Method for preparing nanometer SiC composite Mg-Si-Sn-based thermoelectric material

A mg-si-sn, thermoelectric material technology, applied in the manufacture/processing of thermoelectric devices, etc., can solve the problems of large specific surface area of nanoparticles, inability to achieve uniform dispersion, easy to agglomerate, etc., to achieve a wide range of components, ball milling and Short sintering time, the effect of inhibiting oxidation and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

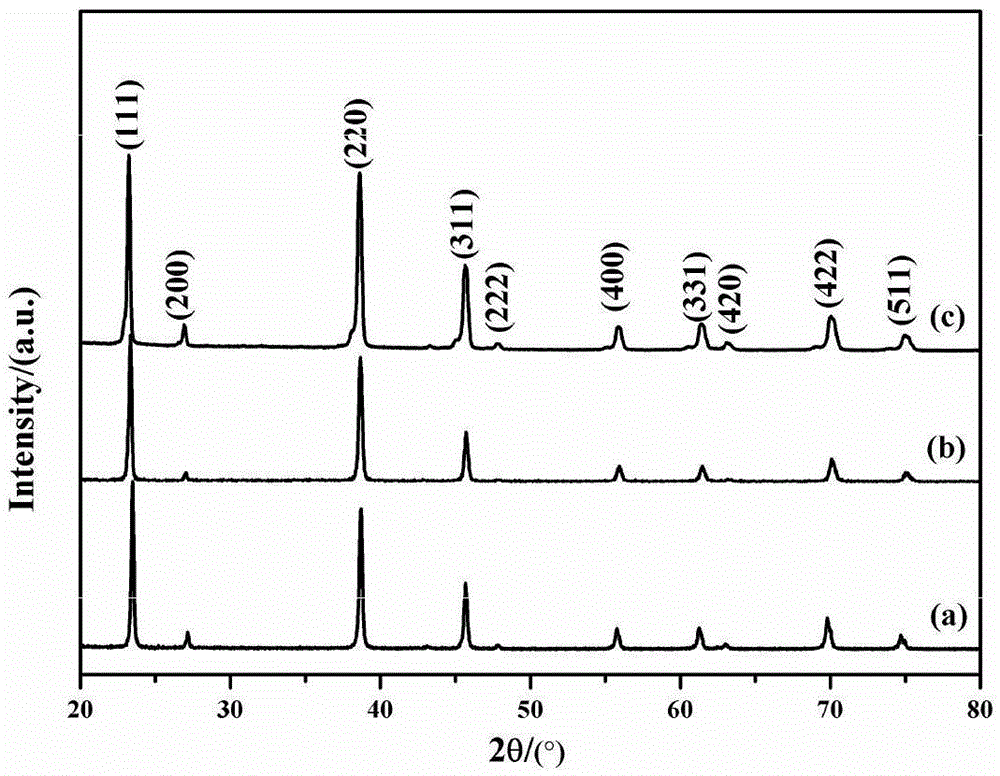

[0023] 1) Induction melting: Mg block (purity 99.99%), Sn block (purity 99.99%) as raw materials, according to the chemical formula Mg 2 Sn proportioning and weighing, put the prepared raw materials into an alumina crucible, and use induction melting equipment for smelting in an argon atmosphere. The smelting time is 75s and the maximum power is 16kw to obtain Mg 2 Sn ingot.

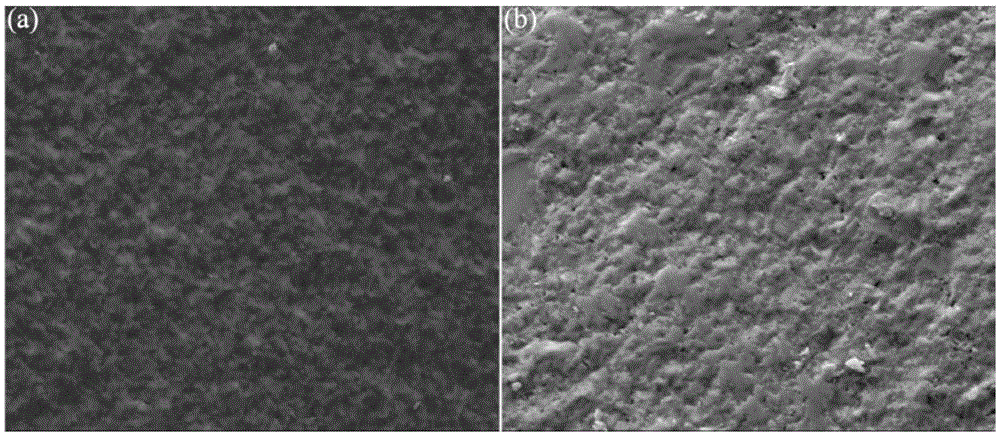

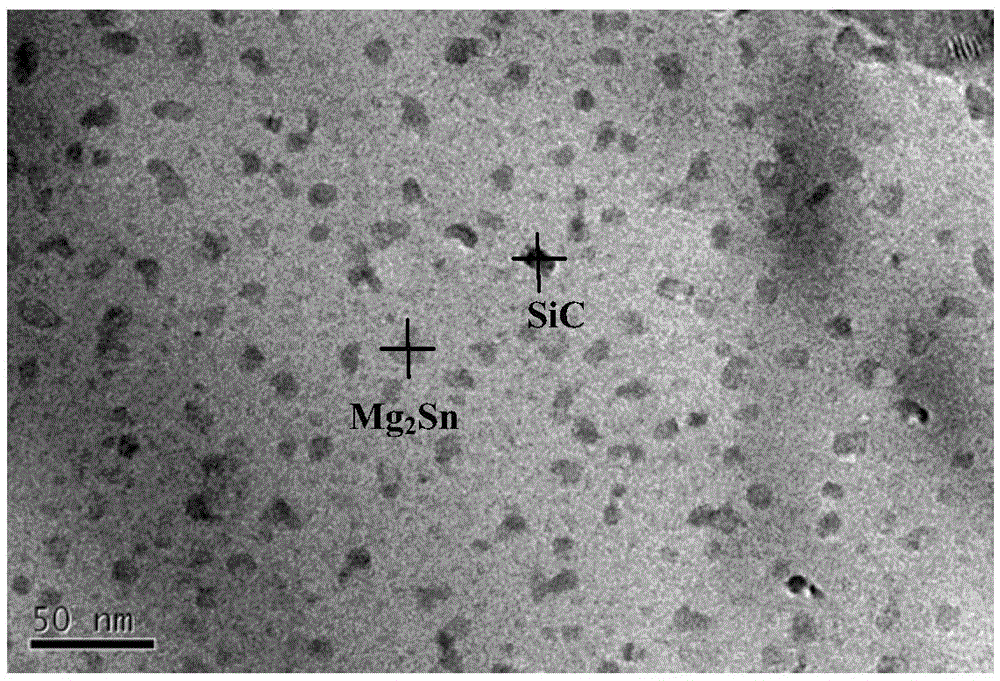

[0024] 2) A mechanical ball milling combined with spark plasma sintering: Mg 2 Sn ingots are placed in a vacuum glove box with an oxygen content of less than 0.5ppm, and the ratio is Mg according to the chemical formula 2 Sn / SiC 0.005 Weigh the SiC nano powder and the broken ingot into a cemented carbide (WC) ball mill tank, set the ball-to-battery ratio to 15:1 (mass ratio), rotate speed 500r / min, ball milling time 3h, in argon gas Ball milling is carried out under a protective atmosphere; the powder that has been mechanically milled is placed in a vacuum glove box with an oxygen content of less than 0.5 ppm...

Embodiment 2

[0027] 1) Induction melting: Mg block (purity 99.99%), Si block (purity 99.999%), Sn block (purity 99.99%) as raw materials, according to the chemical formula Mg 2 Si 0.3 Sn 0.7 Proportioning and weighing, put the prepared raw materials into an alumina crucible, and use induction melting equipment for smelting in an argon atmosphere. The melting time is 75s and the maximum power is 17kw to obtain Mg 2 Si 0.3 Sn 0.7 Ingot.

[0028] 2) A mechanical ball milling combined with spark plasma sintering: Mg 2 Si 0.3 Sn 0.7 The cast ingot is broken in a vacuum glove box with an oxygen content of less than 0.5ppm, and the ratio is Mg according to the chemical formula 2 Si 0.3 Sn 0.7 / SiC 0.01 , Weigh the SiC nano powder and the broken ingots into a cemented carbide (WC) ball mill tank, set the ball-to-battery ratio to 15:1 (mass ratio), rotate speed 500r / min, ball milling time 3h, Ball milling is carried out under a protective atmosphere of air; the powder that has been mechanically milled o...

Embodiment 3

[0031] 1) Induction melting: Mg block (purity 99.99%), Si block (purity 99.999%), Sn block (purity 99.99%) as raw materials, according to the chemical formula Mg 2 Si 0.4 Sn 0.6 Proportioning and weighing, put the prepared raw materials into an alumina crucible, and use induction melting equipment for smelting in an argon atmosphere. The melting time is 80s and the maximum power is 18kw to obtain Mg 2 Si 0.4 Sn 0.6 Ingot.

[0032] 2) One-time mechanical ball milling combined with spark plasma sintering: the obtained ingot is placed in a vacuum glove box with an oxygen content of less than 0.5 ppm and broken, and the ratio is Mg according to the chemical formula 2 Si 0.4 Sn 0.6 / SiC 0.01 , Weigh the SiC nano powder and the broken ingots into a cemented carbide (WC) ball mill tank, set the ball-to-battery ratio to 15:1 (mass ratio), rotate speed 500r / min, ball milling time 3h, Ball milling is carried out under a protective atmosphere of air; the powder that has been mechanically mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com