High-performance energy saving electric iron

A high-efficiency, energy-saving, electric soldering iron technology, applied in the direction of soldering irons, metal processing equipment, manufacturing tools, etc., can solve the problems of low thermal efficiency, scalding the table and hands, and insufficient service life, achieving high thermal efficiency, low shell temperature, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

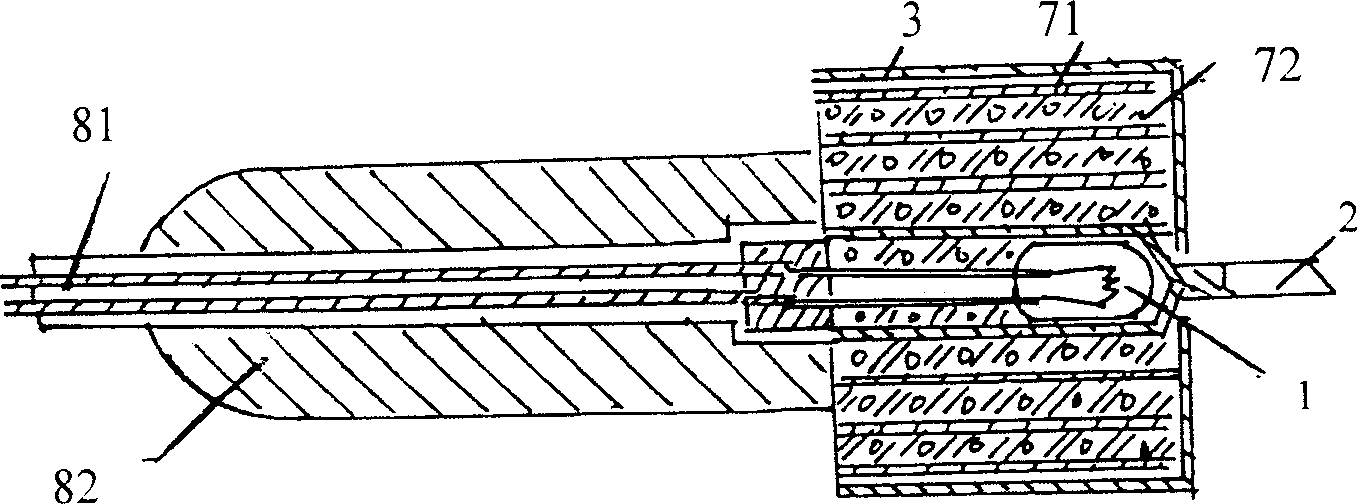

[0019] see figure 1 , 2 , a high-efficiency and energy-saving electric soldering iron, including a power supply, an internal heating type electric heating core and a soldering iron head. The power supply 8 is connected to the electric heating core through the power cord 81, and the power cord 81 is passed through the handle 82. The internal heating electric heating core is a small halogen tungsten lamp 1 as an electric soldering iron, and a thin copper tube is used to make the soldering iron head 2, and a composite type is used. The thermal insulation material is used as the thermal insulation layer, and the metal shell 3 is outsourced.

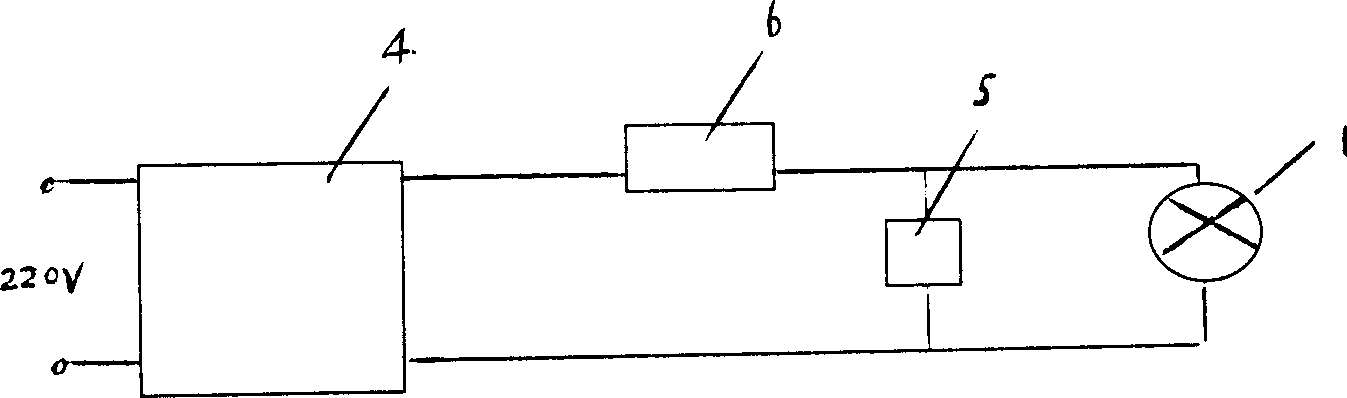

[0020] The thyristor 4 is used to control the output voltage of the power supply, and there are voltmeter 5 and ammeter 6 to display the electric power.

[0021] The composite thermal insulation material is a composite layer material of aluminum foil 71 and aluminum silicate thermal insulation cotton 72 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com