Preparation method of porous polymer

A technology of a porous polymer and a synthesis method is applied in the field of the preparation of porous polymers to achieve the effects of low cost of raw materials, strong hydrogen storage capacity and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

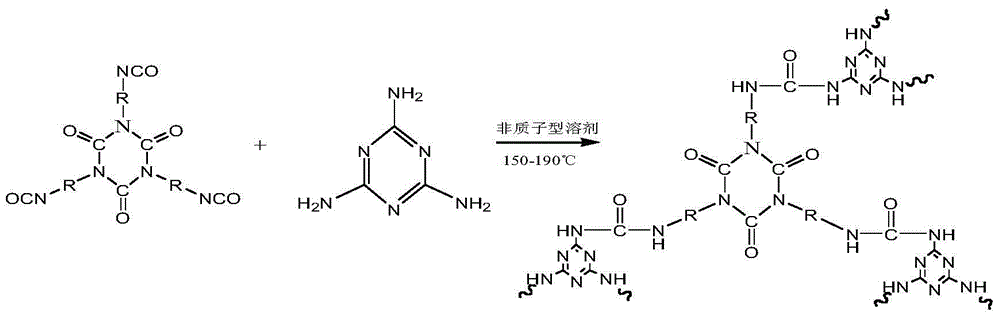

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the synthesis of MDI trimer

[0019] Mix 44.4g of MDI monomer (MDI is 4,4'-diphenylmethane diisocyanate) with 50mL of toluene, turn on the stirrer, and add 2,4,6-tris(dimethylamino Methyl) phenol, when the molar content of isocyanate is 8% at 60°C, add polymerization inhibitor benzoyl chloride, and react at constant temperature for 30 minutes, cool, filter, rinse with toluene to remove MDI monomer and catalyzer, obtain MDI trimer, the mass addition of described 2,4,6-tris(dimethylaminomethyl)phenol, benzoyl chloride is respectively 0.05%, 0.05% of MDI monomer , wherein, the molar content of isocyanate in the reactant is determined by di-n-butylamine titration.

Embodiment 2

[0020] Example 2: Synthesis of Porous Polymers

[0021] 1) Weigh 1.44g of melamine and 30mL of dimethyl sulfoxide (DMSO for English abbreviation) and mix, turn on the stirrer, and after dissolving, add 1g of MDI trimer, react at 180°C for 24h, and filter with suction. Rinse the sample with acetone for 3 times, and then dry it for 24 hours at a temperature of 180°C and a vacuum of -0.1MPa to obtain the intermediate product;

[0022] 2) Put the intermediate product in chloroform, and reflux at 70°C for 12 hours to form a porous polymer. After testing, the specific surface area of the porous polymer is 144m 2 / g, the micropore volume accounts for 12.5% of the total pore volume, the most probable pore diameter in the micropore is 0.88nm, the hydrogen adsorption capacity under the conditions of 77K and 1.5MPa is 0.13wt%, and when the maximum constant volume pressure is 7MPa, The hydrogen adsorption amount under the condition of 5.1MPa is 8.6wt%.

Embodiment 3

[0023] Example 3: Synthesis of Porous Polymers

[0024] 1) Weigh 1.8g of melamine and 30mL of dimethyl sulfoxide and mix it, turn on the stirrer, after dissolving, add 1g of MDI trimer, react at 180°C for 24h, filter with suction, and rinse the sample with acetone for 3 times , and then dried for 24 hours at a temperature of 180°C and a vacuum of -0.1MPa to obtain the medium product;

[0025] 2) Put the intermediate product in chloroform, and reflux at 70°C for 12 hours to form a porous polymer. After testing, the specific surface area of the porous polymer is 276m 2 / g, the micropore volume accounts for 18.3% of the total pore volume, the most probable pore diameters in the micropores are 0.85nm, the hydrogen adsorption capacity under the conditions of 77K and 1.5MPa is 0.95wt%, and the maximum constant volume pressure is 7MPa , the hydrogen adsorption amount under the equilibrium condition of 5.8MPa is 5.8wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com