Nano multilayer structure metal hydrogen absorption film and preparation method and application thereof

A nano-multi-layer and metal technology, applied in the field of hydrogen absorbing materials, can solve the problems such as the hydrogen absorbing ability needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a nano-multilayer structure metal hydrogen-absorbing film described in the above technical solution, comprising the following steps:

[0037] Depositing a nanometer multilayer structure metal layer on the surface of the substrate to obtain a substrate / hydrogen-absorbing metal layer composite film;

[0038] The substrate / hydrogen-absorbing metal layer composite film is subjected to in-situ degassing treatment, and then a metal catalyst layer is deposited on the surface of the nano-multilayer structure metal layer to obtain a nano-multilayer structure metal hydrogen-absorbing film.

[0039] The invention deposits a nanometer multilayer structure metal layer on the substrate surface to obtain a substrate / hydrogen-absorbing metal layer composite film. In the present invention, the substrate preferably includes a silicon substrate. In the present invention, the deposition method is preferably a magnetron sputtering ...

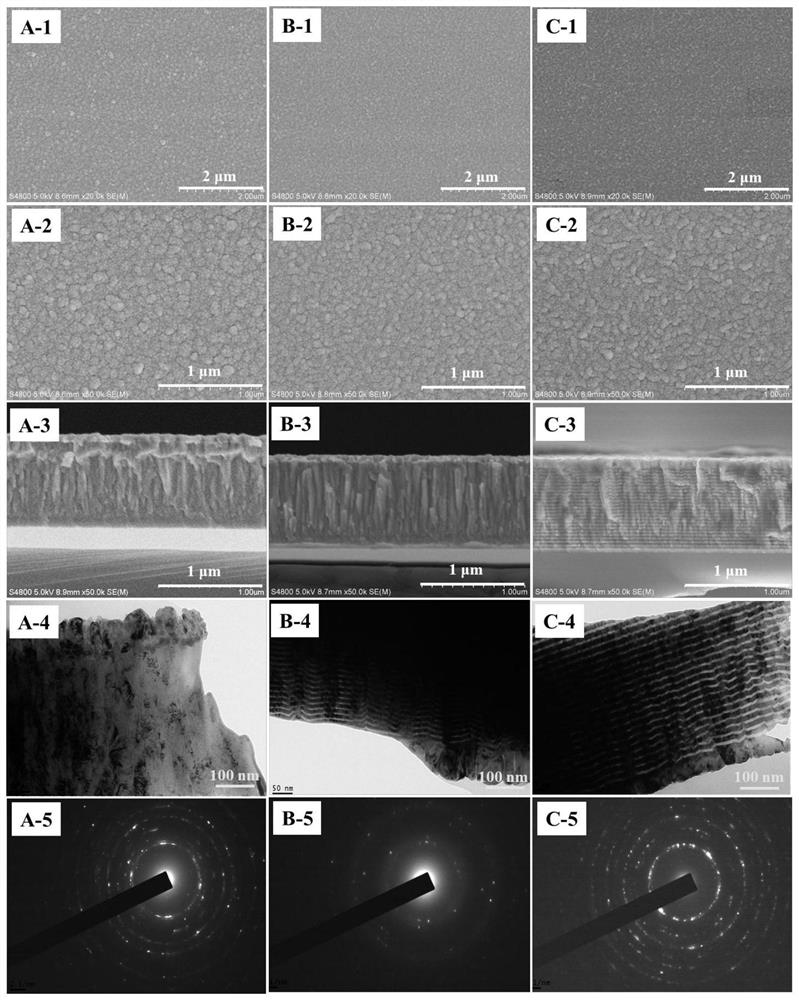

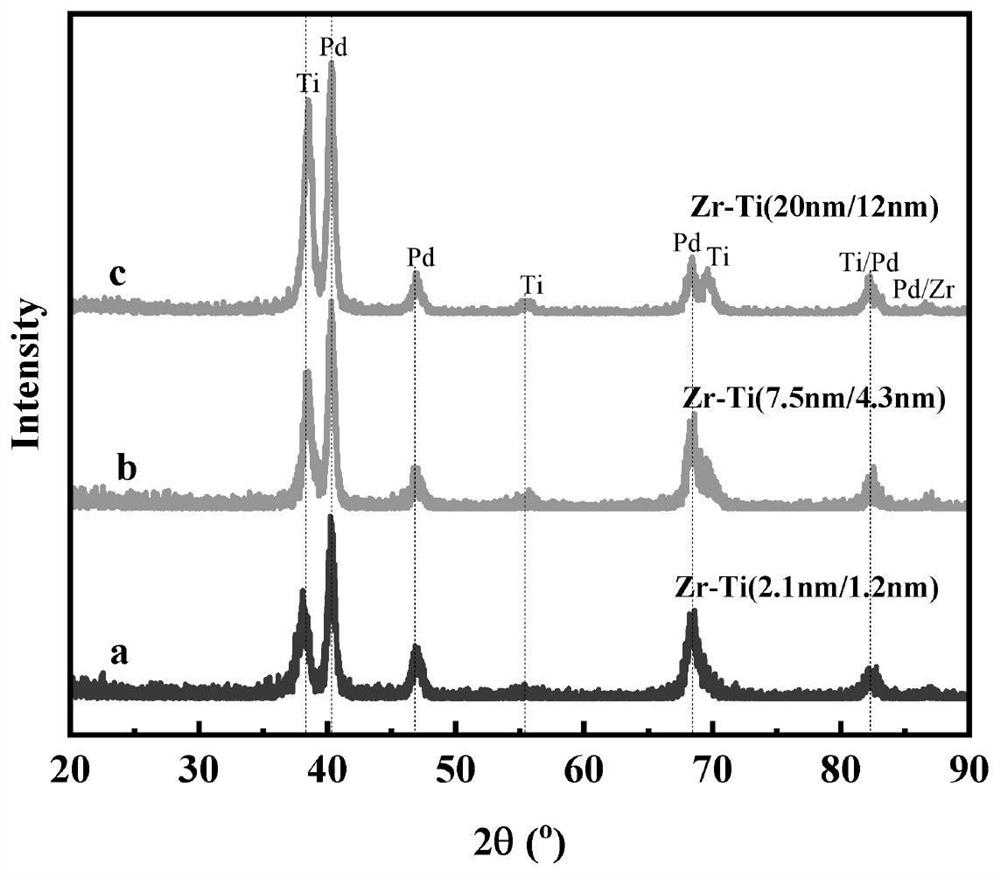

Embodiment 1

[0059] Nanostructured zirconium-titanium hydrogen-absorbing layer / palladium catalytic layer composite film, wherein the zirconium-titanium hydrogen-absorbing layer is 25 cycles of 20nmZr-12nmTi alternating layers; the thickness of the palladium catalytic layer is 100nm.

[0060] Put the silicon substrate into the ultra-high vacuum chamber of the magnetron sputtering system, and evacuate until the background vacuum of the chamber is less than 5×10 -6 Pa; then feed high-purity argon (Ar, 99.999%), when the argon flow rate is 5sccm, the target sputtering power is 100W, and the target base distance is 8cm, a single target is used to alternately deposit zirconium and titanium hydrogen-absorbing metal films, Alternately deposit 25 cycles to prepare a hydrogen-absorbing metal film with a total thickness of 800nm, a zirconium single-layer thickness of 20nm, and a titanium single-layer thickness of 12nm. Palladium deposits palladium catalytic layer, and deposition time is 15min, obtain...

Embodiment 2

[0064] Nanostructured zirconium-titanium hydrogen-absorbing layer / palladium catalytic layer composite film, wherein the zirconium-titanium hydrogen-absorbing layer is 66 cycles of 7.5nmZr-4.3nmTi alternating layers; the thickness of the palladium catalytic layer is 100nm.

[0065] Put the silicon substrate into the ultra-high vacuum chamber of the magnetron sputtering system, and evacuate until the background vacuum of the chamber is less than 5×10 -4 Pa; then feed high-purity argon gas (Ar, 99.999%), when the argon gas flow rate is 5 sccm, the target sputtering power is 100W, and the target base distance is 8cm, a single target is used to alternately deposit zirconium or titanium hydrogen-absorbing metal films, Alternately deposit 66 cycles to prepare a hydrogen-absorbing metal film with a total thickness of 765.6nm, a single layer of zirconium with a thickness of 7.3nm, and a single layer of titanium with a thickness of 4.3nm. The palladium catalyst layer was deposited by si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com