Device for activating large-volume getter and enhancing adsorption rate by radio-frequency discharge plasma

A plasma and radio frequency discharge technology, used in separation methods, dispersed particle separation, other chemical processes, etc., can solve the problems of long activation time of heated getters and slow adsorption rate of some gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in combination with the accompanying drawings in the embodiments of the present invention, and further detailed descriptions will be given, but the embodiments of the present invention are not limited thereto.

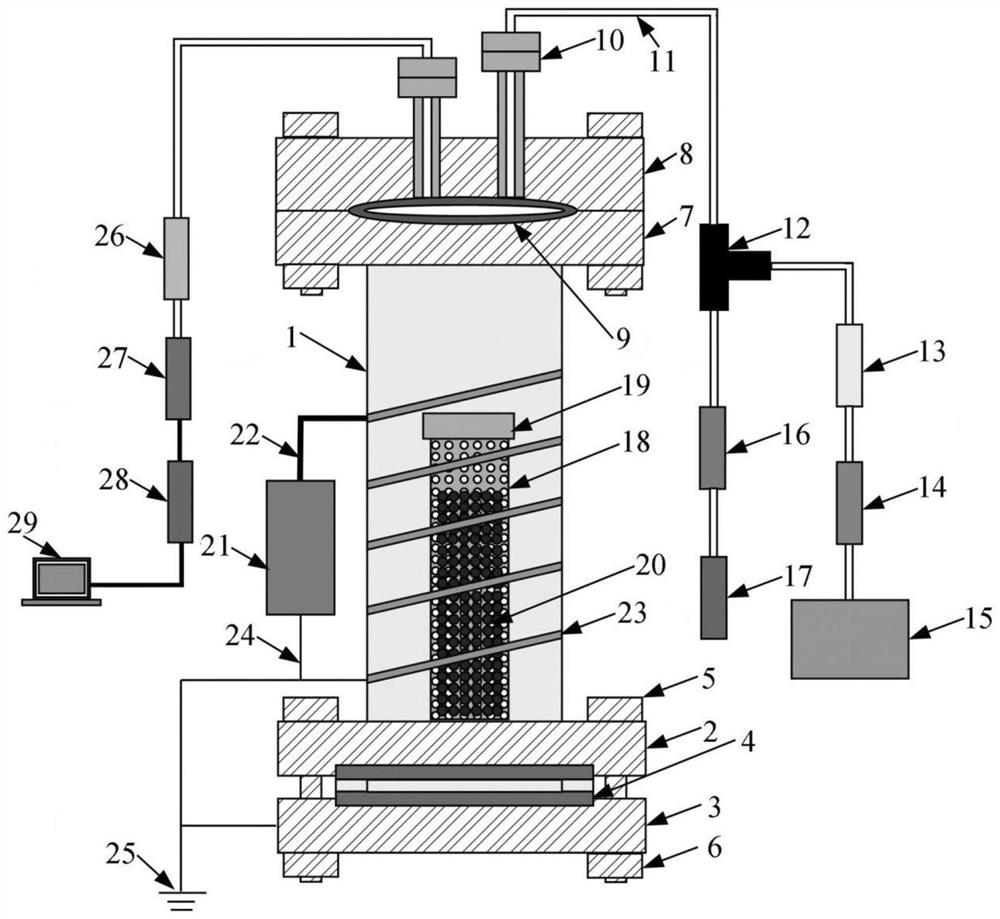

[0025] The accompanying drawing is a schematic diagram of a device for activating a large-volume getter by radio frequency discharge plasma and enhancing the adsorption rate, which includes a vacuum chamber, vacuum system components, gas supply system components, radio frequency power supply system, air pressure acquisition system components and suction Aerosol.

[0026]The vacuum chamber consists of 1-hollow container; 2-the upper cover of the sealing flange at the bottom of the vacuum chamber; 3-the lower cover of the sealing flange at the bottom of the vacuum chamber; 4-graphite gasket; 5-screw; 6-nut; 7- The lower cover of the sealing flange at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com