Method for compounding aluminum alloy composite board used for machining automobile oil cooler bottom board

A technology of aluminum alloy sheet and aluminum alloy, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems affecting the surface quality of parts, loss of activity, and rising melting point of brazing flux, etc., so as to reduce production costs and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solutions of the present invention and the advantages of various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

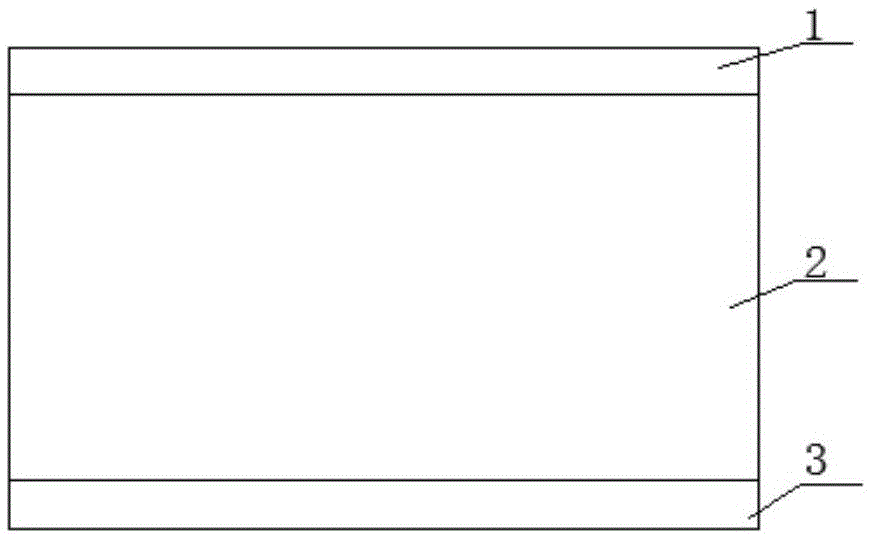

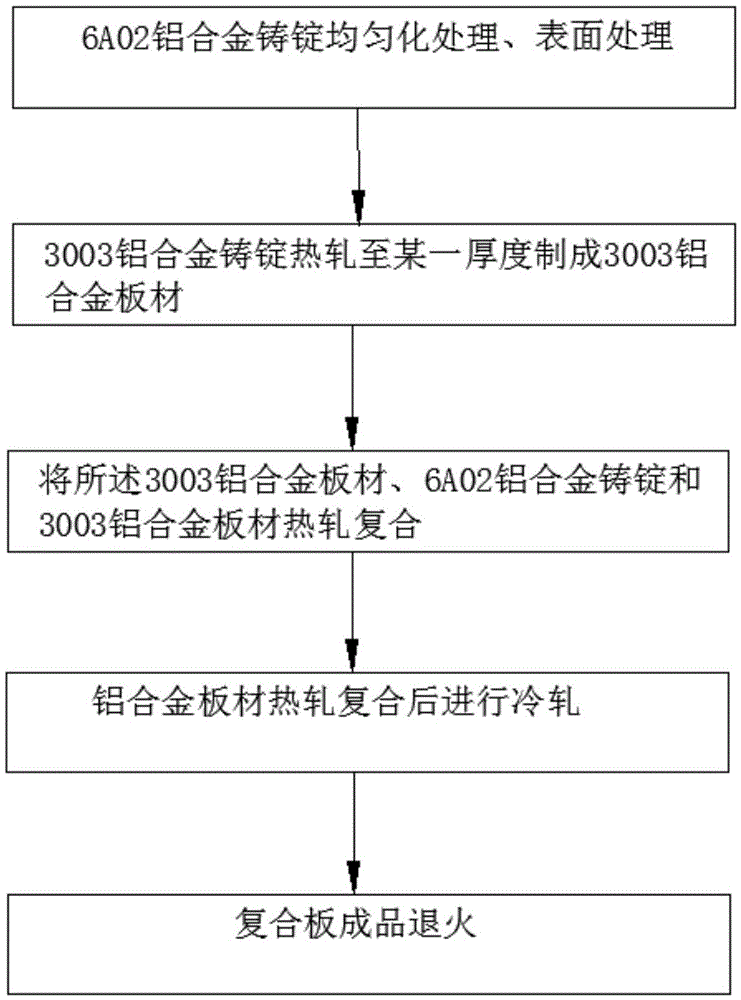

[0022] figure 1 It is a structural schematic diagram of an aluminum alloy composite plate used for processing the bottom plate of an automobile oil cooler according to an embodiment of the present invention. The present invention provides the composite method of this kind of aluminum alloy clad plate, combined below figure 2 The flow chart of the aluminum alloy composite plate used to process the bottom plate of the automobile oil cooler, and the method is explained step by step.

[0023] Such as figure 2 As shown, firstly, the 6A02 aluminum alloy ingot is homogenized and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com