Preparation method of composite hydrogen absorption material

A hydrogen-absorbing material and alloy technology, applied in the direction of reversible hydrogen absorption, chemical instruments and methods, hydrogen, etc., can solve the problems of low hydrogen absorption capacity, poor hydrogen absorption performance, etc., to increase hydrogen absorption capacity, improve hydrogen absorption performance, The effect of effective hydrogen absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

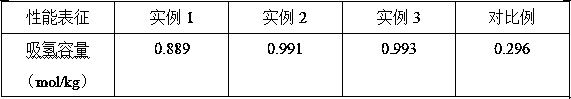

Examples

Embodiment Construction

[0020] Take 60~70g of magnesium aluminum alloy, 30~40g of microcrystalline carbon, 12~15g of sodium tetrachloropalladate and put them into a ball mill jar, and ball mill at 200~300r / min for 5~6h in a hydrogen atmosphere of 1~2MPa, and the ball milling is finished After obtaining alloy carbon powder, take 20~40mmol polyvinyl alcohol and add it to N,N-dimethylformamide whose mass is 30~60 times, stir at 80~90°C until the polyvinyl alcohol is completely dissolved, then add 20 ~40mmol of N,N-carbonyldiimidazole, stirred and reacted at 200~300r / min for 3~4h under nitrogen atmosphere, added 20~48mmol of propargylamine after the reaction, and continued to stir for 15~18h to obtain the reaction solution. Add the mass fraction of 75% ethanol solution and let it stand for precipitation until no precipitation occurs, filter the filter residue, wash the filter residue with absolute ethanol 2~3 times, put it in a drying oven, and dry it at 80~90℃ for 24~30h to obtain the modified product. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com