Composite structure getter film and preparation method thereof

A technology of getter film and composite structure, which is applied in vacuum evaporation coating, coating, sputtering coating, etc., and can solve the problem of low suction capacity of getter film, short vacuum maintenance time, and low ultimate vacuum degree. Advanced problems, to achieve the effects of strong designability, good film mechanical properties, high versatility and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

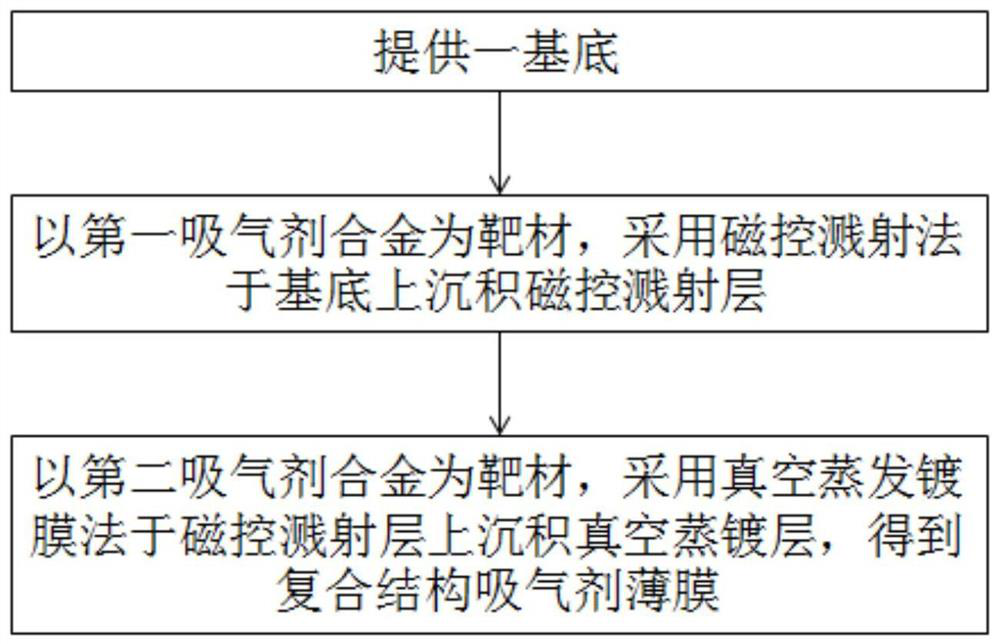

[0038] Such as figure 1 As shown, in this embodiment, the preparation method of the composite structure getter film proposed by the present disclosure includes: providing a substrate; using the first getter alloy as a target material, depositing a magnetic alloy on the substrate by magnetron sputtering a controlled sputtering layer; and using the second getter alloy as a target material, a vacuum evaporation layer is deposited on the magnetron sputtering layer by a vacuum evaporation coating method to obtain a composite structure getter film. Figure 2A-Figure 2D A schematic structural view showing the preparation process of the composite structure getter film according to an embodiment of the present disclosure. The structure, connection mode and functional relationship of each main component of an exemplary embodiment of the composite structure getter film and its preparation method proposed in the present disclosure will be described in detail below with reference to the ab...

Embodiment 1

[0055] Zr-V-Fe composite films with thicknesses of 20nm, 500nm and 0.8μm were prepared by high-power pulse magnetron sputtering, medium-frequency magnetron sputtering and resistance evaporation on glass slides cleaned by alcohol and acetone ultrasonically. The sputtering target used is Zr 73.6 V 3.36 Fe 23.04 at.% alloy target, purity 99.0, circular planar target with size Ф160mm×5mm, the manufacturing process is vacuum melting and casting. in:

[0056] The power of high-power pulsed magnetron sputtering is 15kW, the average current is 0.4A, the duty ratio is 0.02, the pulse frequency is 100Hz, the pulse width is 200μs, the target base distance is 10cm, the coating time is 1800s, and the high power density (greater than 1000W / cm 2 ) under the action, the surface of the obtained film layer is dense, without voids and defects such as large particles.

[0057] The power of medium frequency magnetron sputtering is 8kW, the current is 25.3A, the power frequency is 40kHz, and th...

Embodiment 2

[0060] With P-type Si sheet as the coating substrate, Zr 76.2 co 20.7 Ce 3.1 at.% alloy target, preparation of rare earth Ce-doped Zr-Co composite structure getter film. During the high-power pulse coating process, the substrate is applied with a pulse bias voltage of -80V, and the coating time is 1200s. Other process conditions are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com