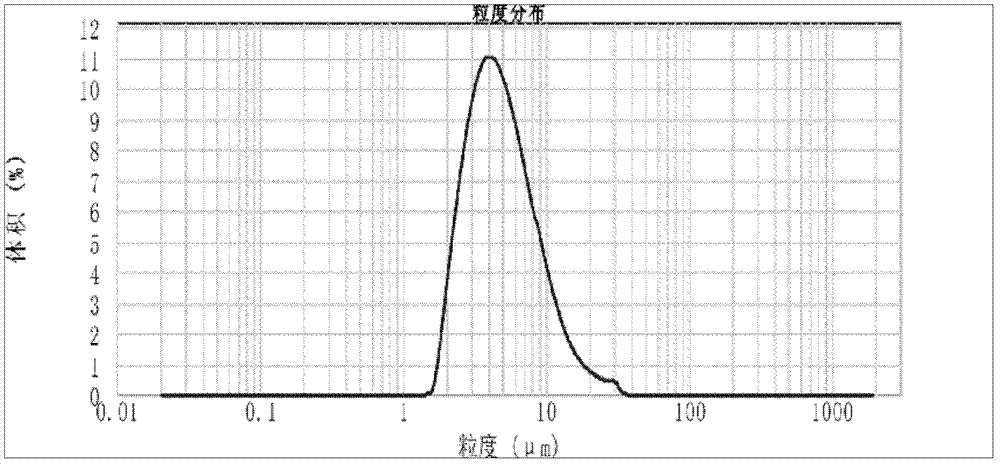

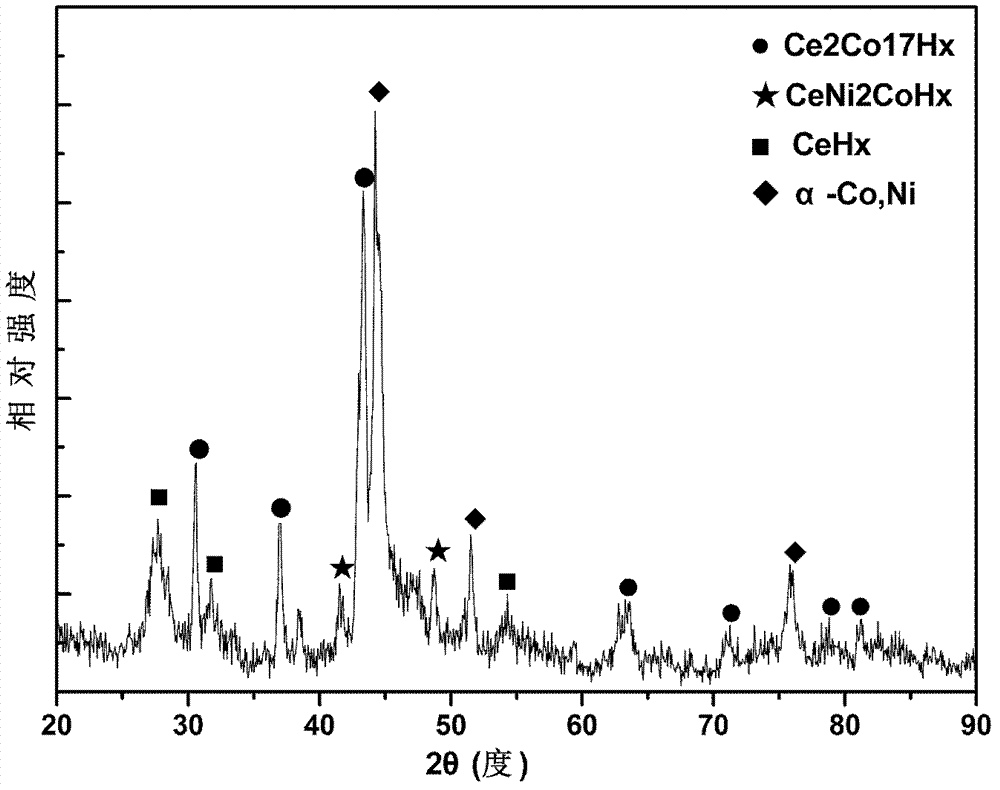

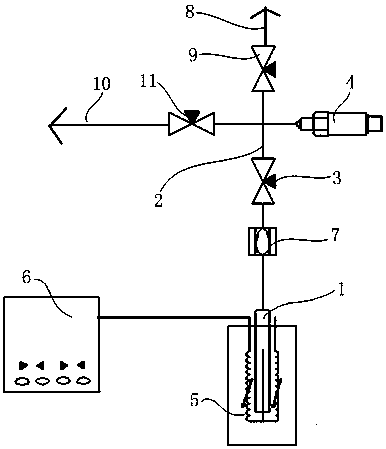

ActiveCN104651652ALarge specific surface areaLow activation temperatureHydrogen separation using solid contactElectric discharge tubesDehydrogenationBiological activation

The invention relates to a preparation method of a hydrogen absorption component. The preparation method comprises the following steps: suspension induction melting or medium-frequency induction melting is carried out on a raw material metal and / or an intermediate alloy to obtain a target ingredient alloy ingot; after vacuum activation of the hydrogen absorption alloy ingot, hydrogenation treatment is carried out to obtain hydrogen-containing alloy particles; the alloy particles undergo ball-milling and screening to make all materials meet jet-milling feeding requirements; the alloy particles are ground into a powder by jet-milling; hydrogenated alloy particles undergo spheroidizing and dehydrogenation by radio frequency plasma discharge spheroidizing; and the obtained powder is pressed or sintered to prepare the hydrogen absorption component. Hydrogen adsorption properties of the hydrogen absorption component prepared by the above method are obviously better than those of a hydrogen absorption component prepared by traditional preparation methods such as a direct crushing method and a hydrogenation crushing method. The prepared hydrogen absorption component has excellent hydrogen absorption properties at high temperature and can replace existing hydrogen absorption components for solar vacuum tubes.

Owner:GRIMAT ENG INST CO LTD

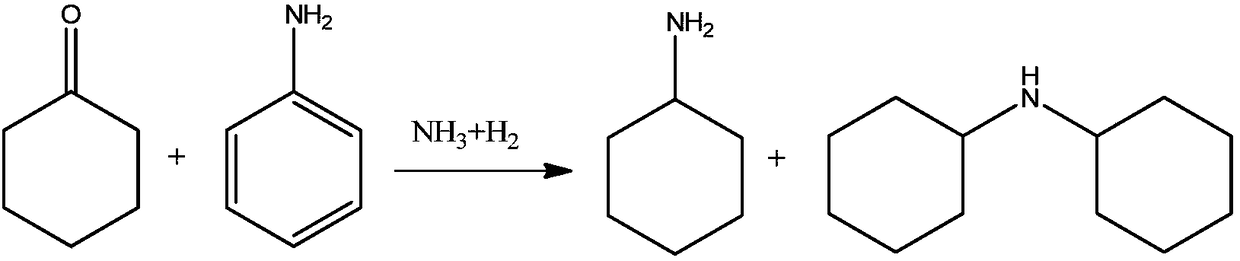

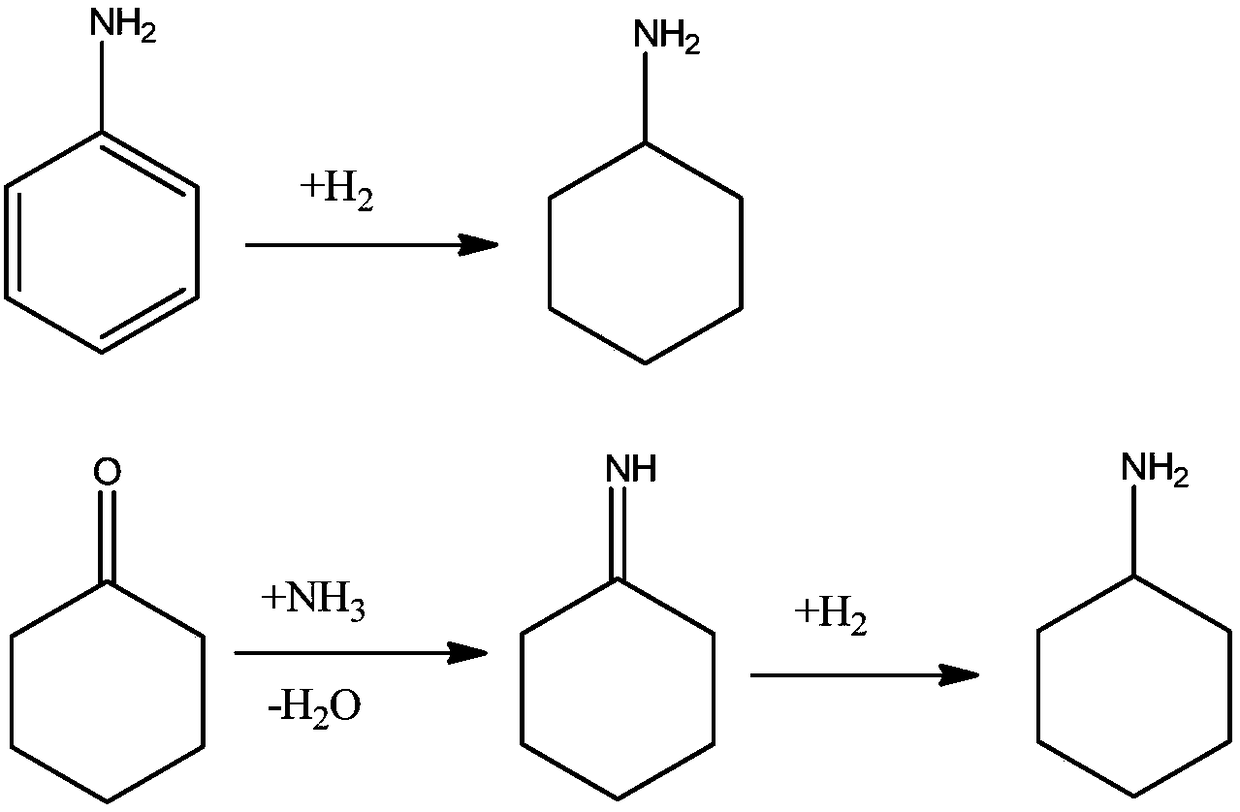

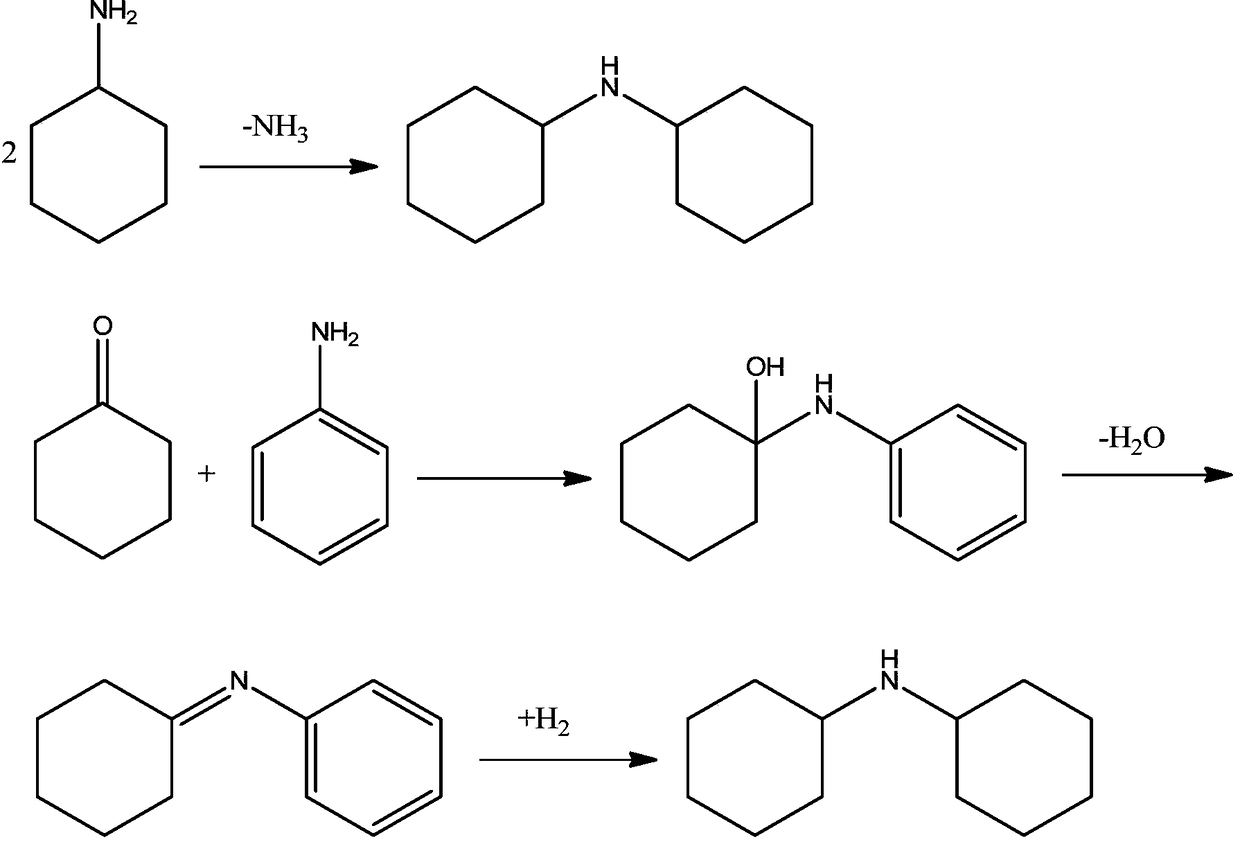

Joint production method for cyclohexylamine and dicyclohexylamine and catalyst system applied to method

ActiveCN109503388AAvoid churnReduce dosageOrganic compound preparationHeterogenous catalyst chemical elementsCyclohexanoneHydrogen

The invention discloses a joint production method for cyclohexylamine and dicyclohexylamine and a catalyst system applied to the method. The method comprises the following steps: (1) enabling the rawmaterials of phenylamine, cyclohexanone, ammonia and hydrogen to pass through a first section of a reactor which an Rh-Ni catalyst is filled into and loaded on to obtain first reaction liquid; (2) enabling the first reaction liquid pass through a second section of the reactor which an Rh-Co catalyst is filled into and loaded on to obtain reaction liquid containing the cyclohexylamine and the dicyclohexylamine. The combined production method disclosed by the invention has the advantages that the raw materials are cheap and easy to obtain, the conversion rate is high, product selectivity is good, service life of catalysts is long, technological processes are simple, a continuous technology is utilized, an automation degree is high, labor intensity is low, production cost is low, and the dicyclohexylamine with a high added value can be jointly produced; furthermore, product composition can be adjusted by changing reaction conditions according to the market need situation of the products;thus, the joint production method is suitable for industrial mass production.

Owner:WANHUA CHEM GRP CO LTD

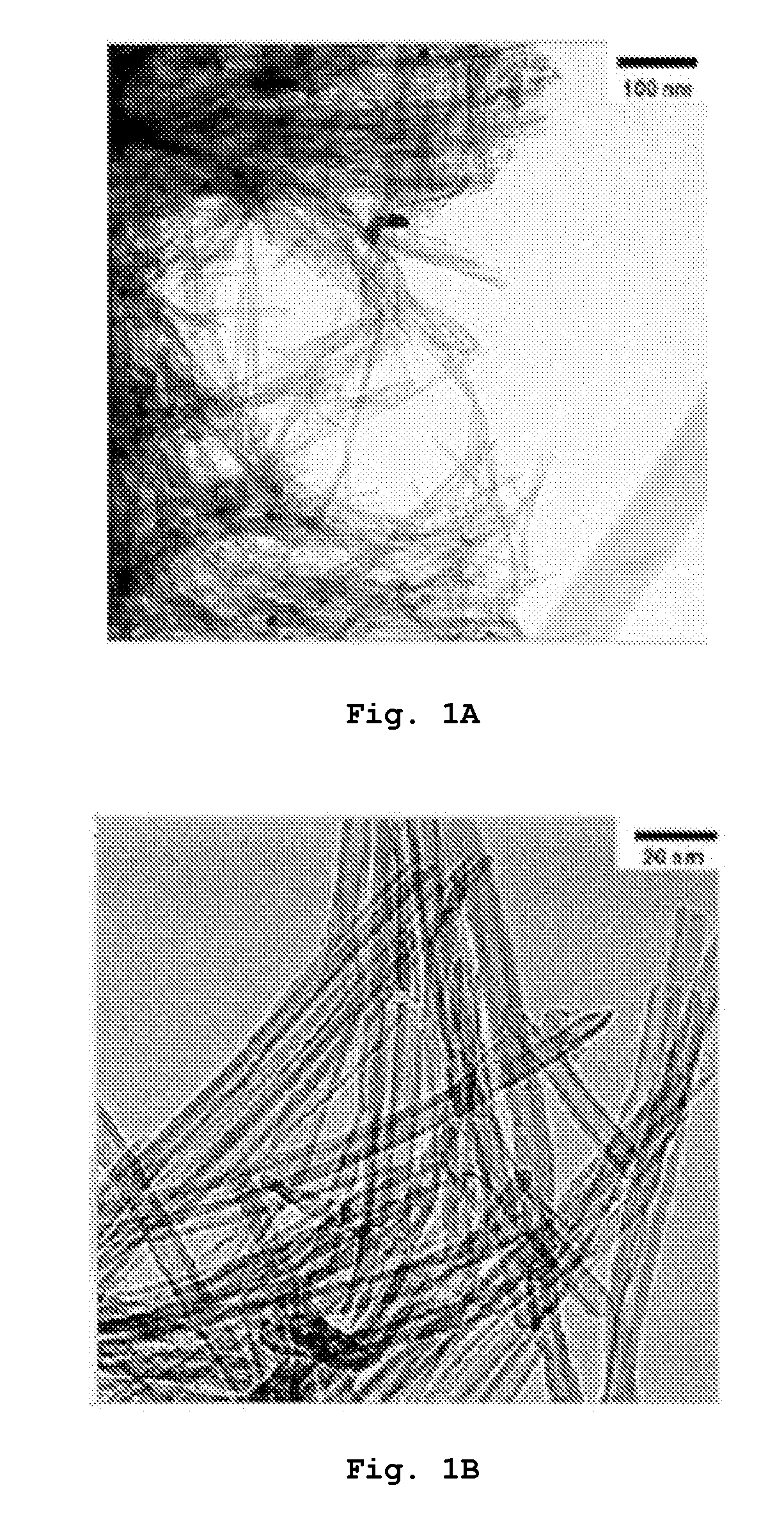

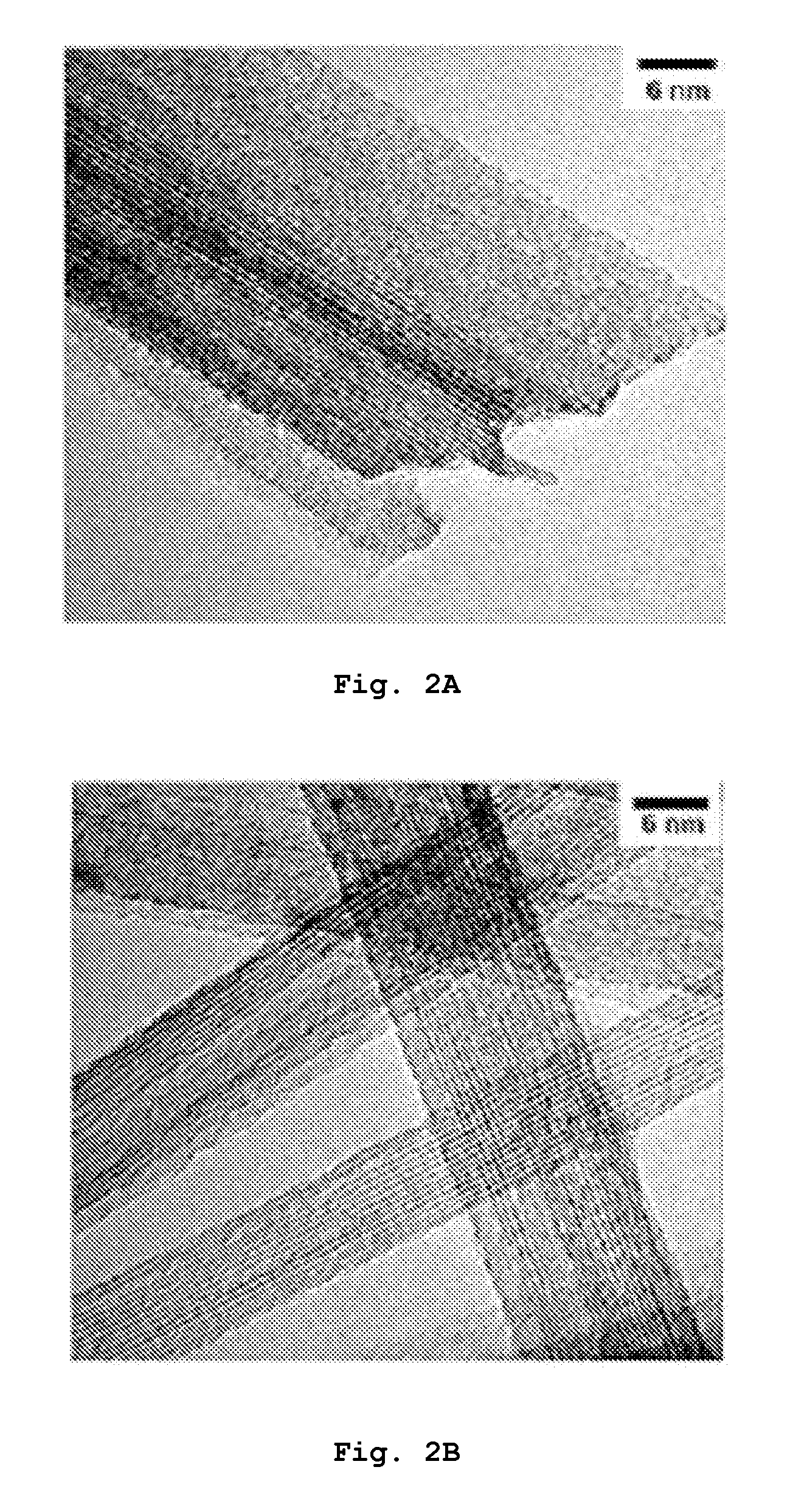

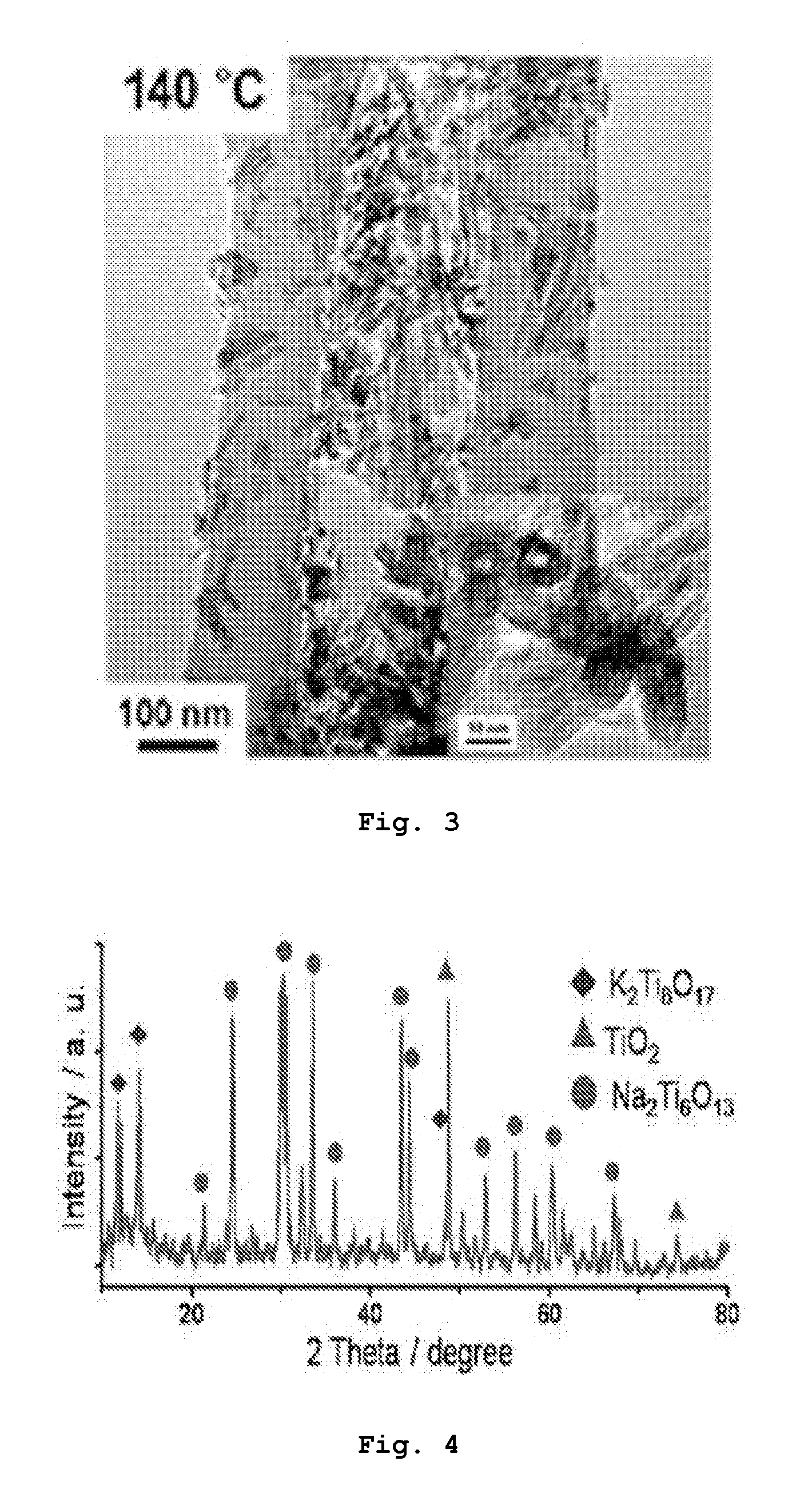

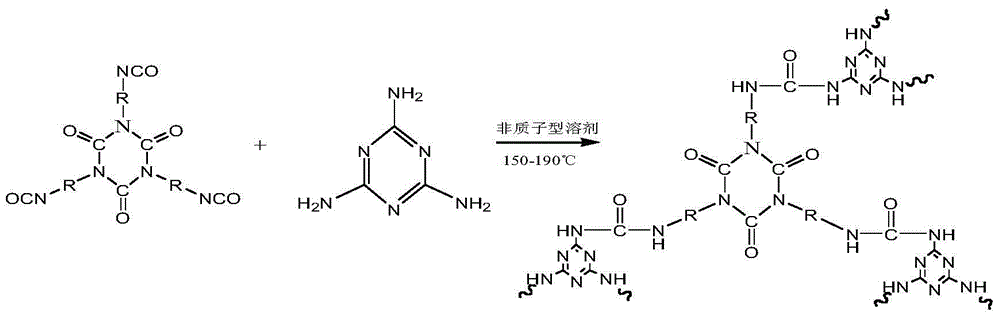

Titanate Nanostructure and Method for Preparation Thereof

InactiveUS20110009258A1Improve hydrogen absorption performanceEasy to useMaterial nanotechnologyAlkali titanatesPhysical chemistryHydrothermal synthesis

Disclosed is a titanate nanostructure, especially, represented by a chemical formula of NaKTi3O7. A method for preparation of a titanate nanostructure is also provided. The method includes mixing titanium dioxide powder with an alkaline solution to prepare a titanium dioxide solution; and carrying out hydrothermal synthesis of the prepared titanium dioxide solution at a temperature of 120° C. to 180° C. for 12 to 72 hours.

Owner:KOREA ADVANCED INST OF SCI & TECH

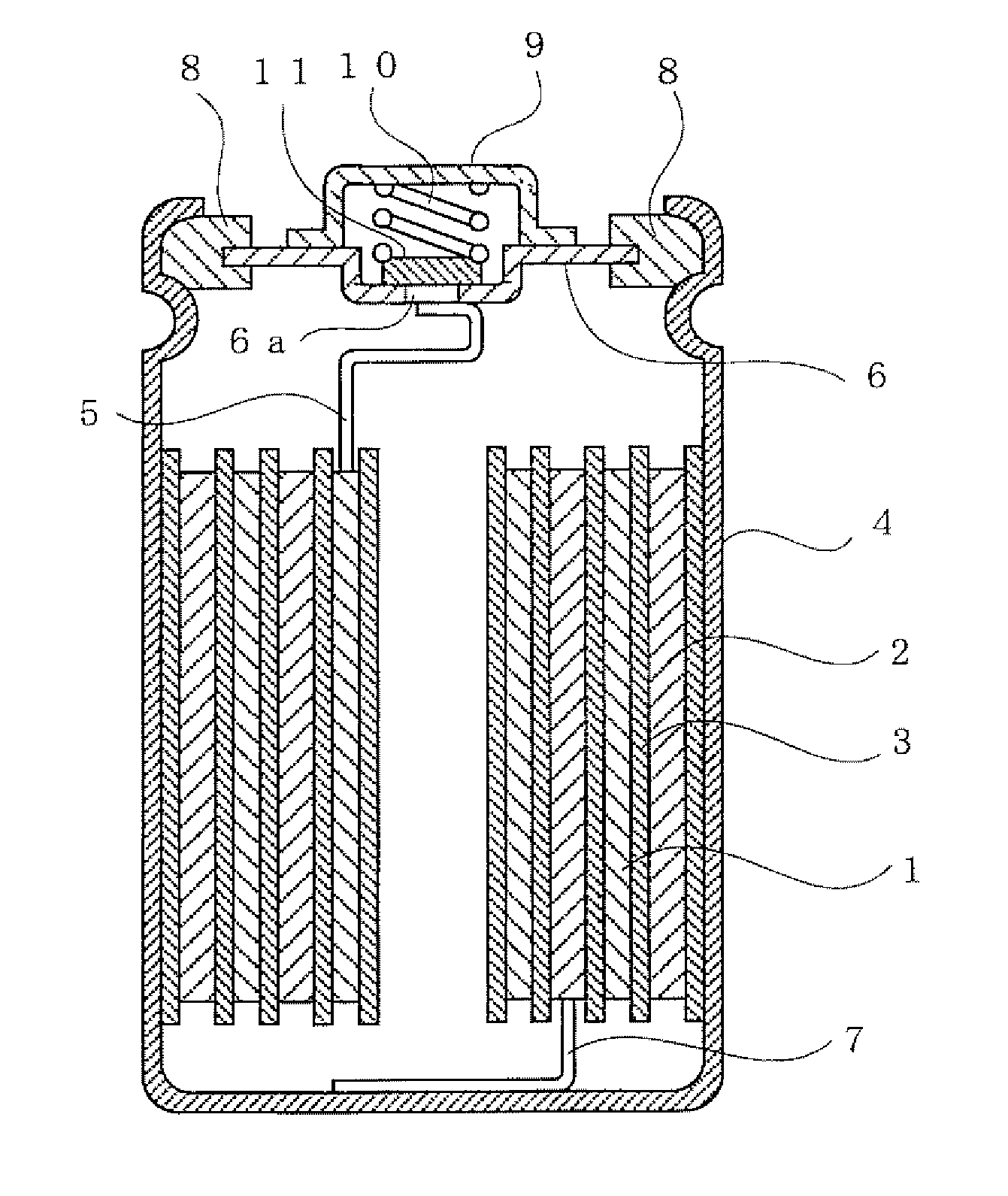

Preparation method of porous polymer

ActiveCN104558515ASimple processProcess conditions are easy to controlOther chemical processesHydrogen separation using solid contactChemical industryPolymer science

The invention belongs to the technical field of chemical industry, and particularly discloses a preparation method of a porous polymer for adsorbing hydrogen. The method comprises the following steps: a) weighing melamine and an aprotic polar solvent, mixing, stirring, dissolving, adding an MDI tripolymer (namely 4,4'-diphenyl-methane-diisocyanate tripolymer), reacting at 150-190 DEG C for 18-36 hours, carrying out suction filtration, washing a sample with acetone, and drying to obtain an intermediate product; and b) putting the intermediate product into a solvent, and refluxing at 40-80 DEG C for 10-15 hours, so as to obtain the porous polymer. The method disclosed by the invention has the advantages of low cost of raw materials for preparing a hydrogen storage material, simple process and short time; the technological conditions are easy to control; the prepared porous polymer can adsorb a great amount of hydrogen under high pressure; through detection, the specific surface area of the porous polymer can be up to 270m<2> / g; the micropore volume accounts for 12%-20% of total pore volume; when the maximal constant volume pressure is 7MPa, the adsorbing capacity of the porous polymer prepared by the method on hydrogen can be up to 8wt%; and the hydrogen storage capacity is high.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

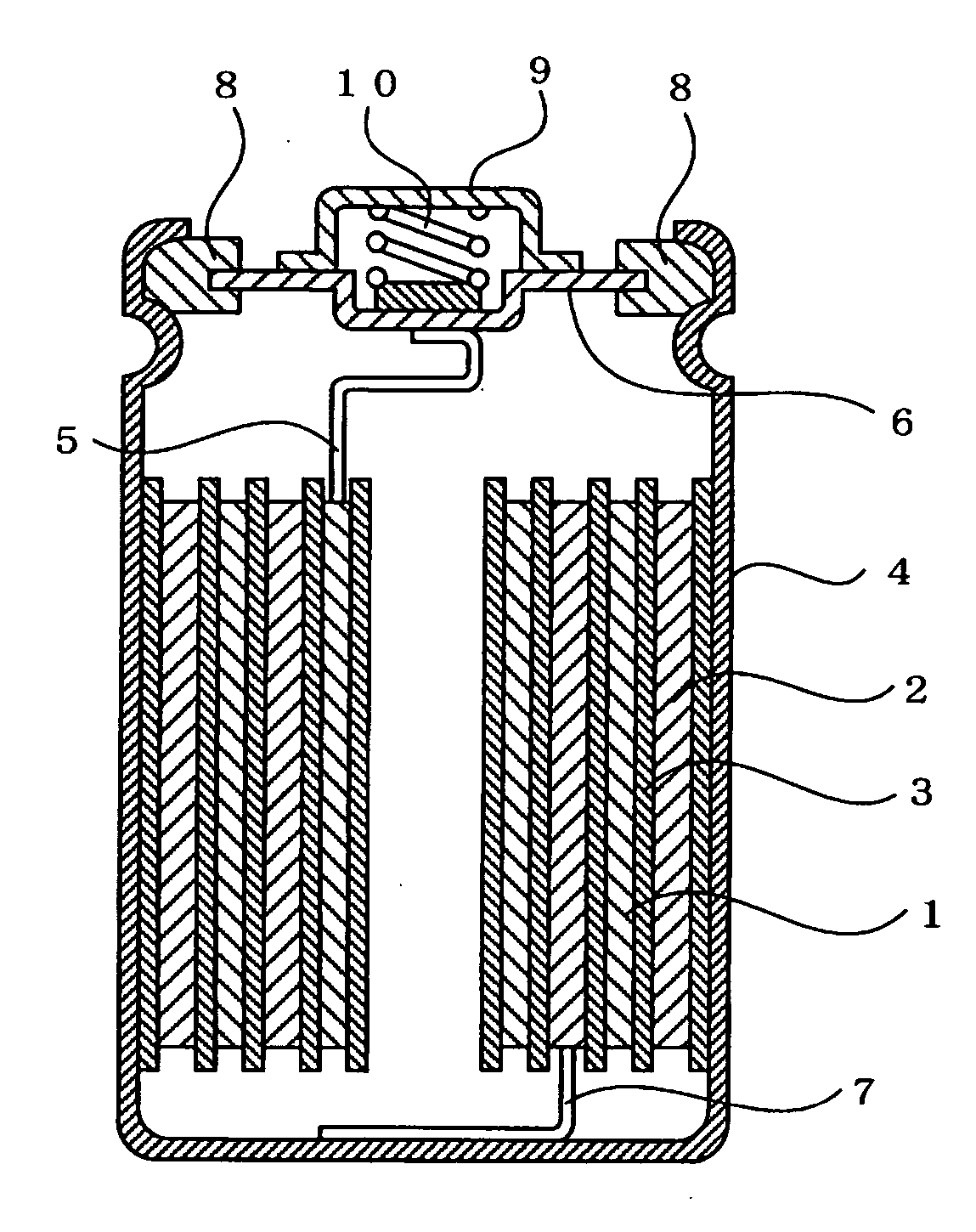

Hydrogen-absorbing alloy, fabrication method thereof and alkaline storage battery

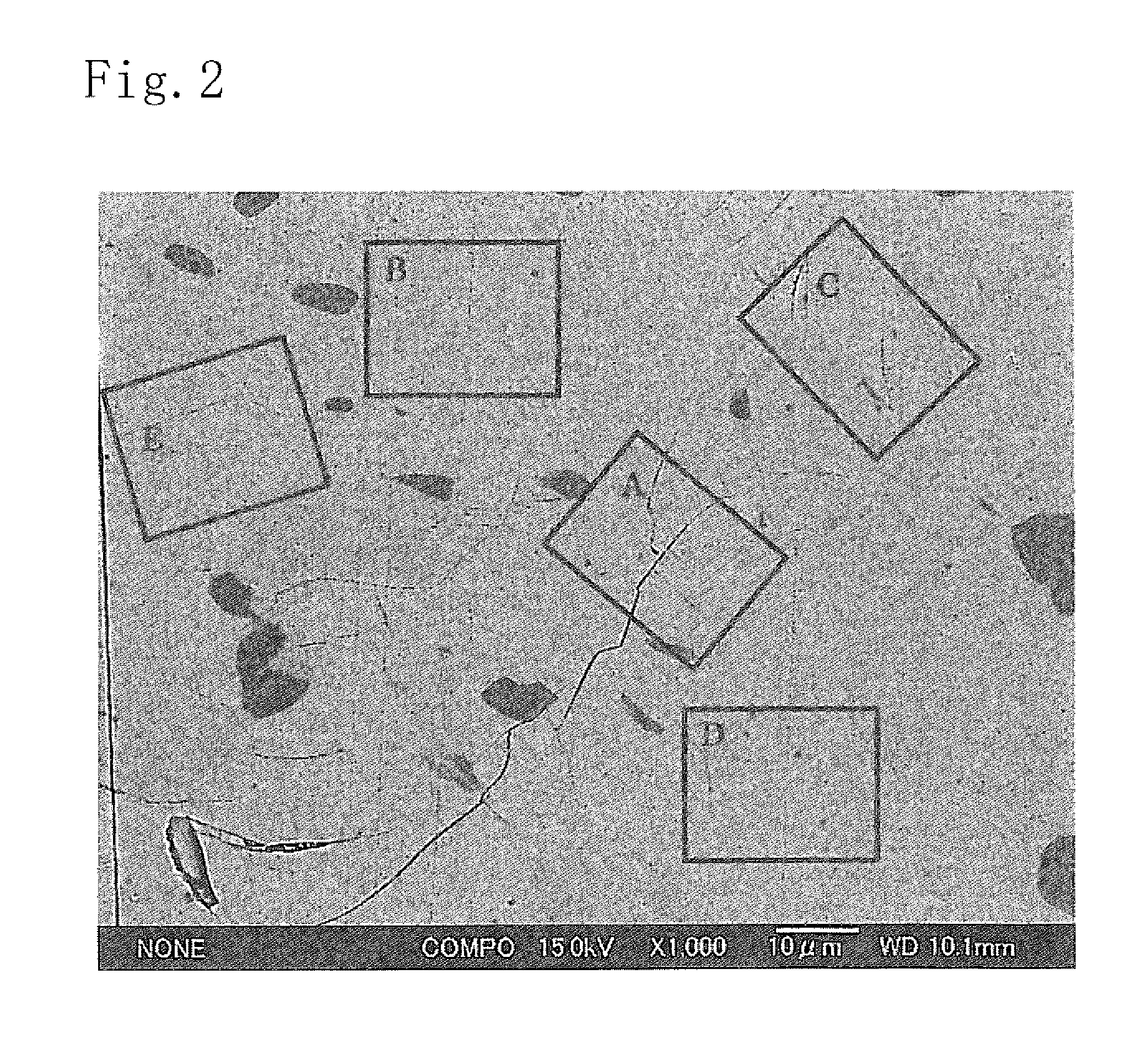

ActiveUS20110151320A1Increased durabilityImprove cycle lifeOther chemical processesActive material electrodesRare-earth elementCrystal structure

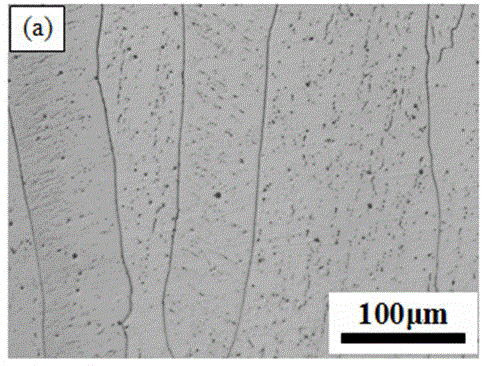

An alkaline storage battery has a negative electrode using a hydrogen-absorbing alloy represented by a general formula Ln1-xMgxNiyAz wherein Ln is at least one element selected from rare-earth elements including Y, Ca, Zr, and Ti, A is at least one element selected from Co, Fe, Mn, V, Cr, Nb, Al, Ga, Zn, Sn, Cu, Si, P and B, and 0.15≦x≦0.30, 0<z≦1.5, and 2.8≦y+z≦4.0 are satisfied. The hydrogen-absorbing alloy has a hexagonal system crystal structure or a rhombohedral system crystal structure as its main phase and has a subphase of line which average number of not less than 50 nm in thickness existing in the range of 10 μm×10 μm in the cross section of the main phase is 3 or less.

Owner:FDK CORP

Zirconium alloy material for light water reactor under higher burnup

InactiveCN104745875AImprove hydrogen absorption performanceImprove corrosion resistanceZirconium alloyCorrosion resistant

The invention discloses a zirconium alloy material for a light water reactor under higher burnup. The zirconium alloy material comprises 0.10-0.40 weight% of tin, 0.50-1.50 weight% of niobium, 0.01-0.20 weight% of iron and 0.06-0.20 weight% of oxygen, and further comprises 0.01-0.09 weight% of vanadium and / or 0.01-0.09 weight% of copper and the balance of zirconium. The zirconium alloy has excellent corrosion resistance; and compared with the zirconium alloy in the prior art, the zirconium alloy has more excellent corrosion resistance in high-temperature pure water, and is suitable for fuel rod cladding materials and corrosion resistant zirconium alloy materials of grillwork strips and structural parts under higher burnout of nuclear reactors.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Formula of hydrogen absorption type fiber paste and manufacture method thereof

The invention relates to a formula of hydrogen absorption type fiber paste, which comprises the following components in percentage by weight: 80-84% of base oil, 9-11% of gelling agent, 0.5-2% of antioxygen, 0.5-2% of viscosity index improver, 0.5-2% of oil-separation inhibitor and 4-6% of hydrogen absorbing agent, wherein the gelling agent is organic-inorganic composite gelling agent; the organic gelling agent accounts for 7-9wt%, and the inorganic gelling agent accounts for 1-3wt%; and the hydrogen absorbing agent is a carbon nanotube. Because the carbon nanotube is added into a fiber paste matrix to serve as the hydrogen absorbing agent in the formula, the hydrogen absorption type fiber paste has a good hydrogen absorption performance, and free nitrogen can be effectively adsorbed to prevent the free nitrogen from damaging an optical fiber.

Owner:JIANGSU QIBAO PHOTOELECTRIC GRP

Catalytic agent for preparing p-aminophenol by using nitrobenzene catalytic hydrogenation and preparation method thereof

InactiveCN102658125BHigh activityHigh selectivityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsM-aminophenolPtru catalyst

The invention relates to a novel catalytic agent for preparing p-aminophenol by using nitrobenzene catalytic hydrogenation and a preparation method thereof. The catalytic agent enables active carbon to serve as a carrier, enables Pt to serve as a main catalytic agent and enables MoS2 to serve as an auxiliary catalytic agent. The preparation step of the catalytic agent comprises (1) preparing Pt / C catalytic agent, namely enabling the Pt to be loaded on the activated carbon through an infusion process; and (2) restoring the auxiliary catalytic agent MoS2 through steeping and roasting under certain H2, loading on the Pt / C, and finally obtaining the catalytic agent for preparing the p-aminophenol. The catalytic agent for synthesizing the p-aminophenol is high in productivity and high in selectivity, and the catalytic agent is good in stability. After 23 times of circulation, the catalytic agent keeps good activity, yield coefficient of the p-aminophenol is above 83%, and the catalytic agent has good industrial application prospect.

Owner:ANHUI UNIV OF SCI & TECH

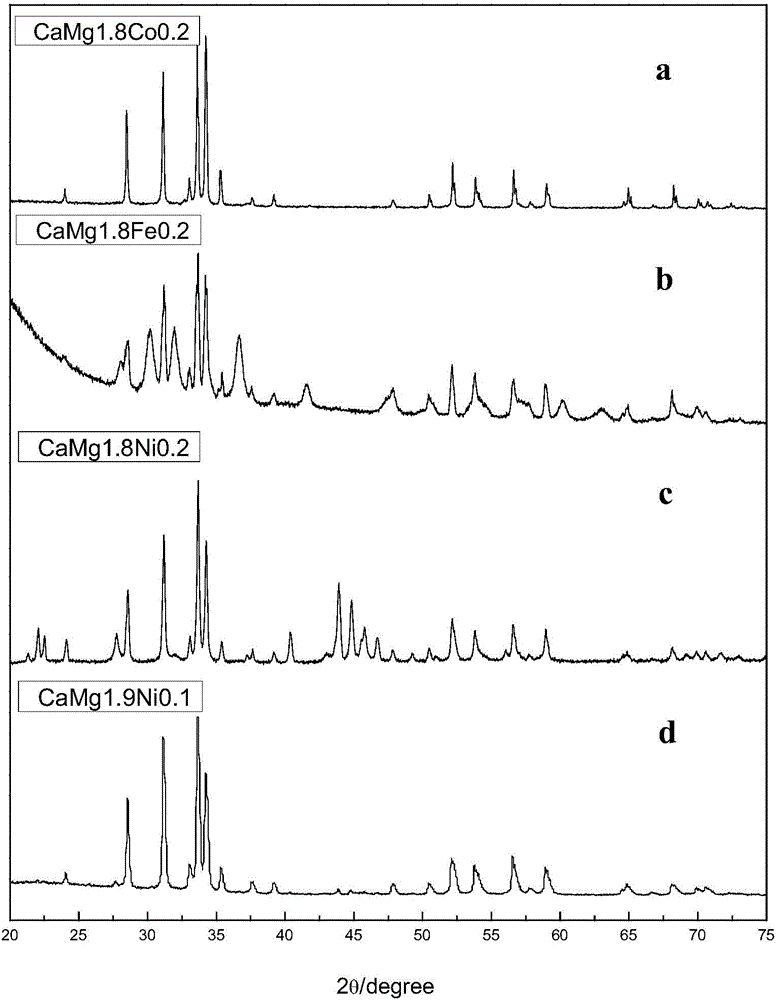

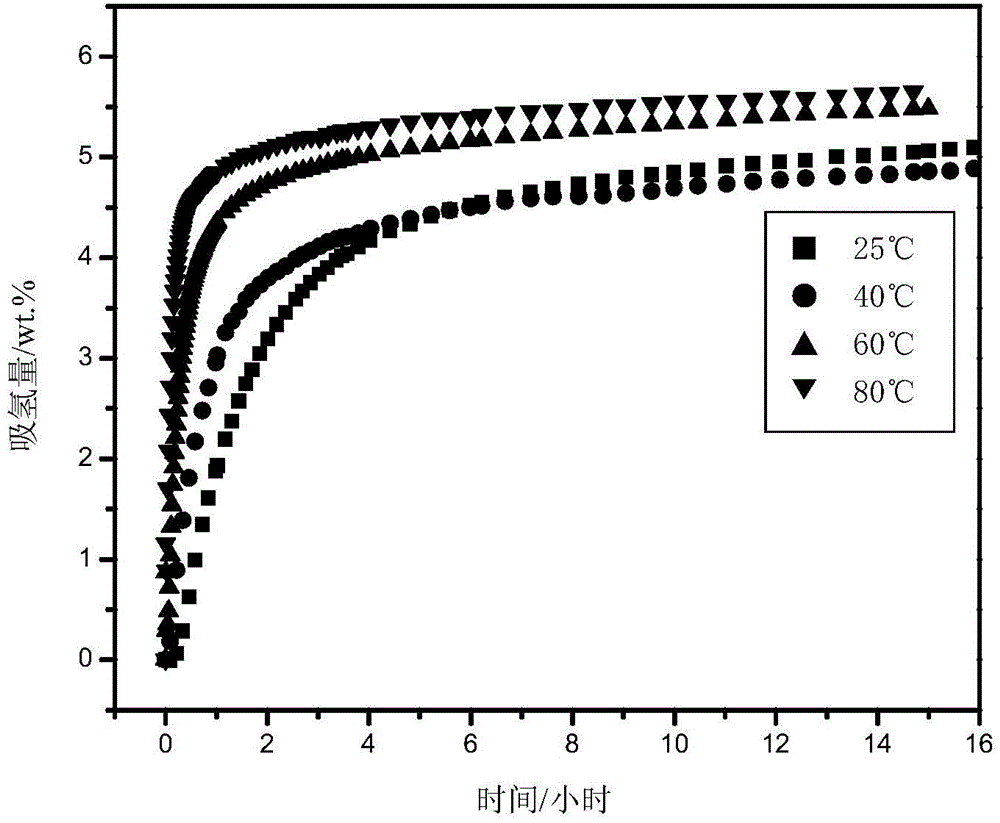

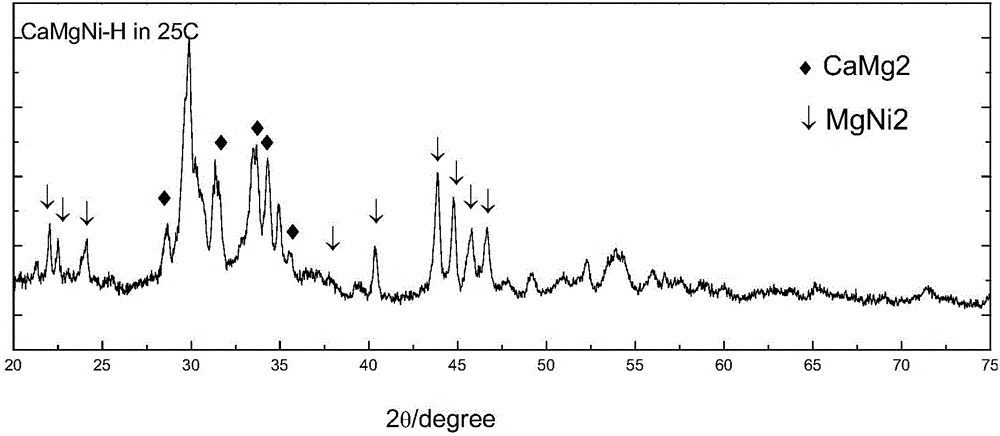

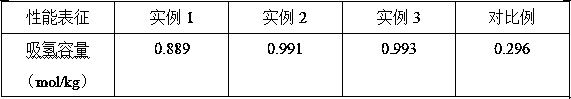

CaMg2-based alloy hydride hydrolysis hydrogen production material and preparation method and application thereof

InactiveCN104528649AImprove hydrogen absorption performanceReduce power consumptionMultiple metal hydridesHydrogen productionCrucibleHydrogen fuel cell

Owner:SOUTH CHINA UNIV OF TECH

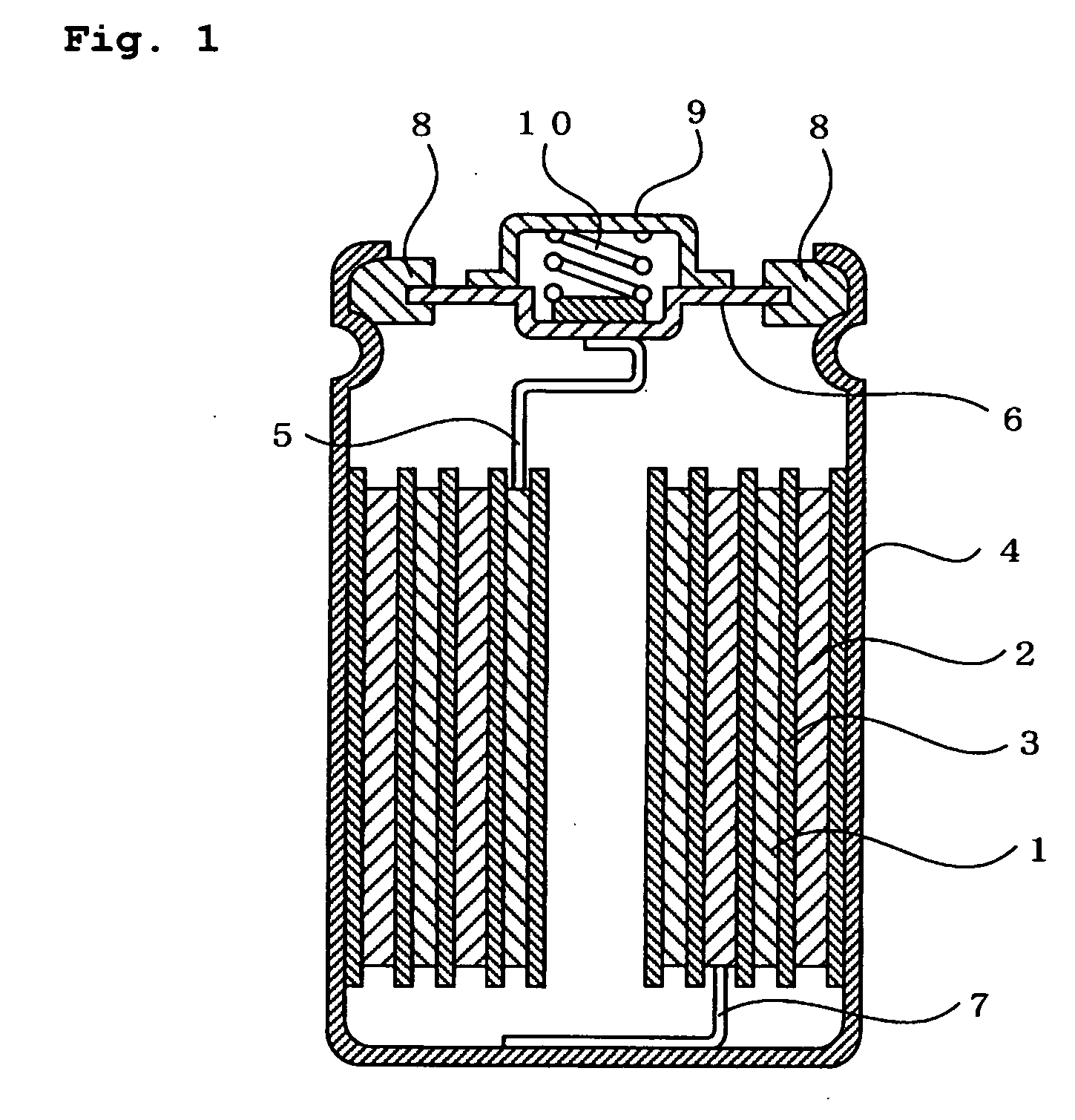

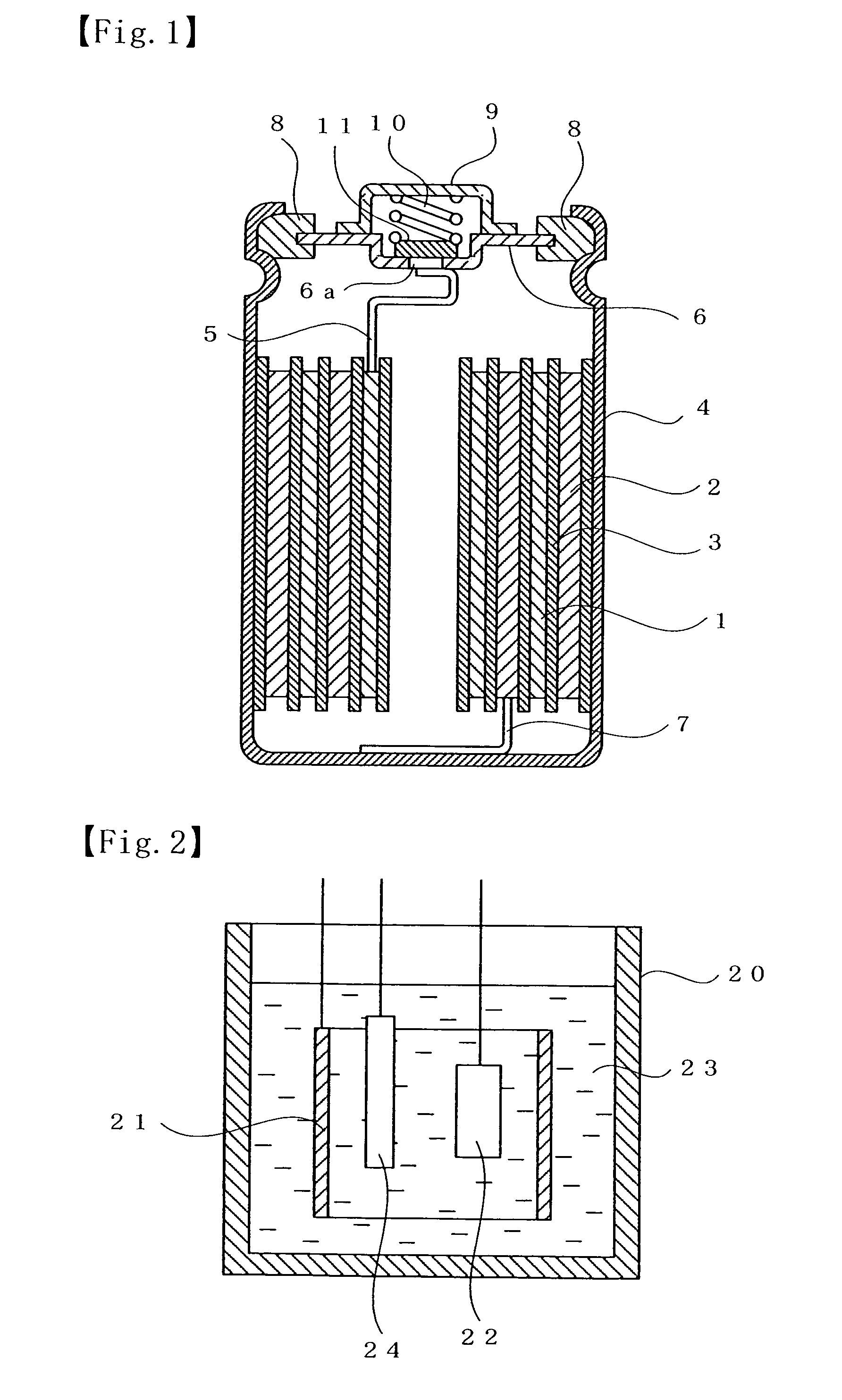

Hydrogen-absorbing alloy electrode, alkaline storage battery, and method of manufacturing the alkaline storage battery

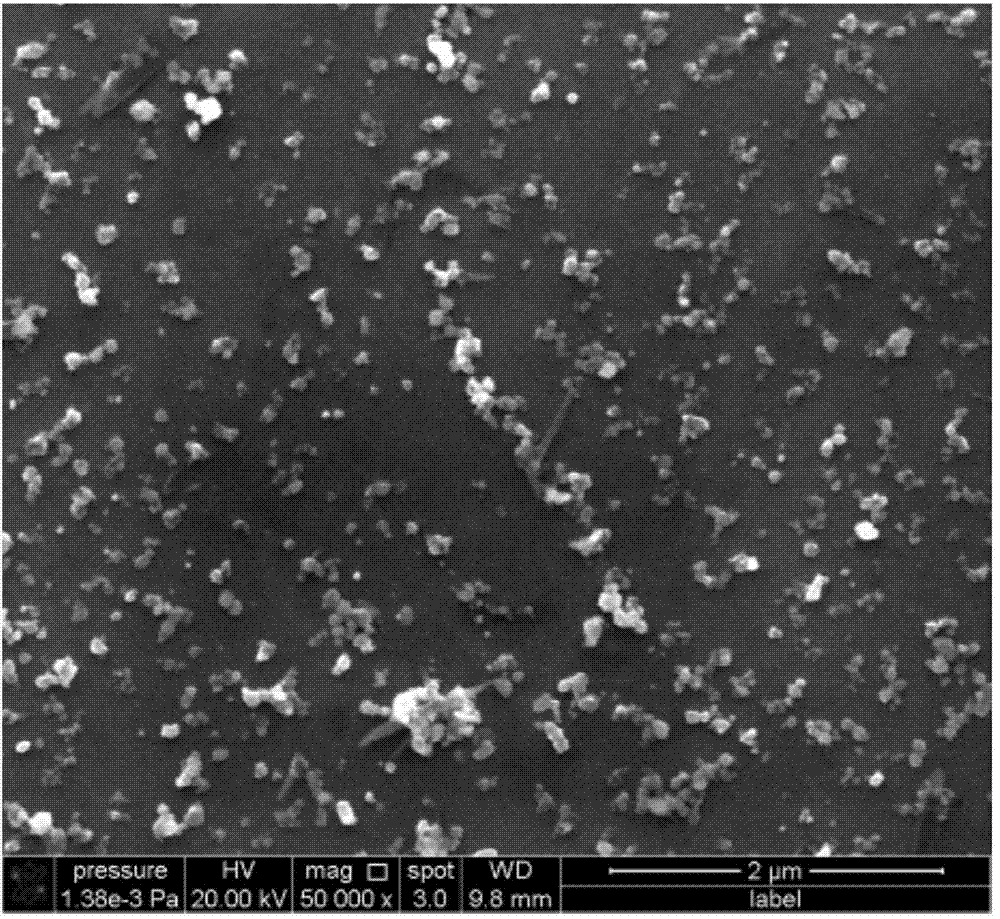

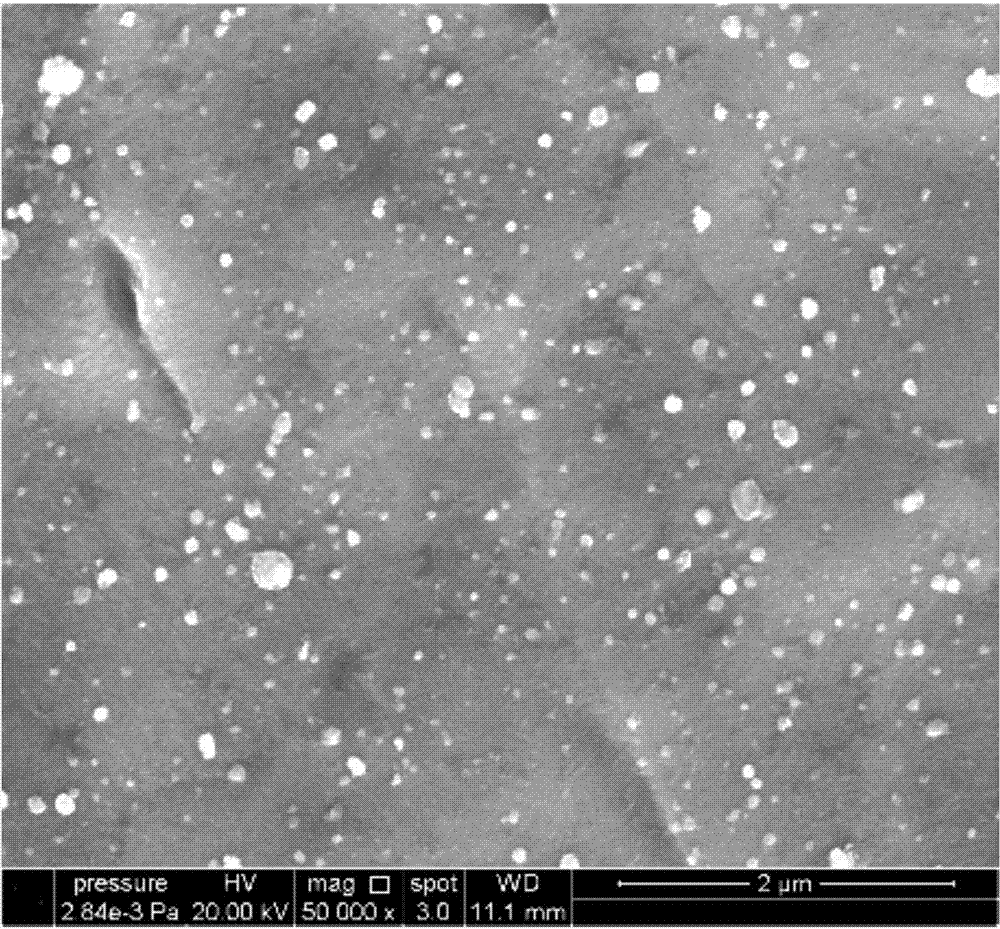

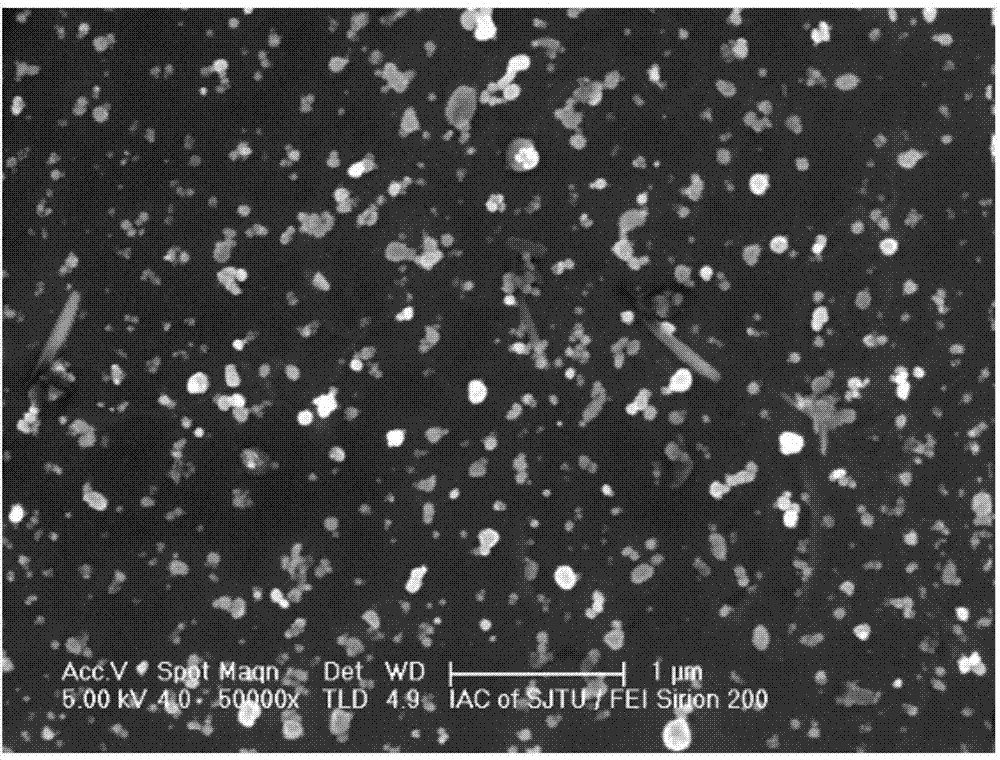

InactiveUS20070105018A1Reduce discharge capacityImprove rate discharge performanceMaterial nanotechnologyFinal product manufactureRare-earth elementHigh rate

Low temperature discharge capability and high rate discharge capability are improved in an alkaline storage battery that uses as its negative electrode a hydrogen-absorbing alloy electrode employing hydrogen-absorbing alloy particles containing at least nickel and a rare-earth element. An alkaline storage battery uses as the negative electrode a hydrogen-absorbing alloy electrode employing hydrogen-absorbing alloy particles containing at least nickel and a rare-earth element. The hydrogen-absorbing alloy particles have a surface layer and an interior portion, the surface layer having a nickel content greater than that of the interior portion, and nickel particles having a particle size within a range of from 10 nm to 50 nm are present in the surface layer.

Owner:SANYO ELECTRIC CO LTD

Preparation method of composite hydrogen absorption material

InactiveCN108609580AEasy to adsorb and dissociateImprove hydrogen absorption performanceReversible hydrogen uptakeTransportation and packagingHigh energyPolyvinyl alcohol

The invention relates to a preparation method of a composite hydrogen absorption material and belongs to the technical field of energy saving and environmental protection. Crystalline carbon is takenas a grinding medium, when a magnesium alloy and carbon granules are extruded under collision, the carbon granules can be embedded into the magnesium alloy, magnesium alloy granules are peeled, refined carbon granules adhere to the surfaces of magnalium granules to disperse the alloy granules, cold welding due to collision between the alloy granules is hindered, fresh surface of magnesium is exposed continuously by ball milling, the surface energy is higher than that of magnesium powder without ball milling, hydrogen molecules are adsorbed and dissociated more easily by magnesium, higher energy is produced at effective collision moment, activation energy needed by H atoms for entering a magnesium lattice is provided, then H supports palladium and compounded with modified polyvinyl alcohol,H2 can be diffused to catalyst surface rapidly and converted into free H radicals, the free H radicals are subjected to addition with acetylene linkage under synergy of palladium, so that effective hydrogen absorption is realized, hydrogen absorption capacity is increased, and hydrogen absorption performance of the material is improved.

Owner:FOSHAN TENGLI NEW ENERGY TECH CO LTD

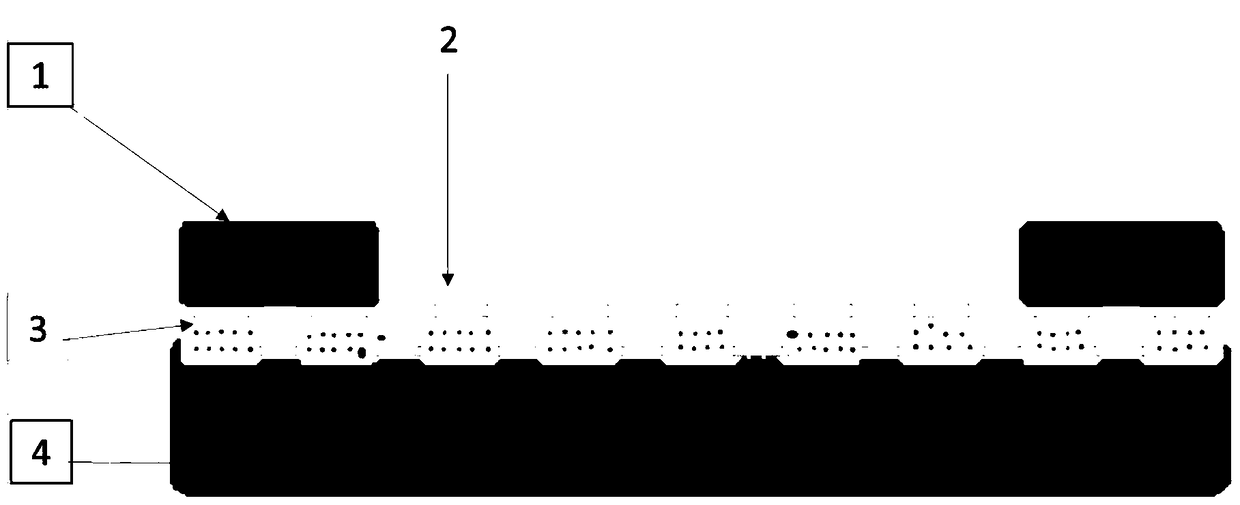

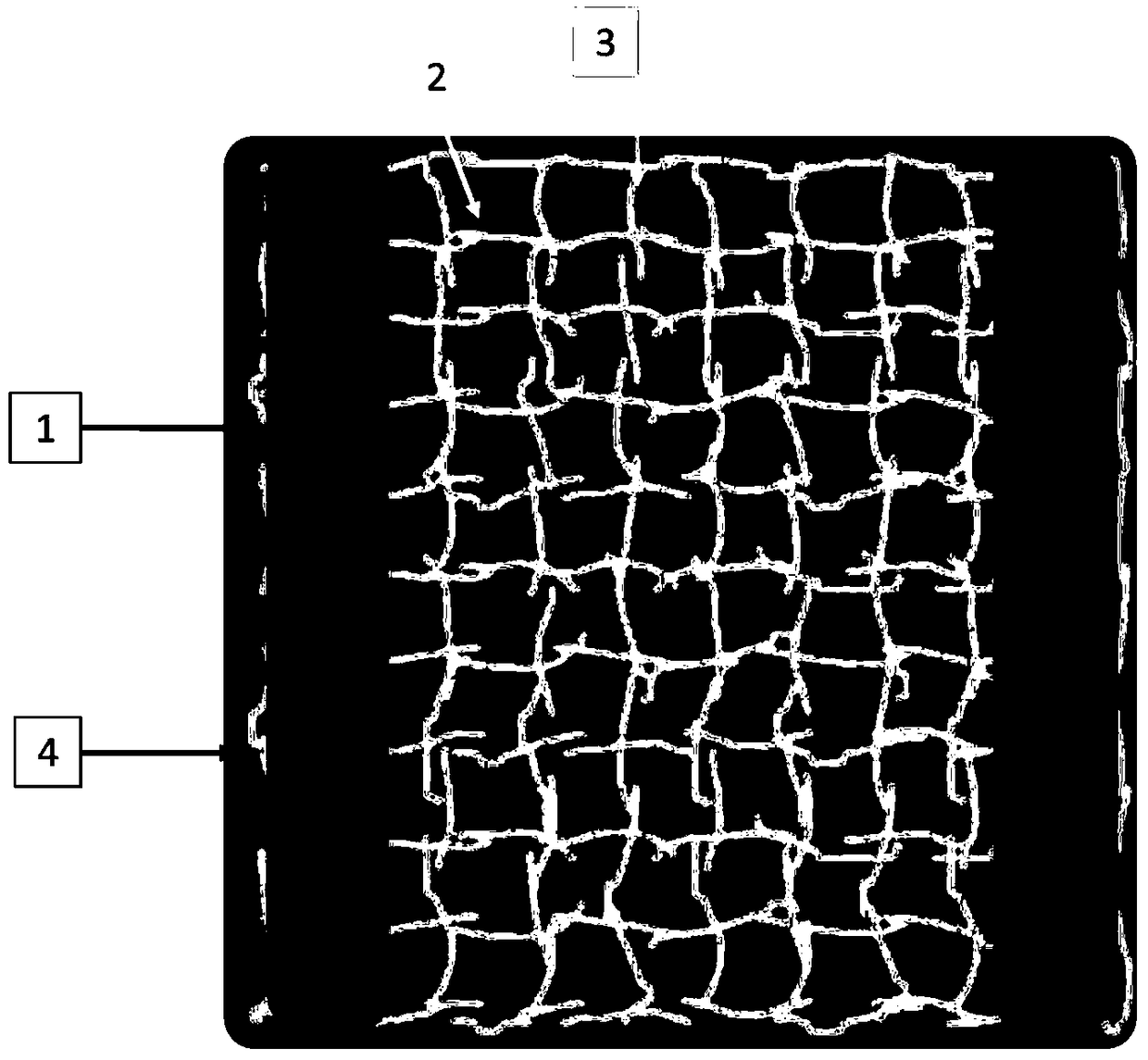

A hydrogen sensor based on carbon nanotube and palladium composite film

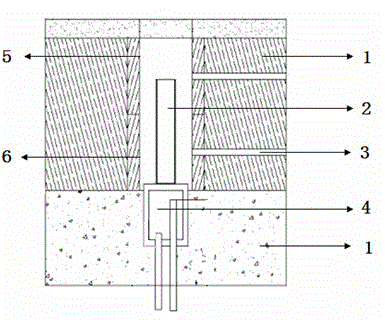

InactiveCN105510400BImprove hydrogen absorption performanceShort response timeMaterial resistanceComposite filmNew energy

The invention relates to new energy-sensitive materials, in particular to a hydrogen sensor based on carbon nanotubes and palladium composite films, which sequentially includes a P-type silicon substrate (4), carbon nanotubes (3), and a metal palladium film (2) from inside to outside and two metal electrodes (1), wherein the carbon nanotubes (3) are arranged vertically and horizontally evenly, and the two metal electrodes (1) are strip-shaped and arranged symmetrically on the metal Palladium film (2) upper surface. The textured carbon nanotubes used in the present invention can effectively improve the hydrogen absorption performance of the metal palladium film, reduce the response time of the hydrogen sensor, and improve the responsivity of the hydrogen sensor; at the same time, the selectivity of the device is also guaranteed; in addition, the present invention can be used in It works at room temperature; moreover, the fabrication process of the device is simple and easy for large-scale production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Polymer film material with hydrogen absorption function and preparation method thereof

The invention discloses a polymer film material with a hydrogen absorption function. The polymer film material comprises the following raw materials: a water absorbent, a noble metal catalyst and a polymer matrix, the preparation method comprises the following steps: uniformly mixing the water absorbent, the polymer matrix and the noble metal catalyst, and preparing thermoplastic and thermosettinghydrogen absorption materials with different structures and application forms by physical and chemical forming methods. Complex chemical preparation is avoided, the preparation process is simple, thehydrogen absorption performance is high, and due to the fact that the hydrogen absorption film is a thin film, machining and cutting can be directly conducted.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

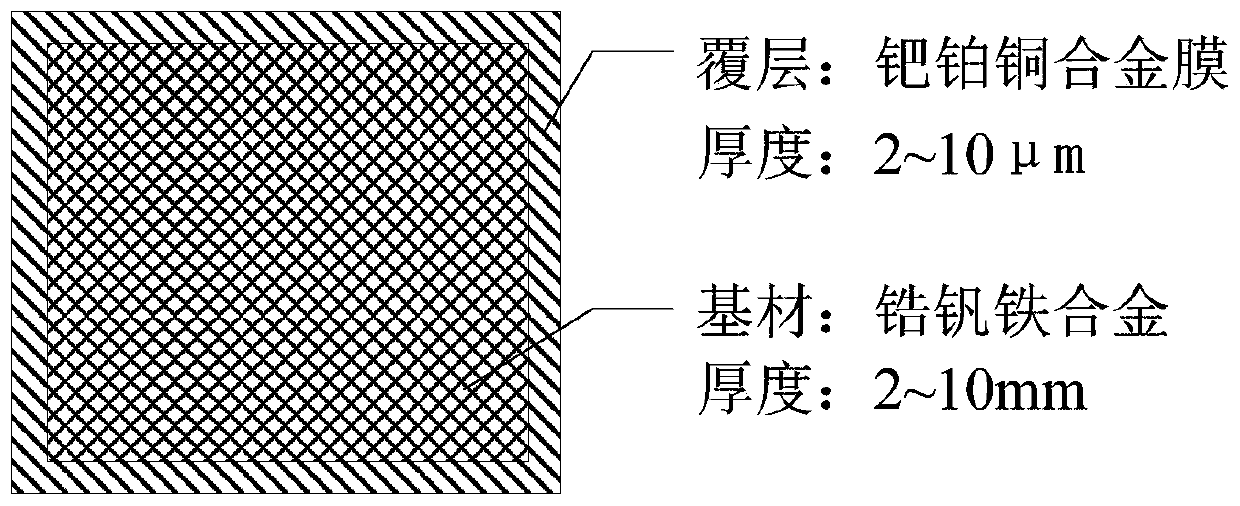

Nuclear facility post-accident hydrogen absorption material preparation process

InactiveCN111519051AImprove hydrogen absorption performanceEasy to handleLiquid/solution decomposition chemical coatingChemical platingElectric arc furnace

The invention provides a nuclear facility post-accident hydrogen absorption material preparation process. A hydrogen absorption material is formed by a Zr-V-Fe alloy coated with a Pd-Pt-Cu alloy film.The process comprises the Zr-V-Fe alloy smelting step, the heat treatment step, the cutting step, the film coating step and the activation step, wherein the Zr-V-Fe alloy is smelted through a vacuumarc furnace or a vacuum induction furnace; a smelted cast ingot is subjected to heat treatment and then is cut into blocks; and the surface of each block is coated with the Pd-Pt-Cu alloy film with acertain thickness through the chemical plating method. The blocky Zr-V-Fe alloy has the excellent hydrogen absorption performance. The surface of the alloy is treated easily. The Pd-Pt-Cu alloy film attached firmly is evenly coated with the surface of the alloy. The Zr-V-Fe alloy and the Pd-Pt-Cu alloy film are matched in size. The excellent performance and material cost of the hydrogen absorptionmaterial are both taken into consideration, and the stability and reliability of the hydrogen absorption material are improved. The blocky hydrogen absorption material can serve as a basic module forconstructing a hydrogen control system and is convenient to use and compact in structure.

Owner:上海申核能源工程技术有限公司

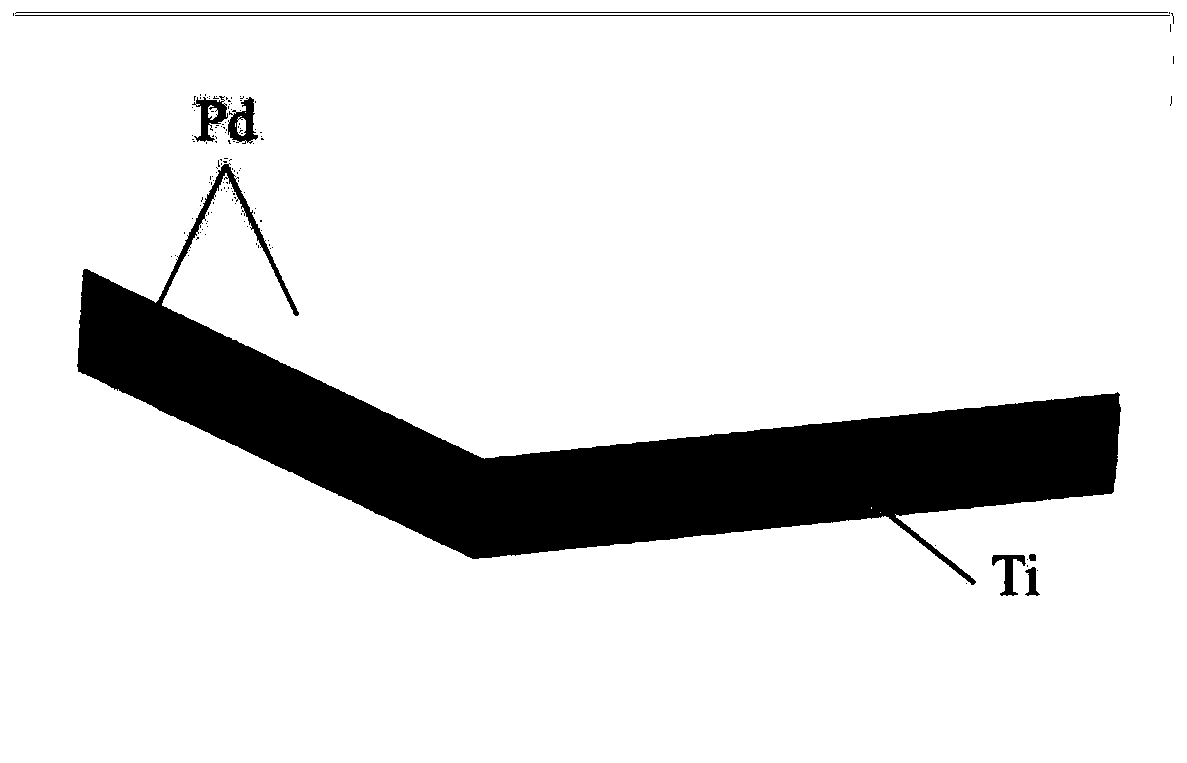

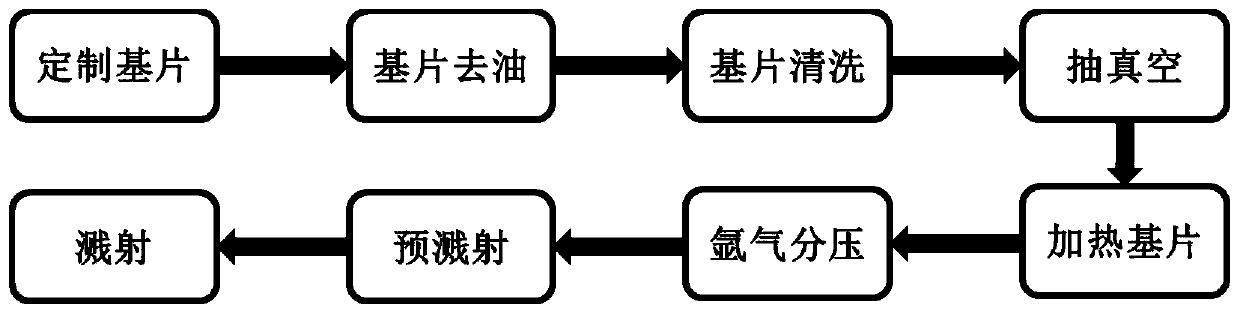

Hydrogen absorption material for electronic packaging and preparation method thereof

InactiveCN110699649AAvoid failureIncrease productivityVacuum evaporation coatingSputtering coatingSputteringPhysical chemistry

The invention discloses a hydrogen absorption material for electronic packaging and a preparation method thereof, and mainly aims at control over the content of hydrogen in sealed electronic devices and assemblies. The hydrogen absorption material comprises a Ti substrate for playing a role of storing hydrogen and a Pd film which is combined on the Ti substrate and achieves the effects of catalytic cracking and penetration. The preparation method comprises the two steps of pretreatment of the hydrogen-storage Ti substrate and magnetron sputtering of the Pd film layer. The hydrogen absorption material can be used in various types of sealed electronic devices and assemblies, absorbs the hydrogen in the sealed devices and assemblies, and therefore, the situation that chips and the like in thesealed devices are affected by the hydrogen to lose efficacy is prevented, the production efficiency and the reliability are high, and it is not required that a packaged shell and a packaged device are additionally subjected to hydrogen removal.

Owner:CETC GUOJI SOUTHERN GRP CO LTD

Hydrogen absorption type fiber paste for optical power grounded waveguide processing and preparation method thereof

InactiveCN108663762AStrong penetrating powerModerate viscosityFibre mechanical structuresFiberWaveguide

The invention discloses hydrogen absorption type fiber paste for optical power grounded waveguide processing, and relates to the technical field of optical cable processing. The paste is prepared from, by weight, 5-10 parts of PEG-sodium of polyaspartic acid, 1-5 parts of sulfated castor oil, 1-3 parts of hydrogen absorption agent, 0.5-2 parts of hydrogenated rosin pentaerythritol ester, 0.5-2 parts of trimethylolpropane triacrylate, 0.05-0.5 part of C5 hydrogenated petroleum resin, 0.05-0.5 part of magnesium dimethacrylate and 50-70 parts of epoxidized soybean oil. According to the paste, thehydrogen absorption agent is added, so that the prepared fiber paste has good hydrogen absorption performance, incompatibility of fiber paste and stainless steel and hydrogen generated in the weldingprocess are effectively eliminated, defects in optical fiber crystal lattices are reduced, and optical fiber consumption is reduced, therefore the transmission performance of optical fibers is improved.

Owner:ANHUI COMM IND SERVICE CO LTD

Regular icosahedron titanium-base quasi-crystal material with hydrogen-storage function and its preparing method

InactiveCN1299819CStrong ability to form quasicrystalsEasy to operateOther chemical processesTitaniumBall mill

The invention provides a kind of single icosahedron quasicrystal material with hydrogen storing function. Its component is Ti100-x-y-zZrxNiyCuz, thereinto, 10 Pa, the heat processing temperature is 480-650 DEG C, the time is 0.5-6 hours. Its craft is simple, the operational ability is strong, and it is easy to be industrialized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method of making hydrogen-absorbing alloy for alkaline storage battery, and alkaline storage battery

ActiveUS20090014100A1Uniform structureSuitable compositionCell electrodesFinal product manufactureQuenchingMaterials science

Owner:SANYO ELECTRIC CO LTD

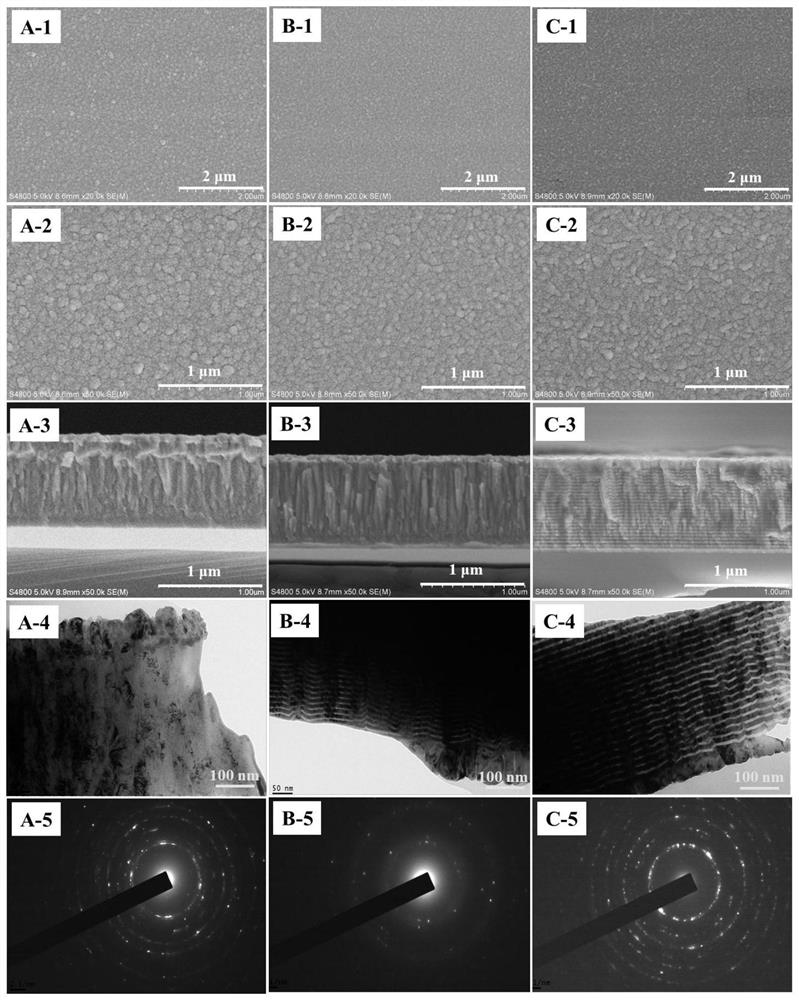

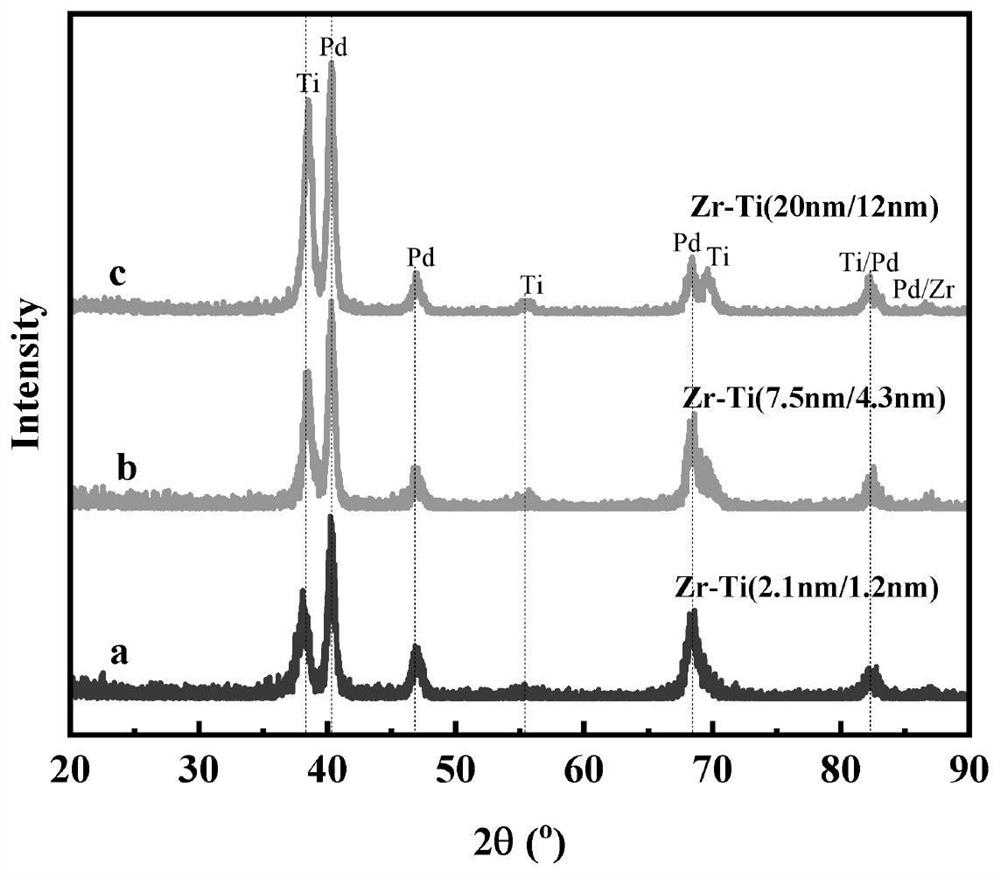

Nano multilayer structure metal hydrogen absorption film and preparation method and application thereof

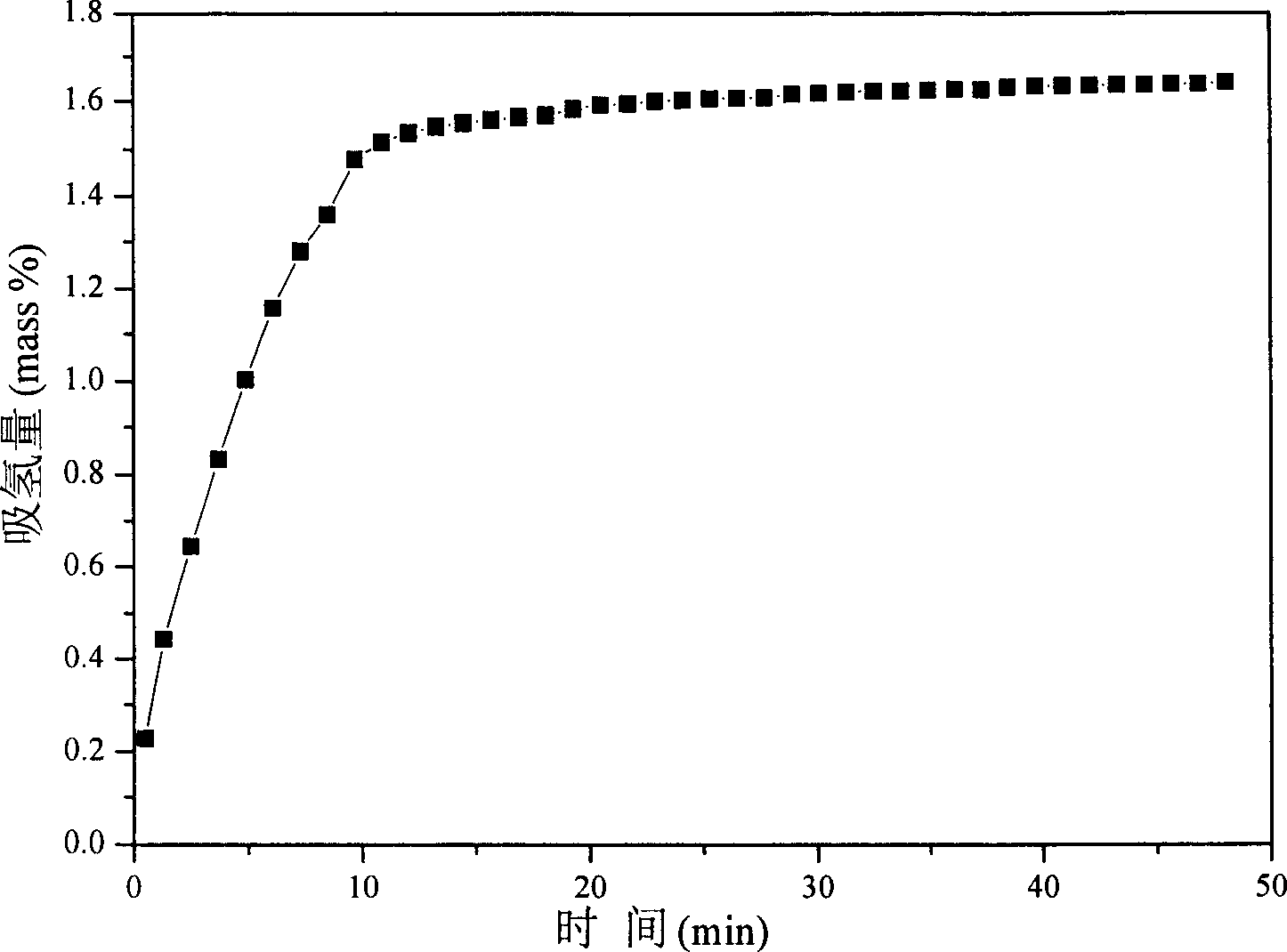

PendingCN114182205AHigh inspiratory rateImprove hydrogen absorption performanceMaterial nanotechnologySemi-permeable membranesPalladiumMetal catalyst

The invention provides a nano multilayer structure metal hydrogen absorption film as well as a preparation method and application thereof, and relates to the technical field of hydrogen absorption materials. The invention provides a nano multilayer structure metal hydrogen absorption film. The nano multilayer structure metal hydrogen absorption film comprises a nano multilayer structure metal layer and a metal catalyst layer which are sequentially arranged in a laminated mode. The nano multilayer structure metal layer comprises a plurality of hydrogen absorption metal layers which are alternately laminated; the hydrogen absorption metal layer comprises a zirconium layer and a titanium layer; the component of the metal catalyst layer comprises palladium. According to the invention, the nanometer multilayer structure metal layer has a good combination effect on hydrogen, the metal catalytic layer has catalytic activity on hydrogen, and the nanometer multilayer structure metal layer and the metal catalytic layer are arranged in a laminated manner, so that hydrogen in a closed space can be effectively absorbed.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

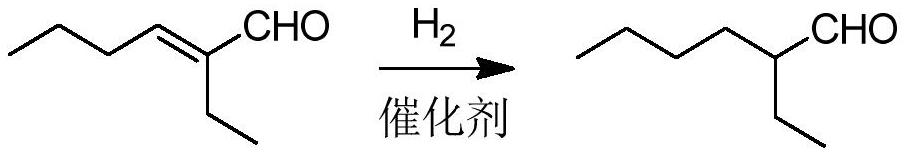

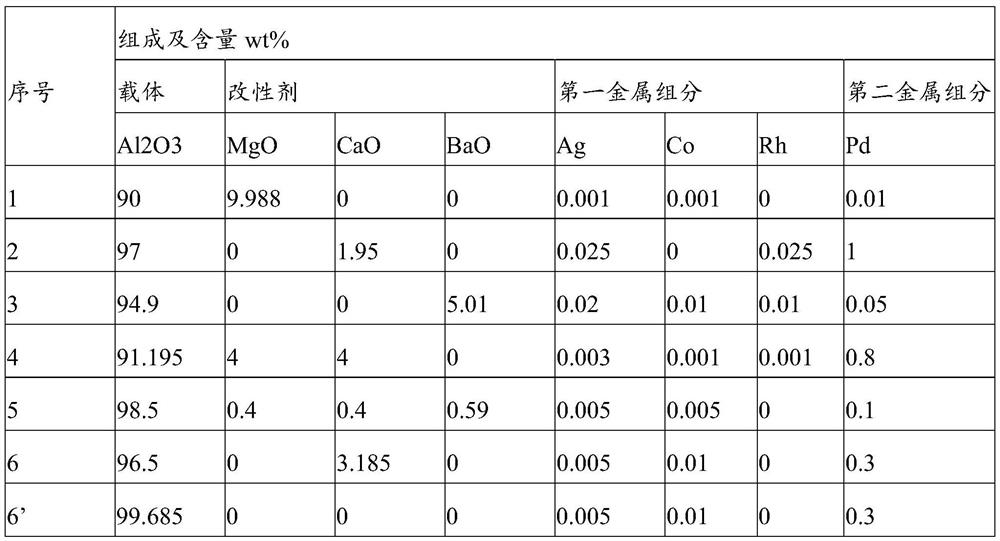

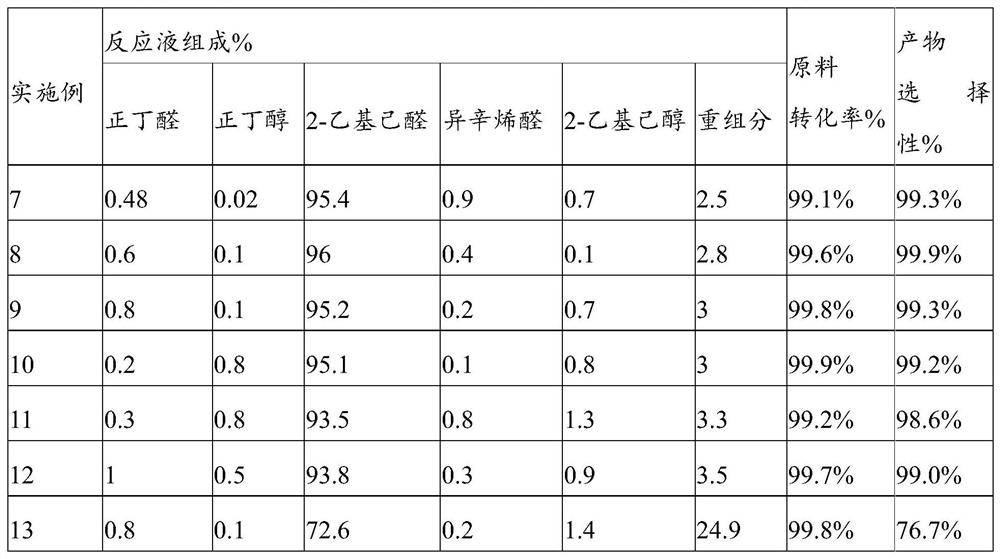

A kind of catalyst, its preparation method and the preparation method of 2-ethylhexanal

ActiveCN107930647BInhibit hydrogenationInhibition selectivityOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystHexaldehyde

The invention discloses a catalyst for preparing 2-ethylhexanal, comprising Al 2 o 3 carrier, and loaded on the Al 2 o 3 The first metal component and the second metal component on the carrier are characterized in that the first metal component is Ag, and one or both of Co and Rh; the second metal component is Pd ; Based on the total weight of the catalyst, the content of the first metal component is 0.01-0.5wt‰, and the content of the second metal component is 0.01-1.0wt%. The present invention also discloses a preparation method of the catalyst and a preparation method of 2-ethylhexanal. The invention can efficiently carry out the selective hydrogenation of isooctenal, greatly improves the catalyst processing capacity, has simple technological process, low energy consumption, and meanwhile, the raw material conversion rate reaches 99%, and the product selectivity reaches more than 98.5%.

Owner:WANHUA CHEM GRP CO LTD

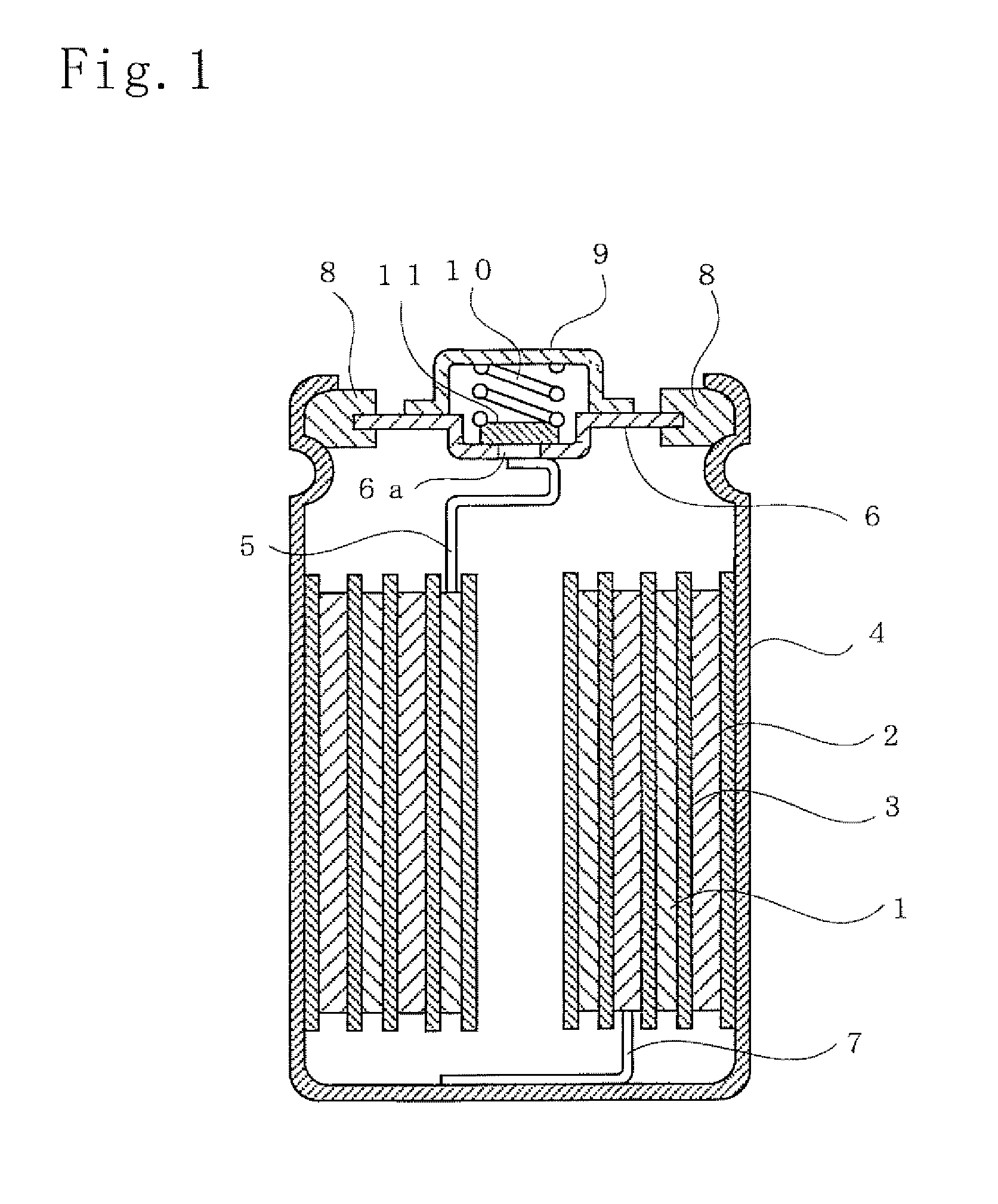

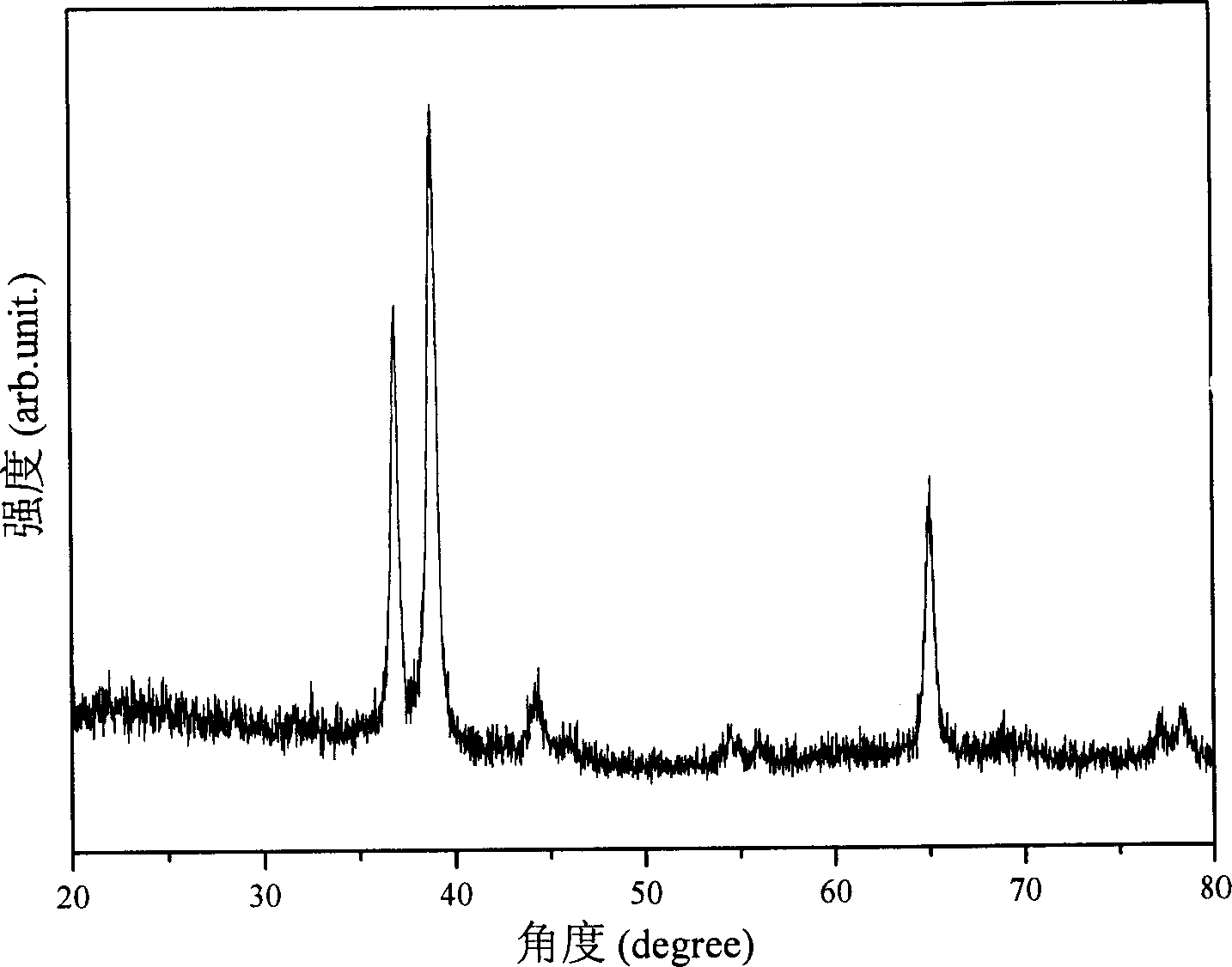

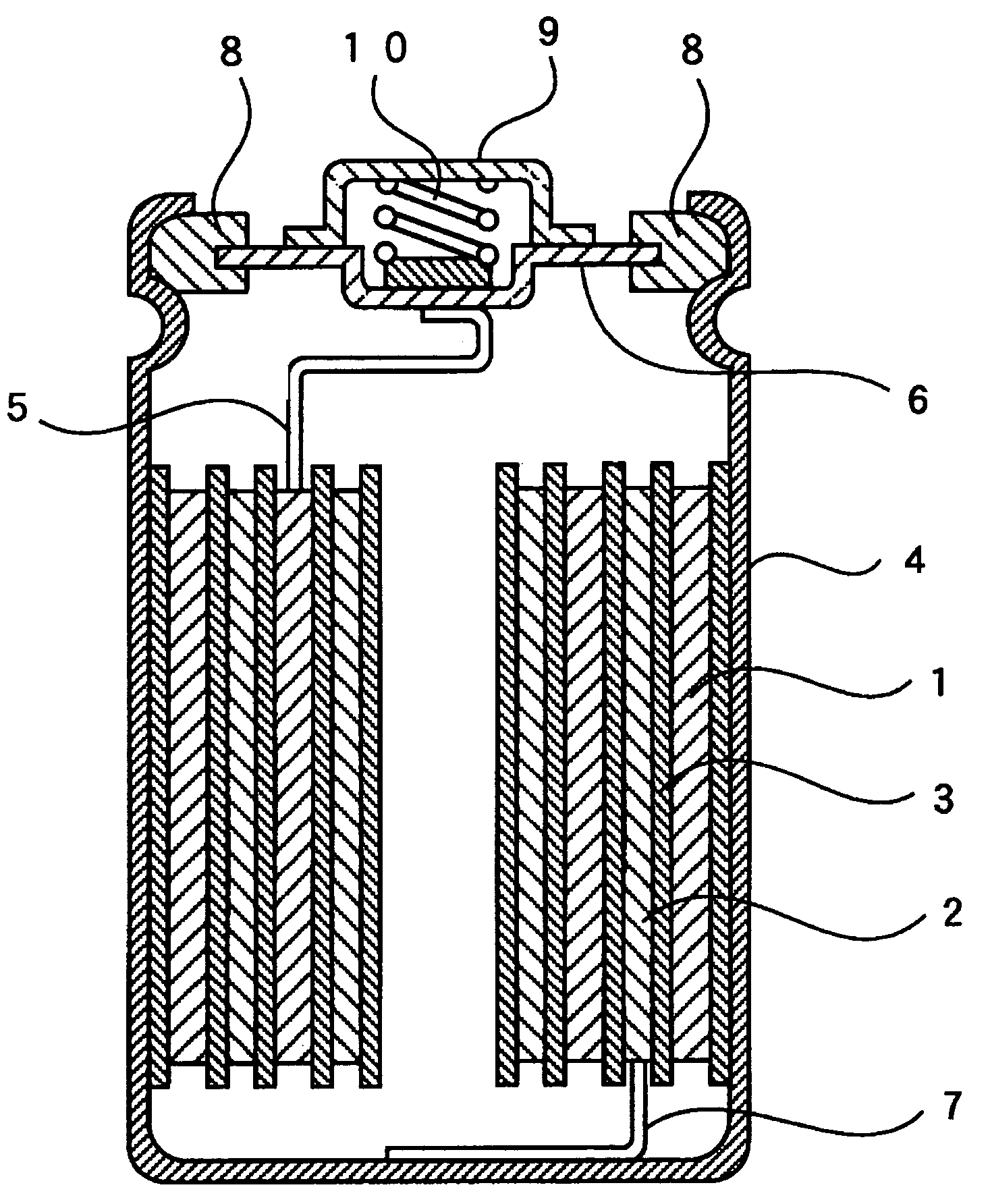

Hydrogen-absorbing alloy for alkaline storage battery, method of manufacturing the same, and alkaline storage battery

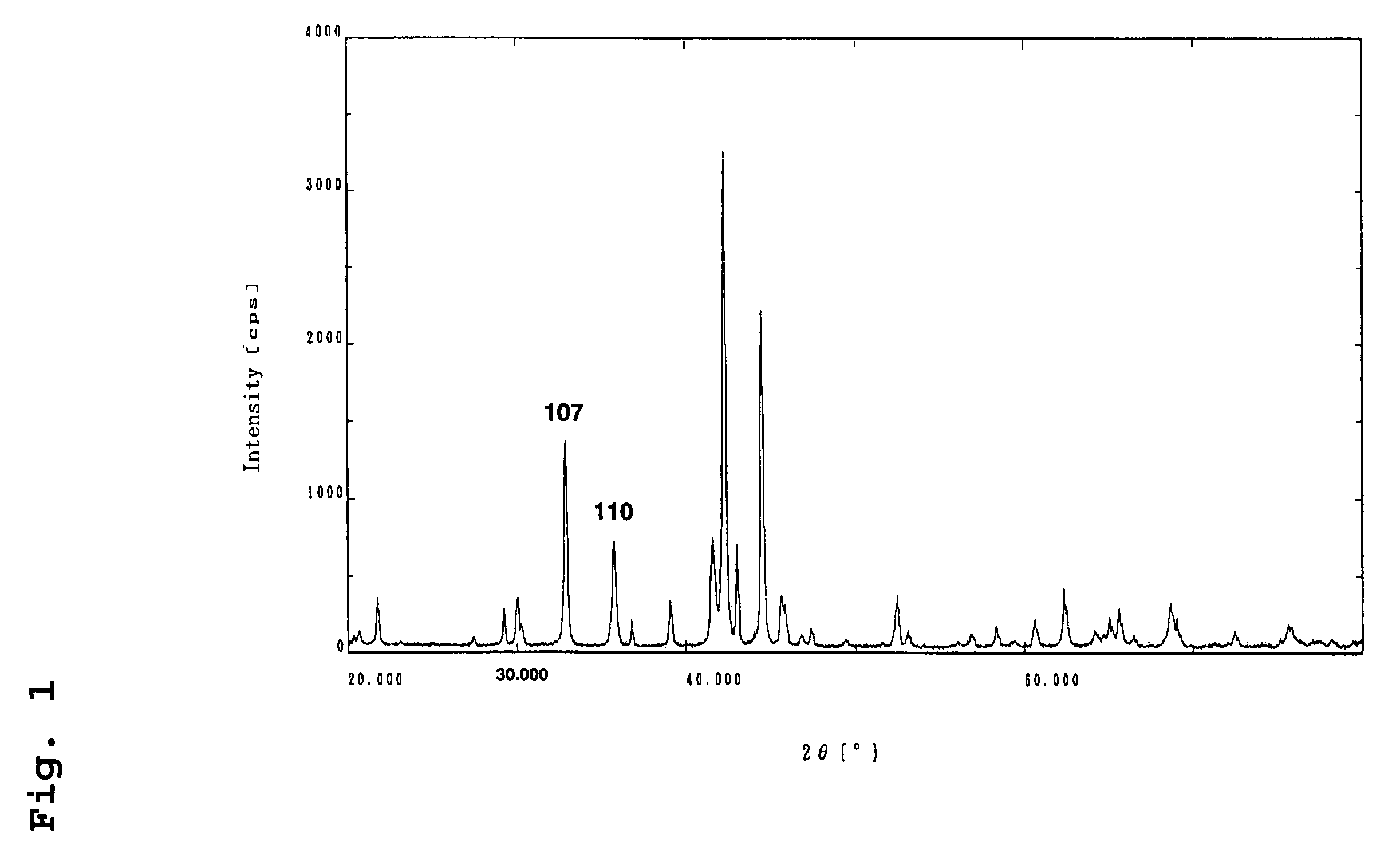

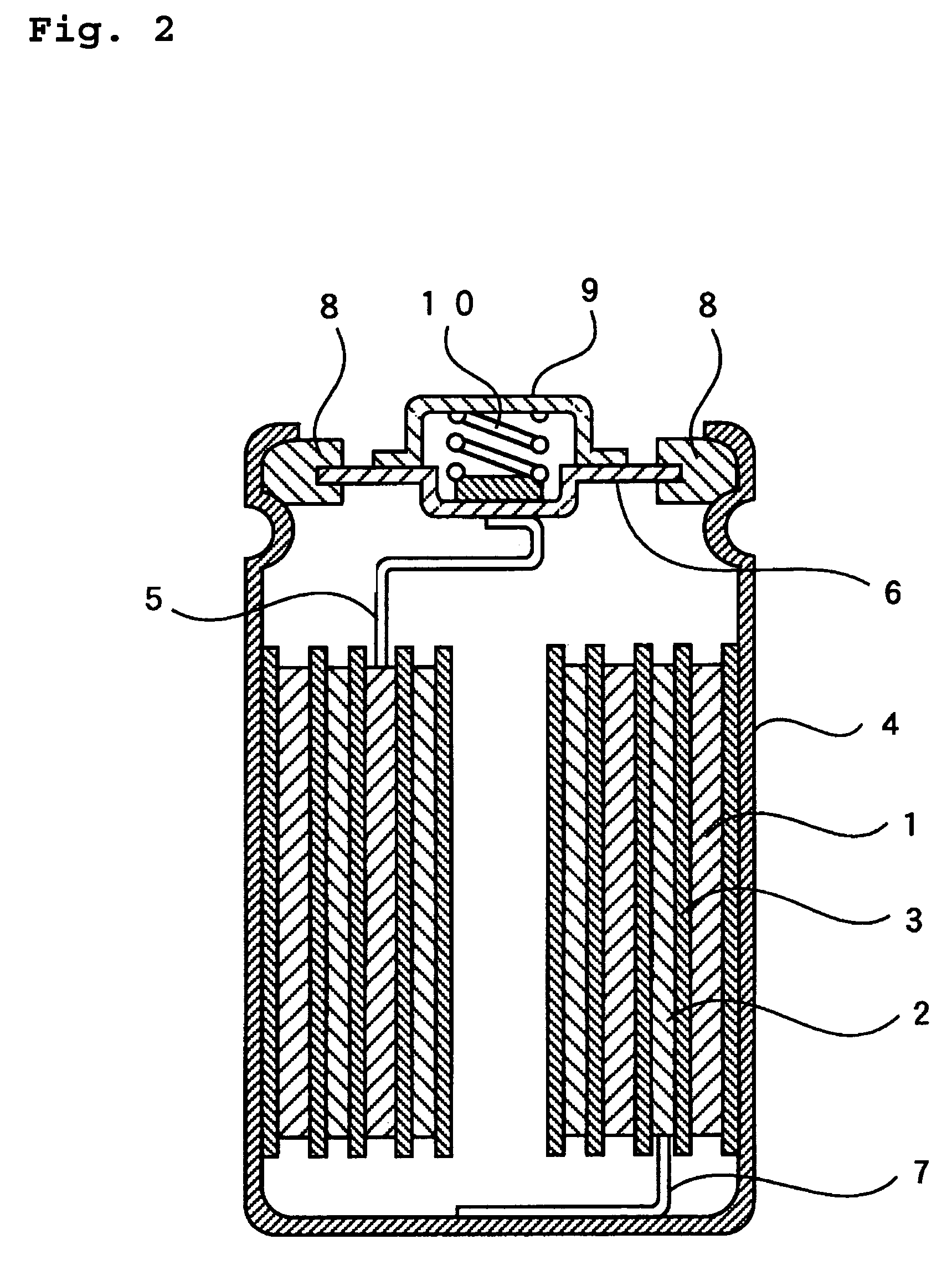

InactiveUS7514178B2Increase battery capacityImprove cycle lifeHydrogenAlkaline accumulatorsRare-earth elementX-ray

An alkaline storage battery including a positive electrode (1), a negative electrode (2) using a hydrogen-absorbing alloy, and an alkaline electrolyte solution employs, as the hydrogen-absorbing alloy in the negative electrode, a hydrogen-absorbing alloy for alkaline storage batteries including at least a rare-earth element, magnesium, nickel, and aluminum, and having an intensity ratio IA / IB of 1.00 or greater, wherein IA is the strongest peak intensity appearing in the range 2θ=32°-33° and IB is the strongest peak intensity appearing in the range 2θ=35°-36° in an X-ray diffraction analysis using Cu- Kα radiation as the X-ray source.

Owner:FDK CORP

A kind of preparation method of hydrogen absorbing element

ActiveCN104651652BLarge specific surface areaLow activation temperatureElectric discharge tubesHydrogen separation using solid contactDehydrogenationBiological activation

Owner:GRIMAT ENG INST CO LTD

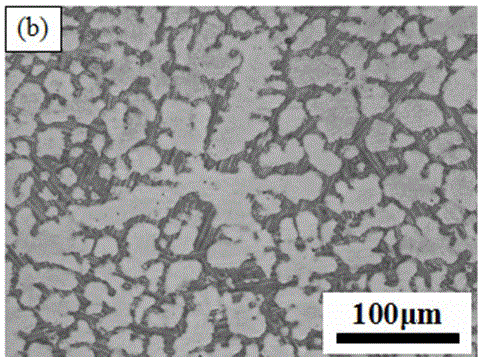

A kind of method for preparing the magnesium alloy gradient material reinforced by LPSO phase

The invention relates to a method for preparing an LPSO (Long Period stacking ordered) phase enhanced magnesium alloy gradient material, belonging to the field of intermetallic compound preparation technology. The method comprises the steps of firstly, mixing pure magnesium and pure yttrium to prepare an Mg-Y alloy block, and then sequentially overlaying a pure magnesium block, a pure zinc block and the Mg-Y alloy block from bottom to top; simultaneously heating the overlaid metal blocks prepared in the above step and divided into the upper part and the lower part so as to remove vapor, and then introducing a protective gas for melting; after the melting process is completed, stopping the heating to the lower part, introducing cooling water so as to cool the lower part, regulating the heating temperature of the upper part to be below 300 DEG C for one-way cooling, then stopping heating, cooling to room temperature, thus preparing the LPSO phase-enhanced magnesium alloy gradient material. According to the method, the LPSO phase enhanced gradient material can be prepared through upward dispersion of Mg element with lower density and downward settlement of Zn and Y atoms with high density in the one-way cooling process.

Owner:KUNMING UNIV OF SCI & TECH

Rare earth additive for hard alloy and preparation method thereof

ActiveCN102528017BImprove solid solution strengtheningImprove mechanical propertiesHydrogenGranularity

The invention discloses a rare earth additive for hard alloy. The rare earth additive for hard alloy is rare earth-binder phase alloy powder with a granularity smaller than 10mum, and the weight percentage of components of the raw materials are as follows: 60-99 percent of binder phase raw material and 1-40 percent of rare earth, wherein the binder phase raw material is formed by Co, Mn and M, and M is at least one out of Ni, Fe, Cr, V, Cu and Al. Two preparation methods are available for the rare earth additive. The first preparation method comprises the steps of casting the binder phase raw material and the rare earth into ingot, smashing the ingot into blocks with size smaller than 20mm, performing homogenizing annealing to the blocks under vacuum condition, or performing rapid quenching to the blocks in an electric-arc remelting rapid quenching furnace to form a rare earth-binder phase alloy thin strip and performing hydrogen absorption, and carrying out ball-milling smashing to the product treated by hydrogen absorption under the protection of argon. The second preparation method comprises the steps of casting the binder phase raw material and the rare earth into ingot, smashing the ingot into blocks with size smaller than 20mm, and performing atomization to the alloy blocks after the alloy blocks are smelted into alloy melts, so as to form atomized powder.

Owner:SICHUAN UNIV

A high-pressure hydrogen supply device and its manufacturing method and use method

The invention discloses a high-pressure hydrogen gas supply device, which comprises a closed hydrogen storage chemical bed filled with an LaNi5 material, an outlet pipeline connected with an inner space of the hydrogen storage chemical bed, a first high pressure valve and a pressure sensor which are arranged on the output pipeline, a heater arranged by wrapping the hydrogen storage chemical bed, and a temperature controller connected with the heater. The hydrogen is stored by adopting a solid hydrogen storage material, a large and bulky steel cylinder for storing high-pressure hydrogen gas is not needed, and the extremely low temperature conditions for the storage of liquid hydrogen are not needed; when the hydrogen needs to be stored, an alloy is reacted with hydrogen to produce a metal hydride and heat is released; when the hydrogen needs to be used, the hydrogen stored in the solid hydrogen storage material is released by heating or decompression.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

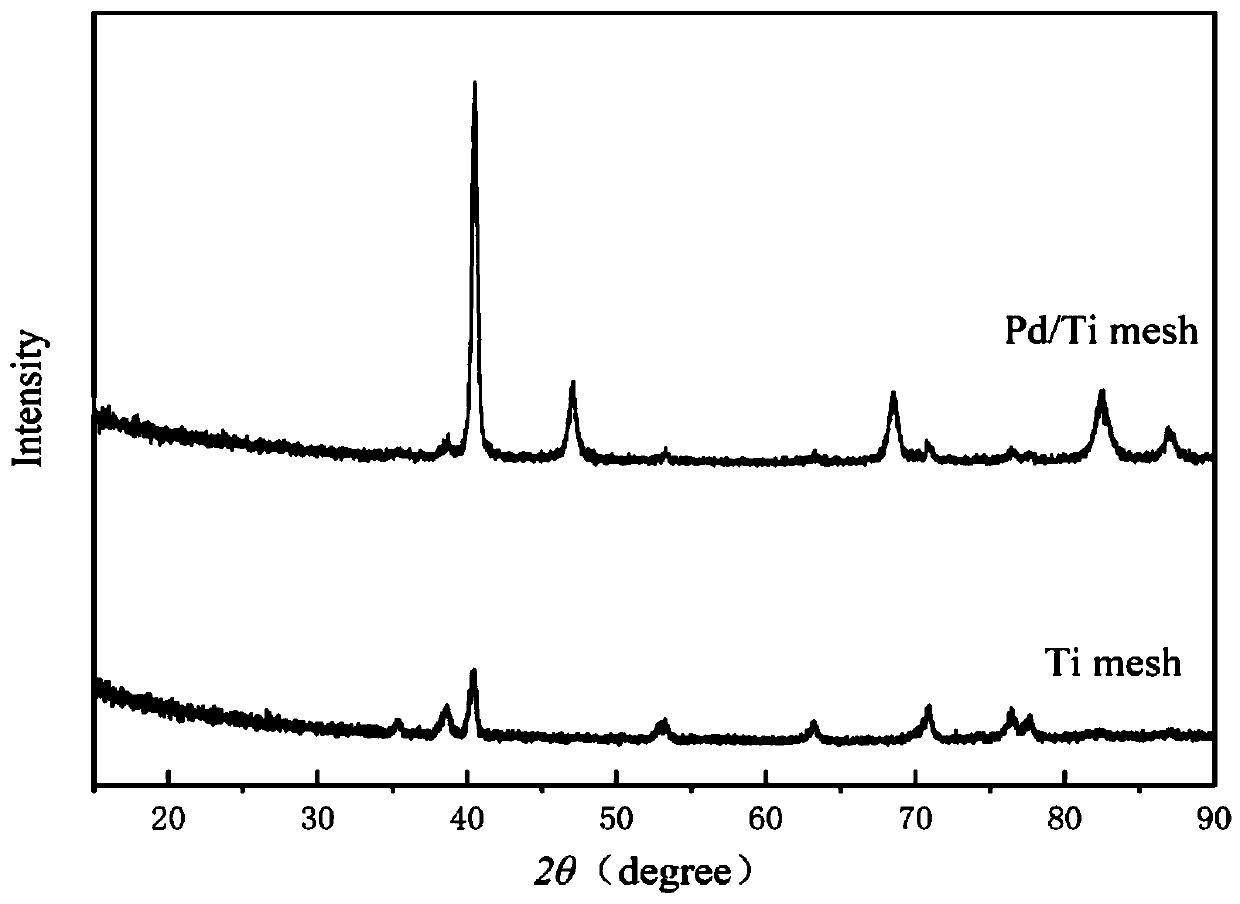

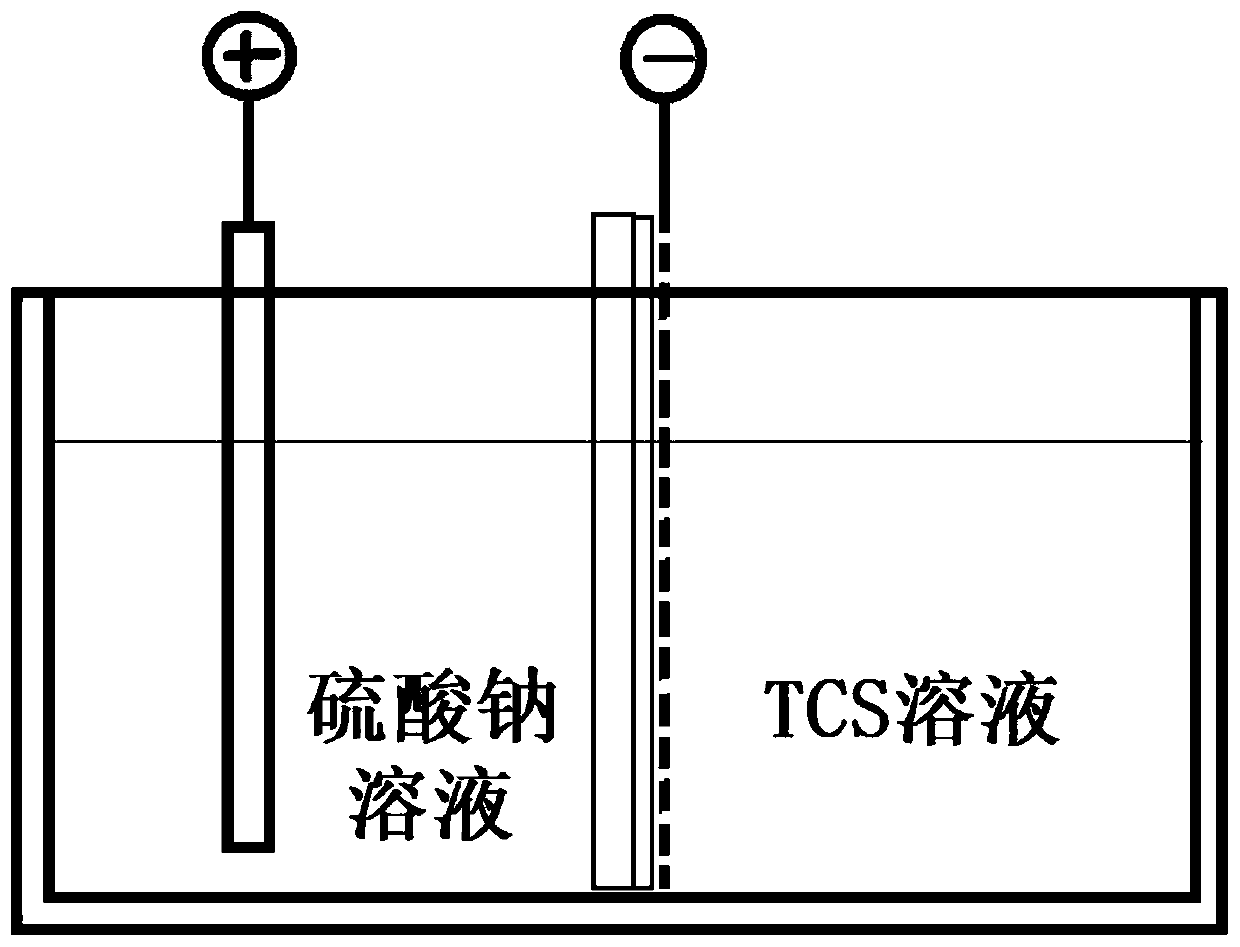

Method for removing trichloroethylene from groundwater through electroreduction

InactiveCN110272098AImprove selective adsorption performanceImprove reduction efficiencyWater contaminantsDispersed particle separationStop timeChemistry

The invention relates to a method for removing trichloroethylene from groundwater through electroreduction. The method includes the following steps that firstly, a trichloro ethylene containing water body is introduced into a cathode chamber of a double-chamber double-electrode electrochemical removal device, and the pH of the cathode chamber is adjusted to be 5.8-6.4; the electrolyte of an anode chamber is a 8-10 g / L sodium sulfate solution; after powering on, the voltage is kept at 2.5 V for chemical treatment, and according to an existing government standard, the chemical treatment stop time is determined. Through molecular imprinting technical process, and the side, at a cation membrane, of a bipolar membrane has selective adsorption performance for TCE so as to improve the reduction efficiency of the TCE by electrodes. Elemental palladium is deposited on Ti-mesh, and the hydrochlorination performance of the TCE by the electrodes is improved. Pd@Ti-mesh is compounded on the side, at the anode membrane, of the bipolar membrane to achieve a zero polar distance between the electrodes and the membrane. H+ produced by hydrolysis can directly reach a cathode, the content of H+ on the electrode surfaces is improved, and the reduction speed of the TCE by the electrodes is promoted.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com