Method for removing trichloroethylene from groundwater through electroreduction

A technology for trichlorethylene and groundwater, applied in reduced water/sewage treatment, polluted groundwater/leachate treatment, separation methods, etc., can solve the problem that it is difficult to meet the TCE content standard in underground drinking water, cannot effectively remove TCE, and remove TCE Reduced efficiency and current efficiency and other issues, to achieve good proton reduction and hydrogen absorption capacity, improve hydrodechlorination performance, and improve the effect of selective adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

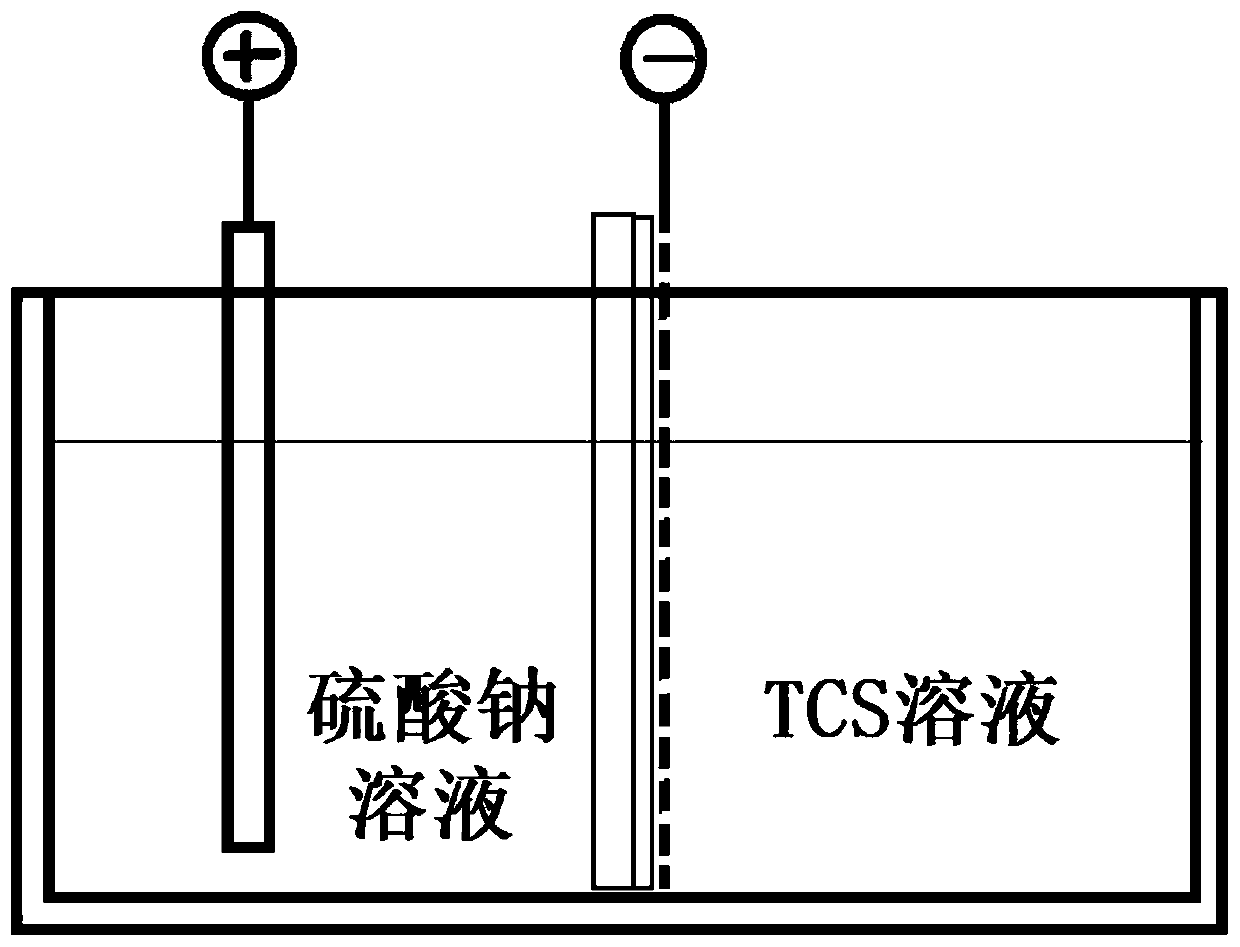

[0036] The double-chamber double-electrode electrochemical removal device used in this embodiment has a structure such as image 3 shown.

[0037] Introduce TCE-containing water into such image 3 In the cathode chamber of the shown double-chamber double-electrode electrochemical removal device, dilute sulfuric acid and sodium hydroxide solution are used to adjust the pH value, and the pH of the cathode chamber is controlled to be 6.0. The whole device is supplied with voltage by an electrochemical analyzer,

[0038] Keep the voltage at 2.5V. The electrolyte in the anode compartment is 10g / L sodium sulfate solution. The total length of chemical treatment is 240min, and the sampling method is interval sampling, and the sampling time is 0, 10, 20, 30, 45, 60, 90, 120, 180, 240min respectively. The data for some time periods are as follows:

[0039] TCE water body 90min 120min 180min 240min TCE concentration (μg / L) 87.9 74.8 68.5 63.8 Removal ...

Embodiment 2

[0047] Introduce TCE-containing water into such image 3 In the cathode chamber of the double-chamber double-electrode electrochemical removal device shown, the pH of the cathode chamber is controlled to be 5.8. Adjust with dilute sulfuric acid and sodium hydroxide solution. The entire device was supplied with voltage by an electrochemical analyzer, and the voltage was maintained at 2.5V. The anode compartment electrolyte is 8g / L sodium sulfate solution. The total time of chemical treatment is 240min, the sampling method is interval sampling, and the sampling time is 0, 10, 20, 30, 45, 60, 90, 120, 180, 240min.

[0048] The TCE-containing water body used in this example is a simulated water body, and the concentration of TCE in the water body is 750 μg / L

[0049] After the TCE-containing water was treated by the device for 240 minutes, the concentration of TCE was reduced to 56.6 μg / L, and the removal rate was 92.5%, which was lower than the TCE content standard (70 μg / L) o...

Embodiment 3

[0052] Introduce TCE-containing water into such image 3 In the cathode chamber of the double-chamber double-electrode electrochemical removal device shown, the pH of the cathode chamber is controlled to be 6.2. Adjust with dilute sulfuric acid and sodium hydroxide solution. The entire device was supplied with voltage by an electrochemical analyzer, and the voltage was maintained at 2.5V. The electrolyte in the anode compartment is 9g / L sodium sulfate solution. The chemical treatment time is 160min, the sampling method is interval sampling, and the sampling time is 60, 80, 100, 120, 140, 160min respectively.

[0053] The TCE-containing water body used in this example is a simulated water body, and the concentration of TCE in the water body is 500 μg / L.

[0054] After the TCE-containing wastewater was treated by the device for a total time of 160 minutes, the concentration of TCE was reduced to 41.2 μg / L, and the removal rate was 91.8%, which was lower than the standard of T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com