Preparation method for Mg3Sb2-based thermoelectric material

A thermoelectric material, mg3-xaxsb2-yby technology, applied in the field of preparation of Mg3Sb2-based thermoelectric materials, can solve the problems of low thermoelectric figure of merit, achieve the effects of improving production efficiency, simple process operation, and wide composition range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

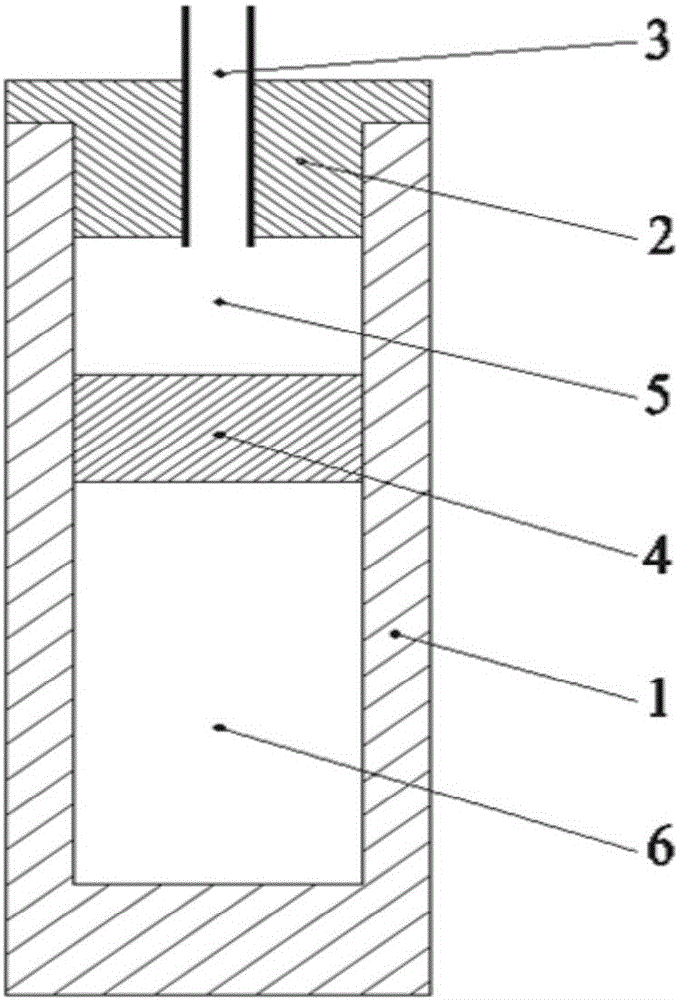

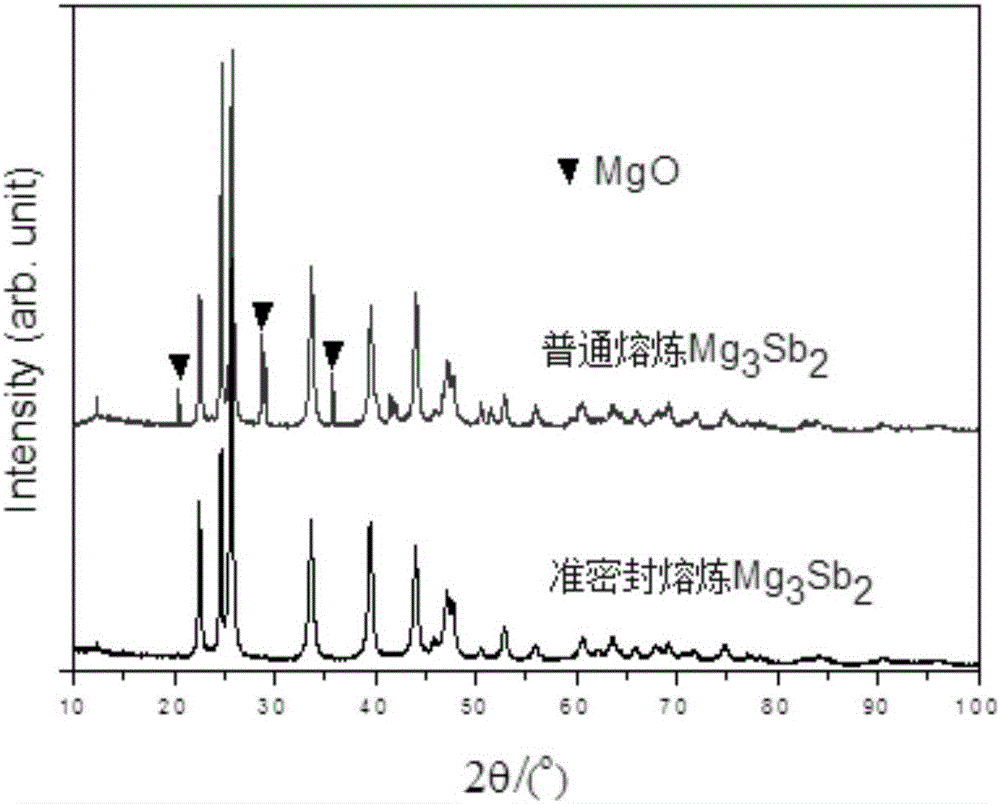

[0022] 1) Induction melting: use Mg block (purity 99.99%) and Sb block (purity 99.99%) as raw materials, according to the chemical formula Mg 3 Sb 2 Argon gas (P0 2 ≤2.47×10 -29 Pa) Proportioning and weighing in an atmosphere, put the prepared raw materials into a quasi-sealed melting crucible, and use induction melting equipment for melting in the same argon atmosphere. The melting time is 80s and the maximum power is 20kw to obtain Mg 3 Sb 2 Ingot.

[0023] 2) Mechanical ball mill: Place the obtained ingots in a vacuum glove box with argon gas to crush them, and put the crushed ingots into cemented carbide ball mill tanks with a ball to material ratio of 15:1 (mass ratio). Under the protective atmosphere of argon gas, mechanical ball milling equipment is used for ball milling. The speed of the ball milling equipment is 500r / min and the milling time is 3h. Under this condition, the two ingots are broken and refined, and they are mixed uniformly to achieve alloying;

[0024] 3) Spa...

Embodiment 2

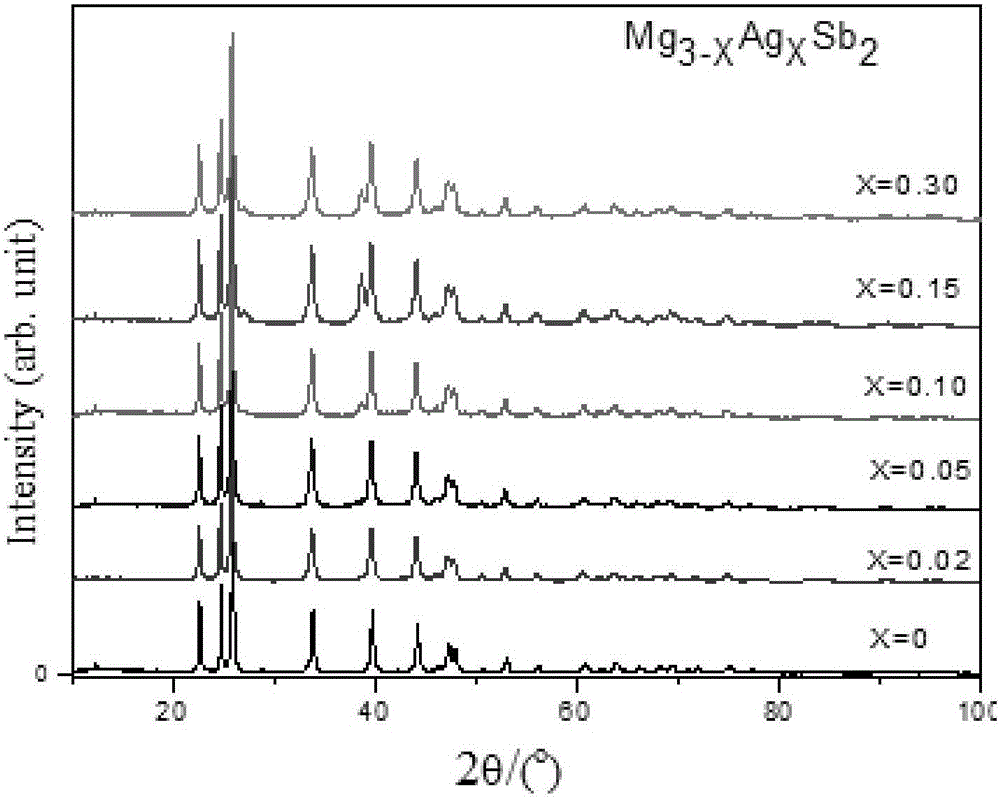

[0026] 1) Induction melting: Mg block (purity 99.99%), Sb block (purity 99.99%), Ag block (purity 99.99%) as raw materials, according to the chemical formula Mg 2.98 Ag 0.02 Sb 2 Argon gas (P0 2 ≤2.47×10 -29 Pa) Proportioning and weighing in an atmosphere, put the prepared raw materials into a quasi-sealed melting crucible, and use induction melting equipment for melting in the same argon atmosphere. The melting time is 100s and the maximum power is 18kw to obtain Mg 2.98 Ag 0.02 Sb 2 Ingot.

[0027] 2) Mechanical ball mill: Place the obtained ingots in a vacuum glove box with argon gas to crush them, and put the crushed ingots into cemented carbide ball mill tanks with a ball to material ratio of 15:1 (mass ratio). Under the protective atmosphere of argon gas, mechanical ball milling equipment is used for ball milling. The speed of the ball milling equipment is 500r / min and the milling time is 3h. Under this condition, the two ingots are broken and refined, and they are mixed uni...

Embodiment 3

[0030] 1) Induction melting: Mg block (purity 99.99%), Sb block (purity 99.99%), Ag block (purity 99.99%) as raw materials, according to the chemical formula Mg 2.95 Ag 0.05 Sb 2 Argon gas (P0 2 ≤2.47×10 -29 Pa) Proportioning and weighing in an atmosphere, put the prepared raw materials into a quasi-sealed melting crucible, and use induction melting equipment for melting in the same argon atmosphere. The melting time is 100s and the maximum power is 18kw to obtain Mg 2.95 Ag 0.05 Sb 2 Ingot.

[0031] 2) Mechanical ball mill: Place the obtained ingots in a vacuum glove box with argon gas to crush them, and put the crushed ingots into cemented carbide ball mill tanks with a ball to material ratio of 15:1 (mass ratio). Under the protective atmosphere of argon gas, mechanical ball milling equipment is used for ball milling. The speed of the ball milling equipment is 500r / min and the milling time is 3h. Under this condition, the two ingots are broken and refined, and they are mixed uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com