Columnar radio frequency inductive coupling discharge plasma enhanced getter device

A technology of discharge plasma and inductive coupling, applied in the direction of plasma, electrical components, separation methods, etc., can solve the problems of slow gas absorption rate, low electrothermal conversion efficiency, and limit the comprehensive application function of getters, so as to achieve faster gas absorption rate, improving the effect of slow inhalation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

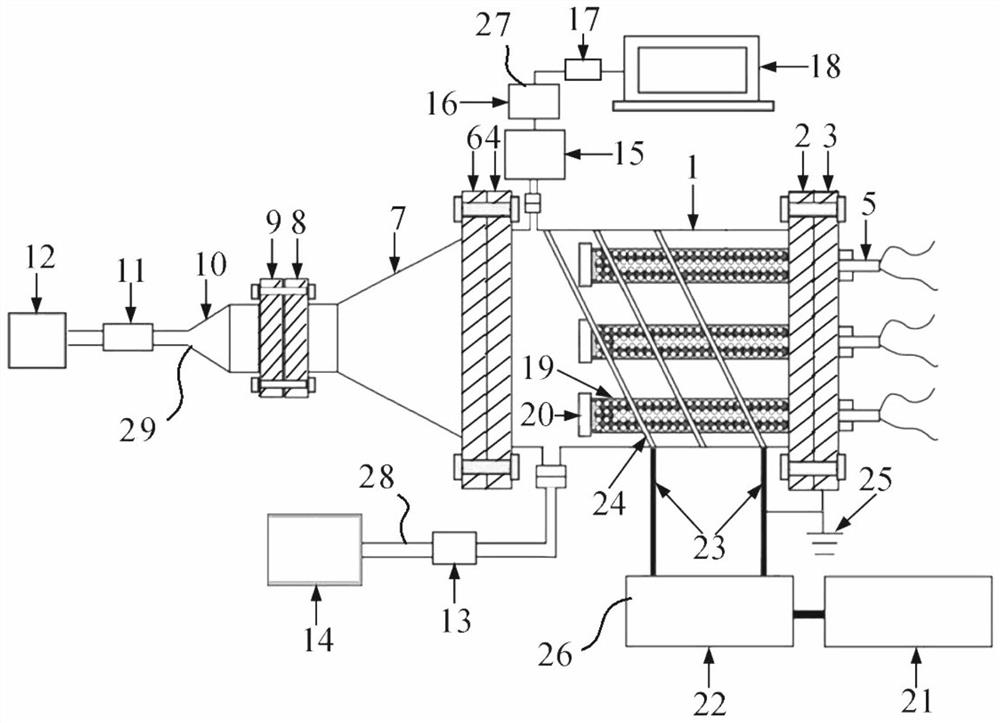

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, the present invention includes an air supply system 29, a diffuser 7 and a vacuum chamber 1 connected in sequence, wherein the vacuum chamber 1 is provided with a hollow cylinder 19 with holes on the wall, and the hollow cylinder 19 with holes on the wall is provided in the vacuum chamber 1 The upper end is sealed, the lower end is open, and the outer wall is sealed with the bottom end of the vacuum chamber 1. An electric heating element 5 is arranged in the hollow cylinder 19 with holes on the wall, and the lower end of the electric heating element 5 is formed by the hollow cylinder 19 with holes on the wall. The opening at the lower end extends out of the vacuum chamber 1 and is connected to an external power supply. The outside of the vacuum chamber 1 is provided with a radio frequency coupling helical coil 24 , and a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com