A device for enhancing adsorption rate by radio frequency discharge plasma

A plasma and radio frequency discharge technology, applied in the direction of plasma, electrical components, etc., can solve the problem of slow gas adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

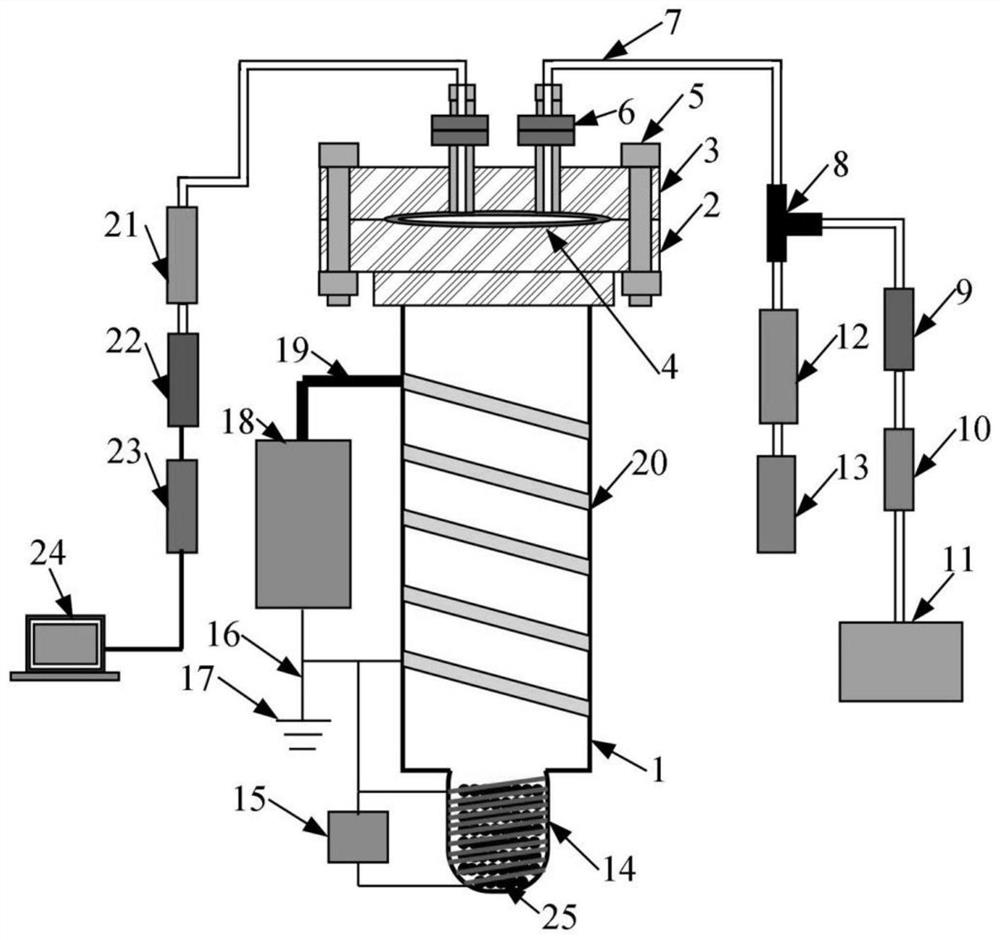

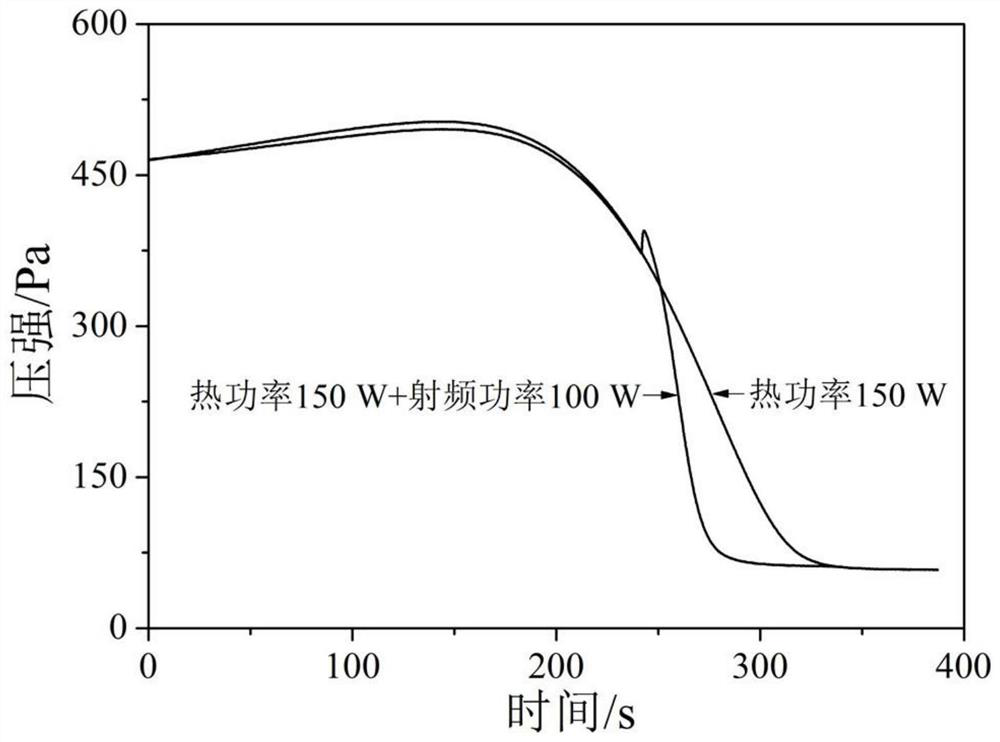

[0032] The radio frequency power source used in this embodiment is 13.56MHz, and the output power is adjustable within 500W. The high-voltage output end of the RF power supply is connected to one end of the copper solenoid with a diameter of 6mm through a high-frequency coaxial line with a metal mesh on the outside, and the low-voltage output end is connected to the ground wire and connected to the copper solenoid through a wire on the other end. The copper solenoid consists of 10 turns, with an inner diameter of 40mm, nested and coiled outside the hollow container of the vacuum chamber. The hollow container is made of high-temperature-resistant quartz material. It is a hollow cylindrical structure with a thick upper end and a thinner end. The outer diameter of the upper end is 40mm, the thickness of the tube wall is 2mm, and the height is 145mm. The outer diameter of the lower end is 20mm, the wall thickness is 2mm, and the height is 50mm. The upper opening of the hollow con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com