CaMg2-based alloy hydride hydrolysis hydrogen production material and preparation method and application thereof

一种水解制氢、氢化物的技术,应用在多种金属氢化物、化学仪器和方法、氢等方向,能够解决氢化反应激活能高等问题,达到资源丰富、价格低廉、功耗少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of CaMg 1.9 Ni 0.1 The procedure for -H hydride is as follows:

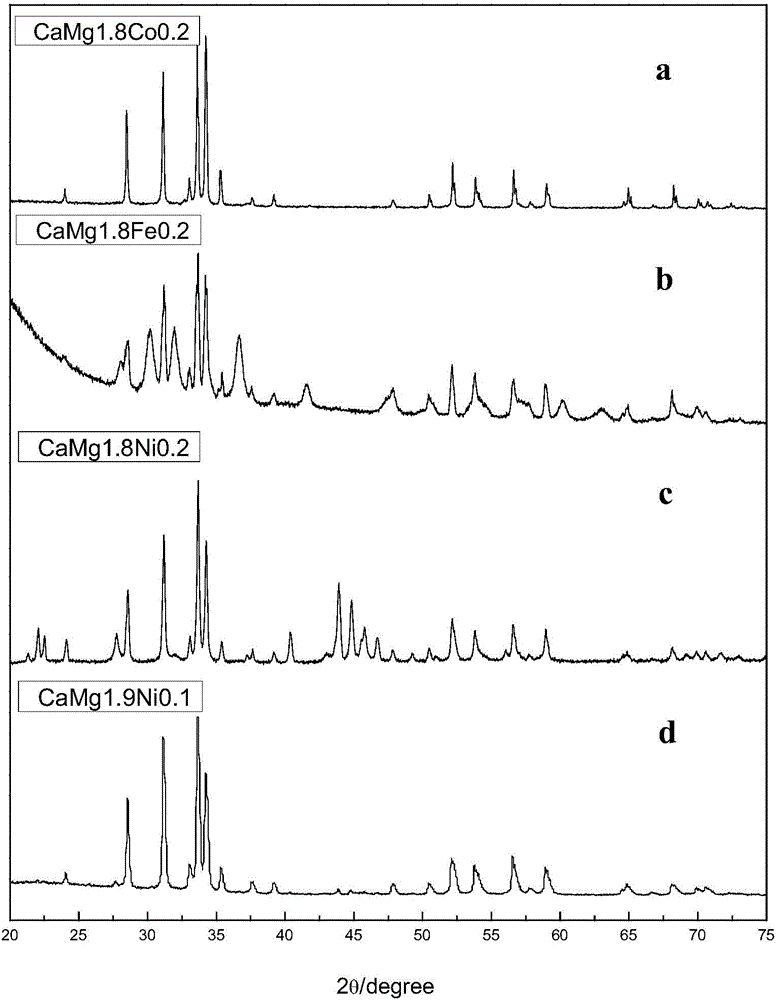

[0041] Weigh the pure metal (purity greater than 99%) with an atomic ratio of Ca:Mg:Ni of 1:1.9:0.1, wherein the burning losses of Ca and Mg are 7% and 6% respectively. Then put the weighed metals Ca, Mg, and Ni into the prepared crucible (the crucible is provided with a vent) in sequence, wherein the metal Ni block is put on top. Install the crucible into the high-frequency induction melting furnace and evacuate to 5×10 -3 Pa, and then 0.5atm argon gas was introduced as a protective gas. Start the high-frequency induction melting furnace, heat at the bottom power for 2 to 3 minutes, then increase the power to melt the alloy to a liquid state and keep it for 1 minute to mix the molten metal evenly, then cool down with the furnace to obtain alloy ingots, remelt twice and then cool with the furnace, obtained as CaMg 2 Based hydrogen storage alloy (see the attached X-ray diffraction pattern ...

Embodiment 2

[0043] Preparation of CaMg 1.8 Ni 0.2 The procedure for -H hydride is as follows:

[0044] Weigh the pure metal (purity greater than 99%) with an atomic ratio of Ca:Mg:Ni of 1:1.8:0.2, and add Ca and Mg to achieve a loss of 7%. Then put the weighed metals Ca, Mg, and Ni into the prepared crucible (the crucible is provided with a vent) in sequence, wherein the metal Ni block is put on top. Install the crucible into the high-frequency induction melting furnace and evacuate to 5×10 -3 Pa, and then 0.5atm argon gas was introduced as a protective gas. Start the high-frequency induction melting furnace, heat at the bottom power for 2 to 3 minutes, then increase the power to melt the alloy to a liquid state and keep it for 1 minute to mix the molten metal evenly, then cool down with the furnace to obtain alloy ingots, remelt twice and then cool with the furnace, obtained as CaMg 2 Based hydrogen storage alloy (see the attached X-ray diffraction pattern figure 1 in part c). Tak...

Embodiment 3

[0046] Preparation of CaMg 1.8 co 0.2 The procedure for -H hydride is as follows:

[0047] Weigh the pure metal with an atomic ratio of Ca:Mg:Co of 1:1.8:0.2 (purity greater than 99%), and add Ca and Mg to achieve a loss of 7%. Then put the weighed metals Ca, Mg, and Co into the prepared crucible (the crucible is provided with a vent hole) in sequence, and the metal Co block is placed on the top. Install the crucible into the high-frequency induction melting furnace and evacuate to 5×10 -3 Pa, and then 0.5atm argon gas was introduced as a protective gas. Start the high-frequency induction melting furnace, heat at the bottom power for 2 to 3 minutes, then increase the power to melt the alloy to a liquid state and keep it for 1 minute to mix the molten metal evenly, then cool down with the furnace to obtain alloy ingots, remelt twice and then cool with the furnace, obtained as CaMg 2 Based hydrogen storage alloy (see the attached X-ray diffraction pattern figure 1 part a)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com