Crystal blank grinding and polishing pick-up device

A technology for picking up devices and blanks, which is applied to grinding/polishing equipment, grinding machines, spherical grinders, etc., and can solve problems such as difficulty in installing clamping parts, low production efficiency, and complex structures for crystal blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

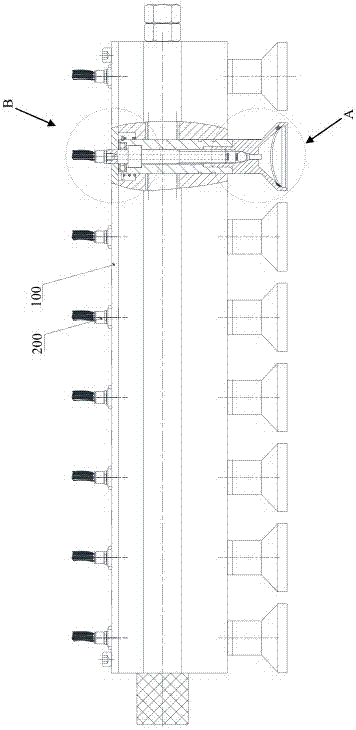

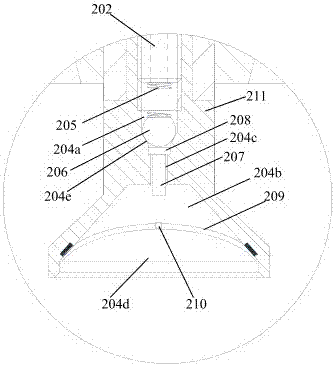

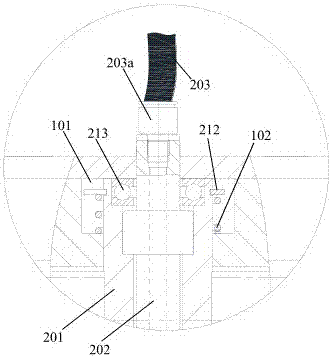

[0018] This embodiment provides a crystal blank grinding and polishing pick-up device, such as figure 1 As shown, it includes a housing 100 and at least one pick-up unit 200 installed on the housing; the pick-up unit 200 includes a shaft sleeve 201 and a hollow shaft 202 vertically arranged on the shaft sleeve 201, and the hollow shaft 202 The upper end is connected with an air pipe 203, and the hollow shaft 202 and the air pipe 203 are connected through a rotary joint 203a, so that the hollow shaft 202 can rotate relative to the air pipe 203, and at the same time, the connection between the air pipe 203 and the hollow shaft 202 can be ensured. connectivity.

[0019] A cavity is provided below the hollow shaft 202, and the trachea 203 and the hollow shaft 202 form an air passage to communicate with the cavity; the cavity includes a first part 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com