A kind of preparation technology of titanium-based getter

A preparation process and getter technology, which is applied in the field of preparation technology of titanium-based getters, can solve the problems such as the decrease in the gettering ability of materials, easy introduction of harmful gases, oxidation, etc. high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

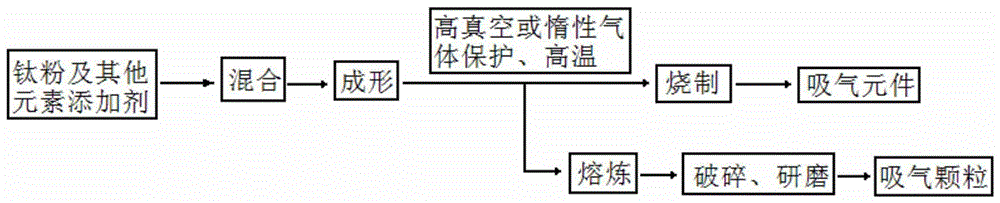

Method used

Image

Examples

preparation example Construction

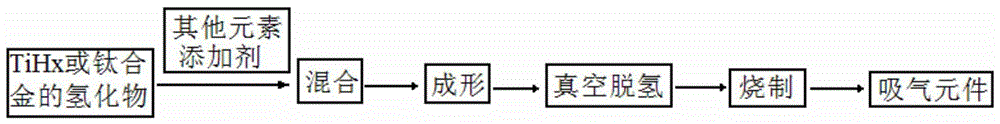

[0016] Such as figure 2 Shown is the flow chart of the preparation process of the titanium-based getter of the present invention. When TiHx is used as raw material, it is mixed with one or more of V, Fe, Nb, Zr, Mn, Al, Mo, Ni, rare earth elements, etc. or alloy powders composed of these elements, and then vacuum desorbed. Hydrogen sintering, and finally a highly active titanium-based getter element is made. The specific operation process is: first weigh a specific mass of TiHx, mix it with other getter elements according to a certain ratio, and then form it, then put the formed billet into the vacuum dehydrogenation and sintering integrated furnace, and evacuate the vacuum in the furnace to 10 -3 ~10 -5 Pa, and heat up to 55-750°C for dehydrogenation. As the dehydrogenation vacuum begins to drop, continue to evacuate to 10 -3 ~10 -5 Pa, after stabilizing for 1-2.5 hours, the temperature is raised to 800-950°C for sintering and forming of the getter, and then the temper...

Embodiment 1

[0020] TiH 2 Mix with Mo according to the mass ratio of 9:1, and then make a green body of a specific shape, and then put it into a vacuum dehydrogenation sintering furnace for dehydrogenation sintering, and vacuumize to 10 -3 Pa, keep it for 1h, stop vacuuming, put in hydrogen to carry out suction reaction, keep the air pressure in the furnace at 1.1MPa, hydrogen flow at 0.6L / min, keep at 900°C for 1.5h, keep the pressure constant, slowly The temperature is lowered to 50° C., and the finished product is ready after cooling. Compared with the air-absorbing element prepared by the traditional process, the air-absorbing rate and air-absorbing capacity are respectively increased by 22% and 24%.

Embodiment 2

[0022] TiH 0.5 Mix with V and Fe according to the mass ratio of 6:1:3, then form a green body of a specific shape, then put it into a vacuum dehydrogenation sintering furnace for dehydrogenation sintering, and vacuumize to 10 -4 Pa, keep it for 1h, stop vacuuming, put in hydrogen to carry out suction reaction, the air pressure in the furnace is kept at 1.1MPa, the hydrogen flow rate is 0.8L / min, keep at 1000°C for 3.5h, after the pressure remains unchanged, slowly The temperature is lowered to 50° C., and the finished product is ready after cooling. Compared with the getter element prepared by the traditional process, the suction rate and the getter capacity are respectively increased by 20% and 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com