Composite aluminum alloy plate for liquid cooling plate of new energy power battery and preparation method of composite aluminum alloy plate

A technology of aluminum alloy plates and power batteries, which is applied in the field of aluminum alloy composite materials, to achieve the effects of increasing cruising range, reducing carbon emissions, and reducing battery weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

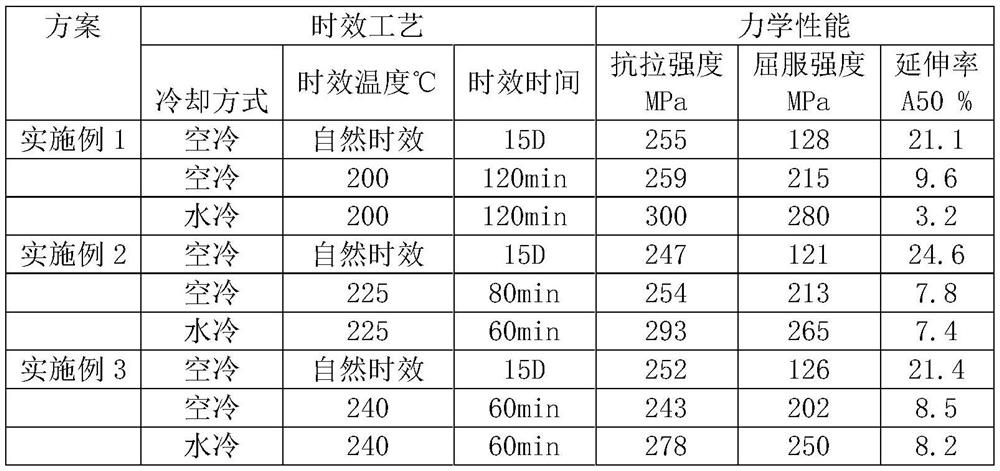

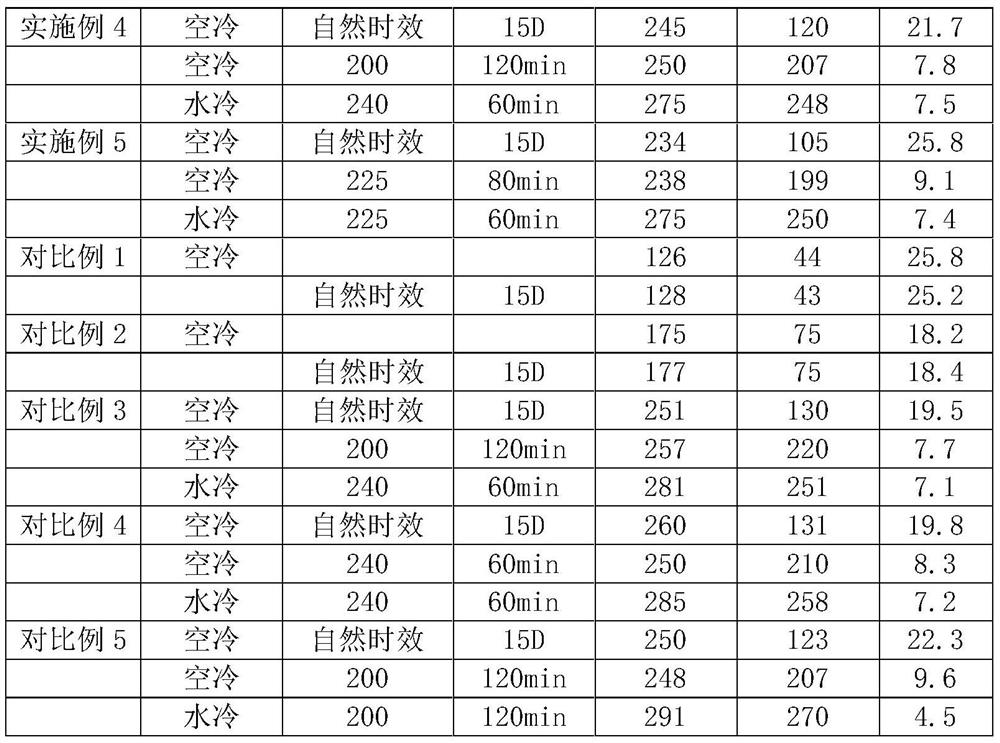

Examples

Embodiment 1

[0046] The preparation of the composite aluminum alloy plate for the liquid cooling plate of the new energy power battery of the present application:

[0047] Core material composition and mass percentage: Si 0.9%, Fe 0.36%, Cu 0.35%, Mn 0.34%, Mg 0.7%, Ti 0.08%, Cr 0.1%, other elements individual content <0.05%, total <0.15%, The balance is aluminum;

[0048] The protective layer is 3003 alloy.

[0049] (1) The core material ingot is not uniform, and the protective layers on the upper and lower sides are subjected to composite hot rolling at a ratio of 5%, the rolling temperature is 500 ° C, and the thickness of the hot rolled coil is 8 mm;

[0050] (2) The hot-rolled coil is cold-rolled into a 3mm cold-rolled coil by 2 passes;

[0051] (3) Finished annealing of the cold-rolled coil is carried out at a temperature of 380°C and a holding time of 2h;

[0052] (4) The cold-rolled coil after annealing is subjected to a brazing process, and the temperature is raised from room t...

Embodiment 2

[0056] The preparation of the composite aluminum alloy plate for the liquid cooling plate of the new energy power battery of the present application:

[0057] Core material composition and mass percentage: Si 1.0%, Fe 0.4%, Cu 0.2%, Mn 0.4%, Mg 0.8%, Ti 0.05%, Cr 0.15%, other elements individual content < 0.05%, total < 0.15%, The balance is aluminum;

[0058] The protective layer is 3003 alloy.

[0059] (1) The core material ingot is not uniform, and the protective layers 3003 on the upper and lower sides are subjected to composite hot rolling at a ratio of 6%, the rolling temperature is 490 ° C, and the hot rolling thickness is 7 mm;

[0060] (2) The hot-rolled coil is cold-rolled into a 2.5mm cold-rolled coil by 2 passes;

[0061] (3) The finished annealing temperature of the cold rolled coil is 370℃, and the holding time is 2.5h;

[0062] (4) The cold-rolled coil after annealing is subjected to a brazing process, and the temperature is raised from room temperature to 60...

Embodiment 3

[0066] The preparation of the composite aluminum alloy plate for the liquid cooling plate of the new energy power battery of the present application:

[0067] Core material composition and mass percentage: Si 0.7%, Fe 0.2%, Cu 0.4%, Mn 0.3%, Mg 0.6%, Ti 0.1%, Cr 0.05%, other elements individual content <0.05%, total <0.15%, The balance is aluminum;

[0068] The protective layer is 3003 alloy.

[0069] (1) The core material ingot is not uniform, and the protective layers 3003 on the upper and lower sides are subjected to composite hot rolling at a ratio of 7%, the rolling temperature is 480 ° C, and the hot rolling thickness is 6.5 mm;

[0070] (2) The hot-rolled coil is cold-rolled into a 2mm cold-rolled coil by 3 passes;

[0071] (3) The finished annealing temperature of the cold rolled coil is 360℃, and the holding time is 3h;

[0072] (4) The cold-rolled coil after annealing is subjected to a brazing process, and the temperature is raised from room temperature to 605 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com